Preparation method and use of shear thickening fluid

A fluid and equipment technology, applied in the application field of low-viscosity silicone oil, can solve problems such as system instability, strong hygroscopicity, and resistance to shearing, and achieve stable product quality, enhanced effect, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Add SiO with an average particle size of 450nm to a mixture of 1.0kg of hydroxyl-terminated polydimethylsiloxane (molecular weight: 200) and 0.2kg of co-solvent absolute ethanol 2 0.3 kg of particles and 0.1 kg of titanium dioxide particles with an average particle size of 250 nm were treated with a planetary stirring device for 3 hours to obtain a shear thickening fluid diluted with absolute ethanol.

[0021] (2) Then, heat up the above-mentioned shear thickening fluid diluted with absolute ethanol to 55°C, slowly stir and volatilize under vacuum to remove absolute ethanol, and obtain the final shear thickening fluid A with a viscosity of 2500 ±500cps.

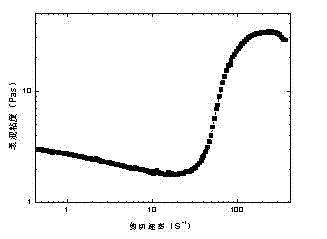

[0022] Shear thickening fluid A has good shear thickening properties and can well meet the needs of subsequent processing.

Embodiment 2

[0024] (1) Add SiO with an average particle size of 100nm to a mixture of 1.0kg of ethoxy-terminated polydimethylsiloxane (molecular weight: 500) and 0.05kg of absolute ethanol 2 0.35 kg of particles and 0.08 kg of titanium dioxide particles with an average particle size of 250 nm were treated with ultrasonic stirring equipment for 1 hour. A shear thickened fluid diluted with absolute ethanol was prepared.

[0025] (2) Then, raise the temperature of the above-mentioned shear thickening fluid diluted with absolute ethanol to 65°C, and at the same time slowly stir and volatilize the absolute alcohol under vacuum conditions to obtain the final shear thickening fluid B , the viscosity is 3000±500cps.

[0026] Shear thickening fluid B has good shear thickening properties, which can well meet the needs of subsequent processing.

Embodiment 3

[0028] (1) In a mixture of 0.5 kg of hydroxyl-terminated polydimethylsiloxane (molecular weight: 800), 0.5 kg of ethoxy-terminated polydimethylsiloxane (molecular weight: 250) and 0.4 kg of anhydrous isopropanol The average particle size of 100nm SiO was added to the mixture 2 Particles 0.25kg and average particle size 50nm SiO 2 Granules 0.20kg, treated with planetary stirring equipment for 3.5 hours.

[0029] (2) Then, the temperature of the shear thickening fluid diluted with anhydrous isopropanol prepared above was raised to 70°C, and at the same time, it was slowly stirred and volatilized under vacuum conditions to remove anhydrous isopropanol to obtain the final shear thickening fluid. Thick fluid C has a viscosity of 4000±600cps.

[0030] Shear thickening fluid C has good shear thickening properties, which can well meet the needs of subsequent processing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com