Two-component binder system for the polyurethane cold-box process

A binder, two-component technology, used in cores, mold components, manufacturing tools, etc., to solve pinhole defects, comma defects, casting defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

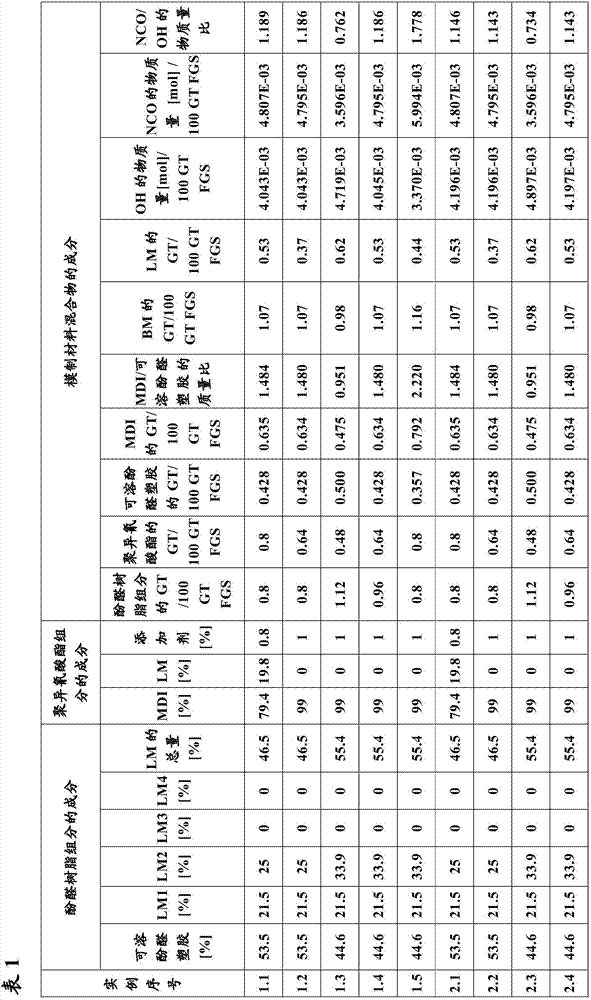

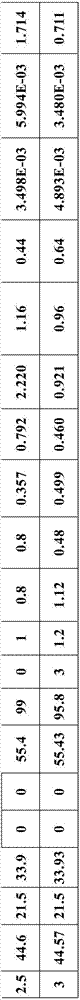

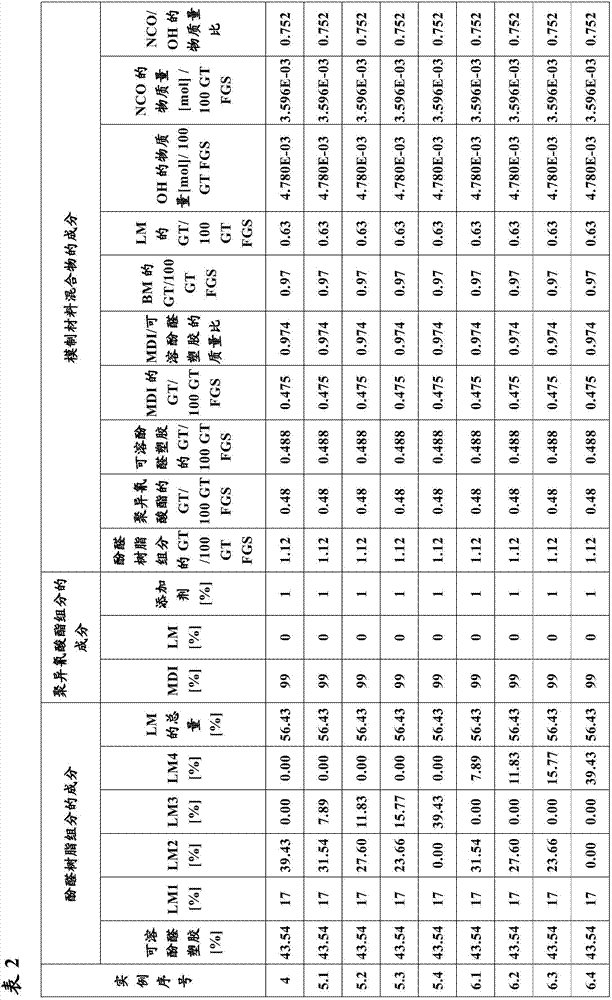

Examples

example 82 and 91

[0259] Furthermore, further advantages of the invention are the low tendency to stick and the high flowability of the molding material mixture with the two-component binder system according to the invention. The molding material mixture acts very dry. Very good sharpness of contour and high shaping accuracy were exhibited during the production of test specimens from the molding compound mixture according to the invention. The samples obtained are characterized by high edge strength.

[0260] BTX emissions of casting cores and molds produced according to the polyurethane cold box process during casting (at 700° C. Measured emissions of benzene, toluene and mixed xylenes) are reduced by 50% or more.

[0261] Table 4

[0262]

[0263]

[0264]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com