Acid recycling and arsenic curing method for acidic waste water

A solidification method and resource utilization technology, applied in chemical instruments and methods, separation methods, water pollutants, etc., can solve the problems of unresourced acid utilization, inconvenient disposal of arsenic sulfide precipitation, long process flow, etc., and achieve easy industrialization The effect of implementation, high resource utilization rate and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

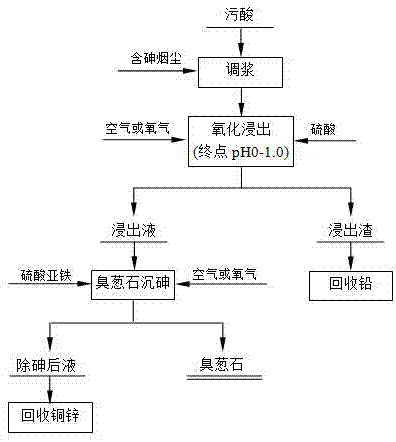

[0018] Such as figure 1 As shown, the resource utilization of the acid in the polluted acid and the solidification method of the arsenic, the arsenic fume and the polluted acid are slurried, and then air or oxygen is introduced for oxidation leaching, the pH value of the leaching end point is controlled, and the arsenic-containing leaching solution is subjected to normal pressure Scoorite arsenic fixation, the specific steps are as follows:

[0019] Step 1, at first the polluted acid (its main chemical composition is: As1g / L, H 2 SO 4 5.5g / L) and arsenic dust (the main chemical mass percentage components are: As0.54%, Cu0.48%, Zn0.54% and Pb0.55%) were mixed and adjusted according to the liquid-solid ratio of 2:1mL / g Slurry, and add sulfuric acid with a concentration of 98% at 20% of the mass fraction of arsenic soot, and carry out oxidation leaching for 1 hour at a temperature of 75°C, an oxygen flow rate of 1.5L / min, an end point pH of 0, and a stirring speed of 300r / min. ...

Embodiment 2

[0023] Such as figure 1 As shown, the resource utilization of the acid in the polluted acid and the solidification method of the arsenic, the arsenic fume and the polluted acid are slurried, and then air or oxygen is introduced for oxidation leaching, the pH value of the leaching end point is controlled, and the arsenic-containing leaching solution is subjected to normal pressure Scoorite arsenic fixation, the specific steps are as follows:

[0024] Step 1, at first the polluted acid (its main chemical composition is: As6g / L, H 2 SO 4 60.4g / L) and arsenic dust (the main chemical mass percentage components are: As10.01%, Cu1.34%, Zn9.76% and Pb10.53%) were mixed and adjusted according to the liquid-solid ratio of 5:1mL / g Slurry, and add sulfuric acid with a concentration of 98% at 10% of the mass fraction of arsenic soot, and carry out oxidation leaching for 3 hours at a temperature of 95 ° C, an air flow rate of 6 L / min, an end point pH of 0.2, and a stirring speed of 300 r / ...

Embodiment 3

[0028] Such as figure 1 As shown, the resource utilization of the acid in the polluted acid and the solidification method of the arsenic, the arsenic fume and the polluted acid are slurried, and then air or oxygen is introduced for oxidation leaching, the pH value of the leaching end point is controlled, and the arsenic-containing leaching solution is subjected to normal pressure Scoorite arsenic fixation, the specific steps are as follows:

[0029] Step 1. First, the dirty acid (its main chemical composition is: As20g / L, H 2 SO 4 400g / L) and arsenic dust (the main chemical mass percentage components are: As8.45%, Cu15.02%, Zn8.21% and Pb25%) are mixed and slurried according to the liquid-solid ratio of 1:1mL / g, and Add sulfuric acid with a concentration of 98% at 0% of the mass fraction of arsenic fumes, carry out oxidation leaching for 6 hours at a temperature of 85°C, an oxygen flow rate of 10L / min, an end point pH of 1.0, and a stirring speed of 500r / min. Liquid-solid s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sedimentation rate | aaaaa | aaaaa |

| Sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com