Continuous straw crushing system

A straw pulverizing and pulverizing bin technology is applied in the field of straw pulverization, which can solve the problems of high feeding intensity and high impurity content of straw, and achieve the effects of high pulverization efficiency, large chain plate width and tight fastening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

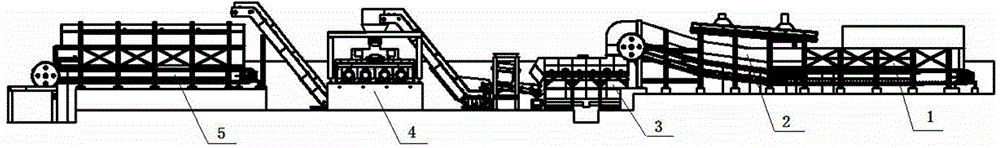

[0029] Such as figure 1 The continuous straw crushing system shown is composed of feeding system 1, pre-powder system 2, impurity removal system 3, fine powder system 4, and material storage system 5 according to the direction of material movement. The dust removal system 6 is connected to the pre-powder system. 2 and fine powder system 4.

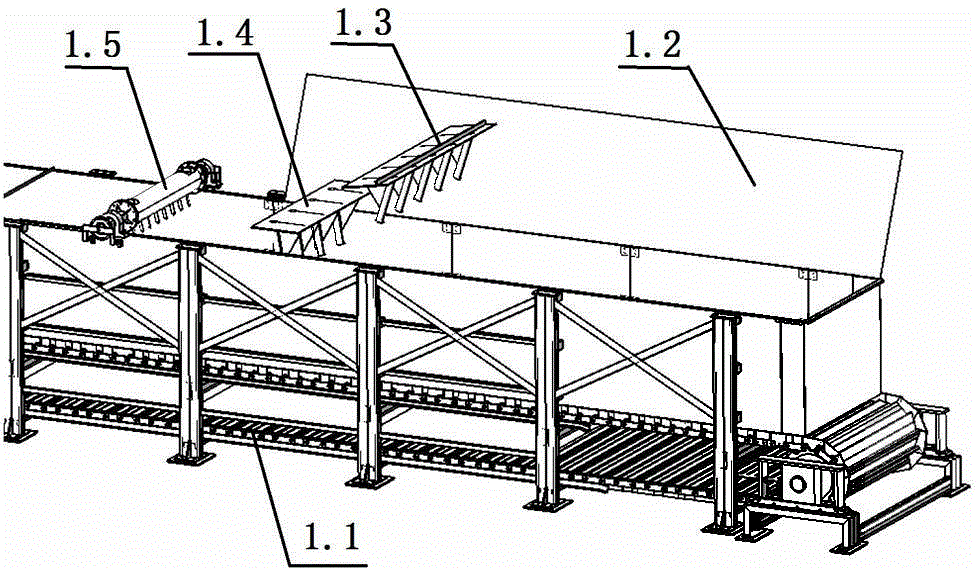

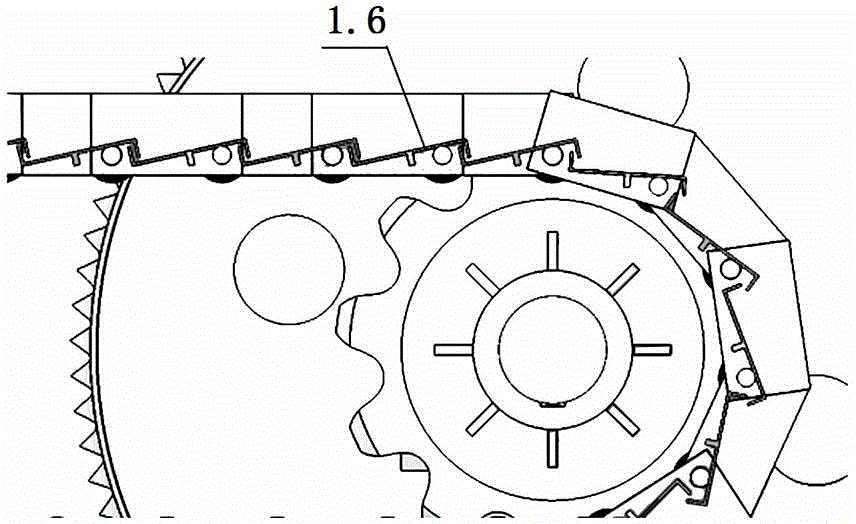

[0030] Such as figure 2 , 3 As shown, the feeding system 1 includes a chain conveyor 1.1, a first-level leveling grid 1.3, a second-level leveling grid 1.4, and a material shifting roller 1.5. The first-level leveling grid 1.3, two-level The leveling grid 1.4 is fixed on the two side plates 1.2 of the chain-plate conveyor, and is staggered up and down by a certain height. The material shifting roller 1.5 is located on the back side of the leveling grid of the second level, and the conveying chain plate 1.6 of the chain-plate conveyor adopts a two-way buckle Combined structure, the first-level leveling grid and the second-level leveling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com