Methods and apparatus for cutting radii in flexible thin glass

A technology of equipment and radius, applied in glass manufacturing equipment, glass cutting device, welding equipment, etc., can solve problems such as bad characteristics, and achieve the effect of reducing particle generation, simplifying cutting equipment, and improving cutting results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

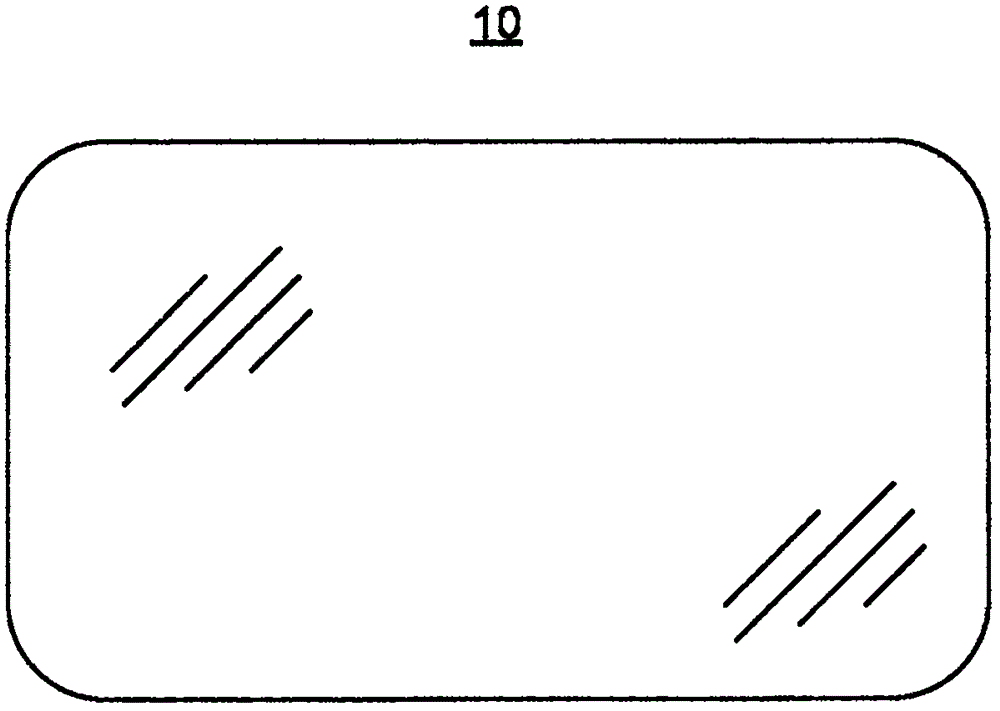

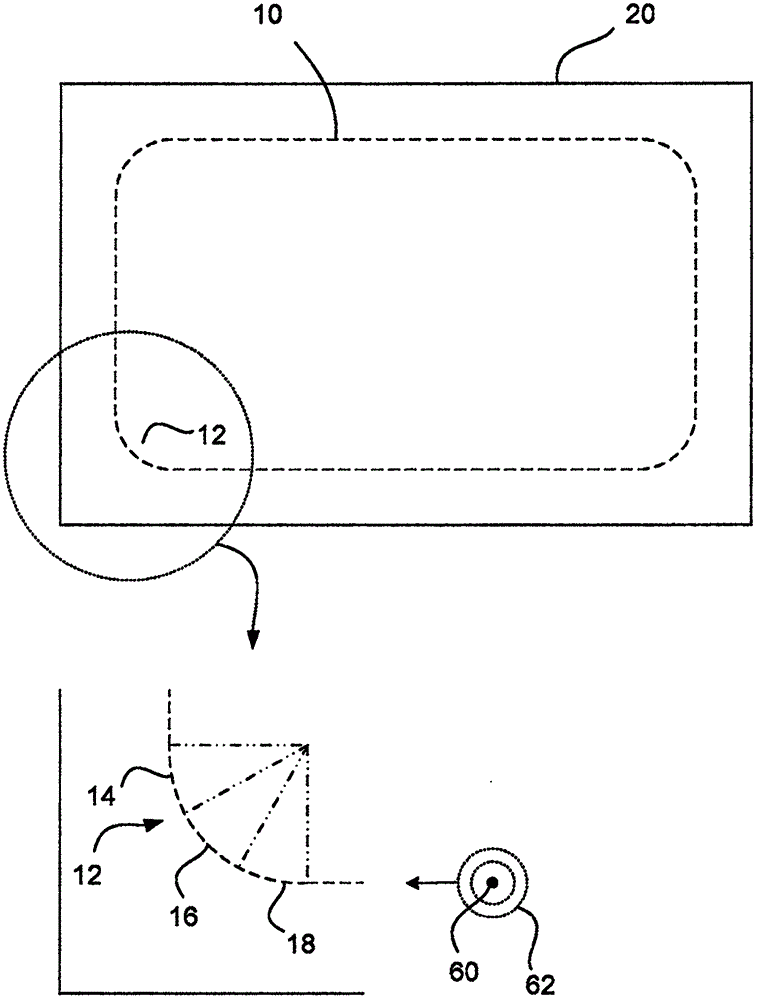

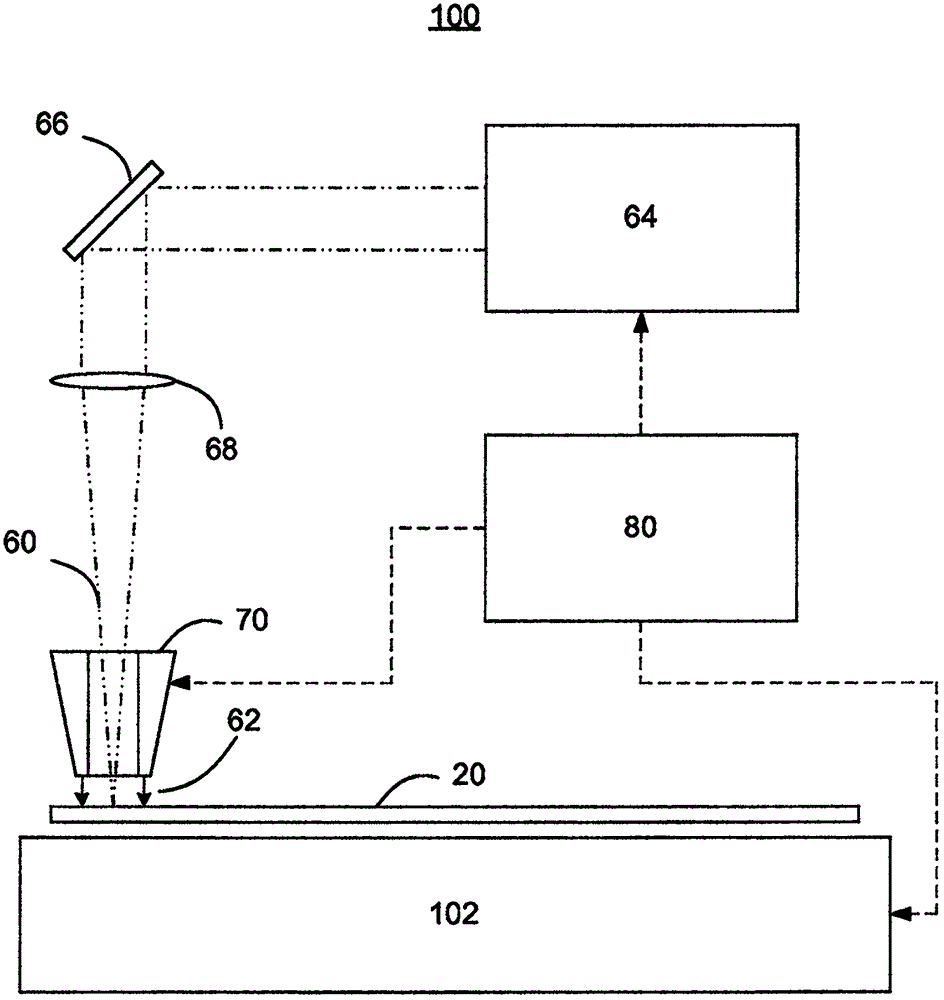

[0024] Reference is made to the figures in which like numerals indicate like elements. exist figure 1 A top view of a thin glass substrate 10 produced using one or more of the cutting methods and apparatus disclosed herein is shown in FIG. A number of properties of glass substrate 10 are of importance when considering the disclosure herein. First, the glass substrate 10 (and the source glass sheet from which it is cut) is thin and / or ultra-thin, having a thickness of less than about 0.2 mm, such as between about 0.01 mm and 0.2 mm, between about 0.05 mm to 0.2 mm, and / or between about 0.1 mm to about 0.2 mm. While these thicknesses are considered preferred, the glass substrate 10 may be thinner and / or thicker than the mentioned ranges. Second, glass substrate 10 is considered to be a free-form shape, eg, having at least one curved portion, with one or more radii of curvature, anywhere from a minimum of about 2mm up to about 20mm. For example, glass substrate 10 is shown wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com