A multi-channel fully automatic basic cover crimping device

A fully automatic, multi-channel technology, applied in the direction of feeding device, positioning device, stripping device, etc., can solve the problems of unstable structure, loss of manufacturers, affecting continuous production, etc., to improve debugging accuracy, save debugging time, The effect of ensuring the quality of the curling edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

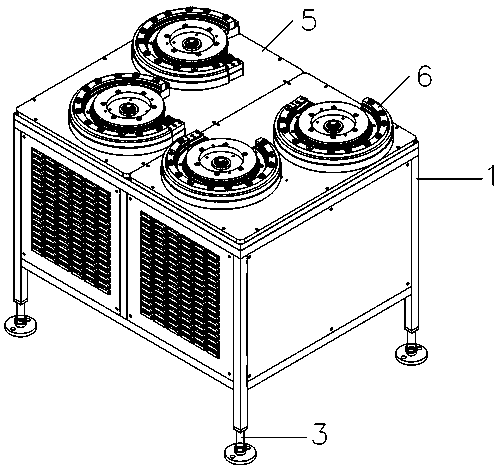

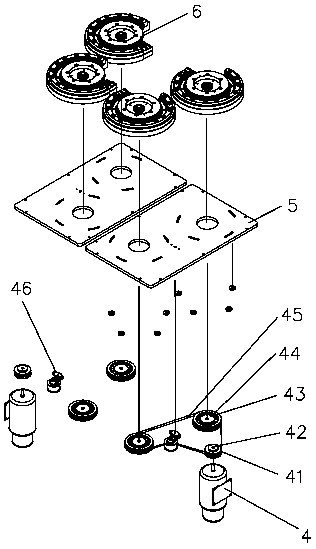

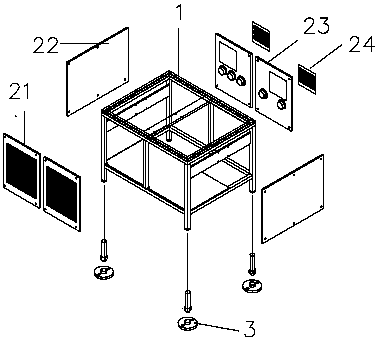

[0024] like figure 1 As shown, a multi-channel full-automatic basic cap curling device includes a machine base, a curling machine (6), a transmission device, a transmission unit and a controller, and the controller and several transmission units are installed on the described machine base. The crimping machine (6) driven by the device, the crimping machine (6) is provided with a guide seat connected to the transmission unit, the transmission unit includes a feeding device and a discharging device, and the discharging device includes a main discharge track and Several discharge sub-tracks overlapped with the main discharge track, and the discharge sub-tracks are connected to the outlet of the corresponding edge curling machine. The feeding device includes the main feed track and several feed sub-tracks. The track includes a connecting mechanism, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com