Start-up element with torsional vibration damper and vibration damper

A technology of torsional shock absorber and starting element, which is applied in the direction of rotation vibration suppression, vibration suppression adjustment, spring/shock absorber, etc., to achieve the effect of suppressing unbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

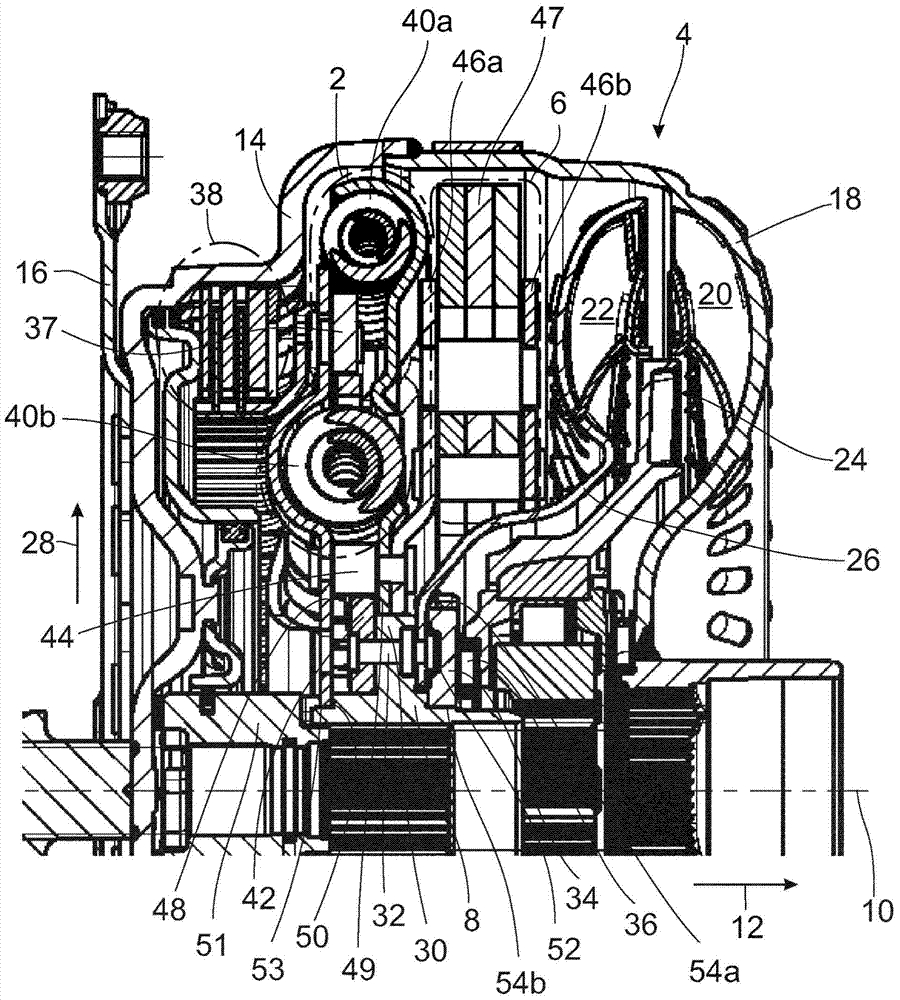

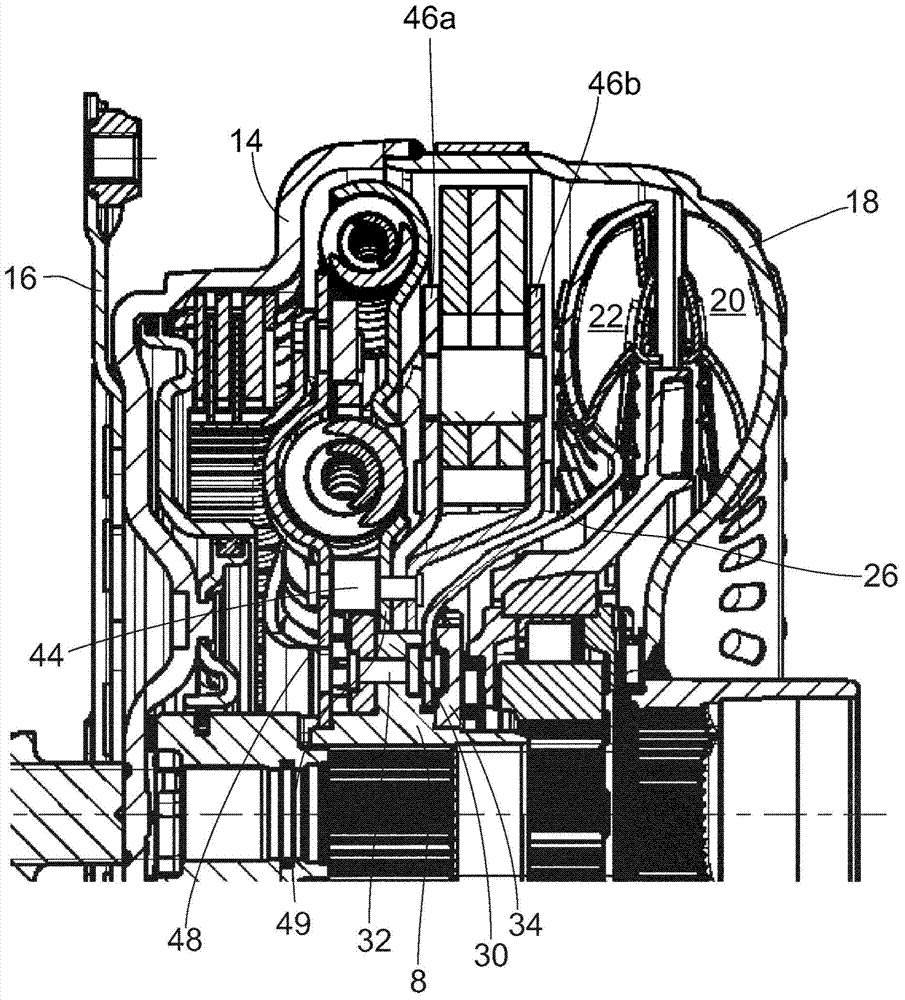

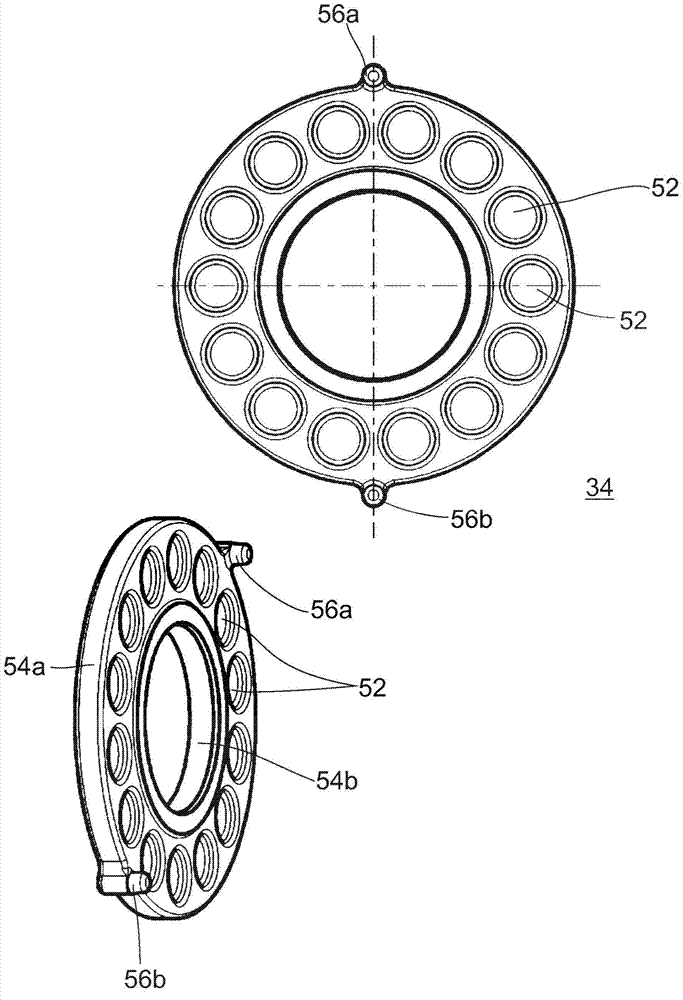

[0032] Exemplary embodiments are now described with reference to the accompanying drawings. Here, it should first be noted that the drawings are not necessarily drawn to scale and certain components may be artificially accentuated by using other line widths or hatching in order to emphasize certain features or properties.

[0033] It should be expressly noted that other embodiments should not be limited to the specific implementations shown in the following figures. In particular, the fact that certain functionality is described in the following figures with respect to a particular entity, particular functional block or particular means shall not be construed as that this functionality should or must be distributed in the same way in other embodiments. In other embodiments, certain functionality assigned to a plurality of separate components or units hereinafter can be combined in a single component or a single functional element, or functions combined here in a single element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com