Pressure regulator for a fuel supply unit

A technology for pressure regulators and delivery units, which is applied in fluid pressure control, control/regulation systems, instruments, etc. It can solve the problems of complex manufacturing valve body production process of pressure regulators, complex insertion of pressure regulators, etc., to achieve simple assembly, The effect of less structure cost and gentle characteristic curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

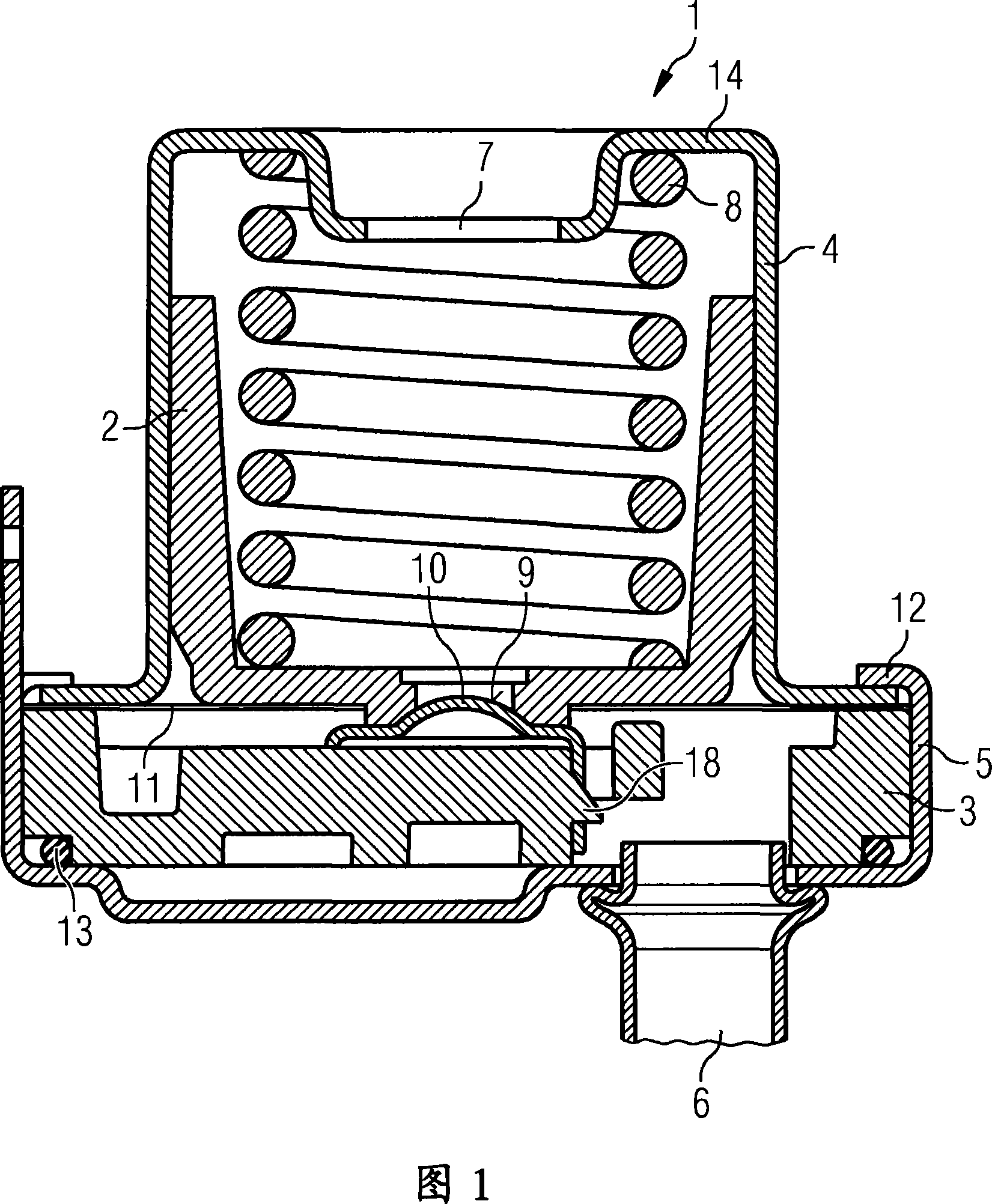

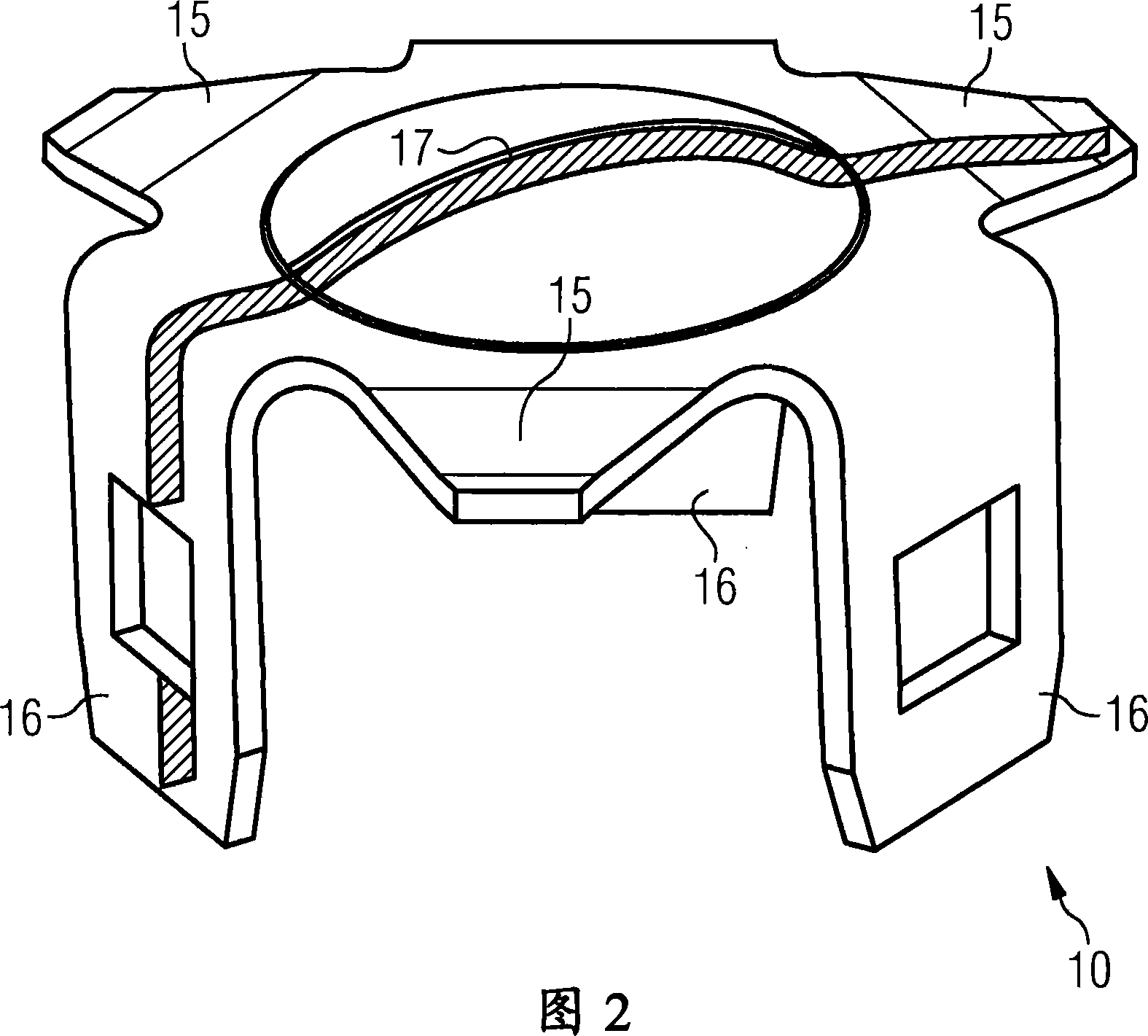

[0020] FIG. 1 shows a pressure regulator according to the invention, designed as a through valve, with a housing 1 and a piston 2 , which is displaceably arranged in the housing 1 . The pressure regulating valve serves to limit the maximum pressure in the feed line (not shown) of the motor vehicle's fuel tank. The housing 1 has two housing parts 4 , 5 spaced apart from the carrier body 3 . The pressure regulator has a connection 6 and an outlet 7 for the pressure line. The piston 2 biases the valve seat 9 against the valve body 10 via a spring 8 designed as a helical spring.

[0021] A membrane 11 connected to the support body 3 and the piston 2 seals the upper area of the piston 2 from the lower area of the piston 2 . This ensures that, when pressure is present in the connection port 6 , the piston 2 is loaded against the force of the spring 8 and, above a predetermined pressure, the piston 2 is displaced so that the valve seat 9 is lifted from the valve body 10 . As a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com