Machining technology for cold saw blade

A processing technology and saw blade technology, which is applied in the processing technology field of cold saw blades, can solve the problems of low finished product rate of cold saw blades, and achieve the effects of high precision, guaranteed cleanliness, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

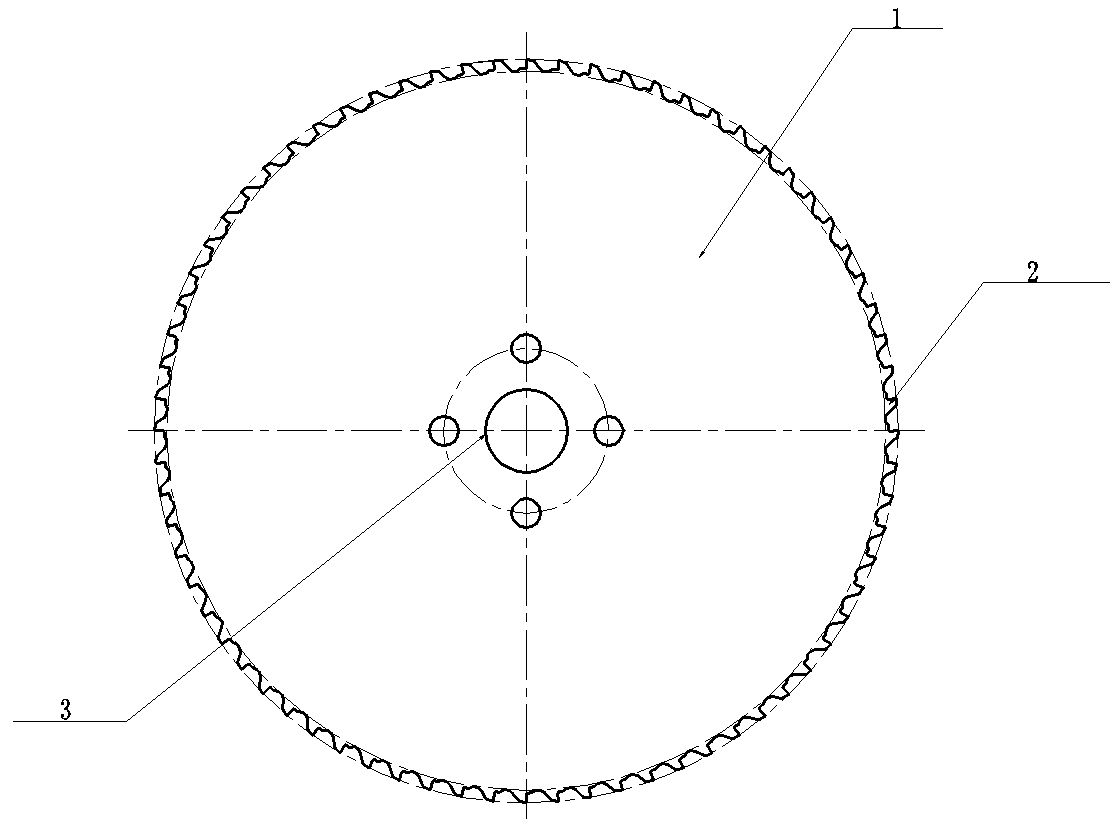

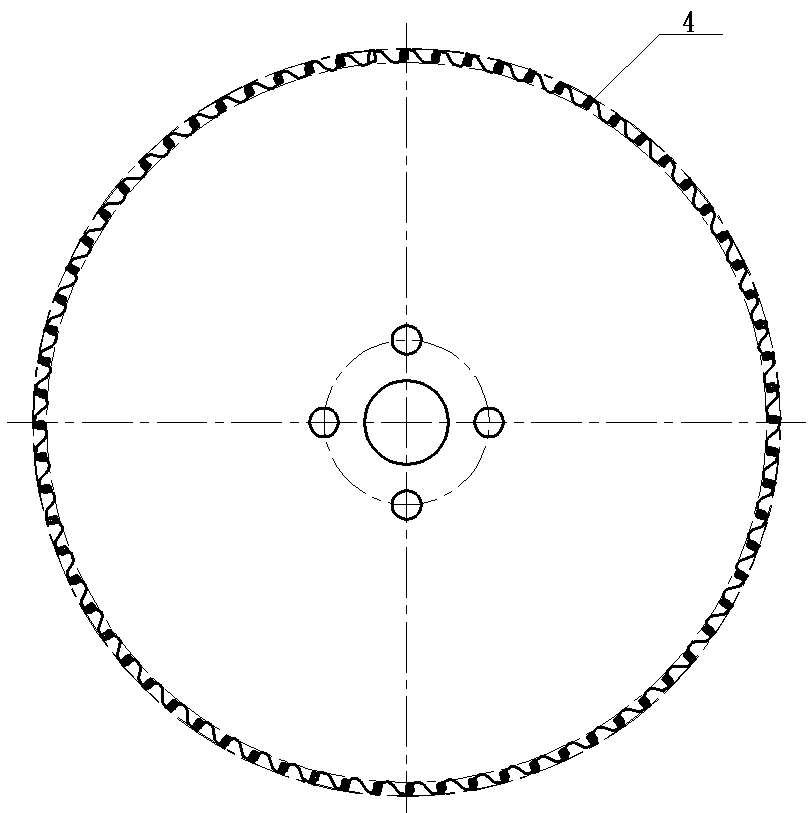

[0032] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0033] Such as Figure 1~2 Shown, the saw blade substrate of the present invention passes through a series of processing to the processing step that finished product figure passes through as follows:

[0034] S1. Cutting the plate: cutting the plate to obtain a circular saw blade base with sawtooth;

[0035] S2. Deburring the surface of the saw blade base: First, use an angle grinder to manually deburr the surface of the saw blade base. After removing the large burrs on the saw blade surface, use a fully automatic deburring machine to deburr the saw blade base again. glitch;

[0036] S3. Tempering the saw blade base: tempering the saw blade base: tempering and stress relief heat treatment on the saw blade base, tempering temperature: 360°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com