Wire cutting cold saw alloy tool bit tooth shifting mechanism

A wire cutting and alloy knife technology, applied in the field of wire cutting and cold saw alloy blade gear shifting mechanism, can solve the problems of large cutting volume, large water volume, fast wear of grinding wheel, etc., achieve high repeat positioning accuracy, simple structure, and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

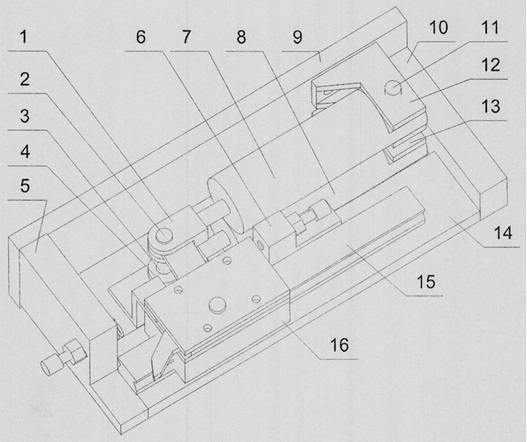

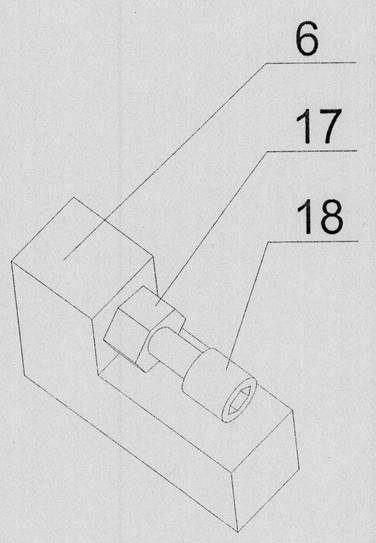

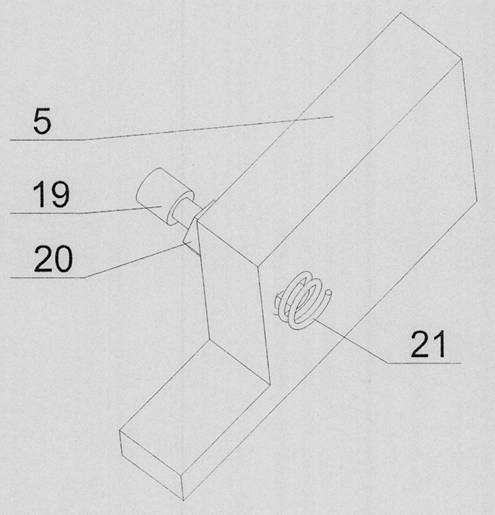

[0013] As shown in the figure, the present invention is provided with a power cylinder frame 12 and a damping cylinder frame 13 on the front mounting plate 9, a left baffle plate 5 and a right baffle plate 10 are arranged at both ends of the front mounting plate 9, and on the power cylinder frame 12 There is a power cylinder 7 connected with the cylinder pendulum shaft 11, the power cylinder 7 is provided with a power cylinder Y joint 1, and the rotating shaft 2 above the power cylinder Y joint 1 is connected with the gear head 25, and the damping cylinder frame 13 is provided with a cylinder The damping cylinder 8 connected to the pendulum shaft 11 is provided with a damping cylinder Y joint 4, the damping cylinder Y joint 4 is connected to the damping cylinder connecting frame 26 with the rotating shaft 3 below the damping cylinder 8, and a bottom plate is provided between the left baffle plate 5 and the right baffle plate 10 14. The bottom plate 14 is provided with a guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com