Winding-type vacuum coater

A vacuum coating and winding technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of complex equipment structure, unsatisfactory tension control effect, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

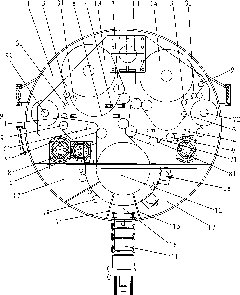

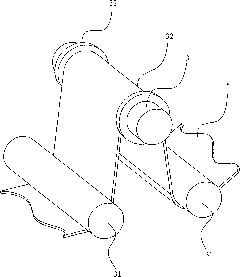

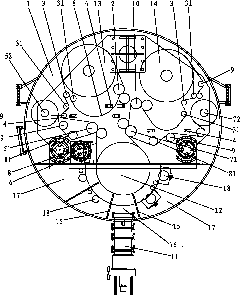

[0031] Below in conjunction with accompanying drawing, the present invention will be further described, see figure 1 and figure 2 As shown, this is a preferred embodiment of the present invention:

[0032] The winding vacuum coating equipment includes a vacuum chamber 1 provided with a vacuum obtaining system, and the vacuum chamber 1 is provided with an unwinding device, a coating chamber and a winding device; the coating chamber is provided with a drive motor output shaft The coating roller 12 that is connected, the coating device 18 of coating chamber is facing the circumferential surface of described coating roller 12; One of the rollers of the unwinding and feeding roller pair 2 is connected to the output shaft of an unwinding and feeding motor, and a tension release roller 3 is arranged between the unwinding and feeding roller pair 2 and the coating roller 12 The winding device includes a winding roller 14 connected to a winding motor output shaft, and a winding feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com