A high-strength and high-toughness large martensitic stainless steel ring forging and its manufacturing method

A martensitic stainless steel, manufacturing method technology, applied in the direction of manufacturing tools, furnace types, engine components, etc., can solve the problems of unstable impact energy, cracking, etc., to shorten the production cycle and manufacturing costs, improve stability, and optimize chemistry The effect of ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A high-strength and high-toughness large-scale martensitic stainless steel ring forging, in terms of weight percentage, the chemical composition of the martensitic stainless steel includes C: 0.22%, Mn: 0.975%, P: 0.015%, S: 0.020%, Si: 0.001%, Cr: 15%, Mo: 0.10%, Ni: 2.5%, Cu: 0.10%, V: 0.005%, Nb: 0.025%, Ti: 0.020%, and the balance is Fe; at the same time, the gas composition meets : H: 1.5ppm, O: 40ppm, N: 200ppm.

[0052] The preparation method of the high-strength and high-toughness large-scale martensitic stainless steel ring forging is: it includes the following process steps,

[0053] Step 1, using the process of EAF+AOD to make the raw materials in the above parts by weight into steel ingots;

[0054] Step 2, forging the steel ingot to obtain a ring-shaped blank forging;

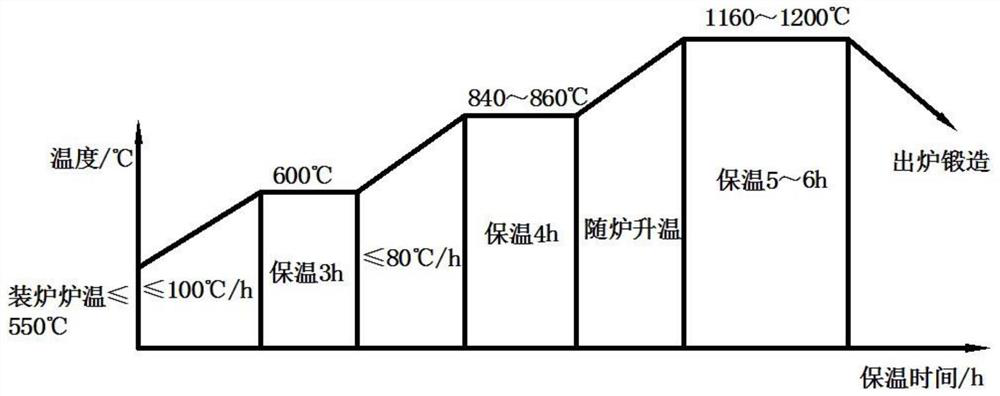

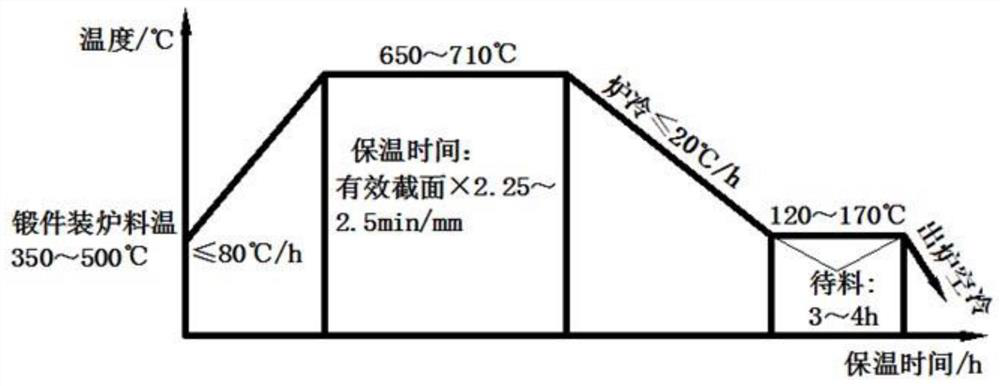

[0055] Step 3, then performing pre-forging heat treatment on the ring-shaped blank forging;

[0056] Step 4, performing mechanical rough machining and flaw detection on the ring forging t...

Embodiment 2

[0071] A high-strength and high-toughness large-scale martensitic stainless steel ring forging, in terms of weight percentage, the chemical composition of the martensitic stainless steel includes C: 0.14%, Mn: 1.5%, P: 0.030%, S: 0.010%, Si: 0.60%, Cr: 15.25%, Mo: 0.0020%, Ni: 2.25%, Cu: 0.001%, V: 0.05%, Nb: 0.010%, Ti: 0.0020%, and the balance is Fe; at the same time, the gas composition meets : H: 0.03ppm, O: 20ppm, N: 300ppm.

[0072] The preparation method of the high-strength and high-toughness large-scale martensitic stainless steel ring forging is: it includes the following process steps,

[0073] Step 1, using the process of EAF+AOD to make the raw materials in the above parts by weight into steel ingots;

[0074] Step 2, forging the steel ingot to obtain a ring-shaped blank forging;

[0075] Step 3, then performing pre-forging heat treatment on the ring-shaped blank forging;

[0076] Step 4, performing mechanical rough machining and flaw detection on the ring forg...

Embodiment 3

[0094] A high-strength and high-toughness large-scale martensitic stainless steel ring forging, in terms of weight percentage, the chemical composition of the martensitic stainless steel includes C: 0.18%, Mn: 0.45%, P: 0.002%, S: 0.003%, Si: 0.030%, Cr: 15.5%, Mo: 0.20%, Ni: 2.0%, Cu: 0.20%, V: 0.10%, Nb: 0.050%, Ti: 0.010%, and the balance is Fe; at the same time, the gas composition meets : H: 3ppm, O: 5ppm, N: 400ppm.

[0095] The preparation method of the high-strength and high-toughness large-scale martensitic stainless steel ring forging is: it includes the following process steps,

[0096] Step 1, using the process of EAF+AOD to make the raw materials in the above parts by weight into steel ingots;

[0097] Step 2, forging the steel ingot to obtain a ring-shaped blank forging;

[0098] Step 3, then performing pre-forging heat treatment on the ring-shaped blank forging;

[0099] Step 4, performing mechanical rough machining and flaw detection on the ring forging that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com