Method for controlling quality of edges of intermediate slabs

A control method and slab technology, applied in contour control and other directions, can solve problems such as unseen technology, and achieve the effects of ensuring edge quality, avoiding jamming, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

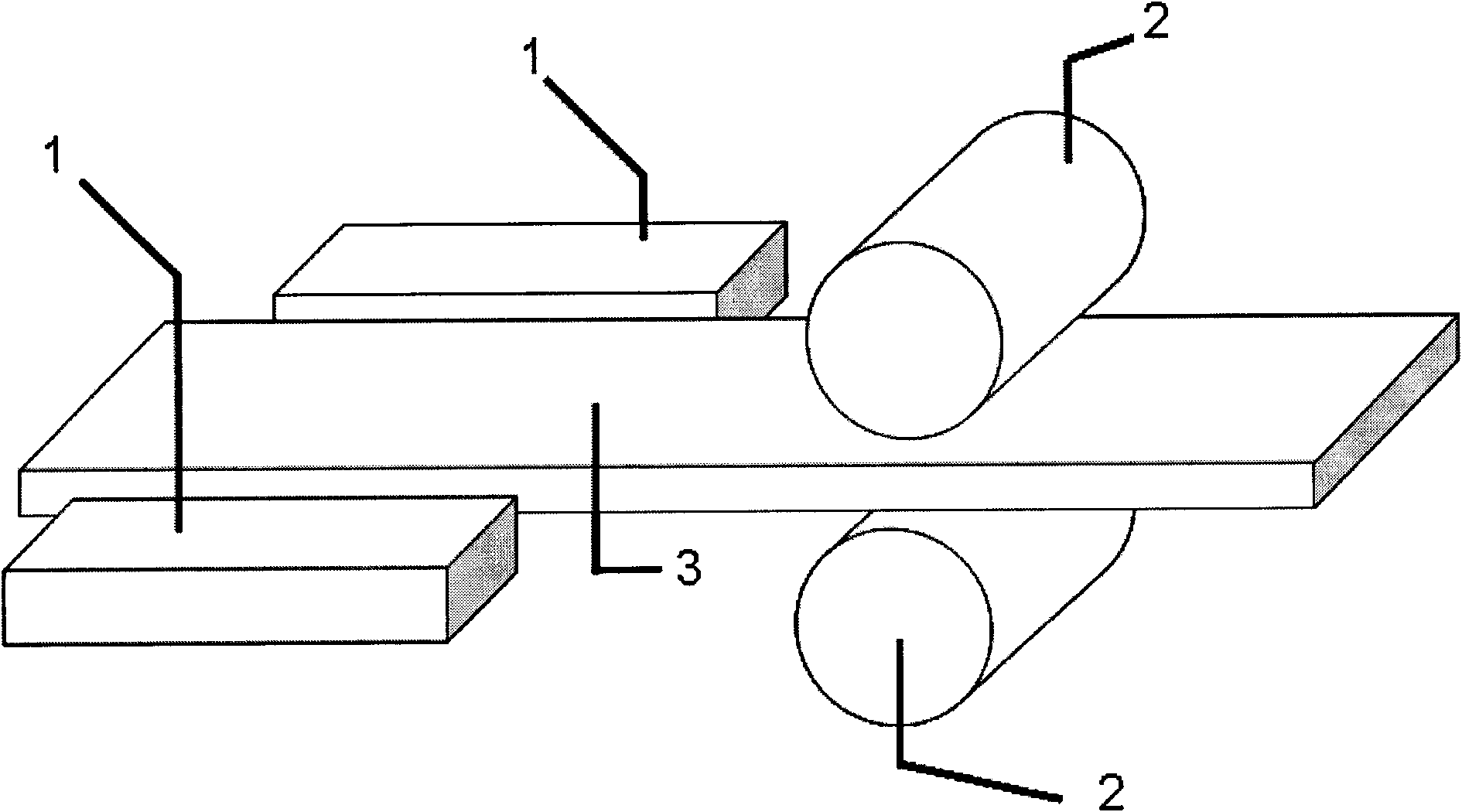

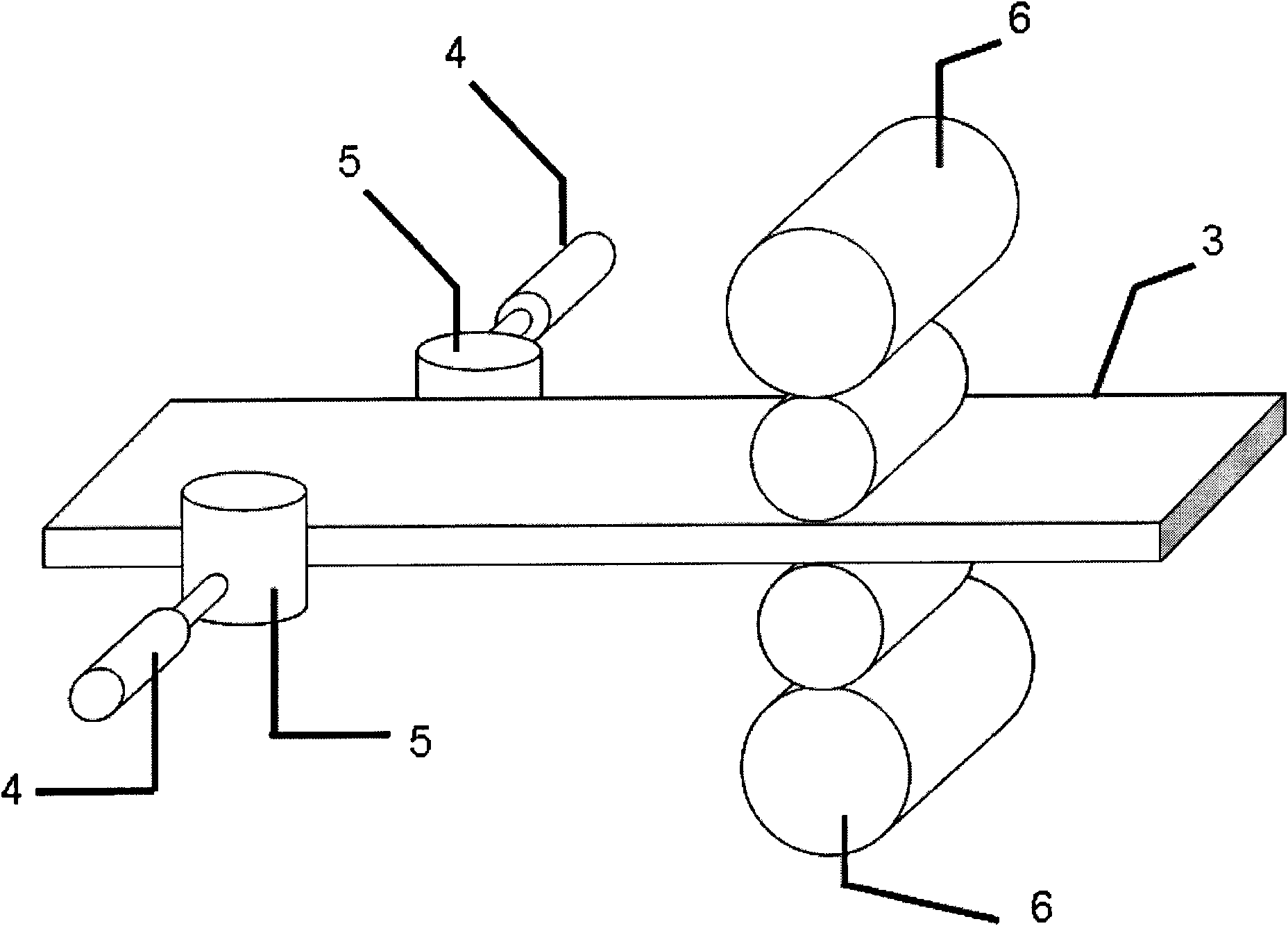

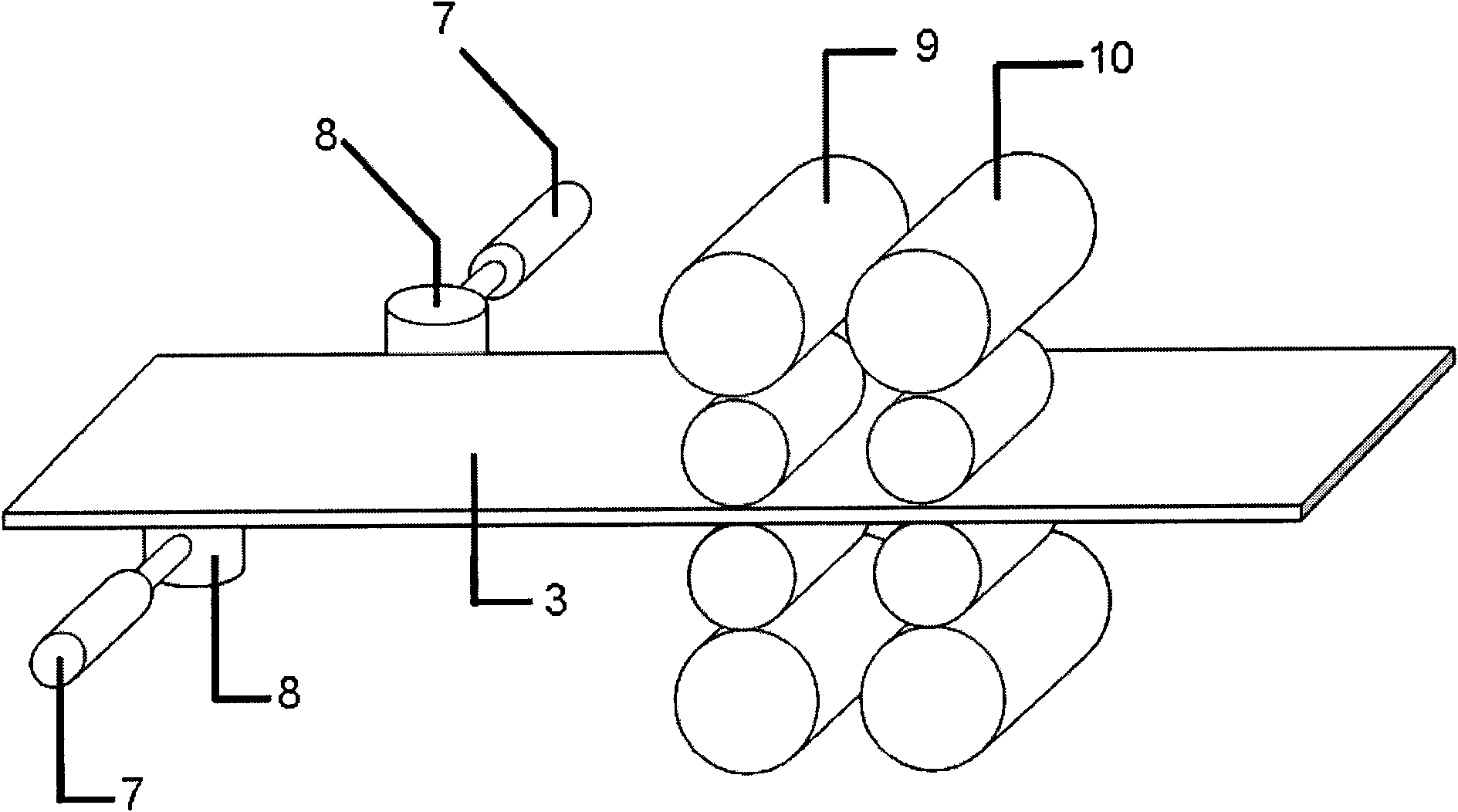

Method used

Image

Examples

Embodiment

[0110] Strip No.: 008572480300

[0111] Slab thickness: 230mm, finished product thickness: 2.52mm

[0112] Slab width: 1100mm, finished product width: 1085mm, lateral pressure: 15mm (the lateral pressure is slab width mm-finished product width mm.).

[0113] According to above-mentioned data, in the concrete enforcement of the present invention, known strip steel finished product width is 1085mm, sets 3mm according to its width additional amount, so its rolling width is controlled by 1088mm, and the side pressure setting of finish rolling vertical roll Set the center, according to the reduction control of 3mm, the calculated natural width of the finish rolling is roughly 1mm, so the exit control of the rough rolling should be 1090mm, in the 3rd and 5th passes of the rough rolling, 3mm and The reduction of 8mm, and according to the calculation of the width of the rough rolling, the width is about 1mm, so the target width of the slab should be 1100mm. The following are the spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com