Compound type cooking fume purifier with coupling function

An oil fume purifier and composite technology, applied in the direction of removing oil fume, chemical instruments and methods, combined devices, etc., can solve the problems of power consumption, secondary pollution, and accelerated plastic aging, etc., to achieve enhanced purification effect, good purification effect, low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

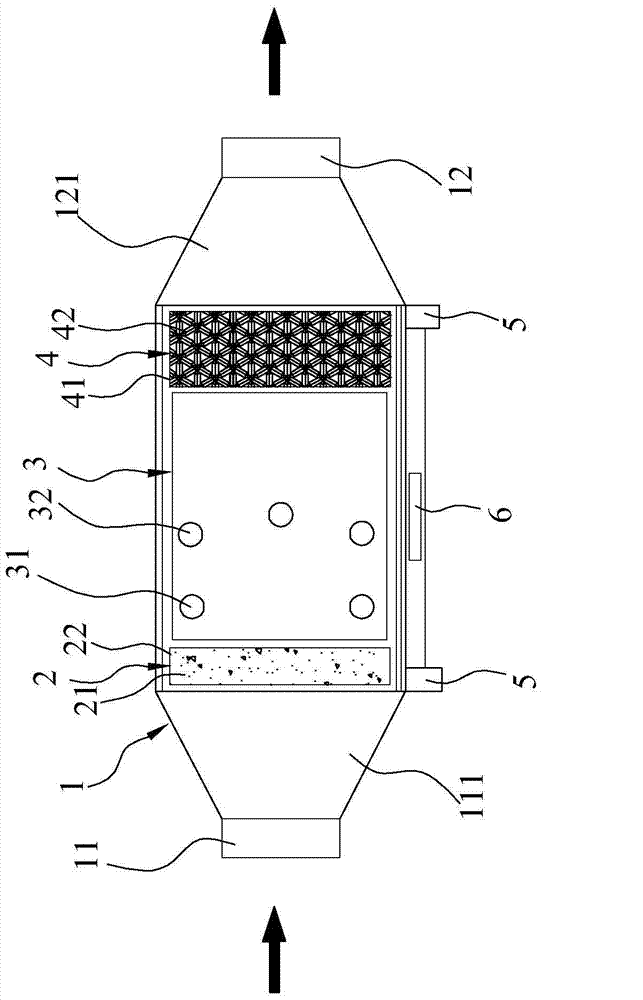

[0044] Such as figure 1 , 2 As shown, a composite oil fume purifier with a coupling function includes a housing 1, the left and right ends of the housing 1 are respectively provided with an air inlet 11 and an air outlet 12, and between the air inlet 11 and the air outlet 12 A gas channel is formed between them, wherein the air inlet 11 and the air outlet 12 are respectively provided with an air inlet hood 111 and an air outlet hood 121, which are used to guide the incoming and outgoing gas, and the cross sections of the air inlet 11 and the air outlet 12 are circular The cross-section of the airflow channel expands into a square shape. At the same time, along the air inlet 11 to the air outlet 12, a fume separation unit 2, an electrostatic collection unit 3, and a catalytic absorption unit 4 are sequentially arranged in the gas passage. The fume gas flows from the air inlet 11 through the The diversion function of the air inlet cover 111 passes through the oil fume separatio...

Embodiment 2

[0065] First 5.1g Al 2 o 3 Mix with 500ml deionized water, emulsify for 5 minutes to form a suspension with a concentration of 0.1mol / L, dip the honeycomb ceramic carrier plate into the above suspension, and dry it in an oven at 100°C.

[0066] Next, to 500ml concentration is 0.1mol / L Fe (NO 3 ) 3 5 g of water glass was added to the solution, and emulsified for 5 minutes to obtain a catalyst active component precursor.

[0067] Finally, immerse the treated honeycomb ceramic plate in the precursor solution, put it in an oven and dry it, then place it in a muffle furnace and heat it at 200°C for 2 hours to obtain the required catalyst. Fe in the prepared catalyst is calculated 2 o 3 with Al 2 o 3 The mass ratio is 12%.

[0068] The FeOx honeycomb ceramic supported catalyst prepared above was placed in the catalytic absorption unit 4, and the oil fume purifier was turned on. It was measured that the grease in the oil fume was removed at one time by 91.8%, the removal effic...

Embodiment 3

[0070] First 20.4g Al 2 o 3 Mix with 500ml of deionized water, emulsify for 5 minutes to form a suspension with a concentration of 0.4mol / L, soak the honeycomb ceramic carrier plate in the above suspension, and put it in an oven for drying at 100°C.

[0071] Next, to 500ml concentration is 0.14mol / L Co (NO3 ) 2 7.5 g of bentonite was added to the solution and emulsified for 5 minutes to obtain a catalyst active component precursor.

[0072] Finally, immerse the treated honeycomb ceramic plate in the precursor solution, put it in an oven and dry it, then place it in a muffle furnace and heat it at 300°C for 3 hours to obtain the required catalyst. The calculated amount of CoO and Al 2 o 3 The mass ratio is 2%.

[0073] The CoOx honeycomb ceramic supported catalyst prepared above was placed in the catalytic absorption unit 4, and the oil fume purifier was turned on. It was measured that the grease in the oil fume was removed at one time by 94.2%, the removal efficiency of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com