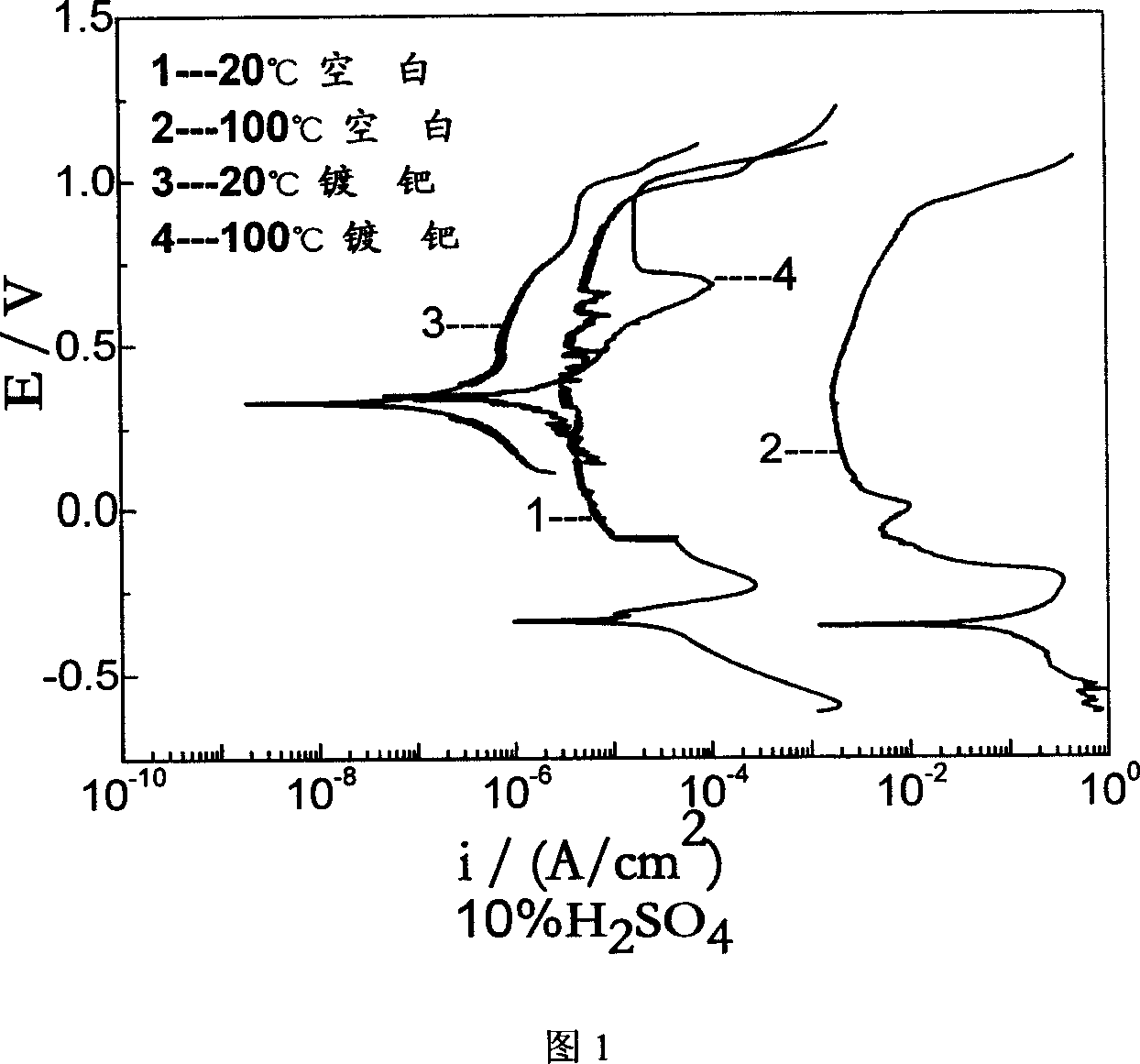

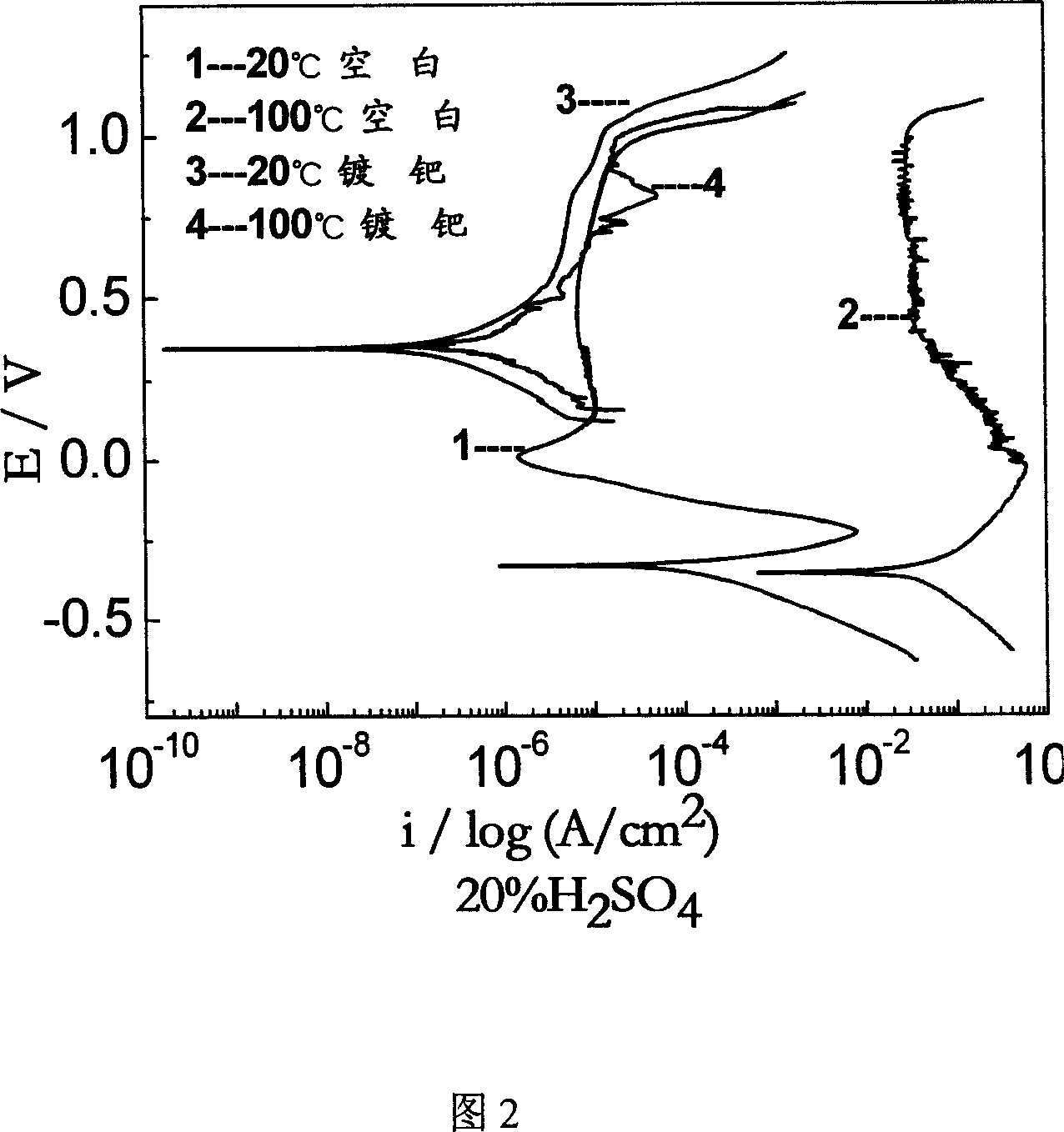

Chemical pd-plating process for stainless steel surface with excellent anticossive performance in non-oxidant medium

A corrosion-resistant, non-oxidative technology, applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of long processing time, complicated operation, equipment corrosion, etc. The process is simple and the effect of improving the passivation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, industrial 304 (GB 1Cr18Ni9) electroless palladium plating on stainless steel plates:

[0042] (1) Grind the steel plate with 300# sandpaper to remove the scale, expose the fresh surface, and wash it with water; put the test piece in a chemical degreasing solution (50g / L Na 2 CO 3 +25g / L NaOH+50g / L NaOH 3 PO 4 12H 2 (0+3ml / L OP-10, the rest is water) for 8 minutes, then rinse with 75°C hot water; then soak the test piece in 80°C pickling solution (40% H 2 SO 4 ) for 4 minutes, rinse with hot water at 75°C after taking it out;

[0043] (2) Carry out electroless Pd plating immediately afterwards, and plating solution consists of:

[0044] Palladium salt Pd(NH 3 ) 4 Cl 2 : 3g / L (with PdCl 2 count)

[0045] Stabilizer NH 4 Cl: 20g / L

[0046] Auxiliary complexing agent (EDTA): 5g / L

[0047] NH 3 ·H 2 O: 100ml / L

[0048] Reducing agent NaH 2 PO 2 ·H 2 O: 10g / L

[0049] the rest is water

[0050] Plating was performed at 50°C for 45 minutes to...

Embodiment 2

[0054] Embodiment 2, chemical industry uses 304 (GB 1Cr18Ni9) stainless steel plate electroless palladium plating:

[0055] (1) Polish the steel plate with 200# sandpaper to expose the fresh surface and wash it with water; put the test piece in a chemical degreasing solution (40g / L Na 2 CO 3 +20g / L NaOH+40g / L NaOH 3 PO 4 12H 2 (0+3ml / L OP-10, the rest is water) for 10 minutes, then rinse with 80°C hot water; then soak the test piece in 75°C pickling solution (50% H 2 SO 4 ) for 1 min, take it out and rinse with hot water at 80°C;

[0056] (2) Carry out electroless Pd plating immediately afterwards, and plating solution consists of:

[0057] Palladium salt Pd(NH 3 ) 4 Cl 2 : 5g / L (as PdCl 2 count)

[0058] Stabilizer NH 4 Cl: 27g / L

[0059] Auxiliary complexing agent (EDTA): 6g / L

[0060] Surfactant (Tween 20): 0.002ml / L

[0061] NH 3 ·H 2 O: 160ml / L

[0062] Reducing agent NaH 2 PO 2 ·H 2 O: 20g / L

[0063] the rest is water

[0064] Plating at 50°C for 3...

Embodiment 3

[0066] Embodiment 3, chemical industry uses 304 (GB 1Cr18Ni9) stainless steel sheet electroless palladium plating:

[0067] (1) Polish the steel plate with 200# sandpaper to expose the fresh surface and wash it with water; put the test piece in a chemical degreasing solution (60g / LNa 2 CO 3 +30g / LNaOH+60g / LNa 3 PO 4 12H 2 (0+2ml / LOP-10, the rest is water) for 5 minutes, then rinse with 70°C hot water; then soak the test piece in 70°C pickling solution (30% H 2 SO 4 +5ml / LHF) for 2min, take it out and rinse with hot water at 70°C.

[0068] (2) Carry out electroless Pd plating immediately afterwards, and plating solution consists of:

[0069] Palladium salt Pd(NH 3 ) 4 Cl 2 : 1.5g / L (as PdCl 2 count)

[0070] Stabilizer NH 4 Cl: 20g / L

[0071] Surfactant (Tween 20): 0.0005ml / L

[0072] NH 3 ·H 2 O: 80ml / L

[0073] Reducing agent NaH 2 PO 2 ·H 2 O: 10g / L

[0074] the rest is water

[0075] Plating at 50°C for 60 minutes can obtain an excellent coating. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com