Steel plate high-speed cold-cutting rotary sawing machine

A circular saw machine, high-speed technology, applied in the direction of sawing machine, metal sawing equipment, sawing machine tool, etc., can solve the problems of unsmooth feeding or sawing, high repair or maintenance costs, and low automation procedures , achieve the effect of saving consumables, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

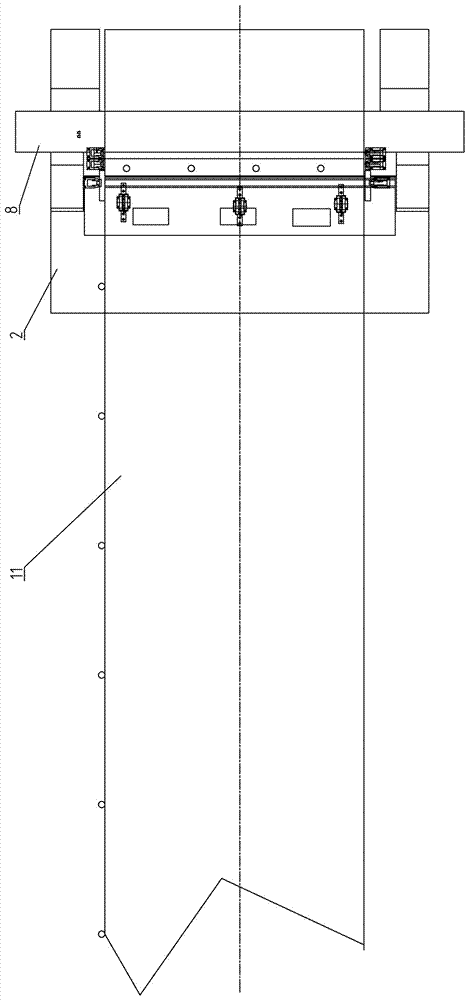

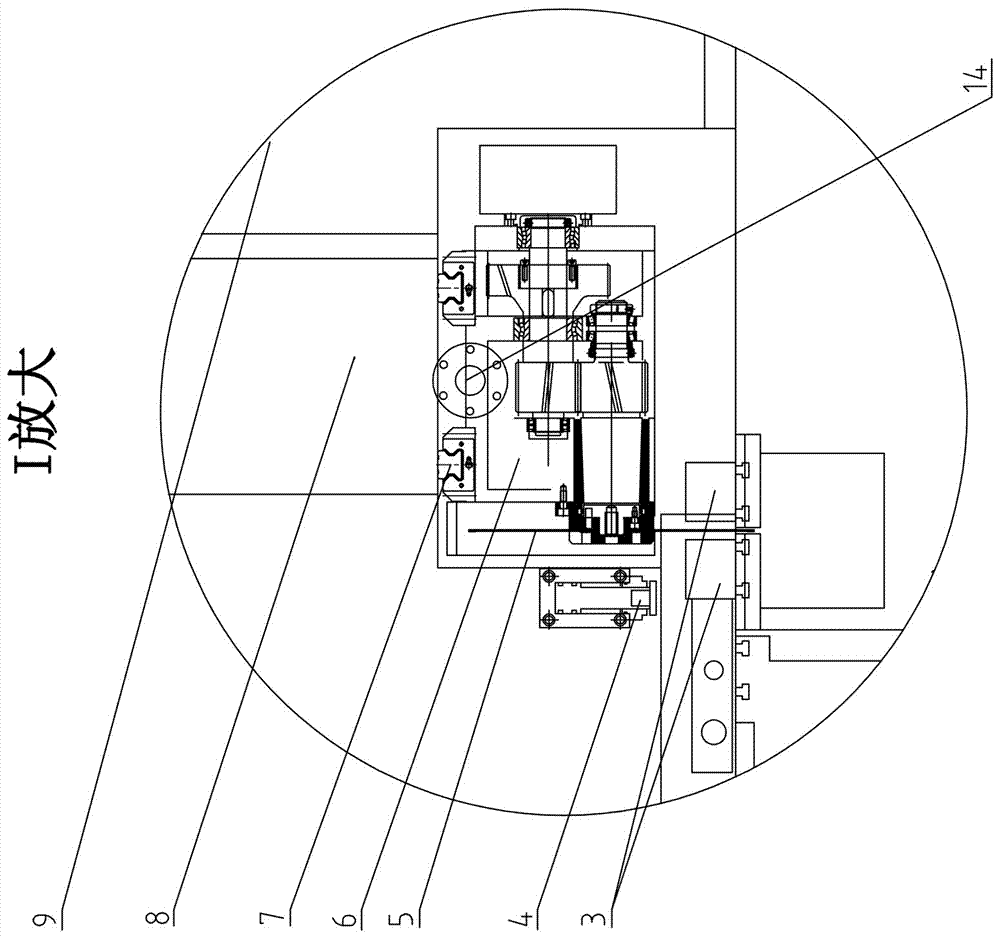

[0024] Such as figure 1 , 2 As shown, the circular saw machine includes a frame part composed of a base 2, a gantry column 9, a feed beam 8, etc.; , feeding screw 13, support 15, roller 16, etc.; composed of pressing oil cylinder 4, saw blade 5, high-speed circular saw gear box 6, precision feed slide rail 7, feed screw 14, etc. The sawing part, and the automatic control part. The steel plate 11 to be sawed is pushed to the sawing part through the feeding part to complete the sawing work.

[0025] Specifically, such as figure 1 , 2 As shown, the gantry column 9 of the frame part is installed on the base 2, and the feed beam 8 is arranged on the gantry column 9 side. The precise feeding slide rail 10 of the feeding part, the feeding screw mandrel 13 and the fixed-size feeding slide table 1 are installed on the base 2 . The precision feed slide rail 7 and the feed screw mandrel 14 of the sawing part are installed on the feed beam 8 .

[0026] Specifically, such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com