A method for recovering gold, palladium, platinum and silver from waste circuit boards

A technology for recycling used circuit boards and gold, applied in the field of recycling gold, platinum, silver, and palladium, can solve the problems that the recovery rate of recycled metals cannot reach a high level, the waste of resources does not meet the requirements, and the secondary pollution of the environment, etc. The effect of low cost, improving utilization rate and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

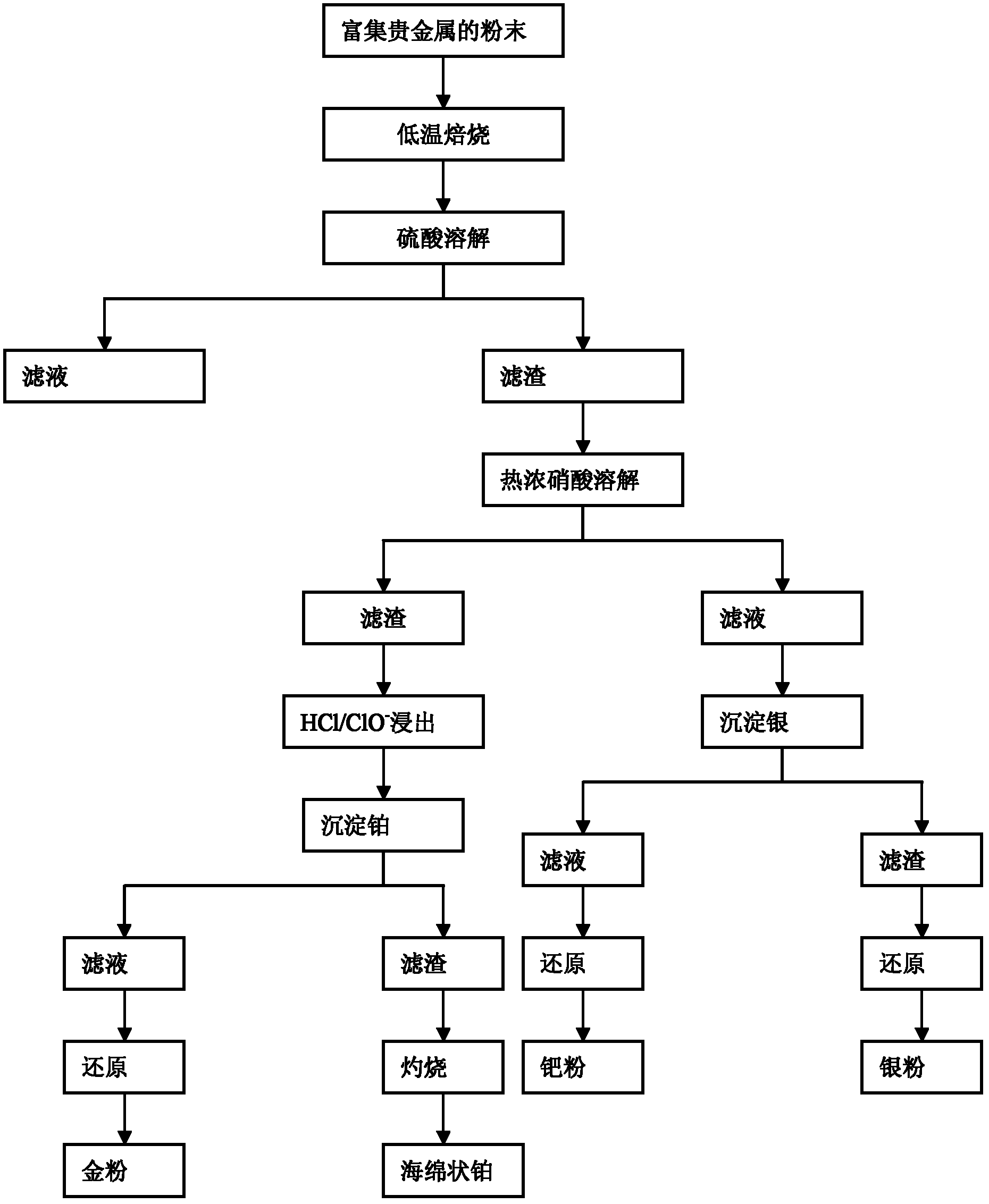

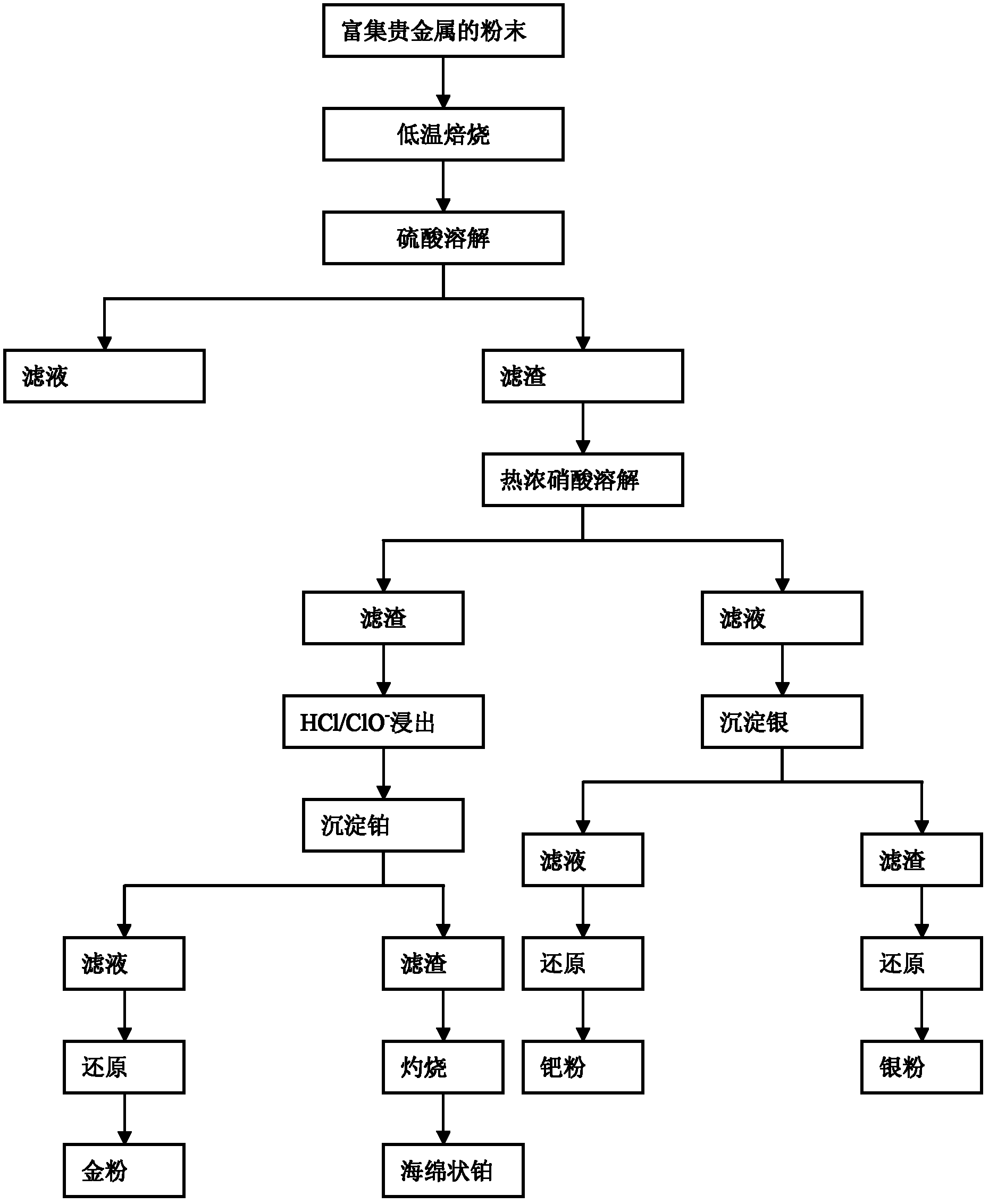

[0021] figure 1 It is the process flow chart of the method for recovering rare and precious metals from waste circuit boards in this embodiment. The "precious metal-enriched powder" refers to the waste circuit board powder after copper, nickel, lead, tin and other metals are extracted.

[0022] (1) Low-temperature roasting. Take the powder after extracting copper, nickel, lead, tin and other metals. It also contains a small amount of other base metals and a small amount of non-metals. It needs to be roasted to remove a small amount of non-metals, volatilize a small amount of other impurities, and oxidize a small amount of base metals. For metals, the firing temperature is about 400°C, and the firing time is 3 hours.

[0023] (2) Sulfuric acid is soluble in acid. Take 10 kg of the above-mentioned roasted material and dissolve it with 6.5L of 150g / L sulfuric acid. The reaction temperature is 85°C and the reaction time is 3 hours. After the reaction, the content of copper, nickel, t...

Embodiment 2

[0027] (1) Low-temperature roasting. Take the powder after extracting copper, nickel, lead, tin and other metals. It also contains a small amount of other base metals and a small amount of non-metals. It needs to be roasted to remove a small amount of non-metals, volatilize a small amount of other impurities, and oxidize a small amount of base metals. For metals, the firing temperature is about 300°C and the firing time is 4 hours.

[0028] (2) Sulfuric acid is soluble in acid. Take 10 kg of the above roasted material, dissolve the roasted material with 100g / L sulfuric acid 9.75L, the reaction temperature is 95℃, the reaction time is 4 hours, the content of copper, nickel, tin, etc. in the remaining filter residue are all lower than 0.1%.

[0029] (3) Separation and recovery of palladium and silver. Use 13L of hot concentrated nitric acid (concentration of 70%) to dissolve palladium and silver. The reaction temperature is 70°C and the reaction time is 4 hours. The generated gas ...

Embodiment 3

[0032] (1) Low-temperature roasting. Take the powder after extracting copper, nickel, lead, tin and other metals. It also contains a small amount of other base metals and a small amount of non-metals. It needs to be roasted to remove a small amount of non-metals, volatilize a small amount of other impurities, and oxidize a small amount of base metals. For metals, the firing temperature is about 500°C, and the firing time is 2 hours.

[0033] (2) Sulfuric acid is soluble in acid. Take 10 kg of the above roasted material, dissolve the roasted material with 4.9L of 200g / L sulfuric acid, the reaction temperature is 95℃, the reaction time is 2 hours, and the content of copper, nickel, tin, etc. in the remaining filter residue is less than 0.1 %.

[0034] (3) Separation and recovery of palladium and silver. Use hot concentrated nitric acid (concentration 60%) to dissolve palladium and silver (the ratio of moles of nitric acid to moles of silver and palladium is 8:1), the reaction temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com