Honeycombed porous ceramic having high thermal conductivity and ultralow expansion coefficient

A technology of low expansion coefficient and porous ceramics, which is applied in the silicate industry and the field of ceramic production and preparation. It can solve the problems of destroying the polymer chain length of organic additives, lack of mineral crystals, reduction, etc., and achieve good catalyst coating performance and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

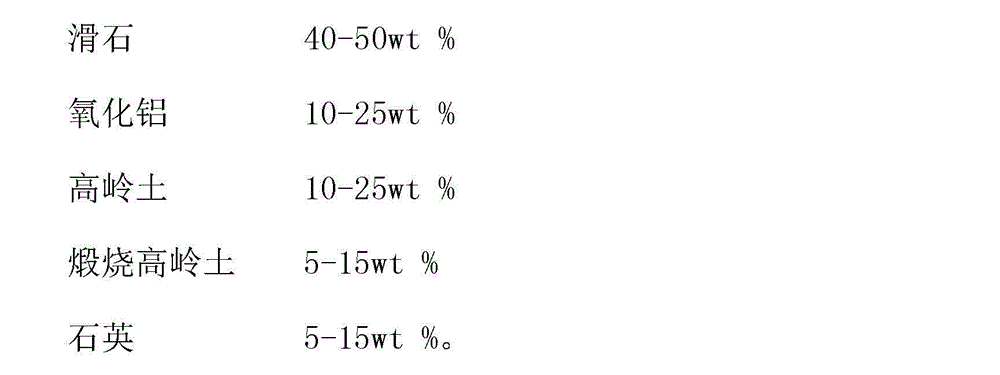

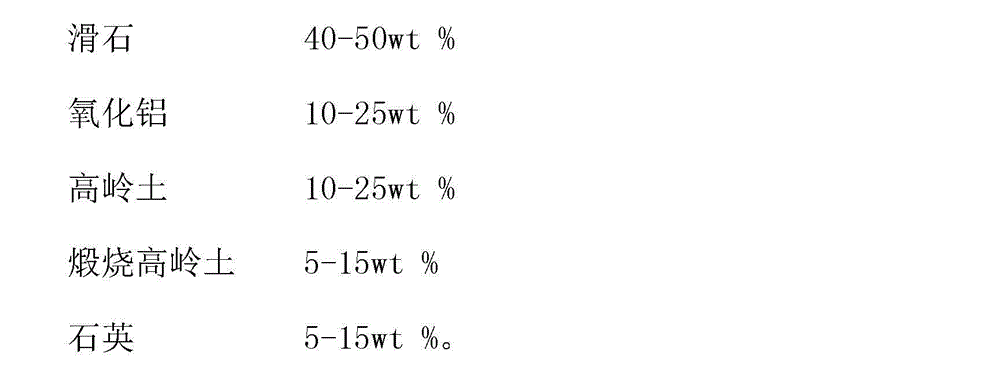

[0042] (1) Main material configuration: 43wt% talc, 19% alumina, 18wt% kaolin, 11wt% calcined kaolin, 9wt% quartz; firing aid configuration (calculated based on the mass percentage of the main ingredient): 0.5 wt% rare earth mixture , 0.1wt% potassium phosphotungstate, 0.1wt% zirconia, 2wt% amorphous quartz particles, 2wt% polyoxyethylene resin with a molecular weight of 600, 2wt% polyoxyethylene resin with a molecular weight of 20000 and 5wt% rapeseed oil .

[0043] (2) The total weight of the batch is 500kg, and an electronic scale with an accuracy of 0.01g is used to weigh 100kg each in 5 batches, while the additive is weighed with a balance with an accuracy of 0.001g. Additives are firstly mixed with 5kg of the main material, then mixed with 100kg of the main material, and then mixed with the rest of the material at high speed without gravity.

[0044] (3) Mix polyoxyethylene resin with a molecular weight of 600 and water at a temperature of 60 to 80°C to form a solution ...

Embodiment 2

[0054] (1) Main material configuration: 43wt% talc, 20% alumina, 17% kaolin, 10wt% calcined kaolin, 10% quartz; firing aid configuration (calculated based on the mass percentage of the main material): 0.5 wt% rare earth mixture , 0.1wt% potassium phosphotungstate, 0.1wt% zirconia, 1.5wt% amorphous quartz particles, 2wt% polyoxyethylene resin with a molecular weight of 800, 2wt% polyoxyethylene resin with a molecular weight of 40000 and 5wt% peanut oil.

[0055] (2) The total weight of the batch is 100kg, and an electronic scale with an accuracy of 0.01g is used to weigh 25kg each in 4 batches, while the additive is weighed with a balance with an accuracy of 0.001g. The additive is firstly mixed with 1kg of the main material, then mixed with 25kg of the main material, and then mixed with the rest of the material at high speed without gravity.

[0056] (3) Mix polyoxyethylene resin with a molecular weight of 800 and water at a temperature of 60 to 80°C to form a solution with a ...

Embodiment 3

[0066] (1) Main material configuration: talc 42wt%, alumina 20%, kaolin 18%, calcined kaolin 11wt%, quartz wt9%; firing aid configuration (calculated by mass percentage of the main ingredient): 0.5 wt% rare earth mixture , 0.1wt% silicotungstic acid, 1wt% potassium feldspar, 0.1wt% zirconia, 1wt% amorphous quartz particles, 2wt% polyoxyethylene resin with molecular weight of 1000, 2wt% polyoxyethylene resin with molecular weight of 40000 And 5wt% rapeseed oil.

[0067] (2) The total weight of the batch is 1000kg, and an electronic scale with an accuracy of 0.01g is used to weigh 100kg each time in 10 batches, while the additive is weighed with a balance with an accuracy of 0.001g. Additives are firstly mixed with 10kg of the main material, then mixed with 100kg of the main material, and then mixed with the rest of the material at high speed without gravity.

[0068] (3) Mix polyoxyethylene resin with a molecular weight of 1000 and water at a temperature of 60-80°C to form a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com