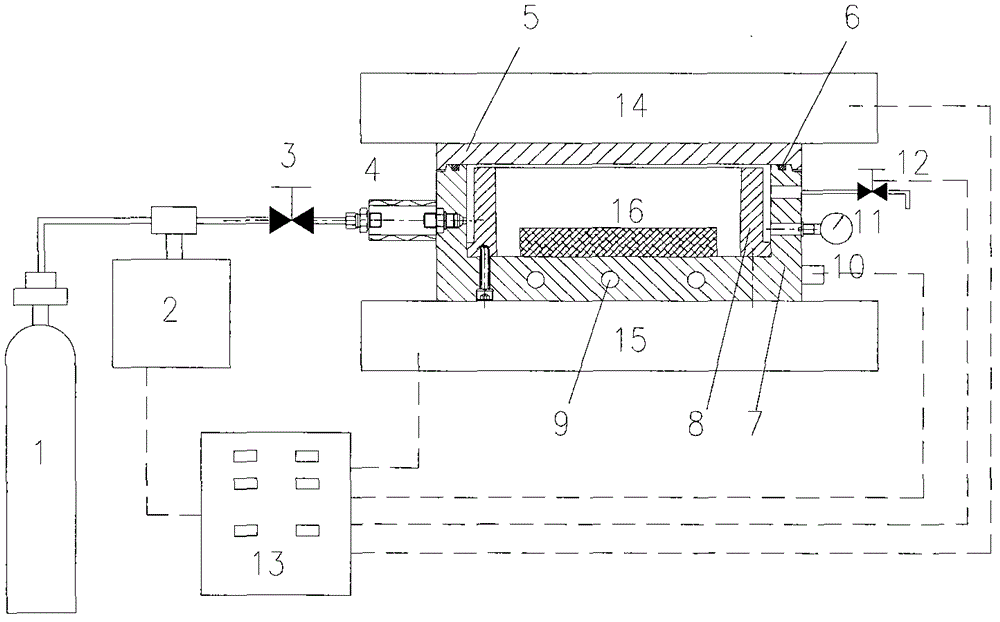

Supercritical fluid-assisted polymer mould foaming apparatus

A supercritical fluid and foaming device technology, applied in the field of polymer material processing, can solve the problems of large equipment investment and low foaming efficiency, and achieve the effects of simple device structure, low cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. Controllable foaming of thermoplastics or thermoplastic elastomers

[0037] With reference to the accompanying drawings, place the mold system between the upper heating plate 14 and the lower heating plate 15 of the molding machine to preheat to the set temperature, open the upper mold 5, put a certain amount of material to be foamed 16 into the forming mold 8, and close it. Mold, preheat the unfoamed material to melting or close to melting, open the intake valve 3, open the pressure relief valve 12, pass a certain pressure of supercritical fluid into the mold, drain the air inside the mold, and then close the pressure relief valve , continue to feed the supercritical fluid until the internal pressure of the mold reaches the set value. Under a certain temperature and pressure, the supercritical fluid gradually diffuses into the polymer matrix until it reaches saturation, stop heating, open the pressure relief valve 12, quickly release the internal pressure of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com