Solar cell passivation antireflection film and preparation technology and method thereof

A technology of solar cell and preparation process, which is applied in the direction of metal material coating process, sustainable manufacturing/processing, circuit, etc., can solve the problems such as difficult to achieve anti-reflection effect, poor battery passivation effect, low battery efficiency, etc., to achieve Improve photoelectric conversion efficiency, reduce recombination, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

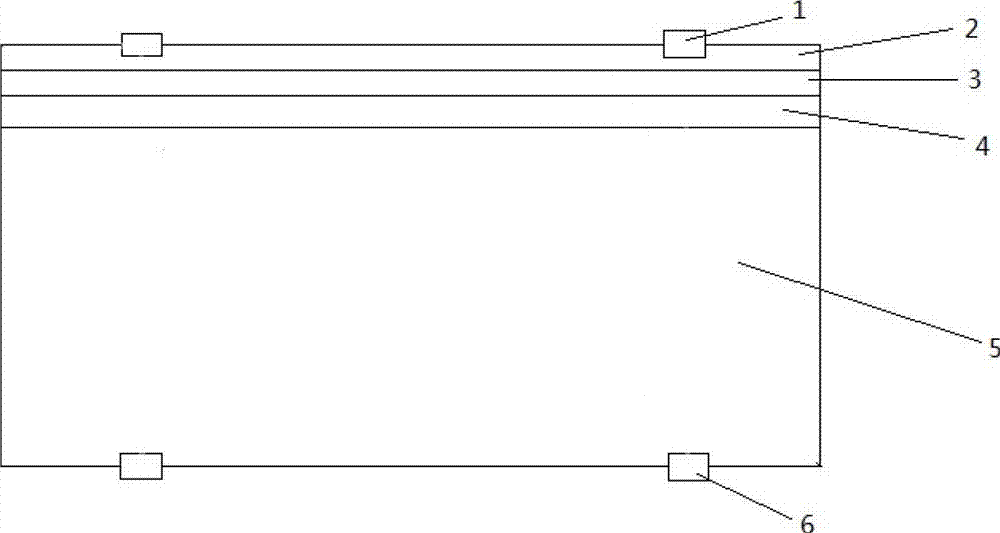

Image

Examples

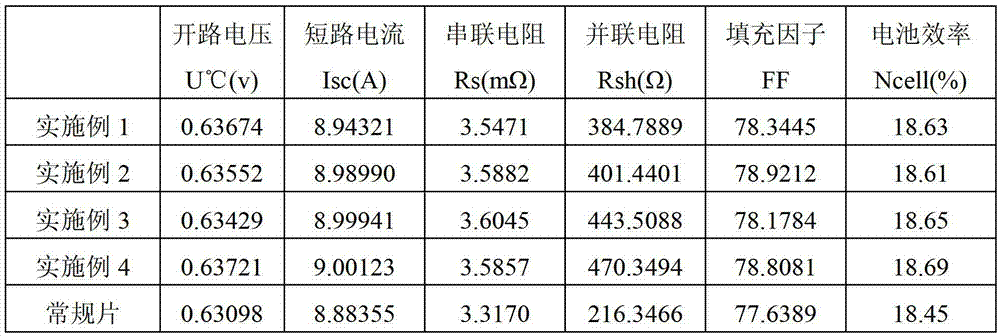

Embodiment 1

[0040] 1. Insert the diffused silicon wafer on the graphite boat. The diffusion surface of the two silicon wafers in each grid of the graphite boat should be opposite, and the non-diffusion surface should be close to the electrode plate of the graphite boat;

[0041] 2. The paddle on the graphite boat, driven by the guide rail, enters the coating furnace tube;

[0042] 3. The temperature of the furnace tube is set at 510°C, the vacuum degree is 1500 mTorr, the power of the radio frequency source is 6500W, and the flow rate of silane into the tube is 100 sccm, CO 2 The flow rate is 1slm, the coating time is 100s, the discharge of the radio frequency source ionizes the reactive gas and undergoes a chemical reaction, thereby depositing a layer of SiO on the surface of the silicon wafer 2 ;

[0043] 4. On the above-mentioned silicon dioxide layer, deposit a layer of first silicon nitride layer whose refractive index n is 2.3. The air flow is 4.6slm, and the coating time is 100s;...

Embodiment 2

[0047] 1. Insert the diffused silicon wafer on the graphite boat. The diffusion surface of the two silicon wafers in each grid of the graphite boat should be opposite, and the non-diffusion surface should be close to the electrode plate of the graphite boat;

[0048] 2. The paddle on the graphite boat, driven by the guide rail, enters the coating furnace tube;

[0049] 3. The temperature of the furnace tube is set at 510°C, the vacuum degree is 1500 mTorr, the power of the radio frequency source is 6500W, and the flow rate of silane into the tube is 500 sccm, CO 2 The flow rate is 3slm, the coating time is 150s, the discharge of the radio frequency source ionizes the reactive gas and undergoes a chemical reaction, thereby depositing a layer of SiO on the surface of the silicon wafer 2 ;

[0050] 4. Deposit a layer of first silicon nitride layer whose refractive index n is 2.1 on the above-mentioned silicon dioxide layer. The air flow is 5.0slm, and the coating time is 150s; ...

Embodiment 3

[0054] 1. Insert the diffused silicon wafer on the graphite boat. The diffusion surface of the two silicon wafers in each grid of the graphite boat should be opposite, and the non-diffusion surface should be close to the electrode plate of the graphite boat;

[0055] 2. The paddle on the graphite boat, driven by the guide rail, enters the coating furnace tube;

[0056] 3. The temperature of the furnace tube is set at 510°C, the vacuum degree is 1500 mTorr, the power of the radio frequency source is 6500W, and the flow rate of the reaction gas silane into the tube is 1000 sccm, CO 2 The flow rate is 5slm, and the coating time is 200s. The discharge of the radio frequency source ionizes the reactive gas and undergoes a chemical reaction, thereby depositing a layer of SiO on the surface of the silicon wafer. 2 ;

[0057] 4. On the above-mentioned silicon dioxide layer, deposit a layer of first silicon nitride layer with a refractive index n of 2.0, the temperature is 510° C., th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com