Blast-furnace channel distributor

A distributor and chute technology, which is applied in the field of blast furnace chute distributors, can solve problems such as complexity, difficulty in use, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] There are many ways to use digital cylinders on the blast furnace distributor. The main methods are single digital cylinder method, two digital cylinder method and three digital cylinder methods.

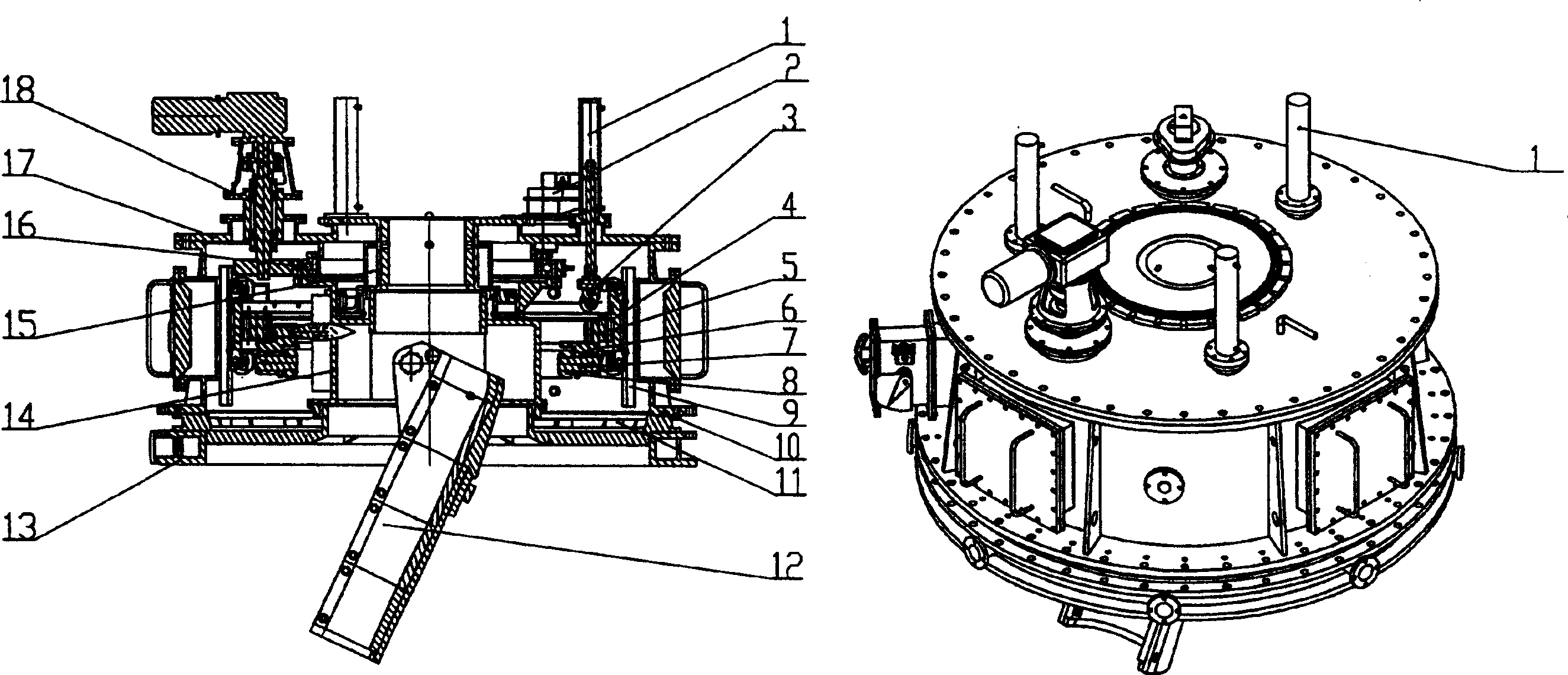

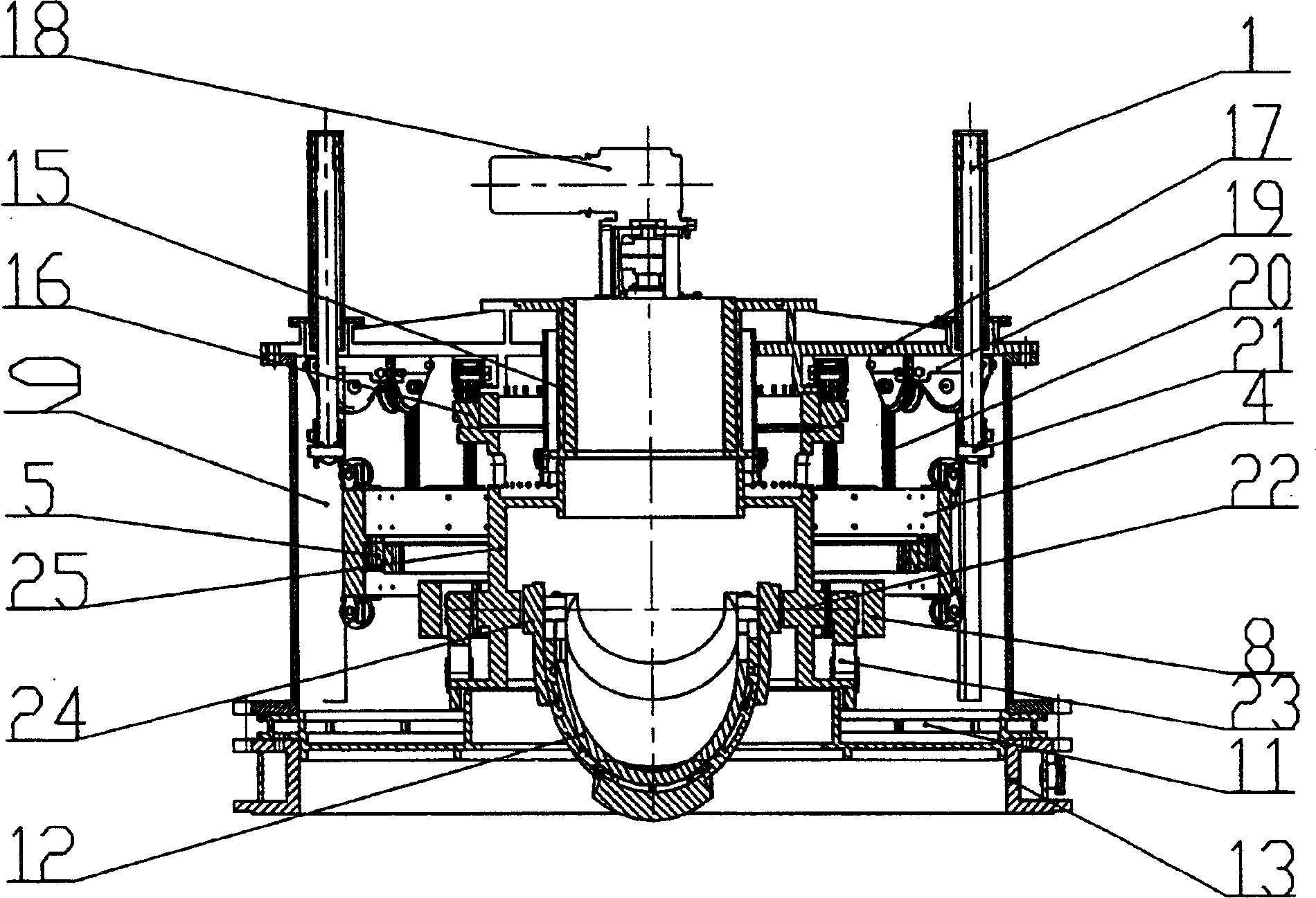

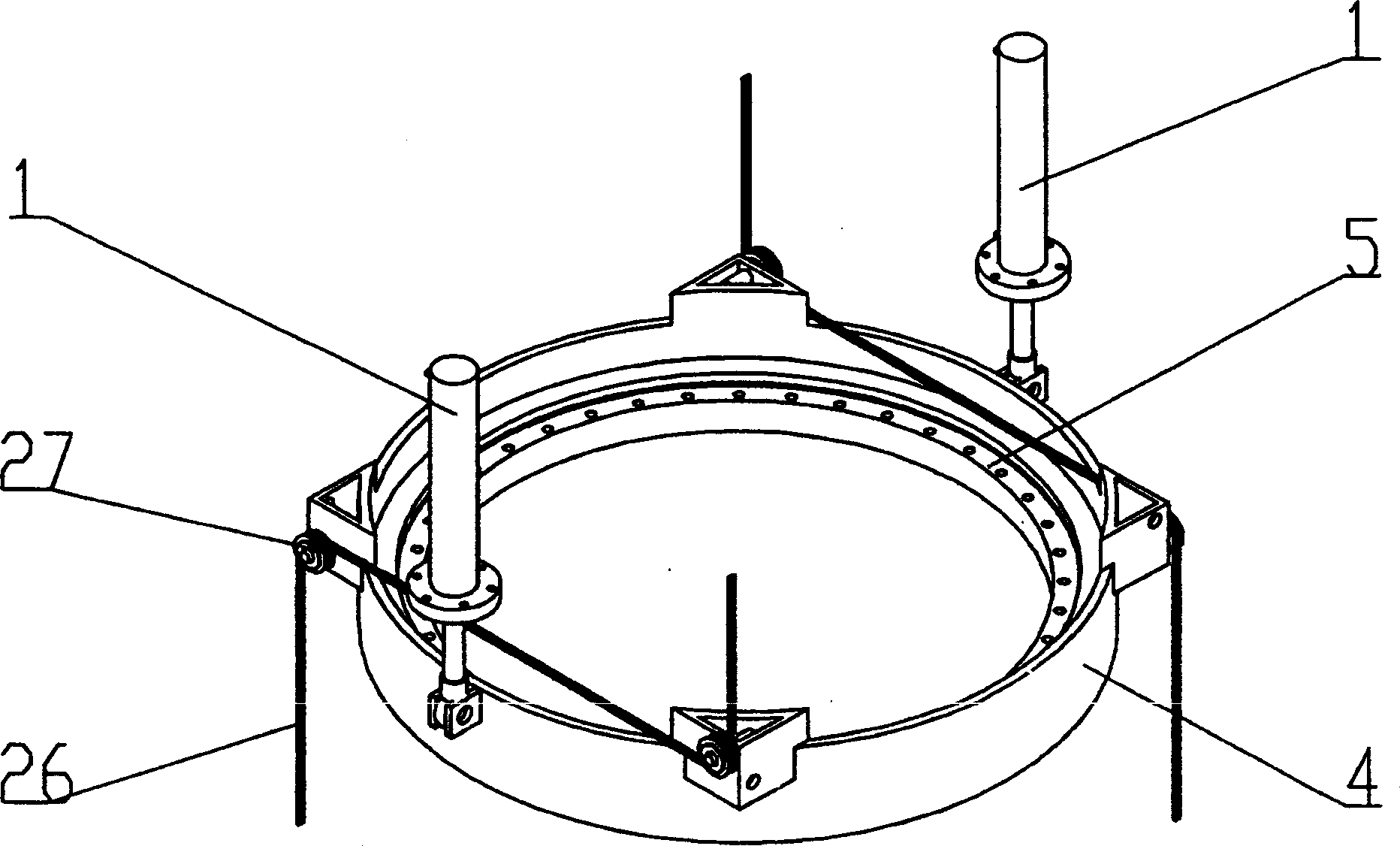

[0027] 1. The method of using three digital cylinders is exactly the same as that of ordinary cylinders, such as figure 1 As shown, the reference numeral 1 is a digital cylinder, 2 is a horizontal rotation detection device, 3 is a connecting rod, 4 is a support ring, 5 is a lower slewing bearing, 6 is a connecting piece, 7 is a connecting shaft, 8 is a frame, 9 10 is the box, 11 is the water cooling plate, 12 is the chute, 13 is the water cooling steel ring, 14 is the rotating sleeve, 15 is the throat, 16 is the upper slewing bearing, 17 is the top cover, 18 is the horizontal rotation drive device. exist figure 1 Among them, the three digital cylinders 1 are installed on the top cover of the distributor with the flange at the front end in a 120° central symmetry form, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com