Preparation method for Carbon 5/Carbon 9 hydrogenated petroleum resin

A technology of hydrogenated petroleum resin and C9 petroleum resin, which is applied in the field of preparation of C5/C9 hydrogenated petroleum resin, can solve the problems of difficult hydrogenation, harsh operating conditions, insufficient hydrogenation degree, etc., so as to improve the effective Catalytic area, reduce equipment investment cost, reduce the effect of fluid pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

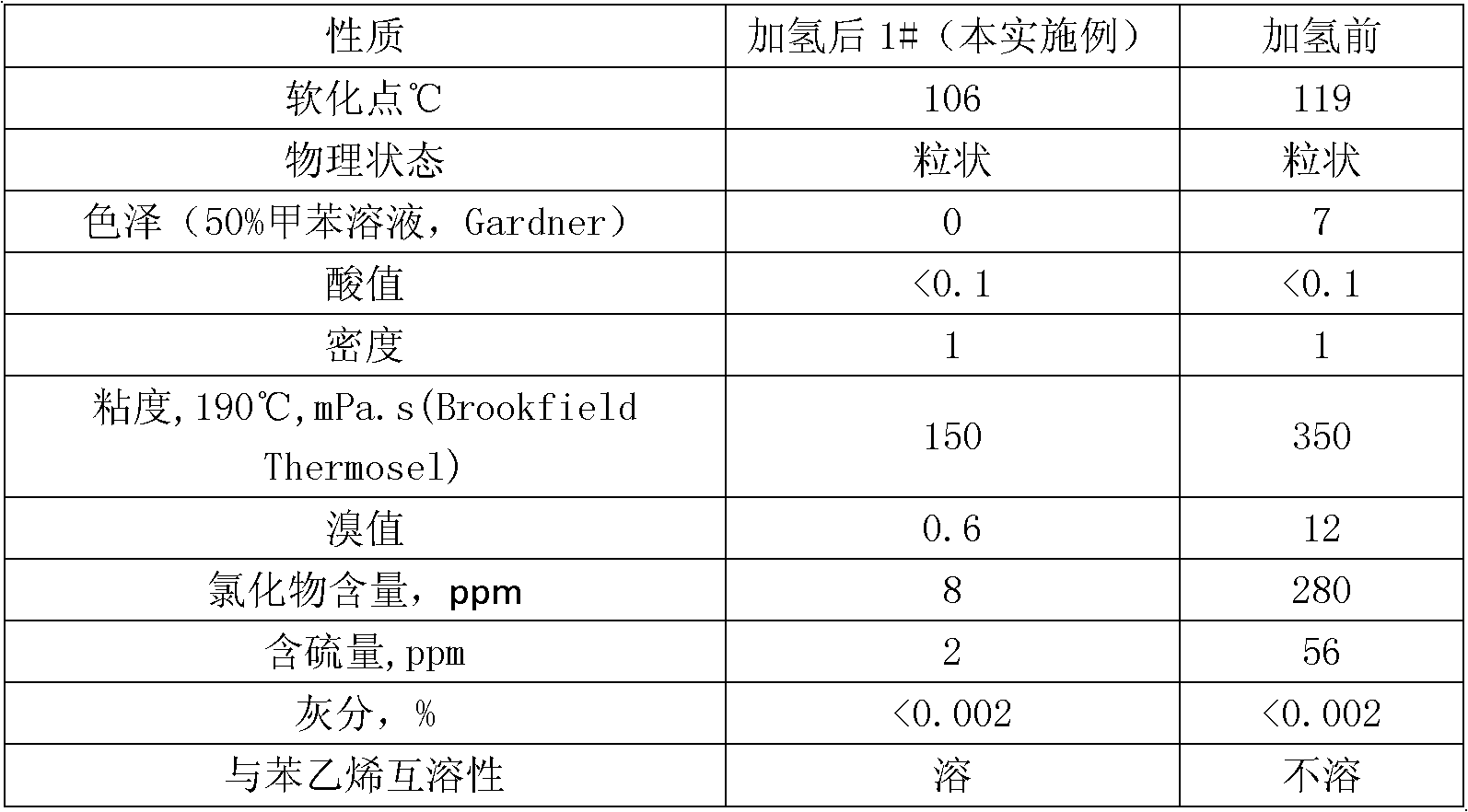

Embodiment 1

[0019] Preparation of Catalyst NiW / SiO 2 : The weight ratio of the catalyst components: the carrier silica is 79%, nickel 6%, tungsten trioxide 15%, and NiW / SiO is prepared by pore saturation co-impregnation method to load active metal components 2 , the specific surface area of the carrier is measured by mercury porosimetry as 14m 2 / g, pore diameter 550nm, pore volume are 1.5cc / g; above-mentioned catalyzer is vulcanized 3-5 hour at 650-750K in hydrogen (90%) and hydrogen sulfide (10%) mixed gas, is cooled to room temperature after vulcanization, and uses Nitrogen was purged for 0.5 hours, and stored in a sealed bottle filled with argon for later use.

[0020] Preparation of Catalyst Ru / SiO 2 : silicon dioxide (mass ratio 99%) is impregnated in the solution that dissolves ruthenium trichloride (ruthenium mass ratio 1%), evaporate to dryness at 100 DEG C then, 200 DEG C dry 3h, hydrogen reduction 2h at 400 DEG C at last, Catalyst Ru / SiO 2 , the carrier and the first-stag...

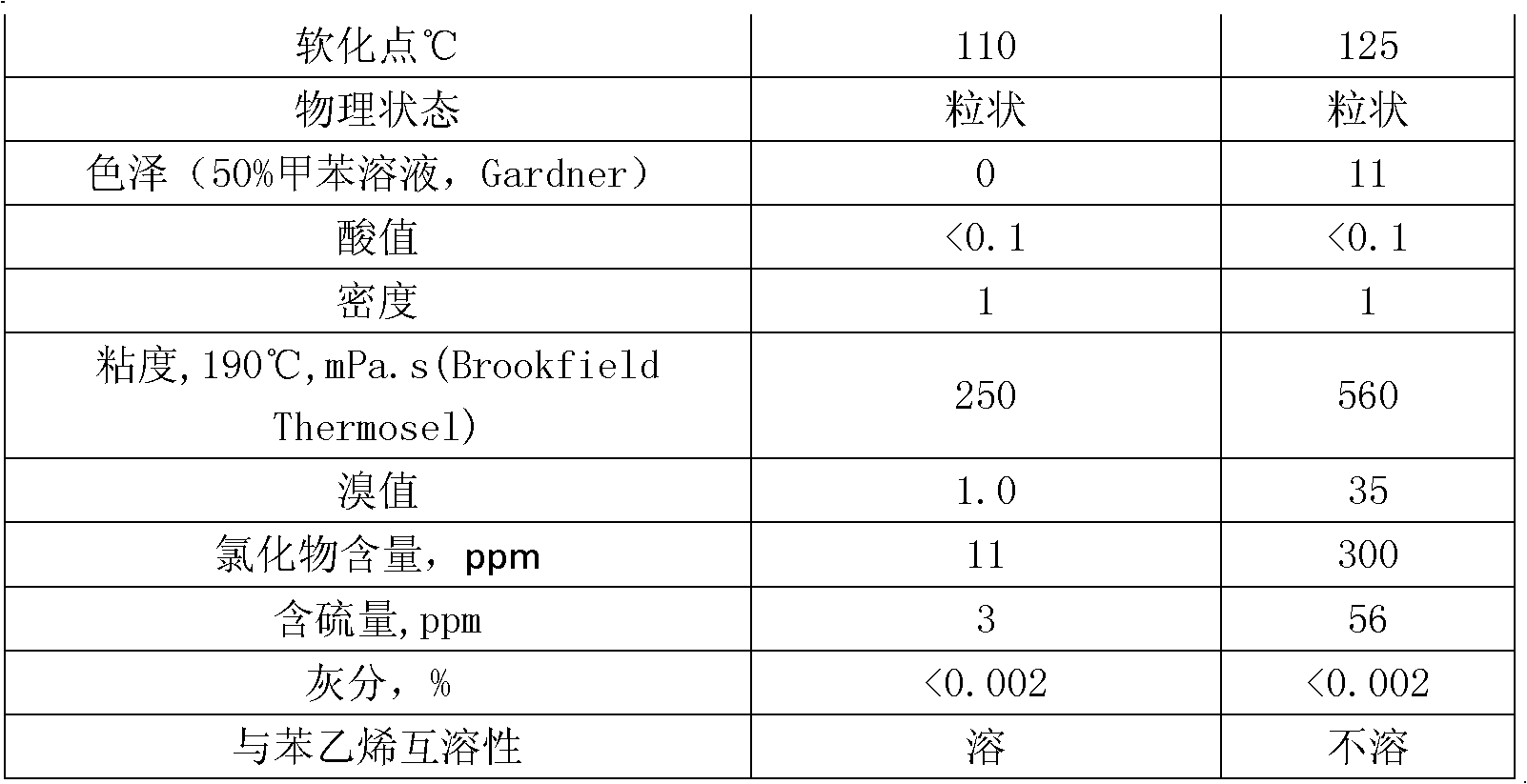

Embodiment 2

[0025] Preparation of Catalyst NiW / SiO 2 : The weight ratio of the catalyst components: the carrier silica is 70%, nickel 10%, tungsten trioxide 20%, and NiW / SiO is prepared by pore saturation co-impregnation method to load active metal components 2 , the specific surface area of the carrier is measured by mercury porosimetry as 13m 2 / g, average pore diameter 720nm, pore volume is 1.6cc / g; above-mentioned catalyst is vulcanized at 650-750K in the mixed gas of hydrogen (90%) and hydrogen sulfide (10%) for 3-5 hours, cool to room temperature after vulcanization, And purged with nitrogen for 0.5 hours, and stored in a sealed bottle filled with argon for later use.

[0026] Preparation of Catalyst Ru / SiO 2 : silicon dioxide (mass ratio 99%) is impregnated in the solution that dissolves ruthenium trichloride (ruthenium mass ratio 1%), evaporate to dryness at 100 DEG C then, 200 DEG C dry 3h, hydrogen reduction 2h at 400 DEG C at last, Catalyst Ru / SiO 2 , the specific surface...

Embodiment 3

[0032] Preparation of Catalyst NiW / SiO 2 : The weight ratio of the catalyst components: the carrier silica is 75%, nickel 8%, tungsten trioxide 15%, and the NiW / SiO is prepared by the pore saturation co-impregnation method to load the active metal component 2 , the specific surface area of the carrier was measured by mercury intrusion porosimetry to an area of 9m 2 / g, average pore diameter 1200nm, pore volume is 1.8cc / g; above-mentioned catalyst is vulcanized at 650-750K for 3-5 hours in the mixed gas of hydrogen (90%) and hydrogen sulfide (10%), cool to room temperature after vulcanization, And purged with nitrogen for 0.5 hours, and stored in a sealed bottle filled with argon for later use.

[0033] Preparation of Catalyst Ru / SiO 2 : silicon dioxide (mass ratio 99%) is impregnated in the solution that dissolves ruthenium trichloride (ruthenium mass ratio 1%), evaporate to dryness at 100 DEG C then, 200 DEG C dry 3h, hydrogen reduction 2h at 400 DEG C at last, Catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com