A kind of equipment for erecting edge of gypsum board

A paper-faced gypsum board and gypsum board technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as waste of gypsum and face covering paper, difficult to control, and affect the effect of decoration, etc., to meet the vertical Accuracy requirements, avoiding edge wear, and convenient control and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

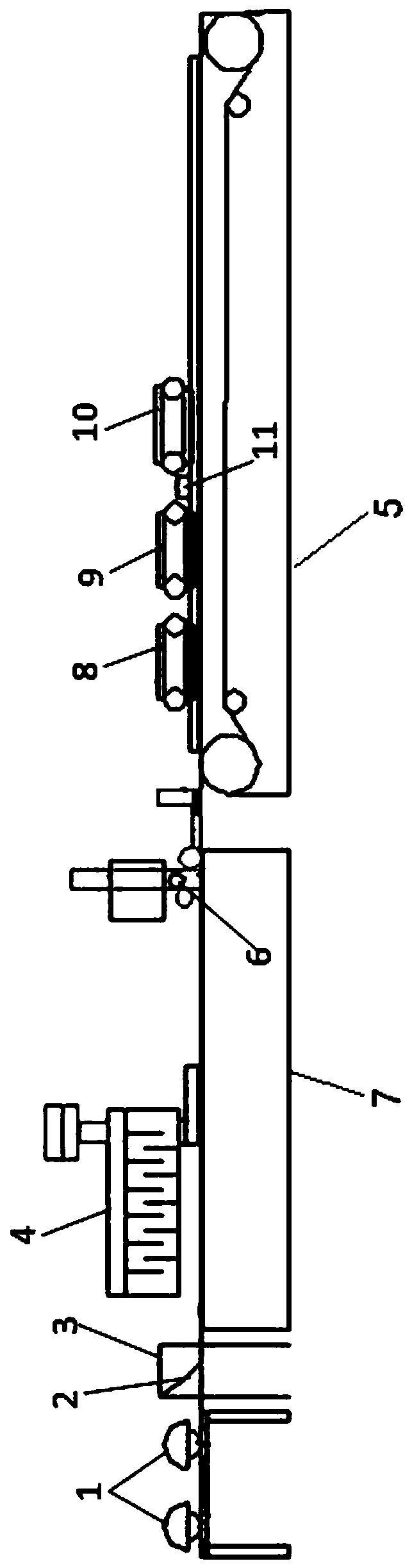

[0042] Such as figure 1 As shown, Embodiment 1 of the present invention provides a kind of vertical edge equipment for gypsum boards, including a forming workbench 7, a control unit and a detection unit; wherein, the forming workbench 7 is provided with an adjustment device for adjusting the verticality of the edge of the board. Wheel 6; the detection unit includes a first detection mechanism arranged at the output end of the molding workbench 7, the first detection mechanism is used to detect the verticality of the edge of the gypsum board output by the molding workbench 7 and generates a detection signal, and the control unit is used for detecting The signal generates the adjustment wheel 6 control signal.

[0043] In the specific operation, through the setting of the above-mentioned detection unit, the edge of the sheet material output by the forming workbench 7 can be detected in real time; through the setting of the above-mentioned control unit, real-time feedback adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com