Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "High flatness precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

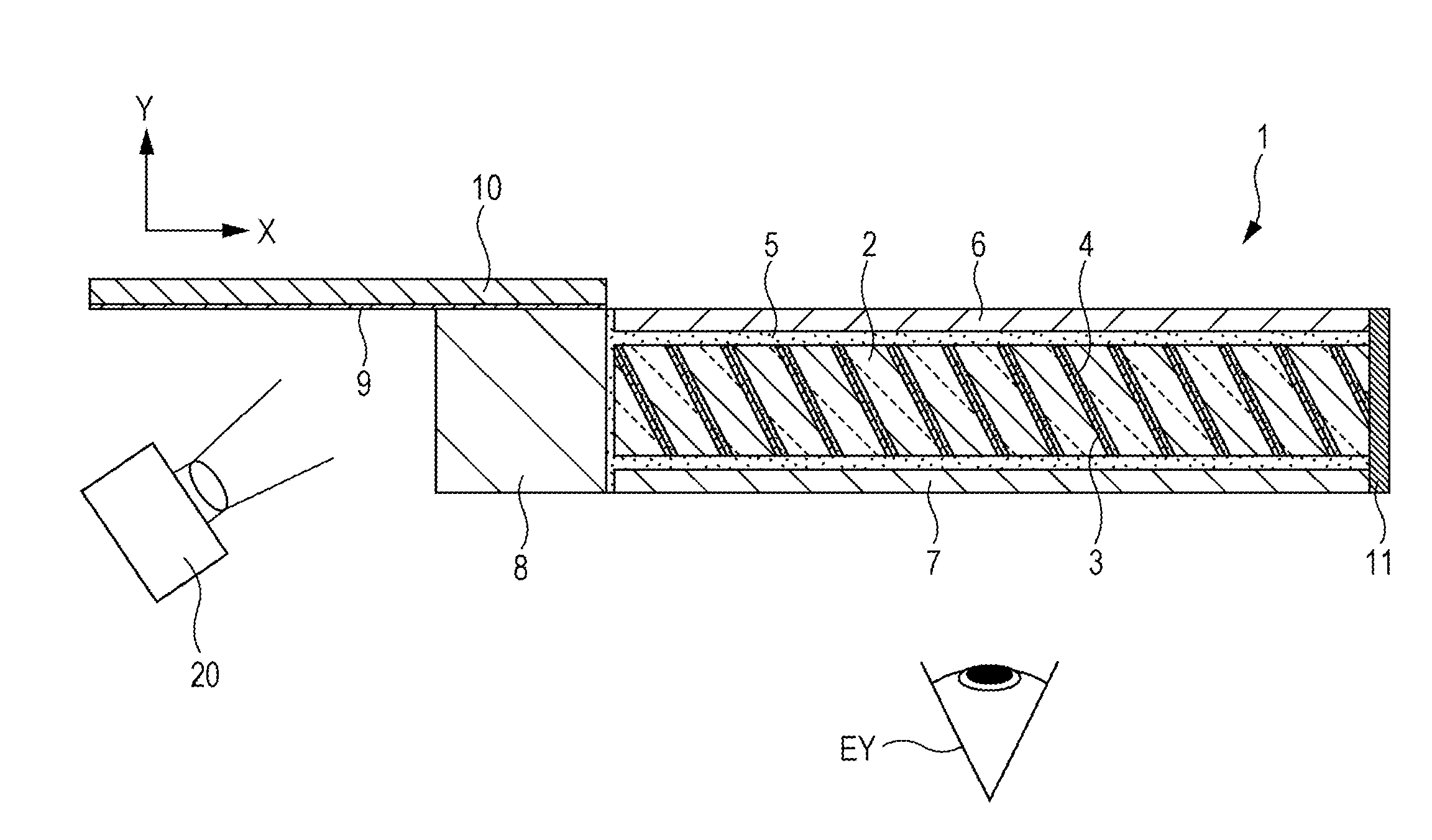

Optical element, image display device and method for manufacturing same

ActiveUS20150138646A1High accuracyHigh flatness precisionLiquid surface applicatorsOptical articlesExit surfaceAdhesive

An optical element includes a light guide plate that has therein a light transmissive flat plate member on which a transflective layer is formed, and a layer of a light transmissive adhesive or a light transmissive resin layer that uniformly covers the light guide plate. The refractive index of the layer of the adhesive or the resin layer is set to a refractive index different from that of the light guide plate. A first surface of the layer of the adhesive or the resin layer that is on the light exit surface side of the light guide plate is kept parallel with a second surface of the layer of the adhesive or the resin layer that is on the opposite side to the light exit surface side of the light guide plate.

Owner:SEIKO EPSON CORP

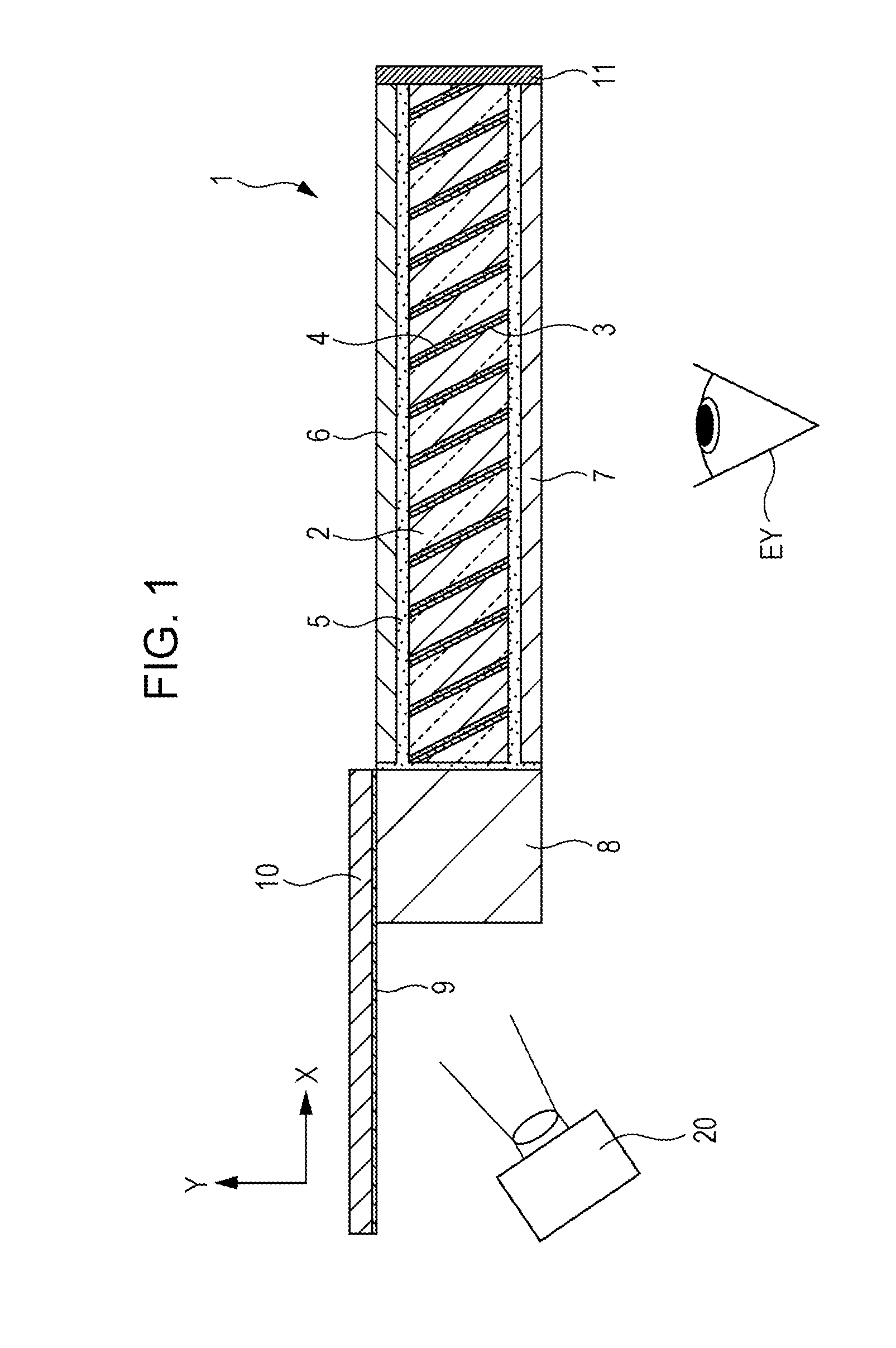

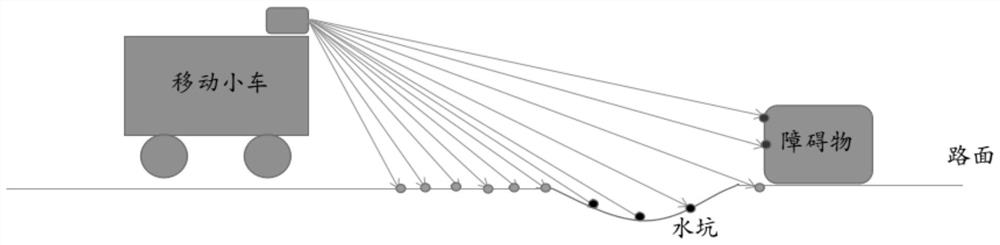

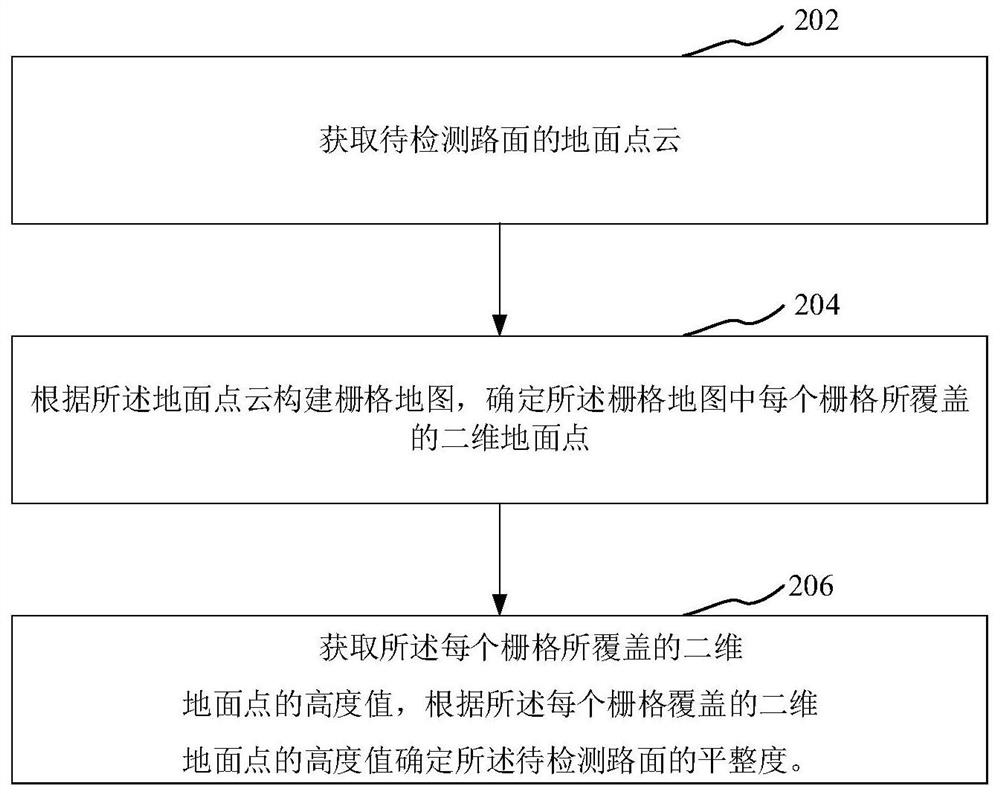

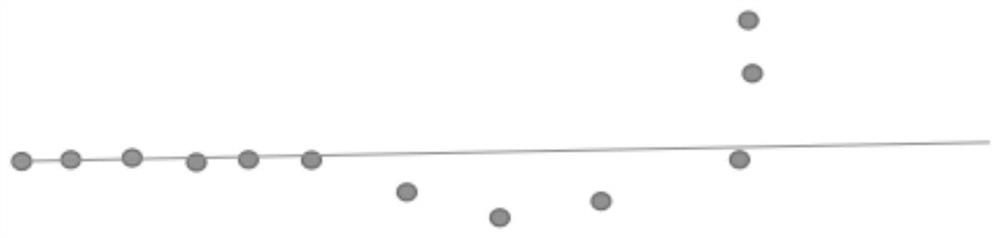

Road surface detection method and device, computer equipment and storage medium

ActiveCN110084116AHigh precisionHigh flatness precisionImage analysisThree-dimensional object recognitionPoint cloudRoad surface

The invention relates to a road surface detection method and device, computer equipment and a storage medium. The method comprises the steps of acquiring ground point cloud of a to-be-detected road surface; constructing a grid map according to the ground point cloud, and determining two-dimensional ground points covered by each grid in the grid map; and obtaining the height value of the two-dimensional ground point covered by each grid, and determining the flatness of the pavement to be detected according to the height value of the two-dimensional ground point covered by each grid. By the adoption of the method, pavement detection with higher precision can be achieved.

Owner:SUTENG INNOVATION TECH CO LTD

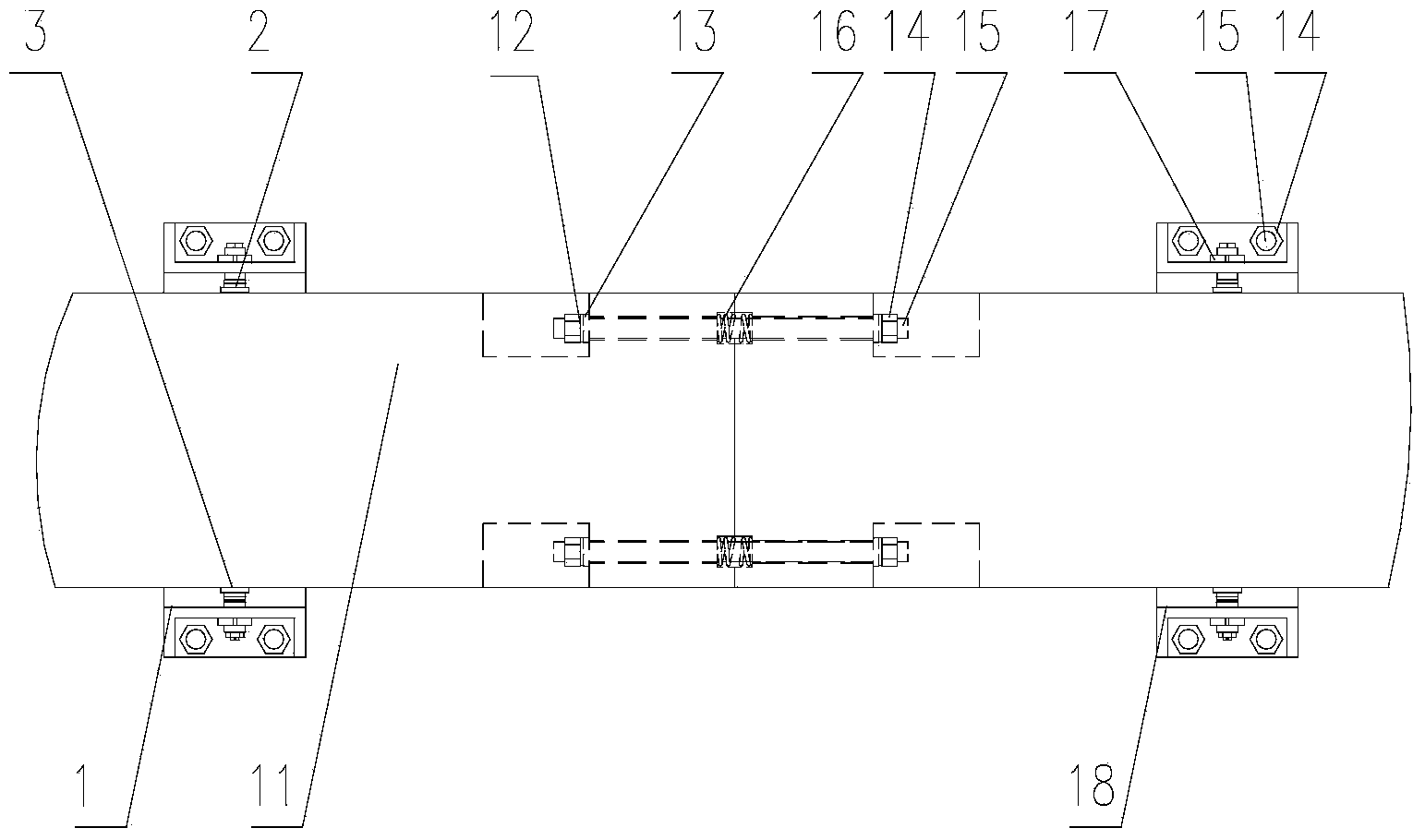

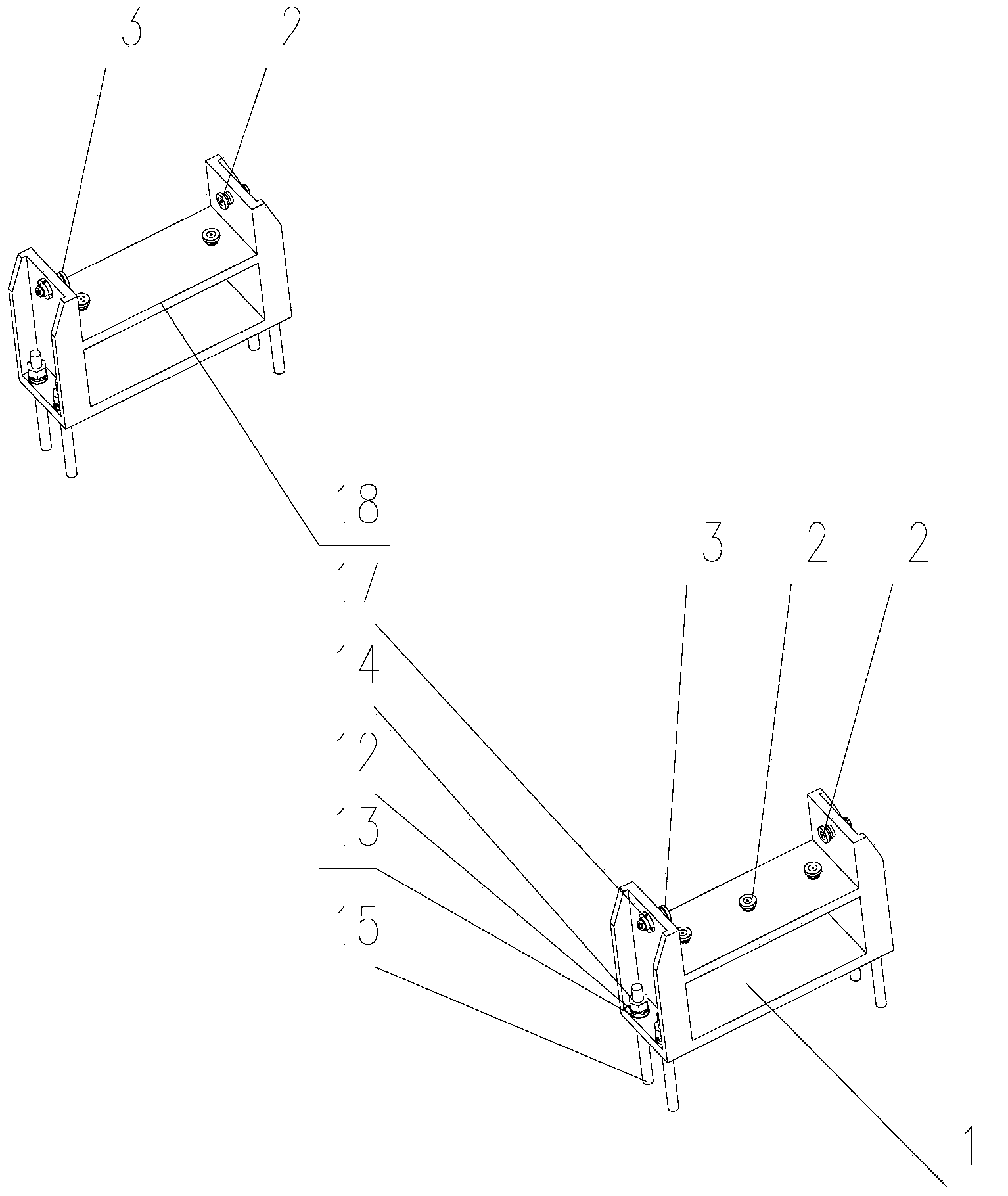

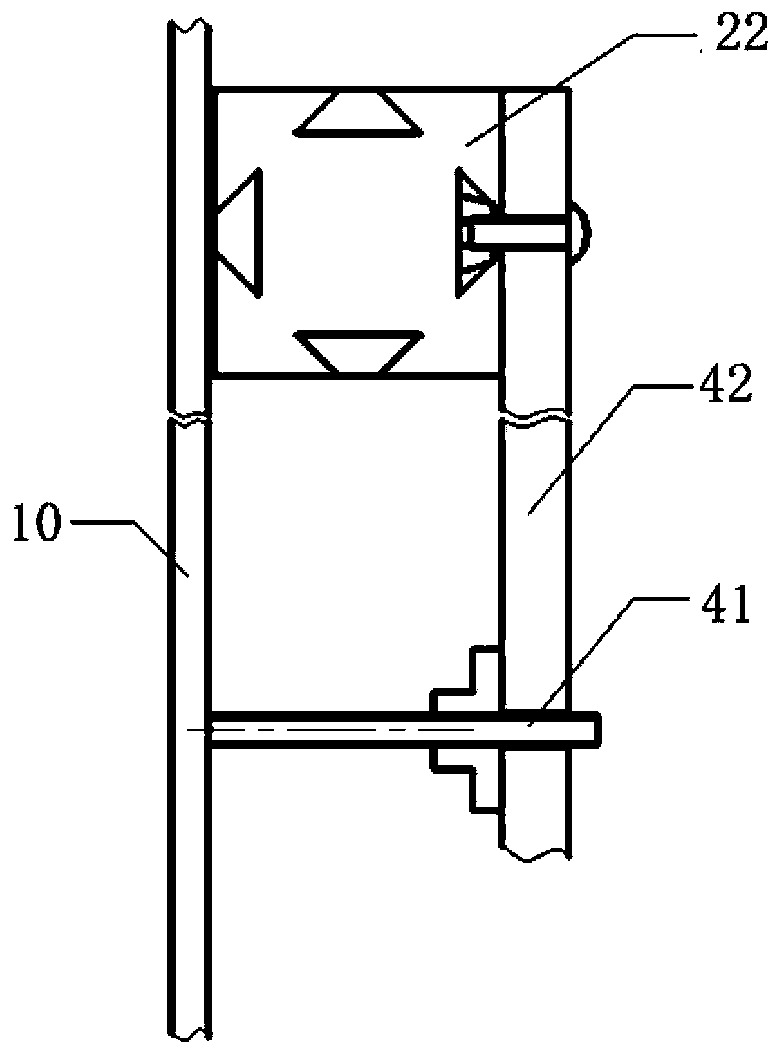

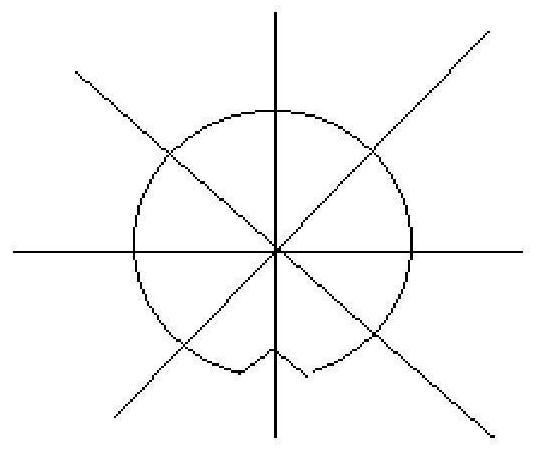

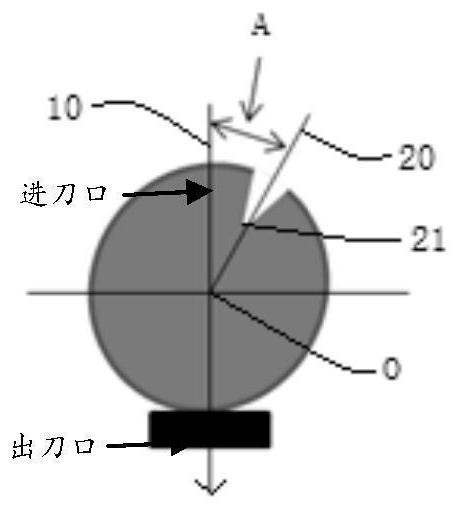

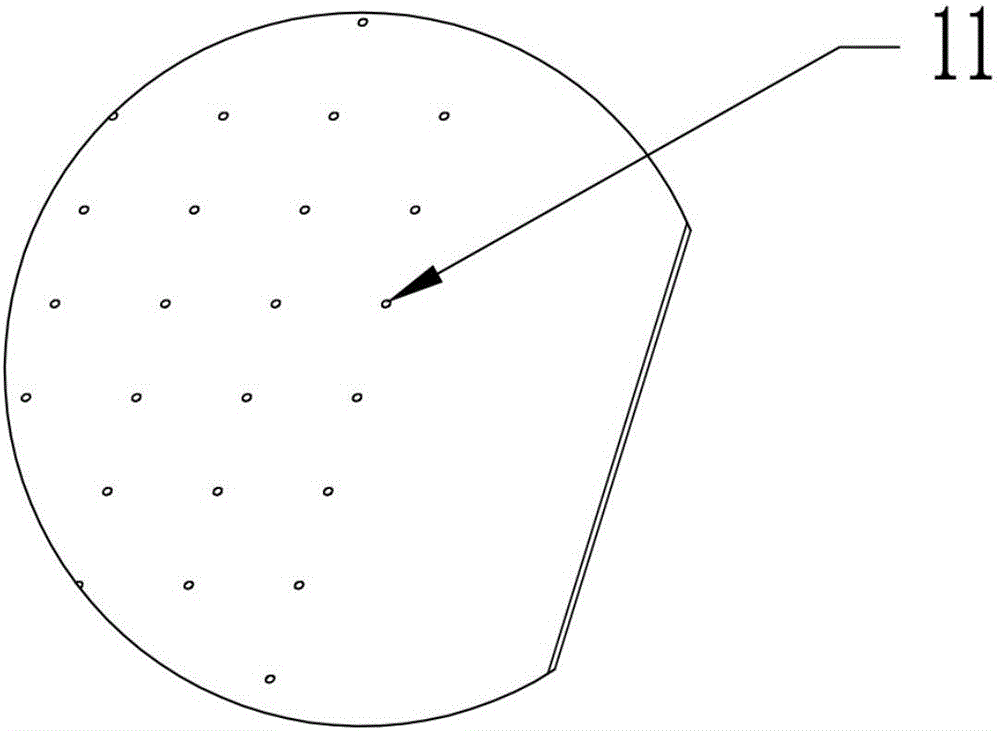

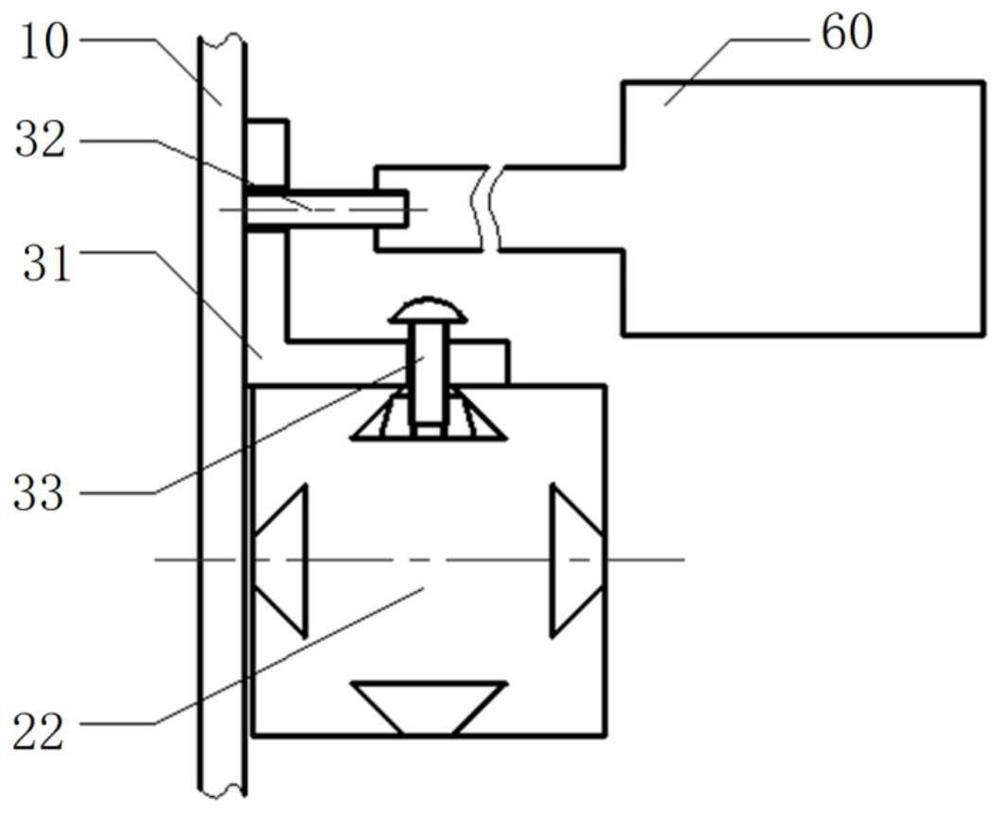

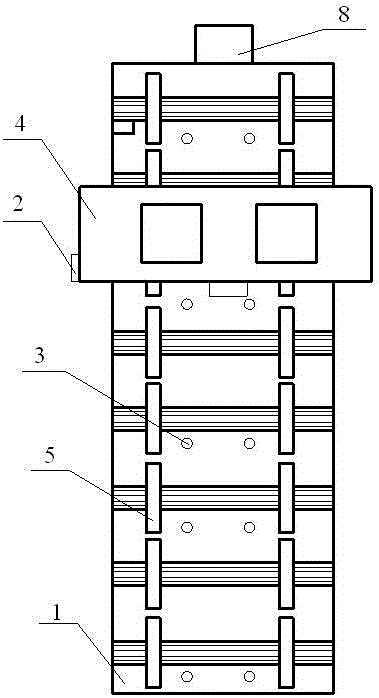

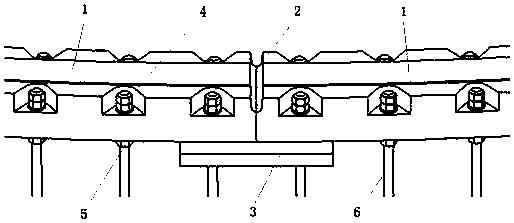

Pile head cutting machine for CFG (cement fly-ash gravel) piles

ActiveCN102172988AAchieve mechanical cuttingGuaranteed 3D cutting controlStone-like material working toolsMating connectionControl system

The invention belongs to the technical field of construction machines and devices for CFG (cement fly-ash gravel) piles in a roadbed and roadbed reinforcement projects and particularly relates to a pile head cutting machine for CFG piles, and the machine provided by the invention is used for solving the problems that the existing cutting machine is incomplete in performances and can not meet the pile head cutting requirement of the CFG piles. The pile head cutting machine for the CFG piles comprises a control system, the control system further comprises a vertical fine adjustment control system for a cutting saw, the vertical fine adjustment control system comprises a vertical transmission lead screw, the vertical transmission lead screw, an upper screw nut which is fixed opposite to a vertical support frame and a lower screw nut which can slide relative to the vertical support frame and be fixed relative to the vertical support frame are matched and connected, and the lower screw nut is connected with an electric motor through a connecting part. By adopting the pile head cutting machine for the CFG piles, the three-dimensional cutting control in the circumferential direction, radial direction and vertical direction can be realized during the cutting process, the stable performances of the device during the cutting process can be ensured, the work efficiency of standardized operation is improved, the operation space is reduced, and the air dust pollution is reduced during the construction.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Optical element, image display device and method for manufacturing same

ActiveUS9738041B2High flatness precisionAvoid it happening againMechanical apparatusOptical articlesAdhesiveLight guide

An optical element includes a light guide plate that has therein a light transmissive flat plate member on which a transflective layer is formed, and a layer of a light transmissive adhesive or a light transmissive resin layer that uniformly covers the light guide plate. The refractive index of the layer of the adhesive or the resin layer is set to a refractive index different from that of the light guide plate. A first surface of the layer of the adhesive or the resin layer that is on the light exit surface side of the light guide plate is kept parallel with a second surface of the layer of the adhesive or the resin layer that is on the opposite side to the light exit surface side of the light guide plate.

Owner:SEIKO EPSON CORP

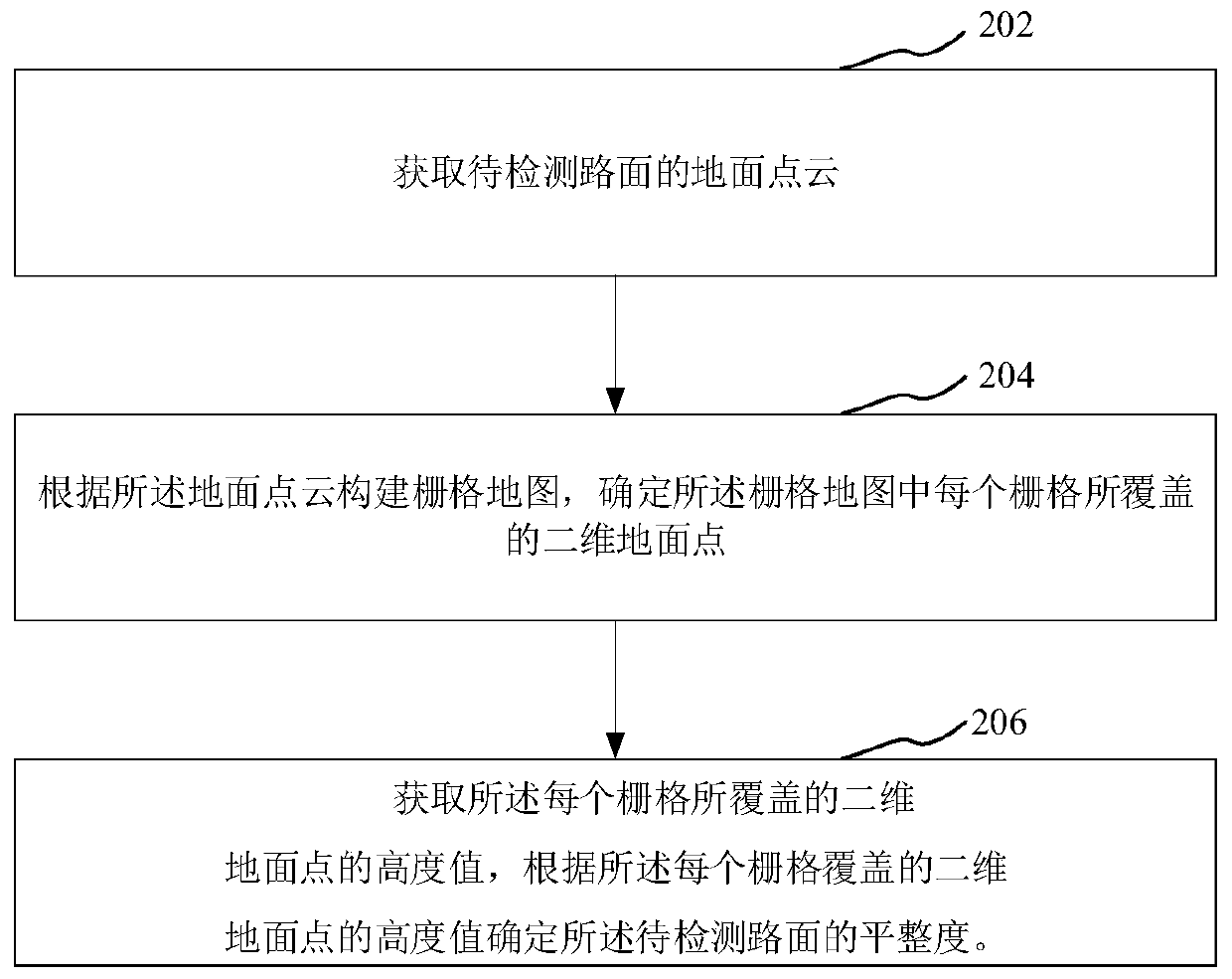

Machining technology for cold saw blade

InactiveCN109317752AGuaranteed cleanlinessHigh flatness precisionMetal sawing tool makingAngle grinderCircular saw

The invention discloses a machining technology for a cold saw blade. The machining technology comprise the following steps that S1, a plate is cut, wherein the plate is cut to obtain a circular saw blade base body with sawteeth; S2, burrs on the surface of the saw blade base body are removed, wherein firstly, the surface of the saw blade base body is de-burred manually by using an angle grinder, and after the relatively large burrs on the surface of the saw blade are removed, a full-automatic de-burring machine is used for carrying out de-burring on the saw blade base body again; and S3, tempering is carried out on the saw blade base body, wherein the saw blade base body undergoes tempering and de-stressing heat treatment, the tempering temperature is 360 DEG C, the tempering time is 4 hours, and the tempering cooling time is 60-72 hours. According to the machining technology, the technological steps are simple, repeated de-burring and cleaning are carried out, the cleanliness degree of the saw blade can be guaranteed during grinding each time, the flatness precision of the saw blade can be improved, through the special angle design of a tool bit, the precision is higher when a workpiece is cut, and the yield of the cold saw blade is improved.

Owner:成都壹佰科技有限公司

Ultra-long guide rail for three-coordinate measuring machine

InactiveCN103528553AHigh flatness precisionImprove straightnessMeasurement devicesAir bearingHigh intensity

The invention discloses an ultra-long guide rail for a three-coordinate measuring machine. The ultra-long guide rail comprises branch guide rails and front and rear bases for the branch guide rails, wherein four bolt holes for arranging full-thread screws are formed in a lower bottom plate of each of the front and rear bases, and threaded holes are formed in vertical plates and upper bottom plates of the front and rear bases; an elastic adjusting bolt is arranged in one threaded hole of each vertical plate, and rigid adjusting bolts are arranged in the other threaded holes of each vertical plate; a square hole is formed in each of the two ends of each of main and auxiliary lateral surfaces of each branch guide rail, and a pair of stepped holes communicated with the corresponding square holes is formed in each of the front and rear end faces of each branch guide rail; springs are arranged in the stepped holes of the spliced end faces; the full-thread screws penetrate through the springs in the stepped holes; the two ends of the full-thread screws are positioned in the corresponding square holes respectively, and are locked by nuts. The ultra-long guide rail is high in planeness accuracy, straightness and splicing seam bonding accuracy, strong in splicing seam bonding strength, small in bonding seam thickness, simple in structure, easy to assemble, free of maintenance and low in cost, influence on accuracy when air bearings pass through bonding seams is avoided, and the accuracy, comprising the planeness and the straightness, of the guide rail is kept unchanged when temperature is changed.

Owner:浙江时代计量科技有限公司

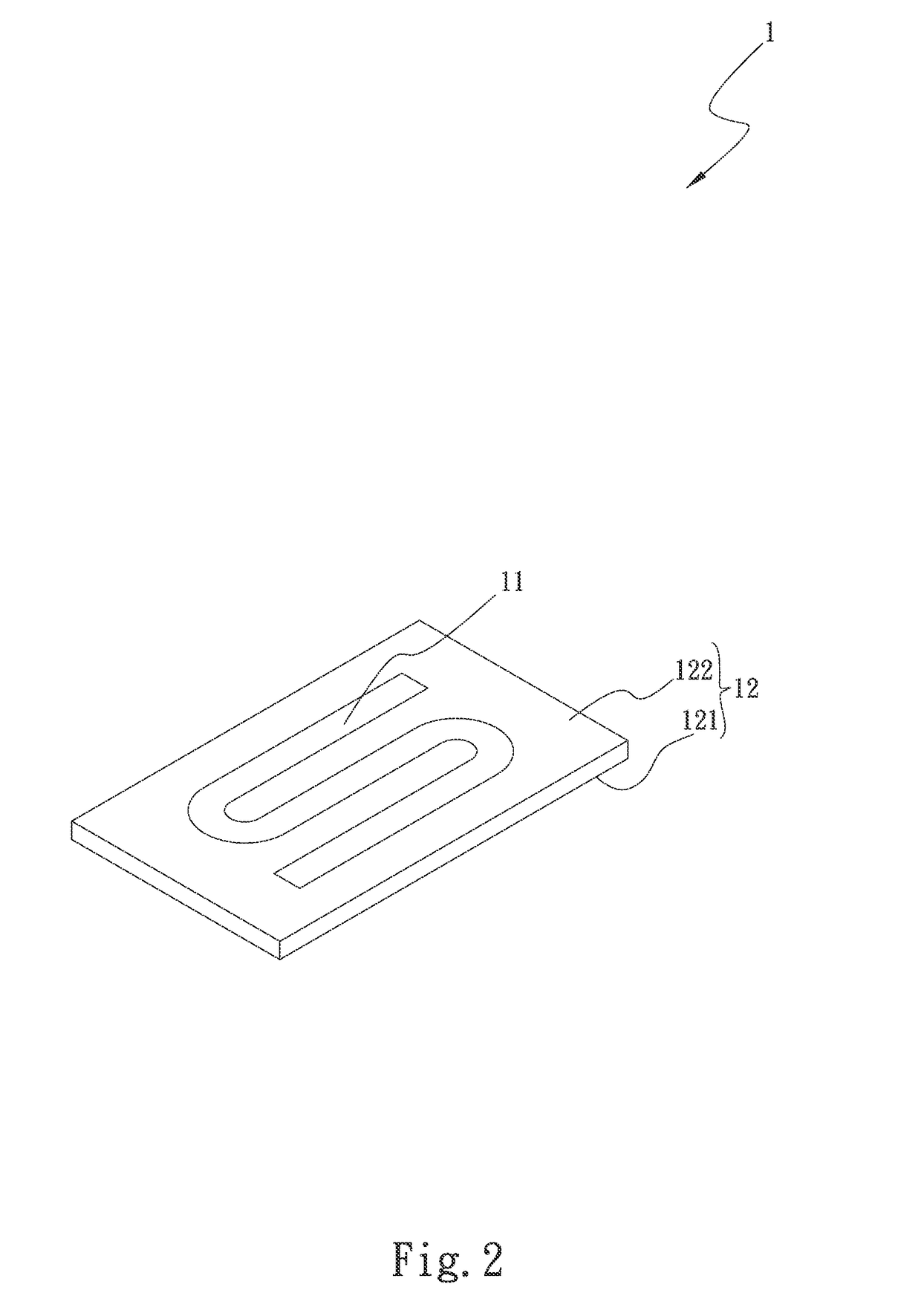

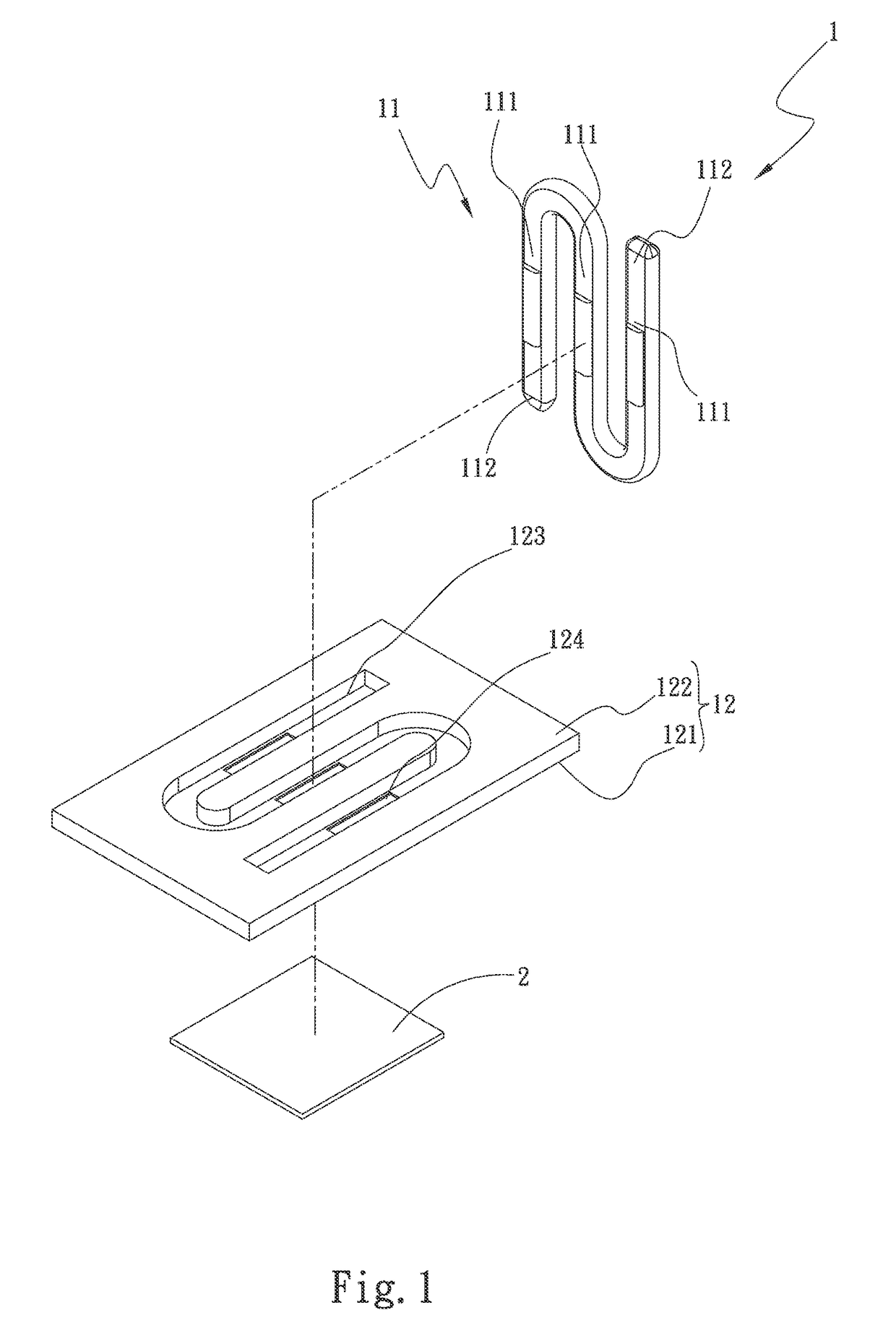

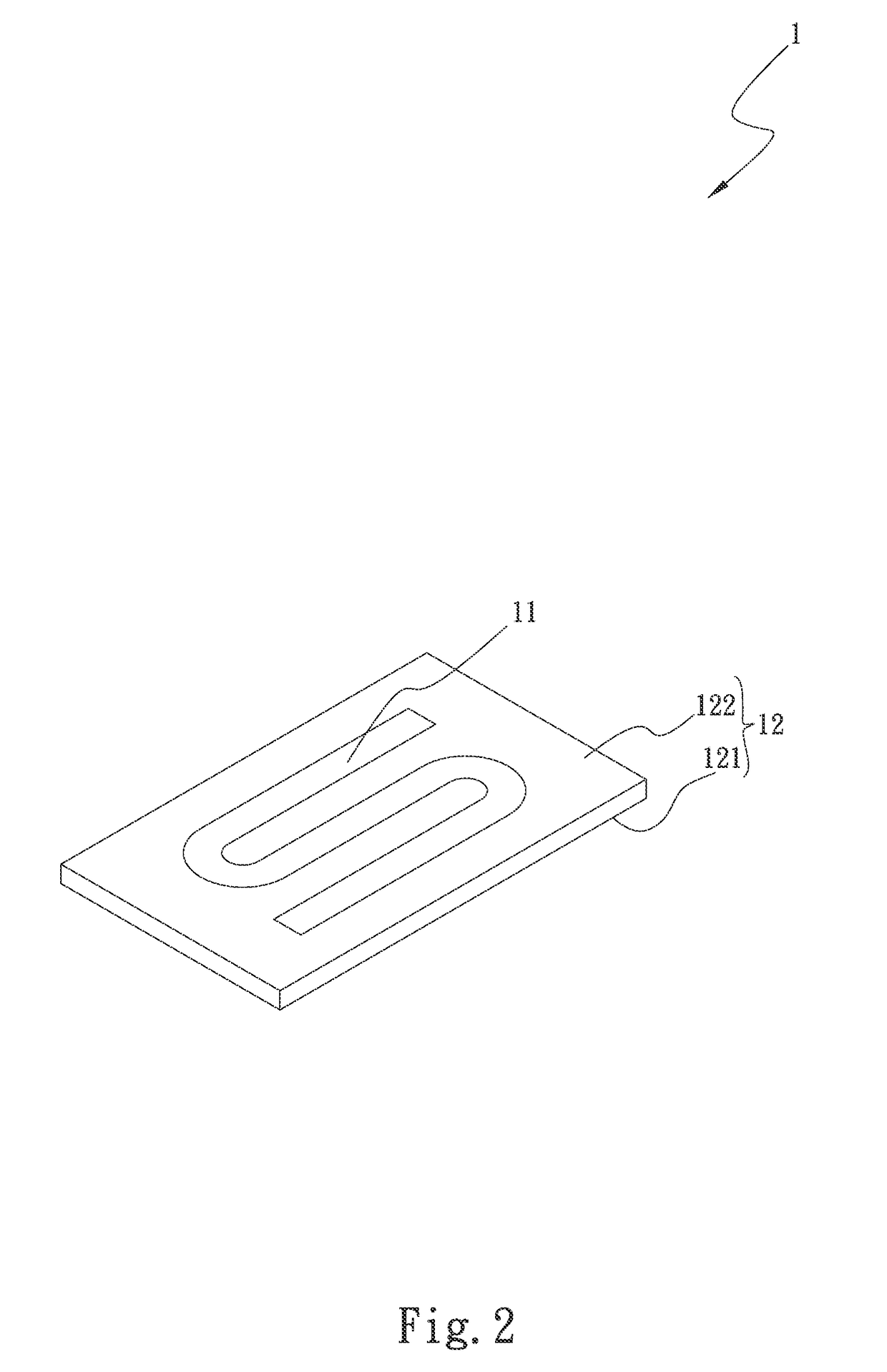

Heat dissipation unit manufacturing method

ActiveUS20170151641A1High flatness precisionSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingMaterial PerforationMechanical engineering

A heat dissipation unit manufacturing method is disclosed. The heat dissipation unit includes a heat pipe and a base seat. The base seat has a first side and a second side. The second side is formed with a channel and multiple perforations in communication with the first and second sides. The heat pipe has a heat absorption section and a conduction section. The conduction section extends from the heat absorption section in a direction to at least one end of the heat pipe distal from the heat absorption section. Several parts of the heat pipe corresponding to the perforations are received in the perforations and flush with the first side of the base seat. The heat dissipation unit manufacturing method improves the shortcoming of the conventional heat dissipation component that the coplanar precision between the heat pipe and the protruding platform of the base seat is hard to control.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

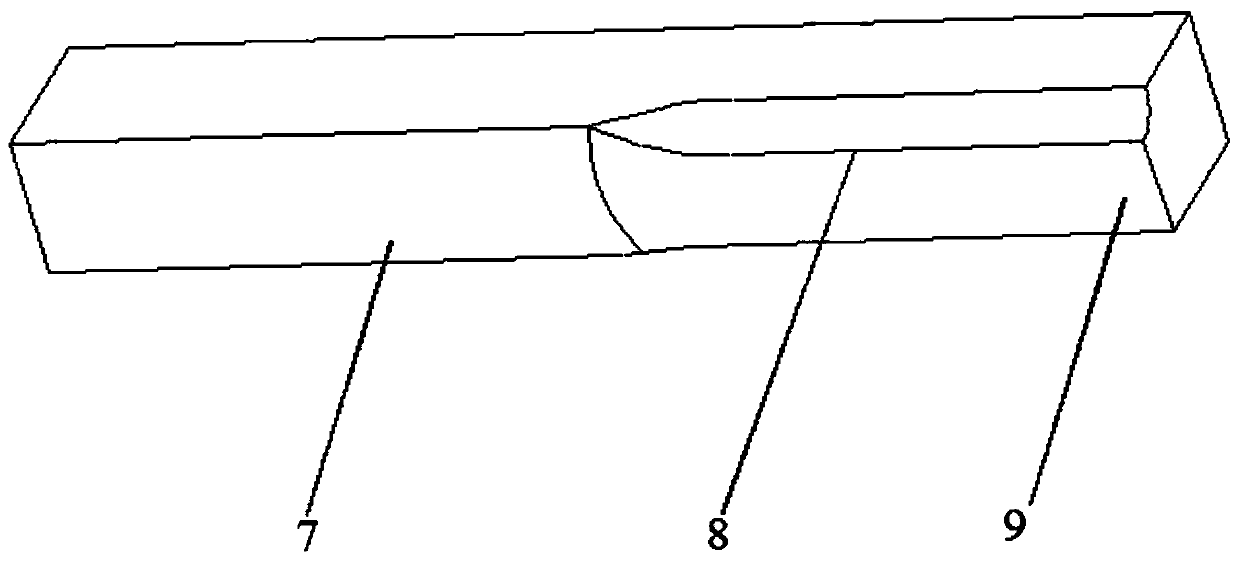

Folding microhole bedding face machining reverse scraping tool

The invention discloses a folding microhole bedding face machining reverse scraping tool. The folding microhole bedding face machining reverse scraping tool comprises an end cover, a tool apron, a joint and a tool bar; the tool bar is connected with a machine tool spindle, the joint is installed on the tool bar, the lower end of the tool apron is movably installed on the joint, the upper end of the tool apron is movably installed on the end cover, a molding blade is installed on the tool apron, and the tool apron can rotate between the end cover and the joint; and when the end cover, the toolapron and the joint are connected together in sequence, the machine tool spindle rotates to drive the tool bar to rotate correspondingly, and thus the molding blade can be automatically folded and unfolded between the end cover and the joint. According to the folding microhole bedding face machining reverse scraping tool, the tool apron automatic folding and unfolding functions are achieved through the machine tool spindle, manual loading and unloading procedures are omitted, the micro-pore bedding face structure machining process is simplified, labor is relieved, and the machining efficiencyis improved.

Owner:XUZHOU HEAVY MASCH CO LTD

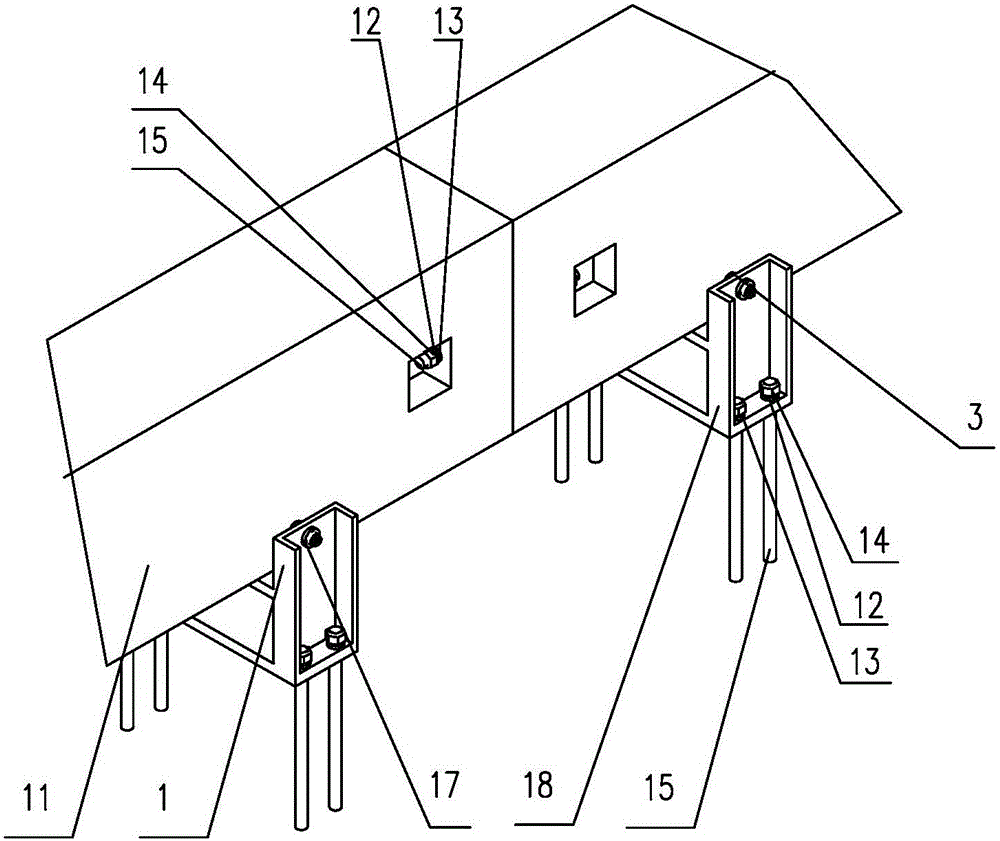

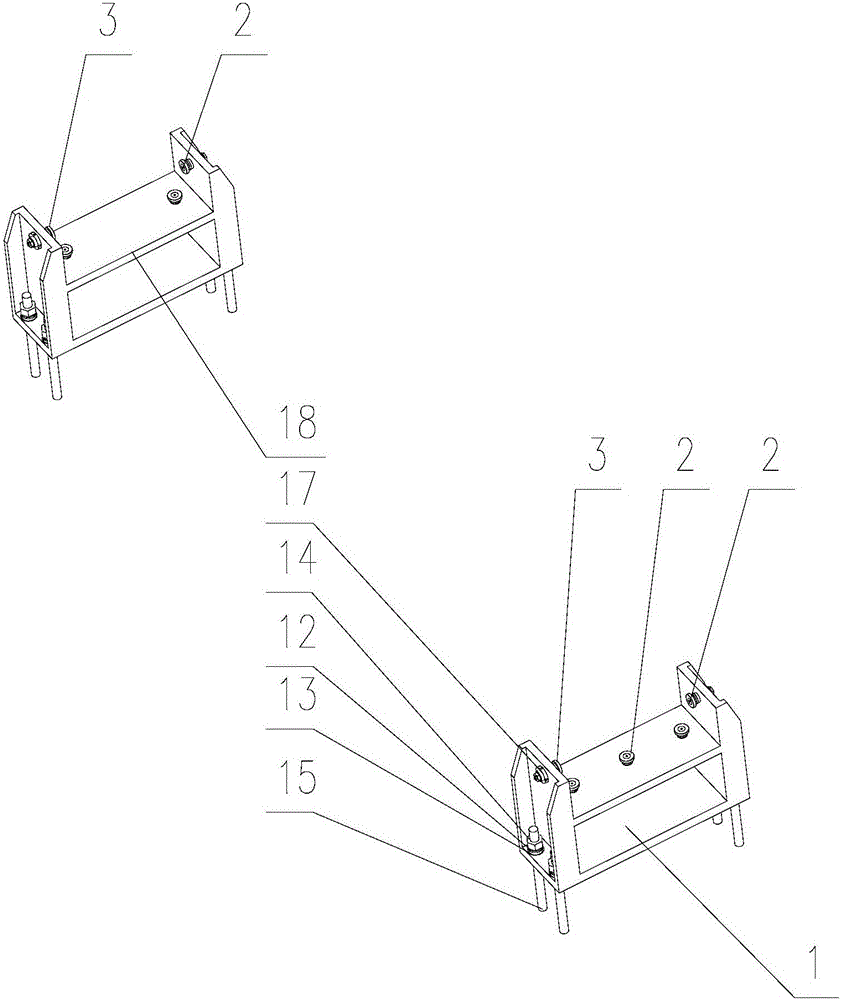

Radar reflecting surface system and leveling method and building method thereof

ActiveCN110879384AHigh precisionReduce the difficulty of assemblyWave based measurement systemsEngineeringMechanical engineering

The invention provides a radar reflecting surface system and a leveling method and a building method thereof. A radar reflecting surface is manufactured by adopting a whole plate. The manufactured radar reflecting surface is installed on a supporting frame, and the radar reflecting surface is divided into a plurality of sub-reflecting surfaces by the supporting frame. A first adjustment point forcontrolling the edge area and a second adjustment point for controlling the center area are set for each sub-reflecting surface. The acting force borne by each adjustment point on each sub-reflectingsurface is comprehensively controlled in an iterative mode, and local flatness adjustment of the radar reflecting surface is realized. Finally, adjustment of the overall flatness of the radar reflection surface is completed.

Owner:JIANGSU NANSHUI TECH +2

Method for determining wafer processing parameters and wafer processing method

PendingCN112071765AReal-time adjustment of processing parametersImproved nanomorphologySemiconductor/solid-state device testing/measurementLapping machinesWaferProcess engineering

The invention provides a method for determining wafer processing parameters and a wafer processing method. The method for determining the wafer processing parameters comprises the following steps: acquiring flatness data of predetermined lines on a plurality of wafers in a wafer processing procedure; determining radial data of the predetermined lines according to the flatness data of the predetermined lines; and determining the silicon wafer processing parameters according to the radial data of the predetermined lines of the plurality of wafers. According to the method, the parameters of the next batch of silicon rods or the subsequent processing procedure of wafers can be determined according to the processing data of the previous batch of silicon rods, so the flatness precision of obtained wafers is higher, processing yield is higher, and cost can be reduced.

Owner:XUZHOU XINJING SEMICON TECH CO LTD +1

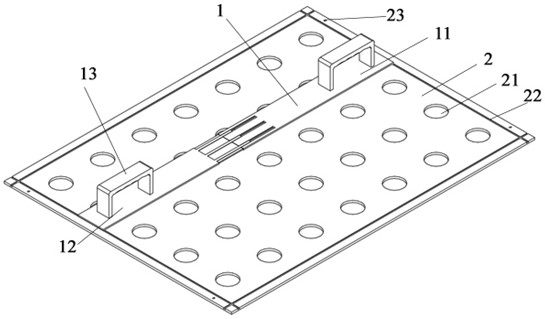

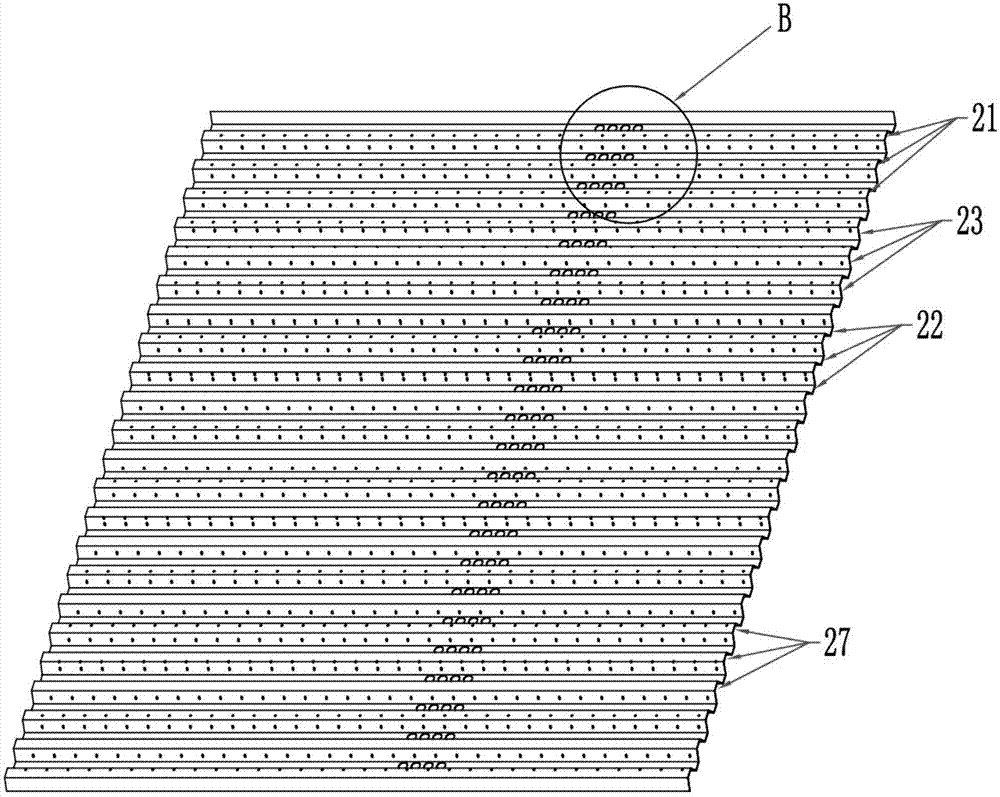

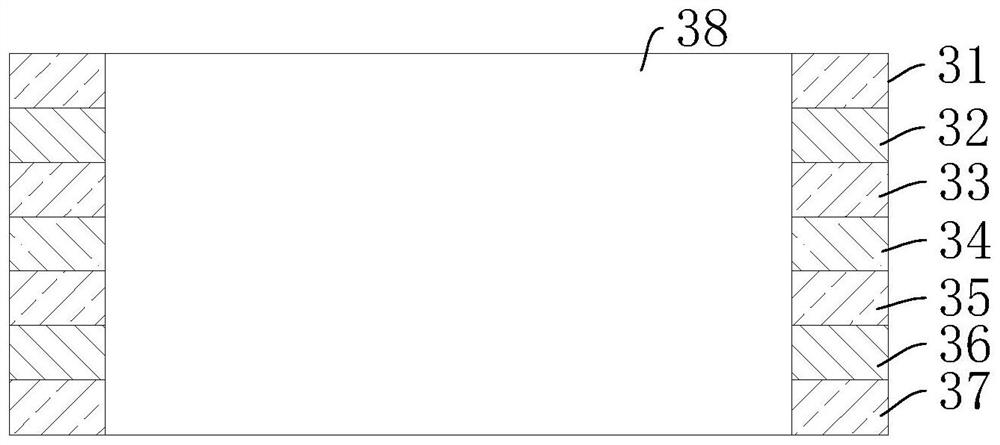

Vacuum suction table of double-layer structure

The invention relates to a vacuum suction table of a double-layer structure. The vacuum suction table comprises a frame, a bottom plate, a panel and honeycomb cores; the bottom plate is provided with bottom plate suction openings and the panel is covered with small adsorption holes; the vacuum suction table is characterized in that the inner region of the frame includes air duct regions and installation regions, the air duct regions and the installation regions are independent mutually, the air duct regions are internally provided with air duct suction openings which are communicated with the bottom plate suction openings in a one-to-one correspondence mode, the installation regions correspond to the honeycomb cores one to one, and the frame is filled with corrugated cores located above the honeycomb cores, each corrugated core includes an upper end face, a lower end face and supporting connection faces, each upper end face is combined with the supporting connection faces located at the two sides of the upper end face to form an aeration area which is communicated with the corresponding air duct region, the upper end faces are connected with the panel and provided with small air holes A which are communicated with the small adsorption holes in a one-to-one correspondence mode, a part of lower end faces are in connection with the corresponding honeycomb cores in a covering mode, and the other part of the lower end faces are connected with the corresponding air duct regions. The vacuum suction table is high in strength, internal gas paths are small in windage resistance, energy loss is low, and adsorption force is large and uniform.

Owner:FOSHAN SHUNDE DISTRICT YINMEI FINE HARDWARE TECH

Heat dissipation unit manufacturing method

ActiveUS9895778B2High flatness precisionSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingEngineeringMaterial Perforation

A heat dissipation unit manufacturing method is disclosed. The heat dissipation unit includes a heat pipe and a base seat. The base seat has a first side and a second side. The second side is formed with a channel and multiple perforations in communication with the first and second sides. The heat pipe has a heat absorption section and a conduction section. The conduction section extends from the heat absorption section in a direction to at least one end of the heat pipe distal from the heat absorption section. Several parts of the heat pipe corresponding to the perforations are received in the perforations and flush with the first side of the base seat. The heat dissipation unit manufacturing method improves the shortcoming of the conventional heat dissipation component that the coplanar precision between the heat pipe and the protruding platform of the base seat is hard to control.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

Sliding liner plate apparatus used in installation bracket

InactiveCN102523718AHigh flatness precisionHigh bonding strengthNon-rotating vibration suppressionSupport structure mountingIsolation effectFriction reduction

The invention belongs to a friction reduction vibration isolation technology and relates to a sliding liner plate apparatus used in installation bracket of an avionic device. The sliding liner plate apparatus comprises: a sliding gasket, a double-sided glue film, a supporting plate, a front fixed block, a rear fixed block, a fixed screw and a rear supported plate. By using the apparatus, a pushing force needed during electronic equipment is pushed into the installation bracket can be reduced. A surface treatment result of a cabinet bottom and a supporting plate surface which are contacted during the mutual sliding of the electronic equipment can not be damaged. Buffering and isolation effects can be achieved when the electronic equipment is impacted and vibrates. By using the apparatus, rapid loading and unloading of the avionic device can be guaranteed.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

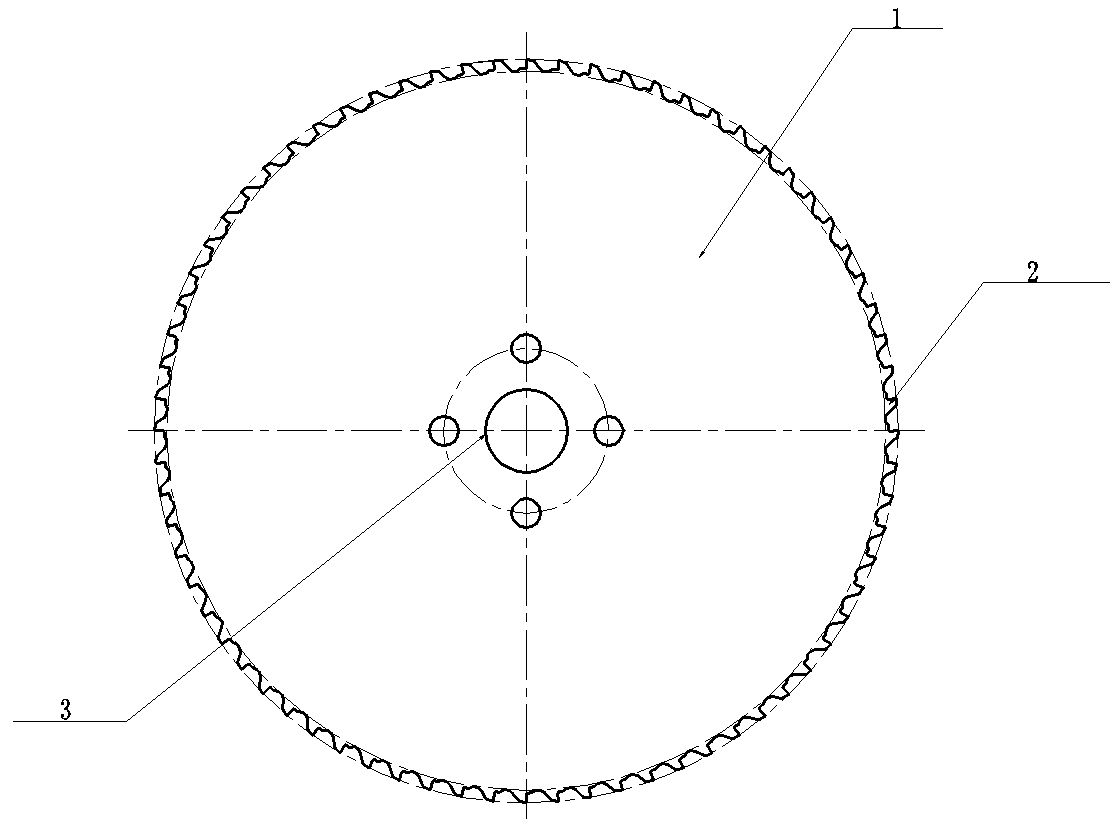

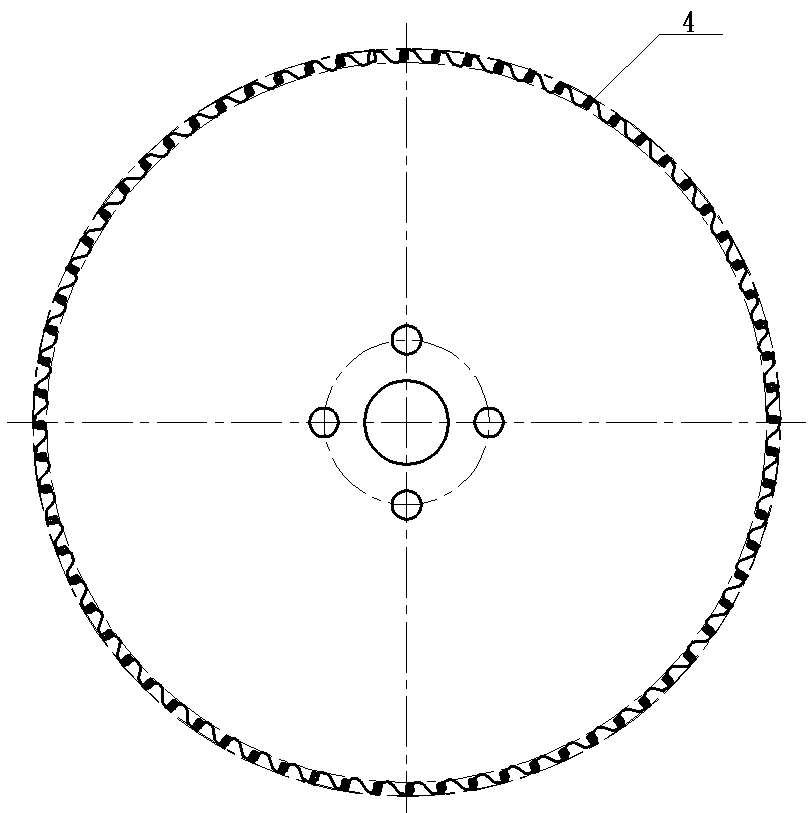

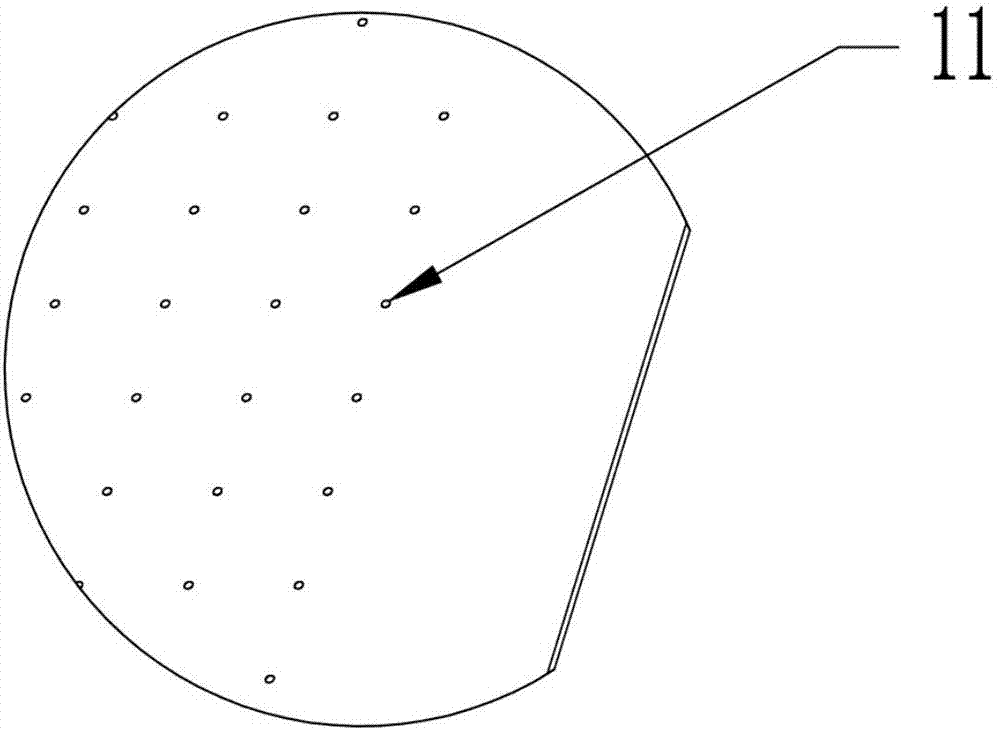

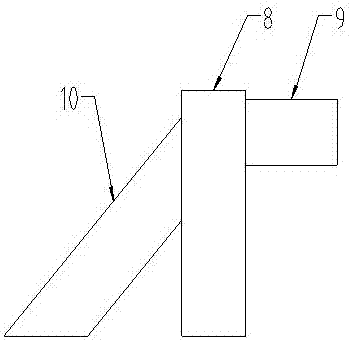

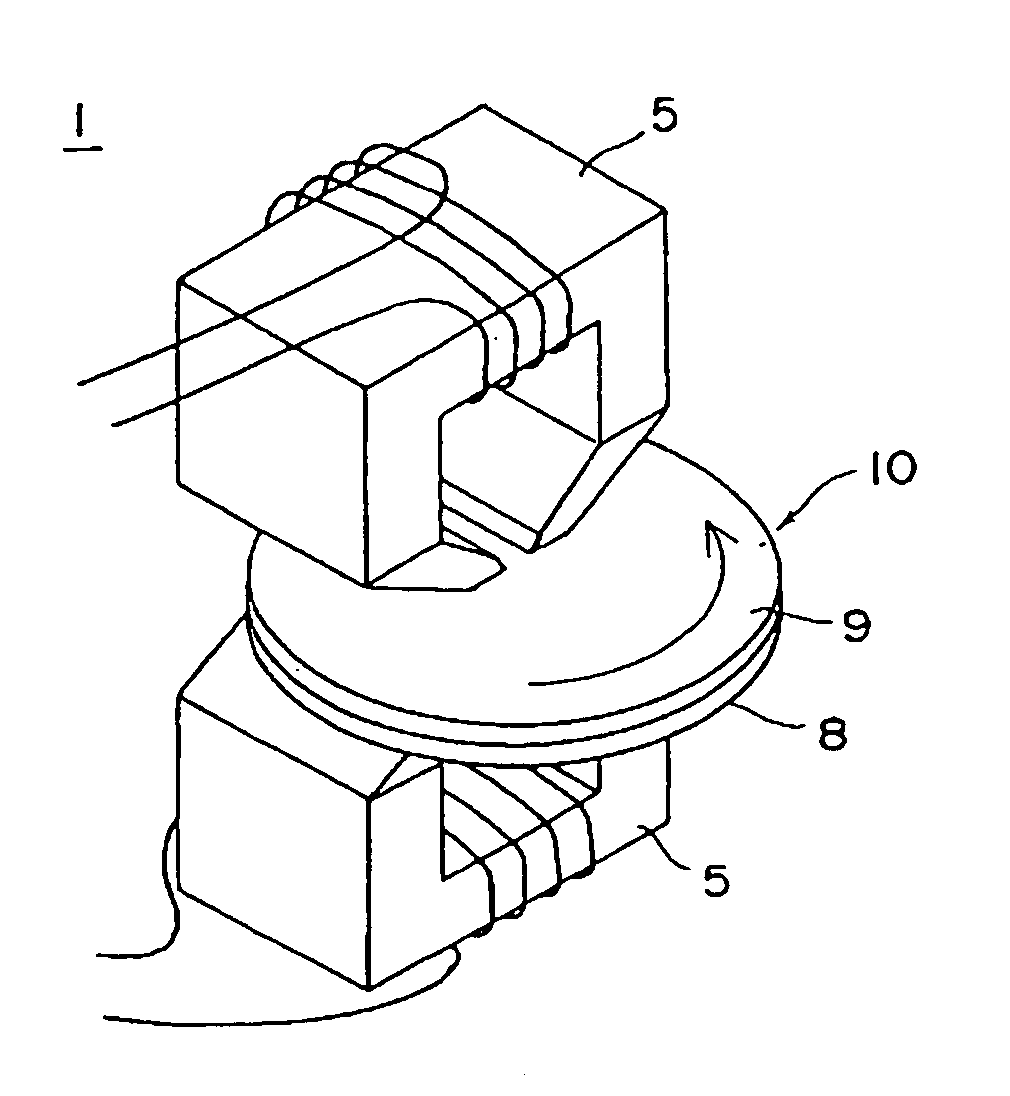

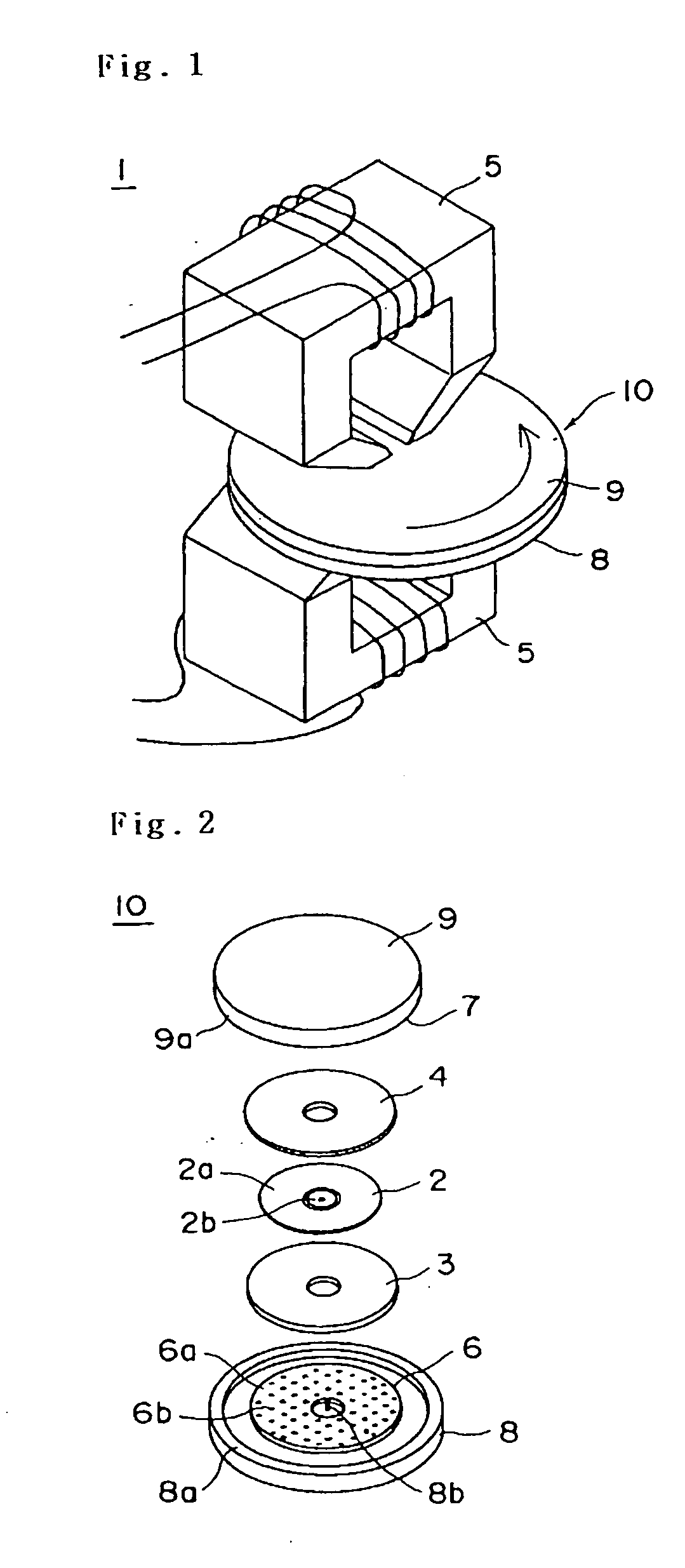

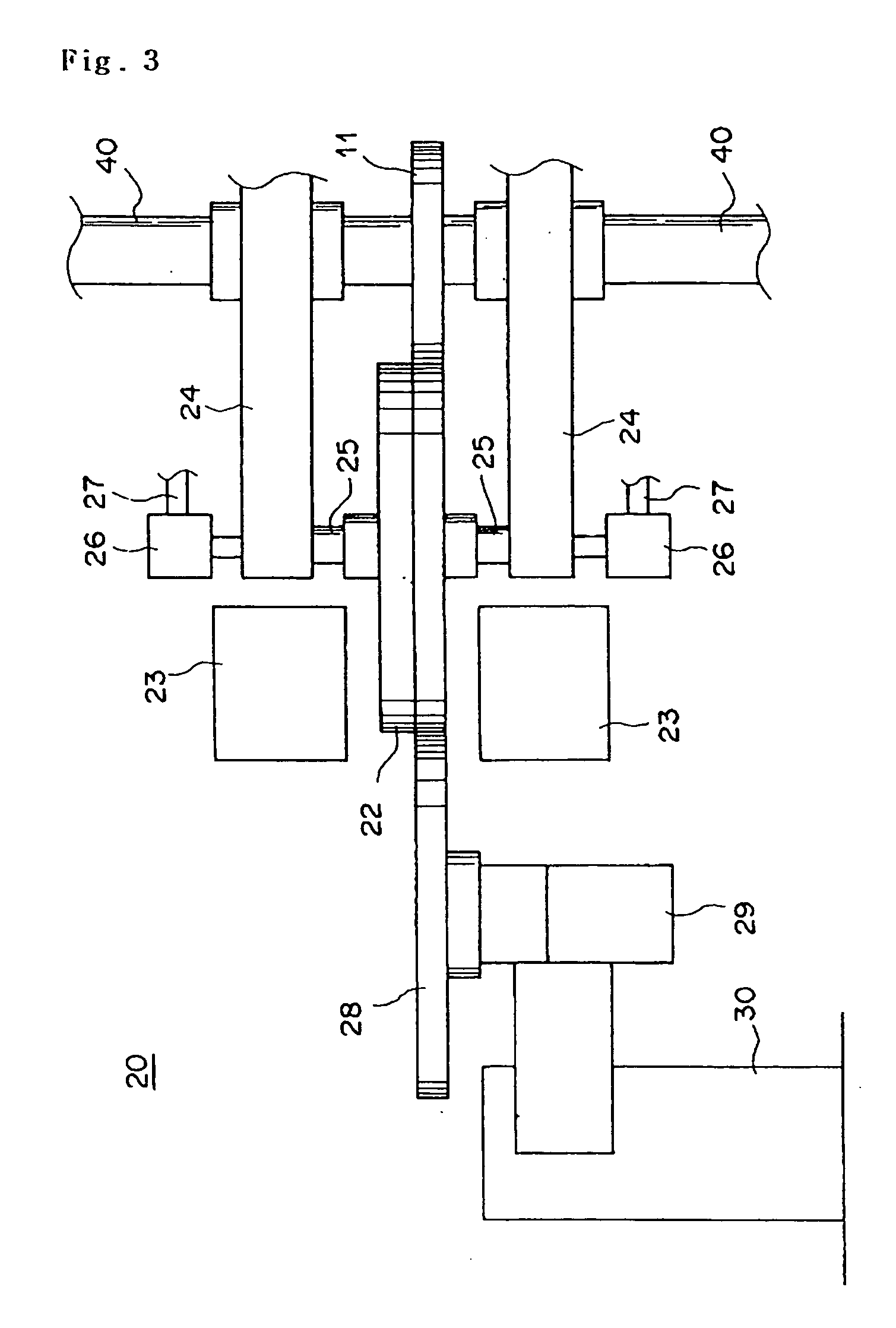

Magnetic transfer apparatus

InactiveUS6909564B2Reduce omissionsLarge signalNanoinformaticsPatterned record carriersYoung's modulusEngineering

By bring a master carrier and a slave medium into close contact with uniform force when executing magnetic transfer by applying transfer magnetic field in the state that the master carrier and slave medium is in confronted close contact and received within a holder, inferiority of transfer such as omission of signals is prevented and quality of transfer signals is enhanced.The magnetic transfer apparatus executes magnetic transfer by applying transfer magnetic field by means of a magnetic field applying apparatus 5 after a master carrier 3, 4 bearing transfer information and a slave medium 2 to be transferred are brought into confronted close contact and received within a holder 10, wherein said holder 10 has a substantially circular shape and in particular, the circularity of holder is not less than 98%, wherein the flexural rigidity=Ed3 / 12 determined by Young's modulus E and thickness d of the holder is in the range of 0.1˜30 kN·m2 when the width of close contact area between the slave medium and master carrier is defined as 1m, and wherein the practical thickness of the holder is not less than 3 mm and not more than 15 mm.

Owner:FUJIFILM CORP +1

Adjustable ground leveling tool

PendingCN113266134AHigh flatness precisionImprove efficiencyBuilding constructionsCement mortarMechanical engineering

The invention discloses an adjustable ground leveling tool, and belongs to the technical field of building construction tools. The adjustable ground leveling tool comprises a ground leveling tool body and a height adjuster; the ground leveling tool body comprises an adjustable scraper and a leveling plate; a plurality of overflow holes are formed in the middle of the leveling plate, and groove type guide rails are arranged on the periphery of the leveling plate; the two ends of the adjustable scraper are buckled in the groove type guide rails on the two sides correspondingly, and a structure capable of sliding front and back is formed; the lower surface of the adjustable scraper makes contact with the upper surface of the leveling plate and is used for scraping away cement overflowing from the overflow holes; the height adjuster comprises a U-shaped structure component and a screw; and the screw sequentially penetrates an upper plane plate of the U-shaped structure component and the edge of the leveling plate, the leveling plate is fixed to the screw, and an opening of the U-shaped structure component faces the leveling plate. According to the adjustable ground leveling tool, cement mortar leveling operation can be facilitated, the ground leveling efficiency and flatness precision are improved, and height finding and slope finding operation can be conducted in cooperation with the height adjuster.

Owner:ZHEJIANG YASHA DECORATION

A double-layer structure vacuum suction table

The invention relates to a vacuum suction table of a double-layer structure. The vacuum suction table comprises a frame, a bottom plate, a panel and honeycomb cores; the bottom plate is provided with bottom plate suction openings and the panel is covered with small adsorption holes; the vacuum suction table is characterized in that the inner region of the frame includes air duct regions and installation regions, the air duct regions and the installation regions are independent mutually, the air duct regions are internally provided with air duct suction openings which are communicated with the bottom plate suction openings in a one-to-one correspondence mode, the installation regions correspond to the honeycomb cores one to one, and the frame is filled with corrugated cores located above the honeycomb cores, each corrugated core includes an upper end face, a lower end face and supporting connection faces, each upper end face is combined with the supporting connection faces located at the two sides of the upper end face to form an aeration area which is communicated with the corresponding air duct region, the upper end faces are connected with the panel and provided with small air holes A which are communicated with the small adsorption holes in a one-to-one correspondence mode, a part of lower end faces are in connection with the corresponding honeycomb cores in a covering mode, and the other part of the lower end faces are connected with the corresponding air duct regions. The vacuum suction table is high in strength, internal gas paths are small in windage resistance, energy loss is low, and adsorption force is large and uniform.

Owner:FOSHAN SHUNDE DISTRICT YINMEI FINE HARDWARE TECH

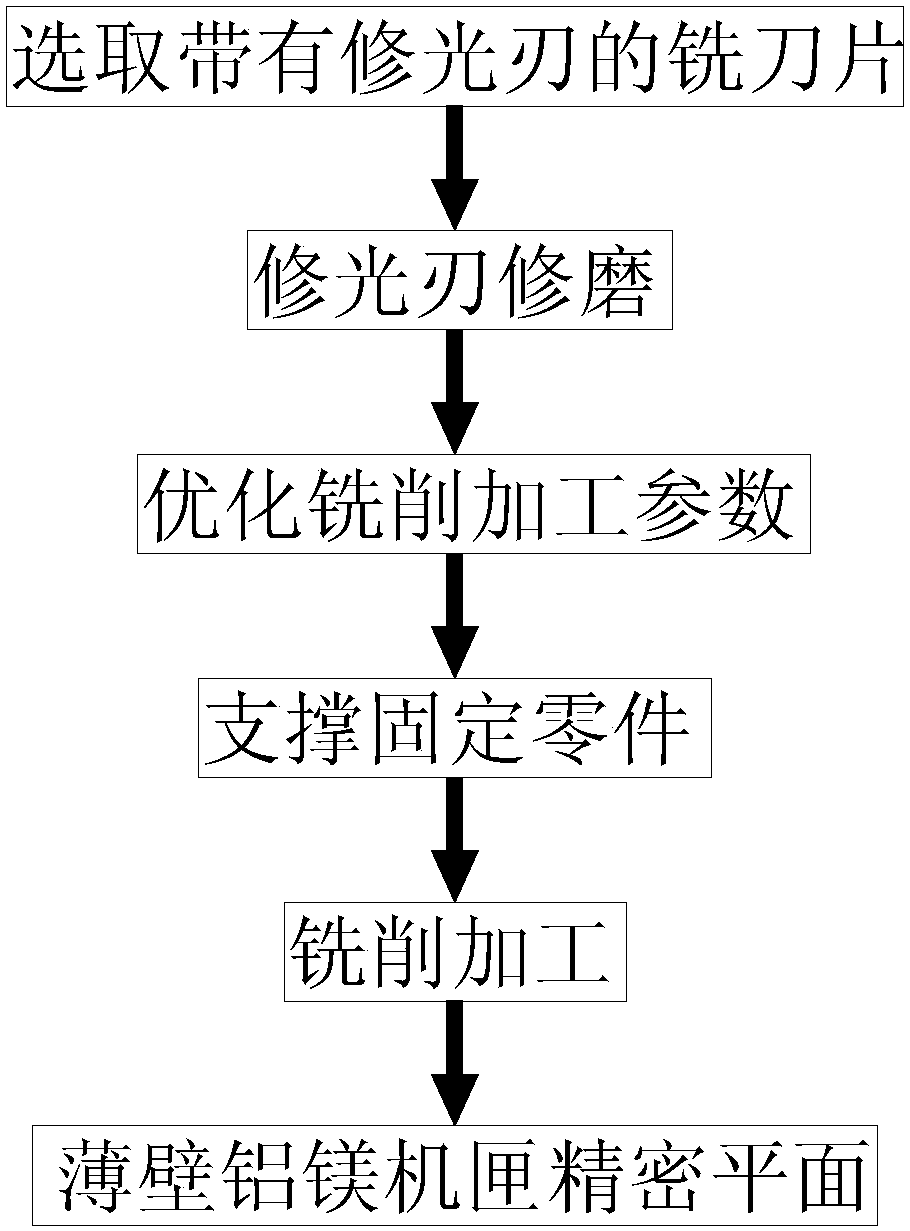

Milling method of precision cavity plane for thin-walled aluminum-magnesium casing of aero-engine

ActiveCN105665800BHigh speedReduce vibrationMilling equipment detailsMilling cutting insertsMachined surfaceEngineering

Owner:CHINA HANGFA SOUTH IND CO LTD

A foldable small hole large noodle machine with anti-scraper

The invention discloses a foldable small-hole large-face machine plus anti-scraping tool, which includes an end cover, a knife seat, a joint and a knife bar; the knife bar is connected to the main shaft on the machine tool, and the joint is installed on the knife bar. The lower end of the knife seat is movably mounted on the joint, and the upper end of the knife seat is movably mounted on the end cover, and a forming blade is installed on the knife seat, and the knife seat can rotate between the end cover and the joint; when the end cover, the knife When the seat and the joint are connected together in turn, the rotation of the main shaft on the machine tool drives the corresponding rotation of the knife rod, so that the automatic folding and unfolding of the forming blade between the end cover and the joint is realized. The foldable small-hole large-face machine plus anti-scraping tool of the present invention realizes the automatic folding and unfolding function of the tool holder by using the machine tool spindle, cancels the manual loading and unloading process, simplifies the machining process of small-hole large-face structure, releases labor force, and improves Machine efficiency.

Owner:XUZHOU HEAVY MASCH CO LTD

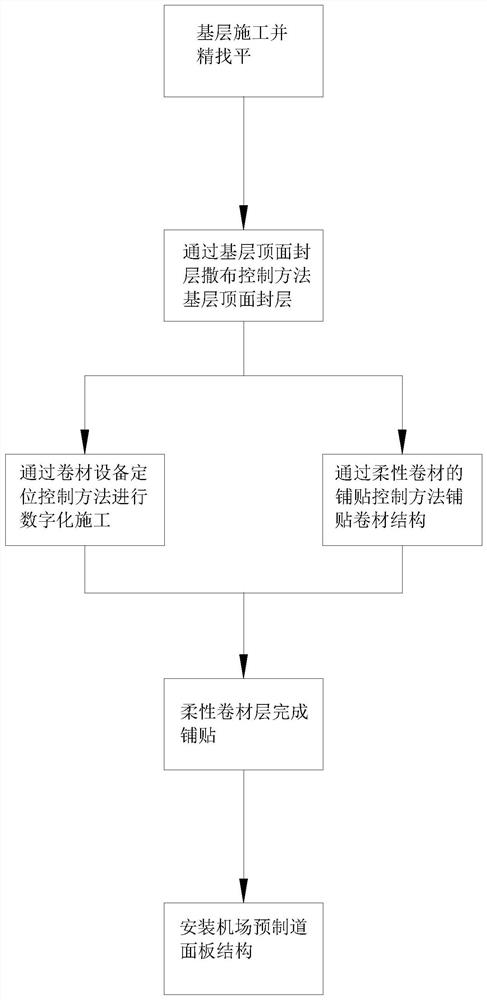

Novel airport fabricated pavement flexible transition layer system and method

ActiveCN113215886AImprove adhesionEfficient pavingClimate change adaptationRoads maintainenceStructural engineeringMechanical engineering

The invention discloses a novel airport fabricated pavement flexible transition layer system and method, and relates to the field of fabricated airport pavements. A sealing layer and a flexible coiled material are spread on the top surface of a court road base layer, the flexible coiled material is mechanically paved, and further the top surface of the court road base layer is leveled through professional spreading equipment, and a coiled material bonding surface is provided; and the laying and pasting of the coiled material are conducted at the same time through laying and pasting professional equipment, and the top face is further leveled. According to the flexible transition layer system and the method, the flatness of the top surface of the court road base layer is further improved, the waterproof performance of the pavement is improved, the seal coat protects the base layer and is free of laying of coiled materials, and the laying and bonding efficiency of the coiled materials is improved; and meanwhile, hard contact between prefabricated plates on the coiled materials and the base layer is avoided through the coiled materials, the stress concentration at the bottom of the plate is reduced, the stress state of the bottom of a prefabricated pavement plate is improved, and the stability of the fabricated pavement is further improved.

Owner:NO 4 ENG COMPANY LTD OF CCCC FIRST HARBOR ENG COMPANY

High-flatness printed circuit board (PCB) embedded with ceramic blocks and preparation process of high-flatness PCB

PendingCN114828406AHigh flatness precisionSimple preparation processPrinted circuit manufacturePrinted circuit non-printed electric components associationHigh volume manufacturingMechanical engineering

The invention discloses a high-flatness printed circuit board (PCB) embedded with ceramic blocks and a preparation process thereof, the high-flatness PCB embedded with ceramic blocks comprises a PCB body, the PCB body comprises a conventional steel plate, a release film, a PCB layer and a release steel plate which are laminated from top to bottom; the PCB layer comprises a first circuit layer, a first core layer, a second circuit layer, a PP bonding layer, a third circuit layer, a second core layer and a fourth circuit layer which are formed by hot melting from top to bottom; the middle part of the PCB layer is provided with an empty groove used for installing a ceramic block. And the empty slot penetrates through the first circuit layer, the first core layer, the second circuit layer, the PP bonding layer, the third circuit layer, the second core layer and the fourth circuit layer. When the PCB body is pressed, the ceramic block is in direct contact with the release steel plate, so that the high flatness precision of the ceramic block and the surface of the PCB layer is within + / -5 microns, and meanwhile, the preparation process is simple, the manufacturing cost is relatively low, and the PCB is suitable for large-scale production.

Owner:CHENGYI ELECTRONICS JIAXING

Road surface detection method, device, computer equipment and storage medium

ActiveCN110084116BHigh precisionHigh flatness precisionImage analysisThree-dimensional object recognitionPoint cloudSimulation

The present application relates to a road surface detection method, device, computer equipment and storage medium. The method includes: acquiring a ground point cloud of the road surface to be detected; constructing a grid map according to the ground point cloud, determining the two-dimensional ground points covered by each grid in the grid map; acquiring the ground point cloud of each grid The height value of the two-dimensional ground points covered by each grid, and the flatness of the road surface to be detected is determined according to the height value of the two-dimensional ground points covered by each grid. By adopting the method, road surface detection with higher precision can be realized.

Owner:SUTENG INNOVATION TECH CO LTD

An extra-long guide rail of a three-coordinate measuring machine

InactiveCN103528553BImprove locking effectHigh flatness precisionMeasurement devicesAir bearingHigh intensity

Owner:浙江时代计量科技有限公司

Radar reflector system and its leveling method and construction method

ActiveCN110879384BRealize local flatness adjustmentHigh flatness precisionWave based measurement systemsRadarEngineering

The invention provides a radar reflective surface system and its leveling method and construction method. The radar reflective surface is fabricated by using the whole board, and the completed radar reflective surface is installed on a support frame, and the support frame divides the radar reflective surface into several sub-reflective surfaces. , and then set the first adjustment point of the control edge area and the second adjustment point of the control center area for each sub-reflection surface, and use an iterative method to comprehensively control the force on each adjustment point on each sub-reflection surface to realize the control of the radar reflection surface. Adjust the local flatness, and finally complete the adjustment of the overall flatness of the radar reflective surface.

Owner:JIANGSU NANSHUI TECH +2

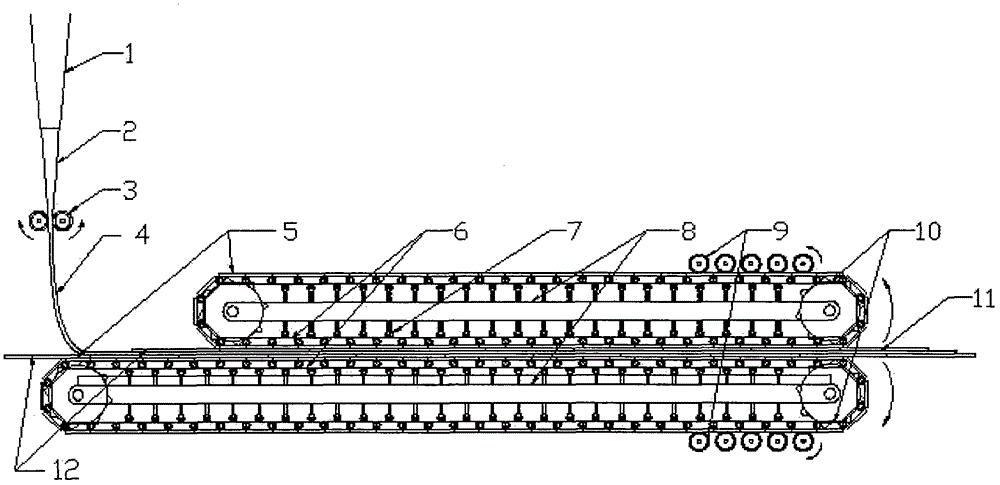

Two-step molding method of thin plate glass pre-pressing

InactiveCN102452787BHigh thickness accuracyHigh flatness precisionGlass rolling apparatusDisplay boardLearning machine

The invention relates to a two-step forming method for pre-pressing and maintaining a thin plate glass, which belongs to the field of liquid crystal display panel glass substrate and panel forming. It installs a pair of pre-pressing rollers with narrow slits parallel to the cross-sectional direction of the molten glass ribbon under the outlet of the high-temperature molten glass, and pre-presses the molten glass ribbon left by the outlet of the molten glass with narrow slits. Under it are installed two crawlers composed of flat track shoes that run relatively synchronously, and the pre-pressed glass liquid belt is introduced into it, and after extrusion, shaping and gradually cooling and annealing, it becomes the extrusion gap of the flat track shoes on the same track. Thick sheet glass. As shown in Figure 1. Because of the forced pressing of mechanical molds, the thickness and flatness precision of thin plate glass can be guaranteed. The surface of the glass sheet is controlled by the surface quality of the extruded flat die, so mirror precision can be achieved. This molding method is a molding technology for flat display substrates and touch panel glass of mobile phones, car GPS, PDA, learning machines, notebook computers and other products.

Owner:王建伟

Pile head cutting machine for CFG (cement fly-ash gravel) piles

ActiveCN102172988BAchieve mechanical cuttingGuaranteed 3D cutting controlStone-like material working toolsControl systemFly ash

The invention belongs to the technical field of construction machines and devices for CFG (cement fly-ash gravel) piles in a roadbed and roadbed reinforcement projects and particularly relates to a pile head cutting machine for CFG piles, and the machine provided by the invention is used for solving the problems that the existing cutting machine is incomplete in performances and can not meet the pile head cutting requirement of the CFG piles. The pile head cutting machine for the CFG piles comprises a control system, the control system further comprises a vertical fine adjustment control system for a cutting saw, the vertical fine adjustment control system comprises a vertical transmission lead screw, the vertical transmission lead screw, an upper screw nut which is fixed opposite to a vertical support frame and a lower screw nut which can slide relative to the vertical support frame and be fixed relative to the vertical support frame are matched and connected, and the lower screw nut is connected with an electric motor through a connecting part. By adopting the pile head cutting machine for the CFG piles, the three-dimensional cutting control in the circumferential direction, radial direction and vertical direction can be realized during the cutting process, the stable performances of the device during the cutting process can be ensured, the work efficiency of standardized operation is improved, the operation space is reduced, and the air dust pollution is reduced during the construction.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

High-strength heat-resistant chip removal titanium film saw blade and machining process thereof

PendingCN114012179AHigh strengthExtend your lifeMetal sawing toolsSawing tools dressing arrangementsTool bitEngineering

The invention discloses a high-strength heat-resistant chip removal titanium film saw blade and a machining process thereof. The high-strength heat-resistant chip removal titanium film saw blade comprises a saw blade base body; the outer surface of the saw blade base body is plated with a titanium film; a center hole is formed in the center of the saw blade base body; a plurality of heat dissipation holes are formed in the outer side of the center hole in the circumferential direction; a plurality of sawteeth and chip grooves are arranged on the outer surface of the saw blade base body in a staggered mode; tool bits are welded and fixed to the sawteeth; and the sides, close to the center of the saw blade base body, of the chip grooves are communicated with extension grooves. The saw blade has the advantages that accumulation of flying chips generated by the saw blade on the saw blade is reduced through the design of the chip grooves, the saw blade can generate a large amount of heat in the high-speed cutting process, the heat dissipation holes form convection heat dissipation, the heat dissipation effect is good, the service life of the saw blade is prolonged, and the adaptability of the saw blade is improved.

Owner:ZHEJIANG JUNYE TOOL CO LTD

Multifunctional aluminum and aluminum alloy plate full-size hydraulic leveler

Owner:DALIAN HUICHENG ALUMINUM

Final joint transporting base and construction method

ActiveCN107419750AEasy material selectionEasy to useArtificial islandsUnderwater structuresEngineeringBearing capacity

The invention discloses a final joint transporting base and a construction method. The final joint transporting base comprises concrete layers arranged on a barge deck and sleeper layers next to the upper portions of the concrete layers. The concrete layers are symmetrically arranged with respect to the center lines of the width direction and the length direction of the barge deck, and the sleeper layers are formed by horizontally laying a plurality of sleepers next to one another; and a plurality of limiting block frames making contact with the sleeper layers are arranged on the barge deck. According to the final joint transporting base and the construction method, the final joint transporting base is designed to be of a structure that the concrete layers and the sleeper layers are combined, the structure can eliminate the impacts brought by the uneven surface of the deck, meanwhile deformation of the ship body deck in the transportation process can be avoided, the bearing capacity of the barge deck is ensured, and thus the effects of the high overall planeness precision, low manufacturing cost, simple construction technology and good stiffness are achieved.

Owner:SHANGHAI ZHENHUA HEAVY IND

Preparing method of whole welding type guide rail

InactiveCN111168264ASmooth runningPrecise positioningRailsWelding/cutting auxillary devicesIndustrial engineeringGrinding

The invention discloses a preparing method of a whole welding type guide rail. The whole welding type guide rail serves as a motion basis of a certain large rotation device, and has the advantages ofbeing large in diameter, high in precision and stability and the like. The basis problems about high-precision motion and precision positioning of the certain large rotation device can be solved, a main structure is formed through whole welding of multiple segments of single-rail parts, and the design and manufacturing process comprises the six steps of single-rail part design, welding groove design, single-rail part manufacturing, guide rail mounting, guide rail welding, U-shaped welding line grinding and the like. Guide rail mounting and guide rail welding serve as key processes, and the method has the important significance in ensuring precision and stability of the whole guide rail.

Owner:CHINA PRECISION ENG INST FOR AIRCRAFT IND AVIC

Magnetic transfer apparatus

InactiveUS20050190470A1Reduce omissionsLarge signalNanoinformaticsPatterned record carriersYoung's modulusFlexural rigidity

By bring a master carrier and a slave medium into close contact with uniform force when executing magnetic transfer by applying transfer magnetic field in the state that the master carrier and slave medium is in confronted close contact and received within a holder, inferiority of transfer such as omission of signals is prevented and quality of transfer signals is enhanced. The magnetic transfer apparatus executes magnetic transfer by applying transfer magnetic field by means of a magnetic field applying apparatus 5 after a master carrier 3, 4 bearing transfer information and a slave medium 2 to be transferred are brought into confronted close contact and received within a holder 10, wherein said holder 10 has a substantially circular shape and in particular, the circularity of holder is not less than 98%, wherein the flexural rigidity=Ed3 / 12 determined by Young's modulus E and thickness d of the holder is in the range of 0.1˜30 kN·m2 when the width of close contact area between the slave medium and master carrier is defined as 1 m, and wherein the practical thickness of the holder is not less than 3 mm and not more than 15 mm.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com