Electric machine

A machine and shaft technology, applied in the field of motors, can solve the problems of high production costs, achieve the effects of increasing power, reducing axial extension size, and avoiding overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

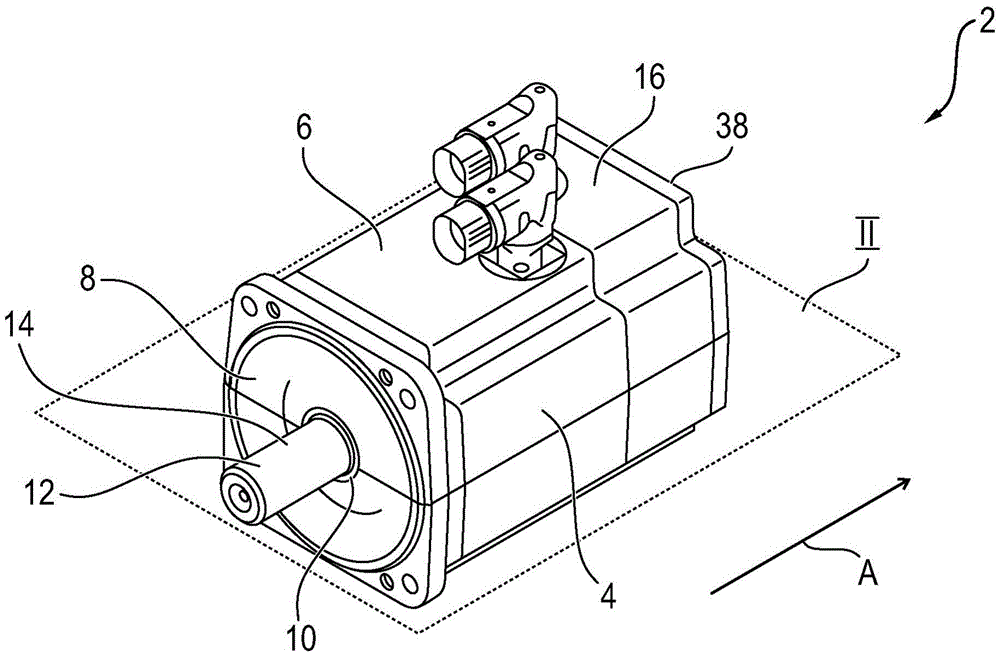

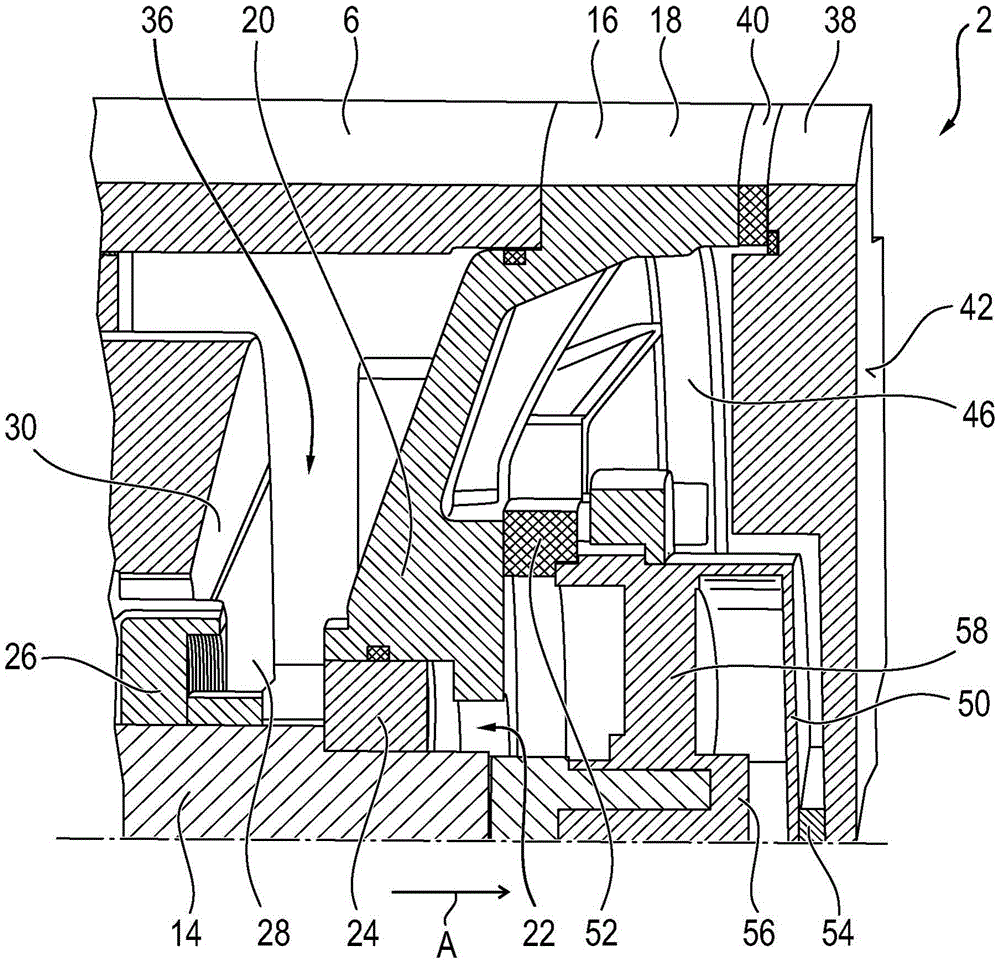

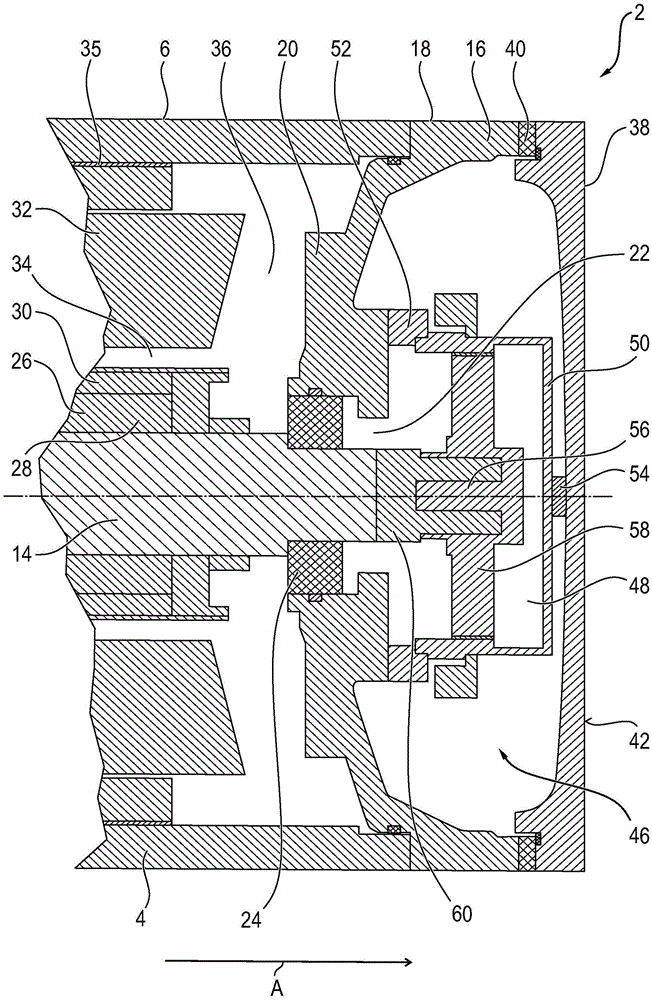

[0028] exist figure 1 The diagram shows an electric machine 2 in the form of an alternating current synchronous motor with a maximum power of 5 kW in a perspective view. The electric machine 2 includes a machine housing 4 made of aluminum. The machine housing 4 itself has a hollow-cylindrical central section 6 , on one end side of which an A-side bearing cap 8 with a ball bearing 10 is fastened. The journal 12 of the crankshaft 14 , which is made of steel, passes through the central recess formed by means of the ball bearing 10 . In the installed state, the structural elements operated by the electric motor 2 are connected to the journal 12 . In other words, the journal 12 forms the drive side of the electric motor 2 . On the side of the middle section 8 opposite the A-side bearing cap 8 , the B-side bearing cap 16 is connected to the middle section 6 , wherein the B-side bearing cap 16 has a collar 18 which is connected to the center Section 6 is aligned. The central sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com