Divided toothed wheel

A split-type, gear technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems such as large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

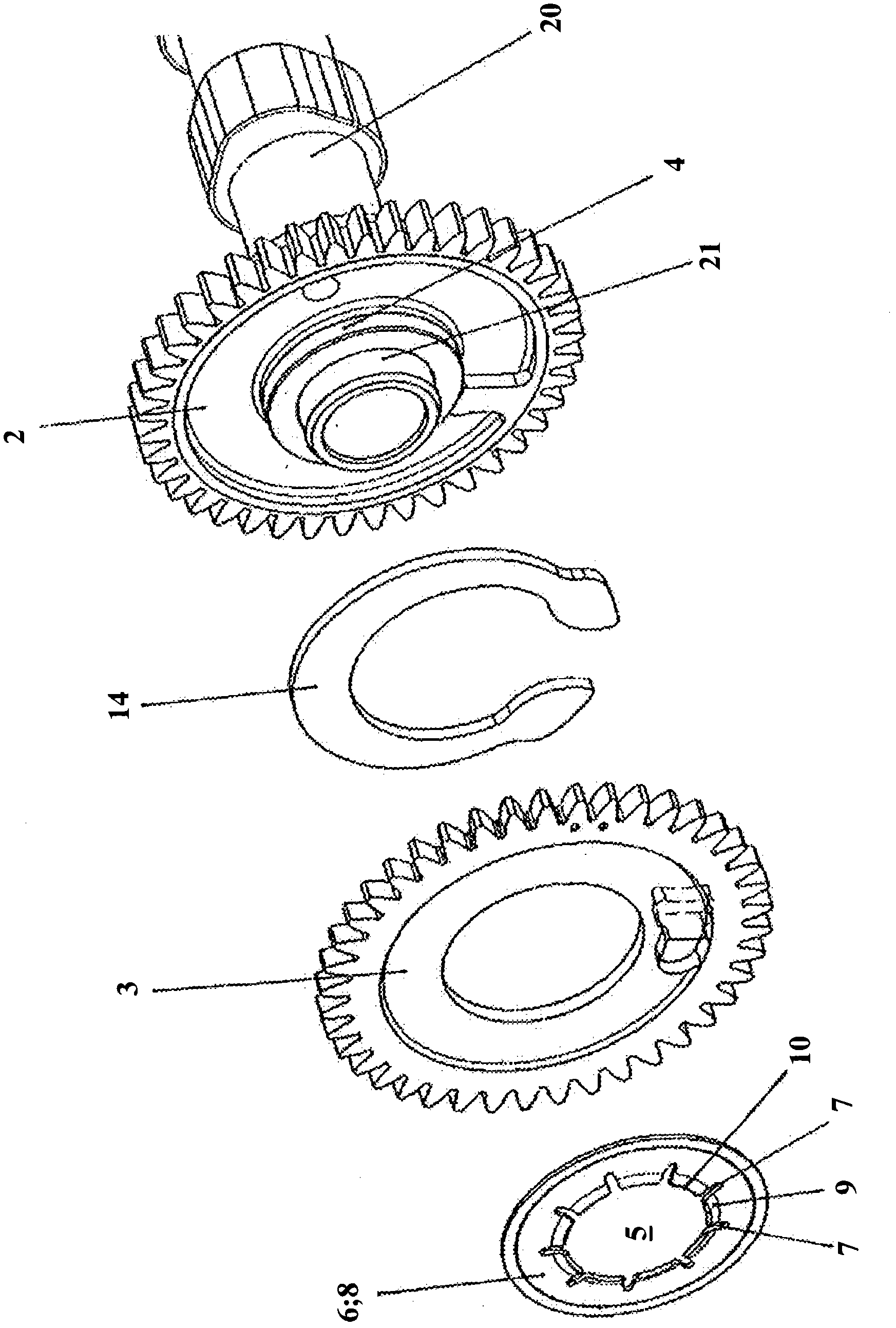

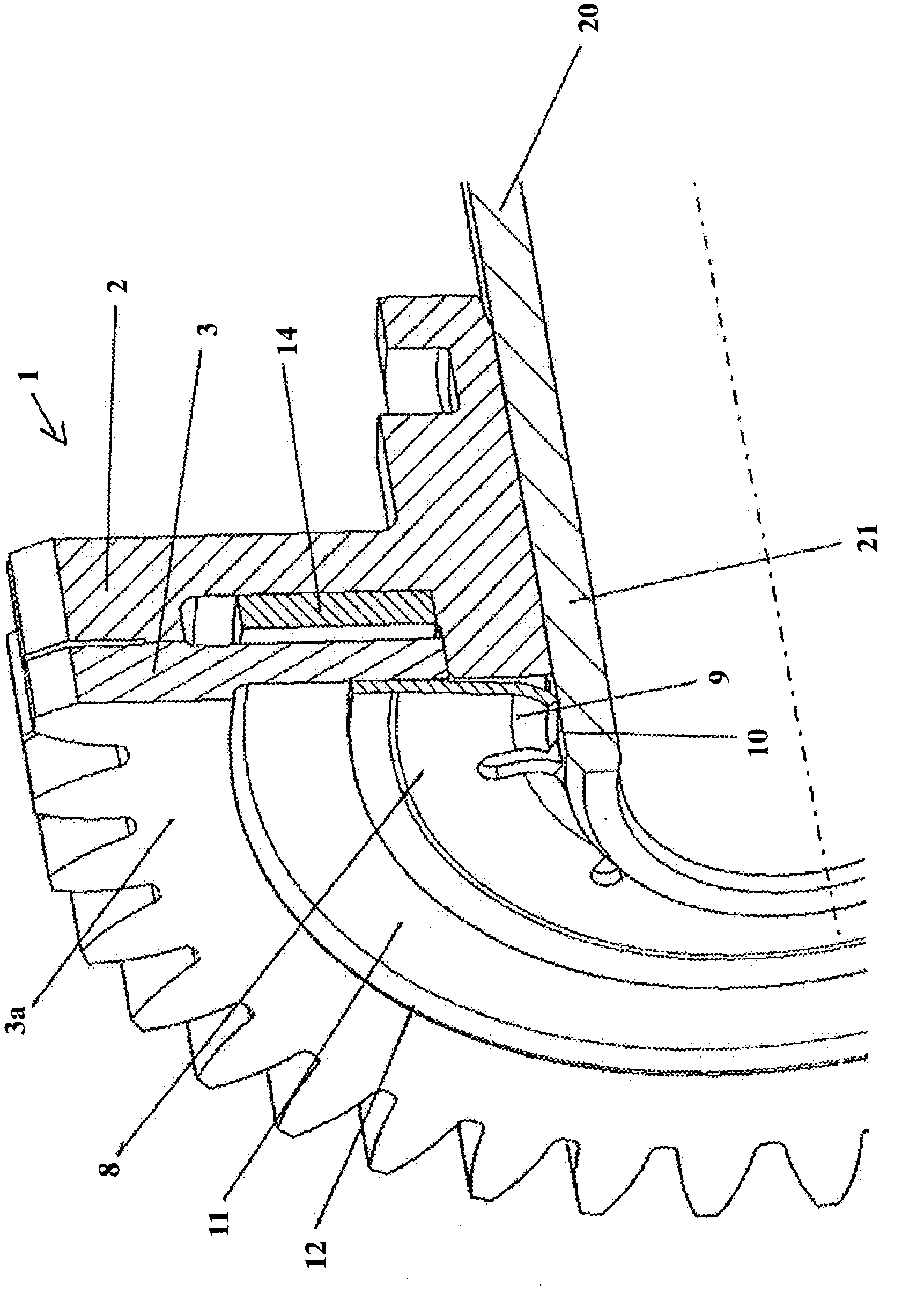

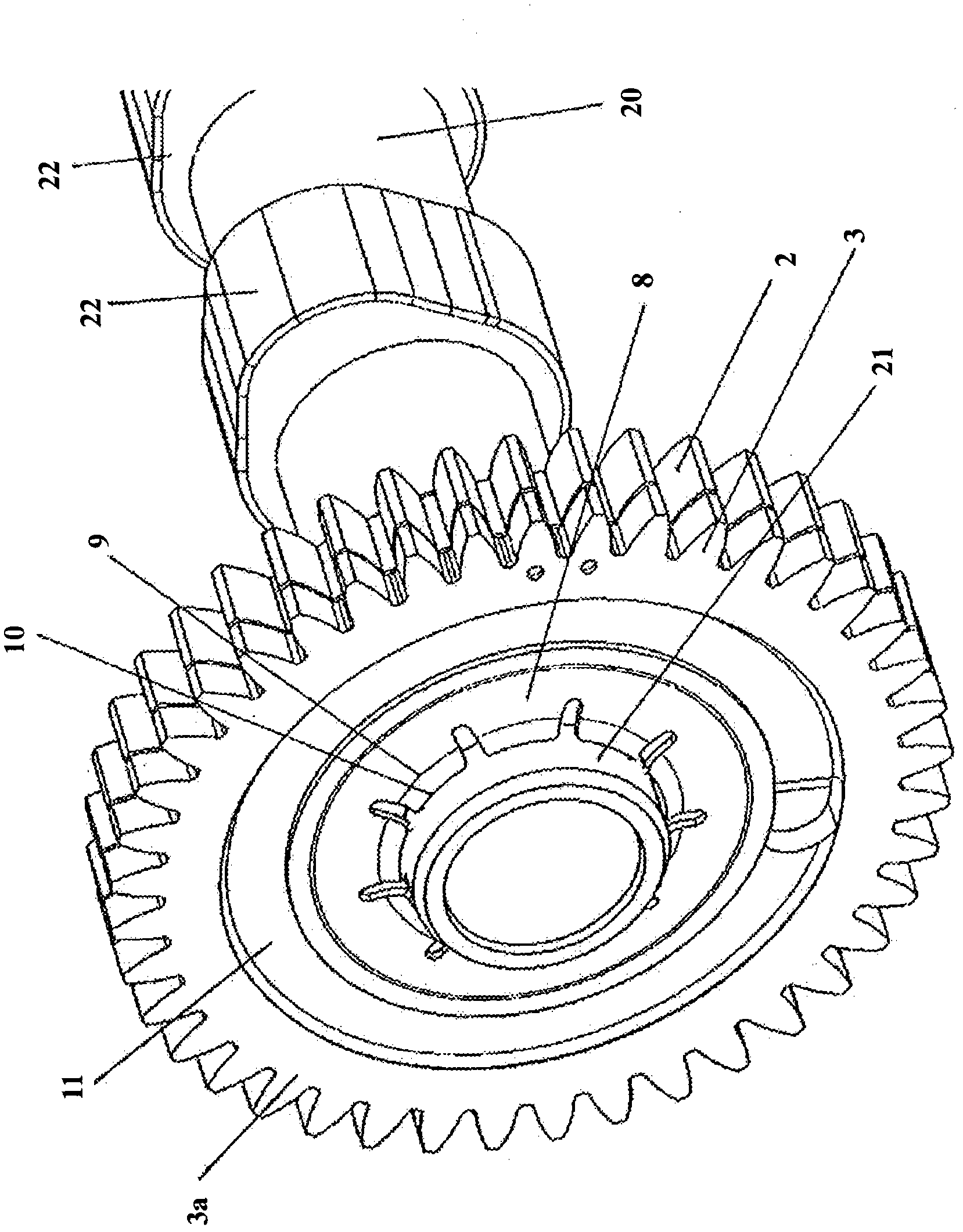

[0028] exist figure 1 The exploded view in shows the first gear half 2 which is fastened to the shaft end 21 of the camshaft 20 . The first gear half 2 has a flange 4 extending in the axial direction. The second gear half 3 is pushed onto the flange 4 in the axial direction for fitting the gear. Arranged between the two gear halves is a spring element 14 which, when assembled, is supported on the first gear half 2 on the one hand and on the second gear half 3 on the other hand. In the mounted state, the two gear halves are clamped against each other by the spring element 14 in a known manner.

[0029]If the second gear half 3 is pushed onto the flange 4 , the two gear halves 2 , 3 are fastened to the shaft end 21 of the camshaft 20 . Of course it is also possible first to fasten the first gear half 2 to the shaft end 21 and then to mount the second gear half 3 with the elastic element 14 . According to the invention, the annular disk 8 serving as the fastening element 6 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com