Cutting device and cutting blade for cutting rod-shaped product of tobacco processing industry

A cutting device and technology in the processing industry, applied in tobacco, metal processing, application and other directions, can solve the problems of uneven cutting surface of rod-shaped products, being placed in fire, damaged product strips, etc., so as to improve service life and reduce wear and tear. degree, the effect of prolonging the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

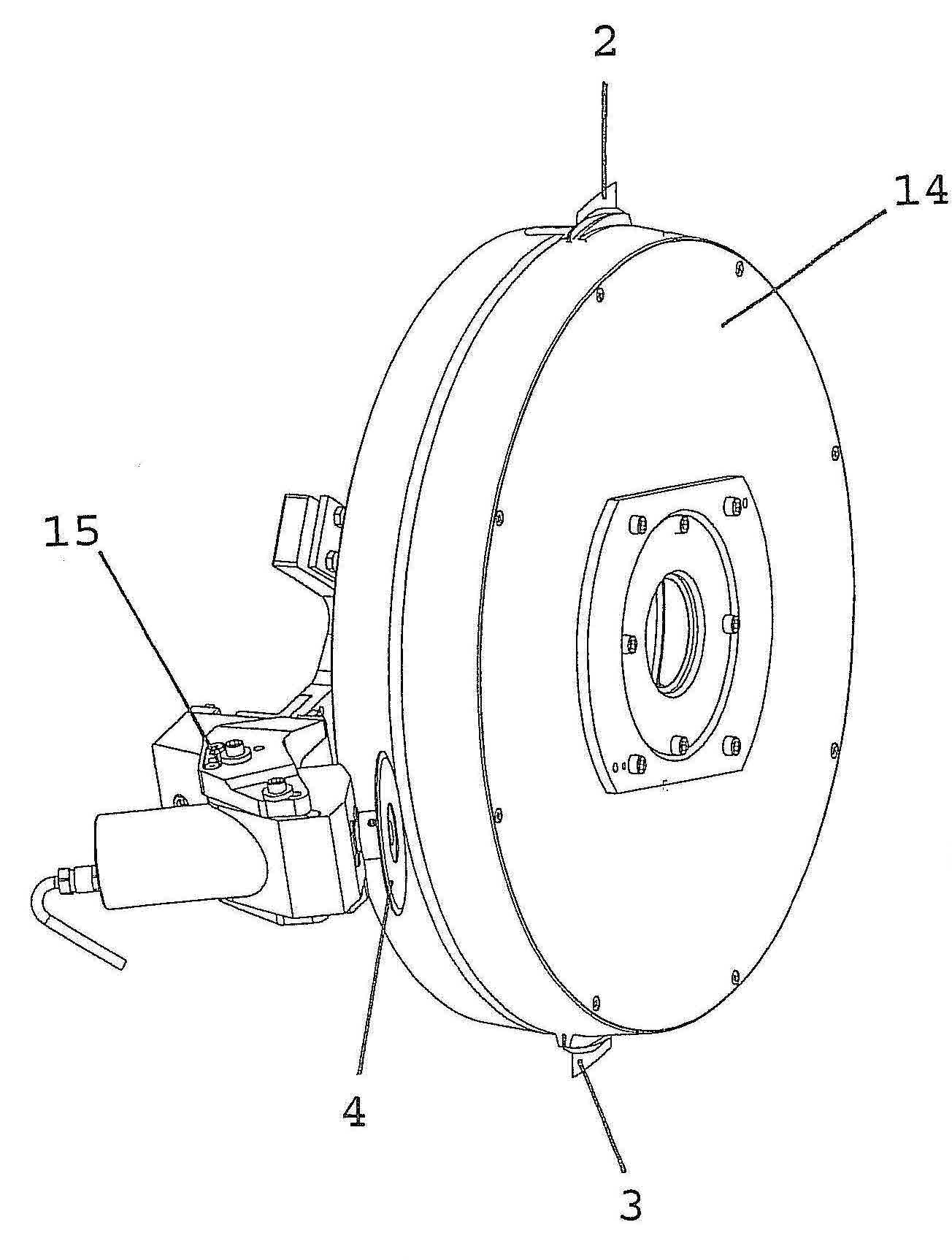

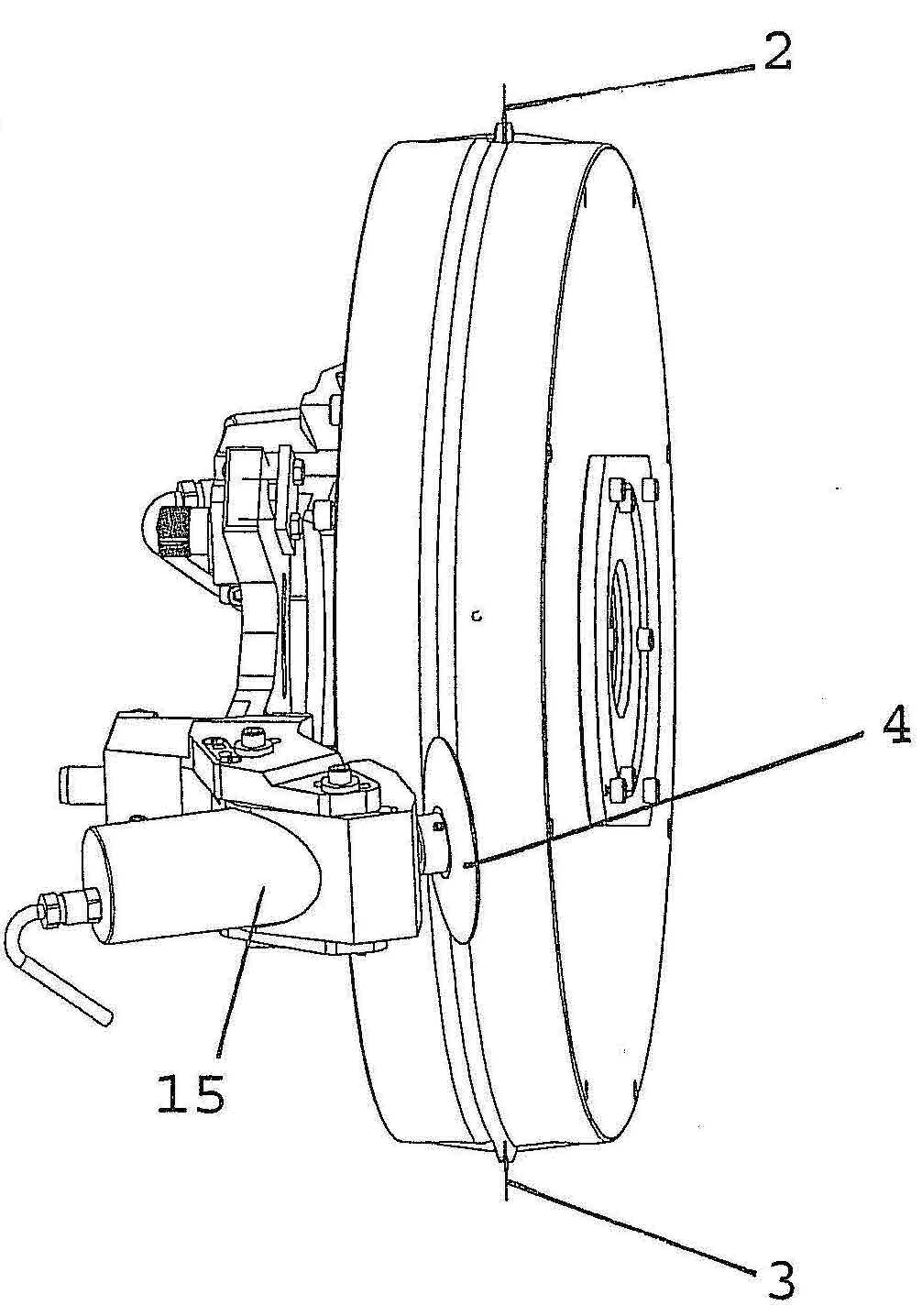

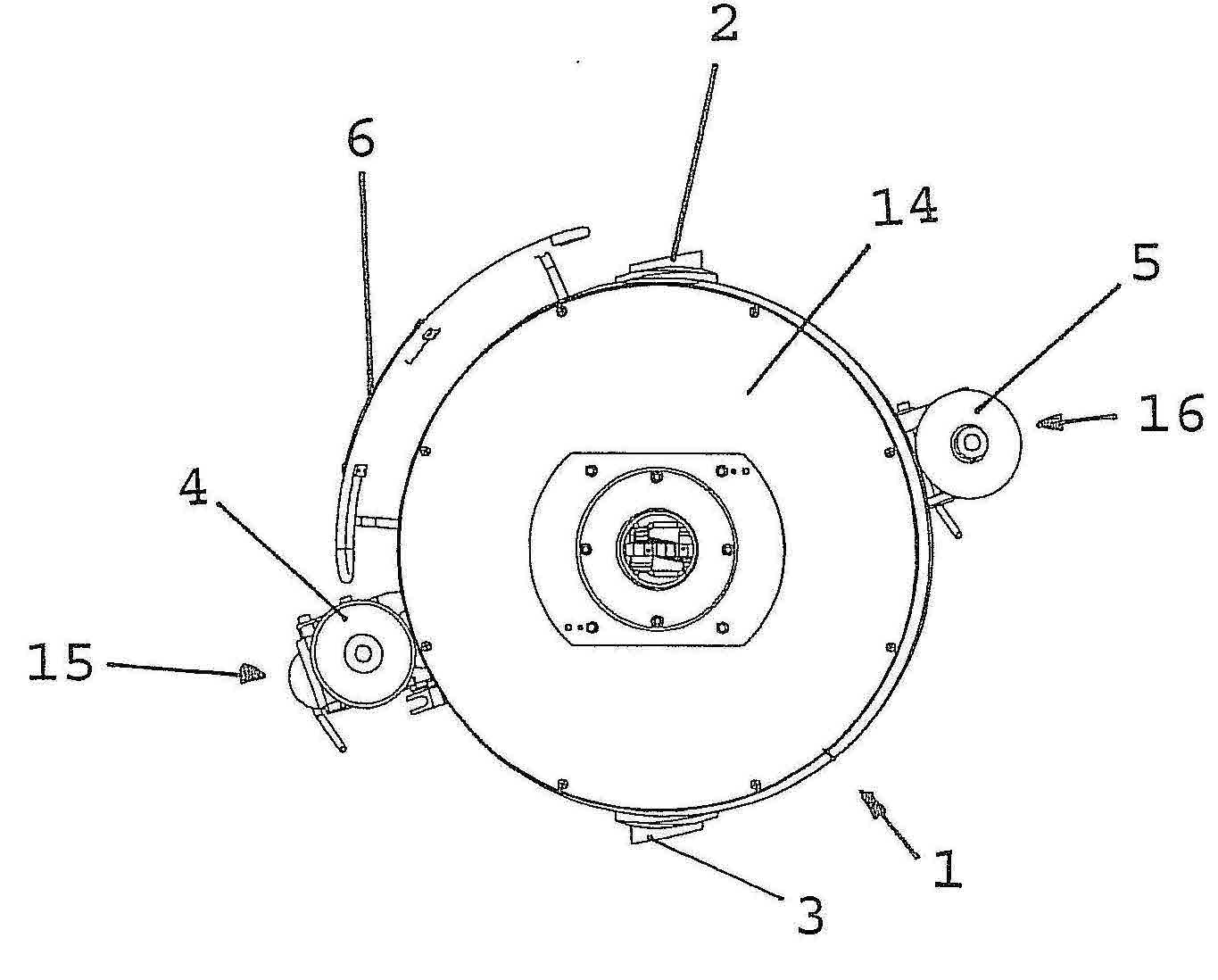

[0024] exist Figure 1a and 1bIn the figure, a cutting device 1 can be seen with a knife holder 14 which can be placed in rotation, on which two cutting knives 2 and 3 are clamped. Furthermore, a grinding device 15 is arranged on the cutting device 1 , fixed relative to the knife holder 14 , with a grinding wheel 4 , the grinding surface of which is oriented at an angle relative to the axis of rotation of the knife holder 14 . The grinding device 15 includes an electric motor, by means of which the grinding wheel 4 can be driven in rotation. The cutting knives 2 and 3 can be pivoted additionally relative to the knife holder 14 for producing cuts perpendicular to the feed direction of the rod-shaped product, wherein the rotary movement of the cutting knives 2 and 3 is carried out by means of a not shown in the knife holder 14 organization to trigger. Furthermore, a protective device 6 is provided, by means of which the operator is to be prevented from inadvertently reaching i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com