Thermoplastic polymer compositions with improved flexibility

A thermoplastic composition, polymer technology, used in building construction, roof insulation, roof cladding, etc., can solve problems such as less successful, unsuitable TPO materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

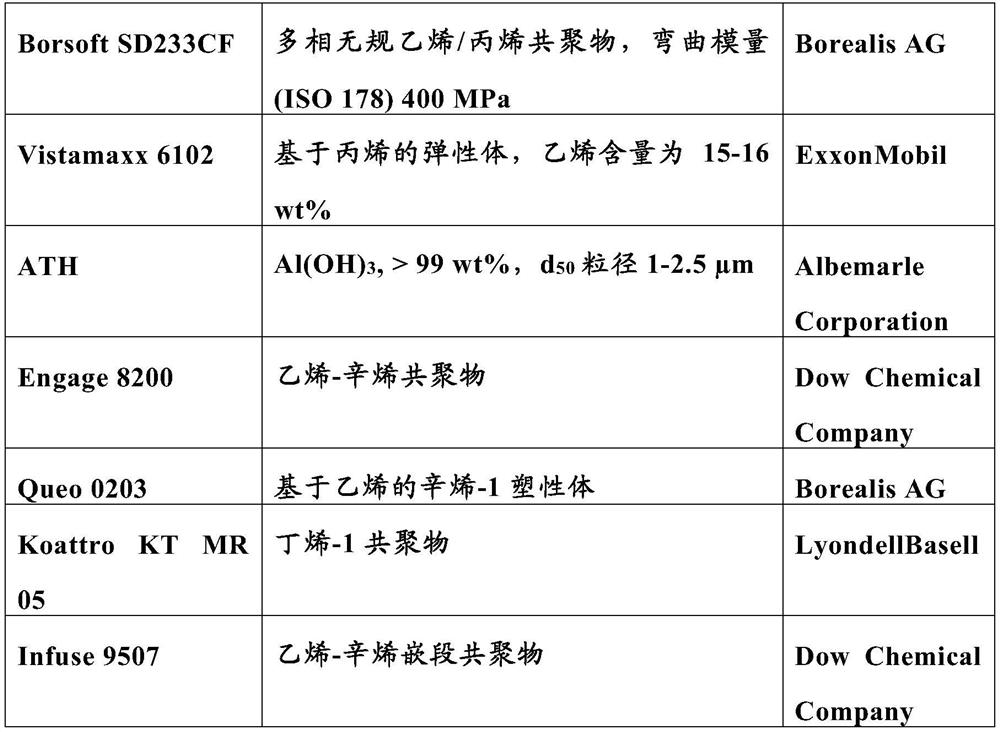

[0134] The following materials were used in the examples:

[0135] Table 1

[0136]

[0137] Preparation of shaped articles

[0138] Shaped articles (sheets) were produced using a laboratory-scale extrusion-calendering plant consisting of a twin-screw extruder (Berstorff GmbH), a flat die and a set of water-cooled calender rolls.

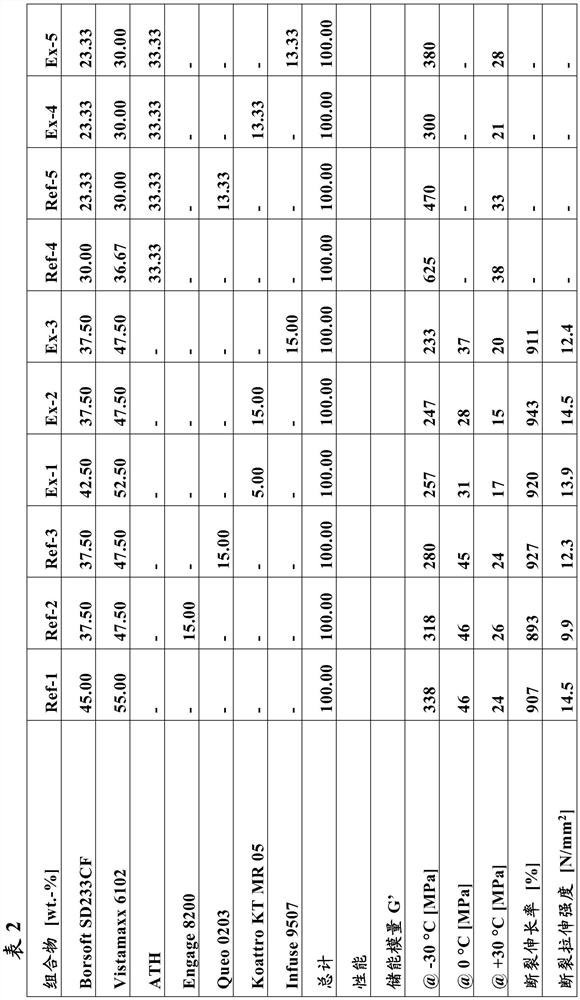

[0139] In the production of shaped articles, the ingredients of the thermoplastic composition shown in Table 2 were fed into the hopper of the extruder. The blend was melt processed in an extruder and extruded through a flat die into a single layer sheet having a thickness of about 1.5 mm. Extrusion was performed using an extrusion temperature of approximately 180°C.

[0140] Flexibility

[0141] Flexibility of the molded articles was determined by measuring the storage modulus (G') of the test specimens at temperatures of -30°C, 0°C and +30°C. The storage modulus was measured by dynamic mechanical analysis (DMA) using a method based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com