Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "High debugging accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

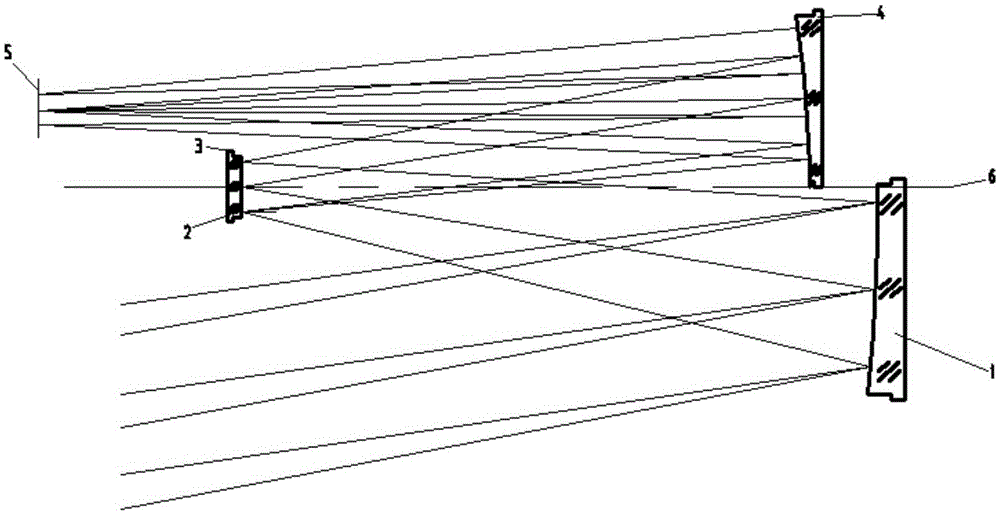

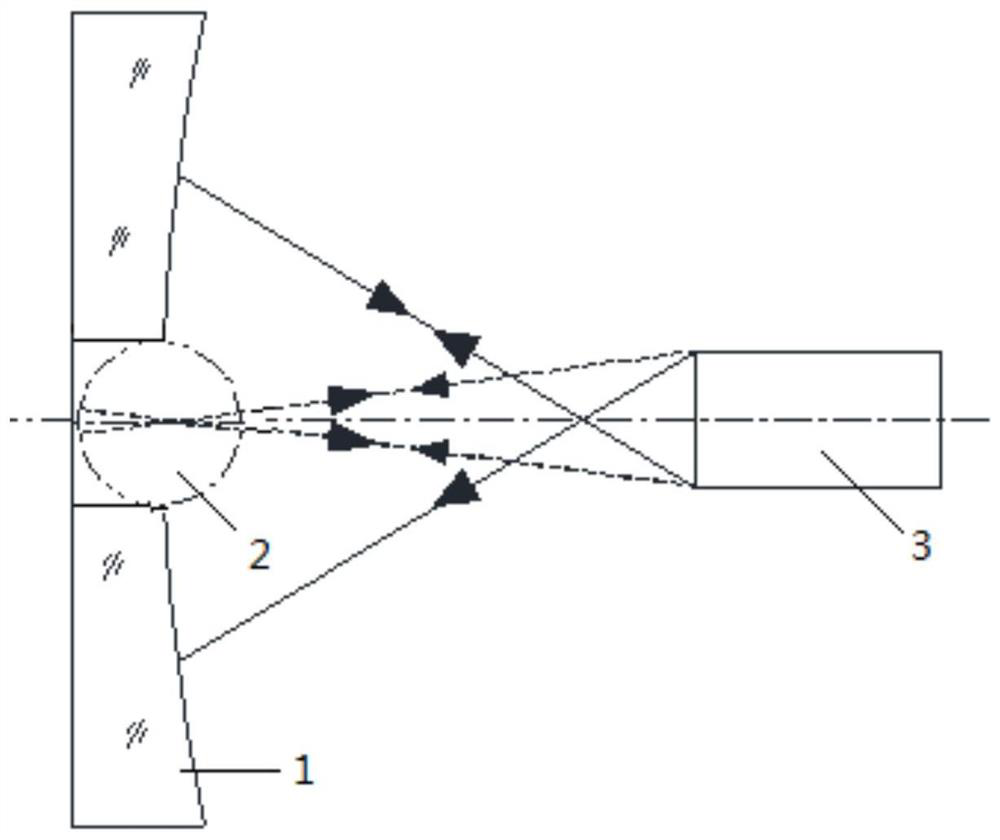

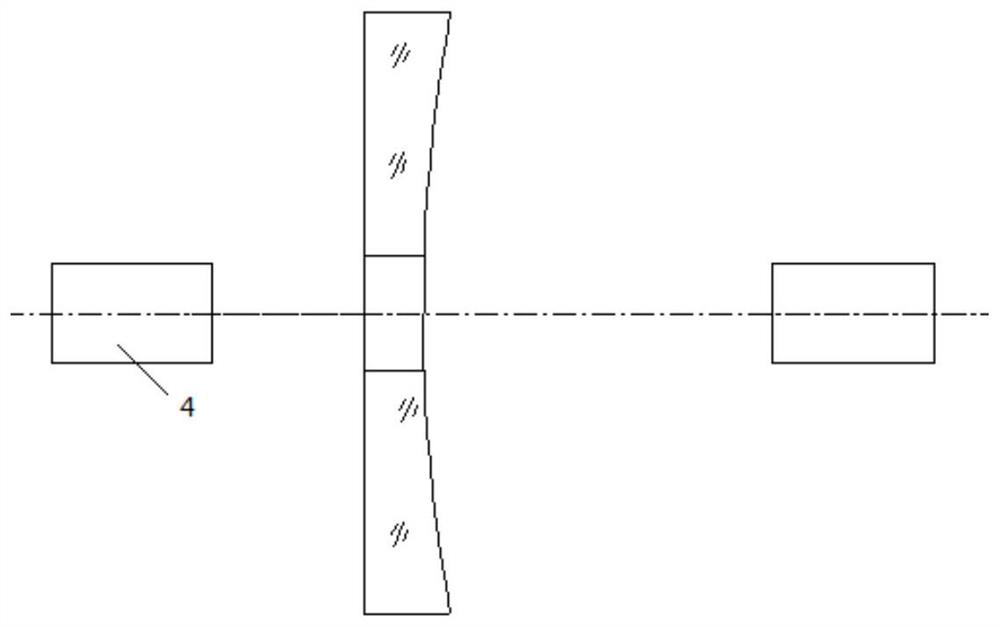

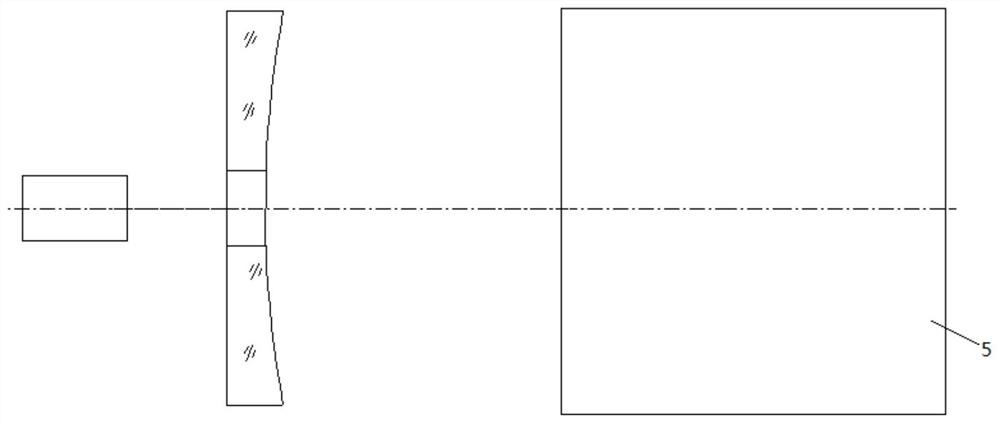

Large view field off-axis three-reflector system and adjusting method

ActiveCN105242387ASimple structureReduce the difficulty of assembly and adjustmentOptical elementsHyperboloidSystems design

The invention relates to a large view field off-axis three-reflector system and an adjusting method. The large view field off-axis three-reflector system comprises a main mirror, a secondary mirror, an aperture diaphragm, a third mirror and a focal plane. The main mirror is an off-axis hyperboloid reflector; the secondary mirror is a protruding spherical surface reflection mirror; the third mirror is an off-axis secondary recessed flat spherical mirror; the master axes of the master mirror and the third mirror are superposed as a reference axis; the aperture diaphragm is successively arranged on the secondary mirror; the optical axis of the secondary mirror is superposed with the master axis of the third mirror; a target light ray from infinity enters the secondary mirror after reflection of the main mirror and enters the third mirror through the reflection of the secondary mirror; and then the light ray is imaged on the focal surface. The invention solves the contradiction between the large view field off-axis three-reflector system, the processing and adjusting. The large view field off-axis three-reflector system adopts a simple structure and can realize the wide width imaging, wherein the effective view field reaches 12 degree*3.5 degree.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

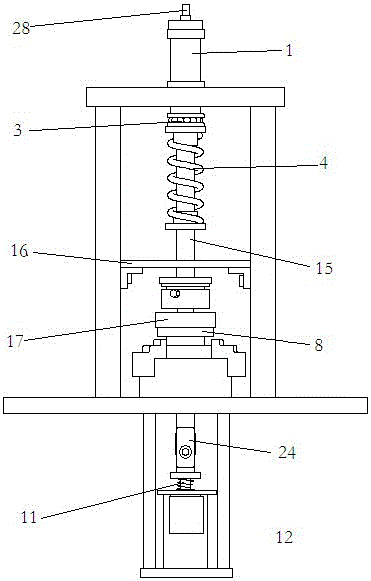

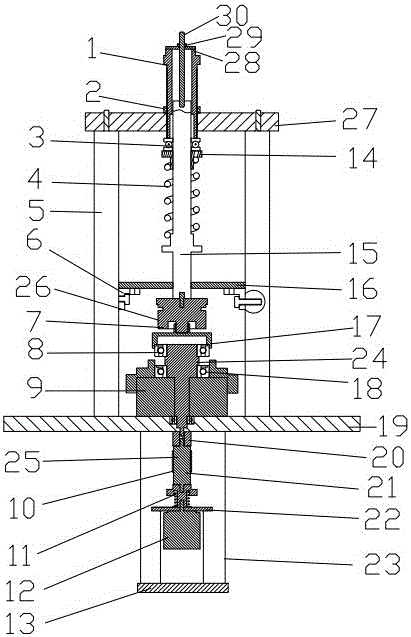

Bearing rotation torque test device

Provided is a bearing rotation torque test device. The center shaft of an axial loading member is connected with a thrust bearing and a spring spacer. A micro-load rod matches a pressure sensor connected with an axial loading sleeve. A measuring member is formed through clearance fit between the inner holes of two identical upper and lower detection bearings and a test shaft. The lower end of the test shaft is connected with an elastic coupler. The outer diameter of the upper detection bearing matches the axial loading sleeve mounted on the pressure sensor, and the outer diameter of the lower detection bearing matches a three-claw chuck mounted on a test bench. The shaft of a stepper motor is additionally equipped with a torque overload device, so damage to a torque sensor by detection overload is avoided. The thrust bearing, the spring spacer and the elastic coupler are provided with an aligning function, so the concentricity of the device is guaranteed. After loading, the three-claw chuck is released. The bearings are undirected, and are completely unaffected by tilting load and other pressures. The test values are more accurate. The trouble of detection tool replacement for test of bearings of different specifications is reduced. The problem that inaccurate values, poor repeatability and poor practicability are caused by loading deformation of the detection bearings is solved completely.

Owner:CIXING GROUP

Air conditioning testing and regulating device and method

InactiveCN102141483AReduced commissioning timeImprove cooling effectStructural/machines measurementControl electronicsEngineering

The invention discloses an air conditioning testing and regulating device which comprises an air conditioner to be debugged, an electronic expansion valve, a refrigerant increasing and decreasing device, a value control unit and a central control module, wherein the air conditioner to be debugged comprises a compressor, a condenser and an evaporator which are connected through a refrigerant pipeline, the electronic expansion valve is detachably installed on a pipeline between the condenser and the evaporator, the refrigerant increasing and decreasing device is detachably connected with the refrigerant pipeline, the value control unit is used for controlling the action of the electronic expansion valve, and the central control module is used for controlling the value control unit. The invention also discloses an air conditioning testing and regulating method. The size of a path of the electronic expansion valve and the volume of the refrigerant are regulated by the central control module. With the adoption of the air conditioning testing and regulating device and method, the debugging process of an air conditioning is greatly simplified, the debugging time of the air conditioning is saved, the production efficiency of the air conditioning is enhanced, and the production cost of the air conditioning is lowered.

Owner:苏州恒兆空调节能科技有限公司

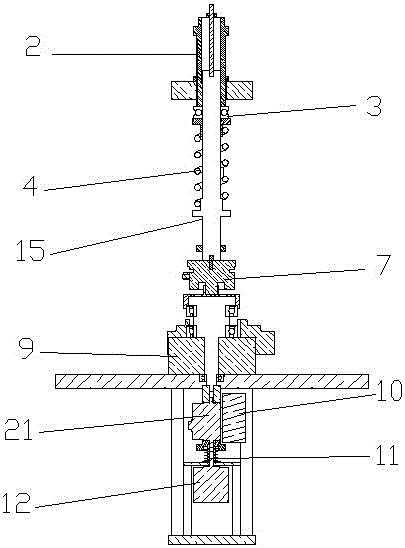

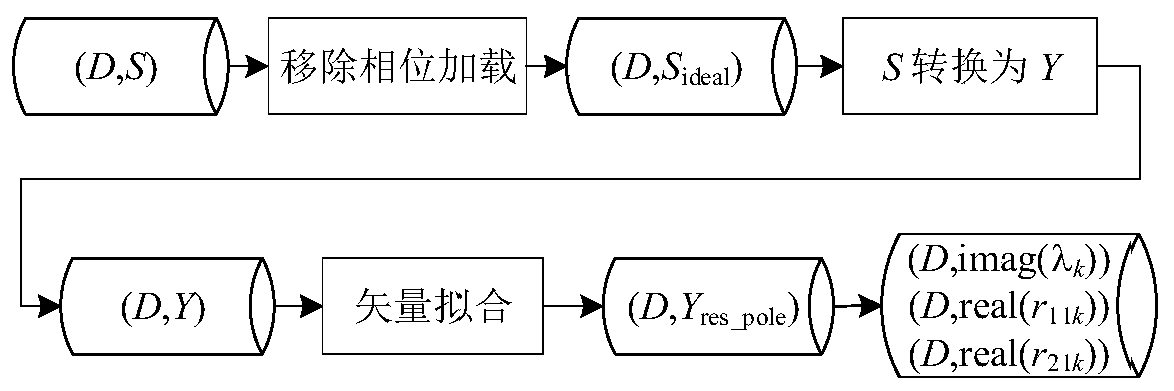

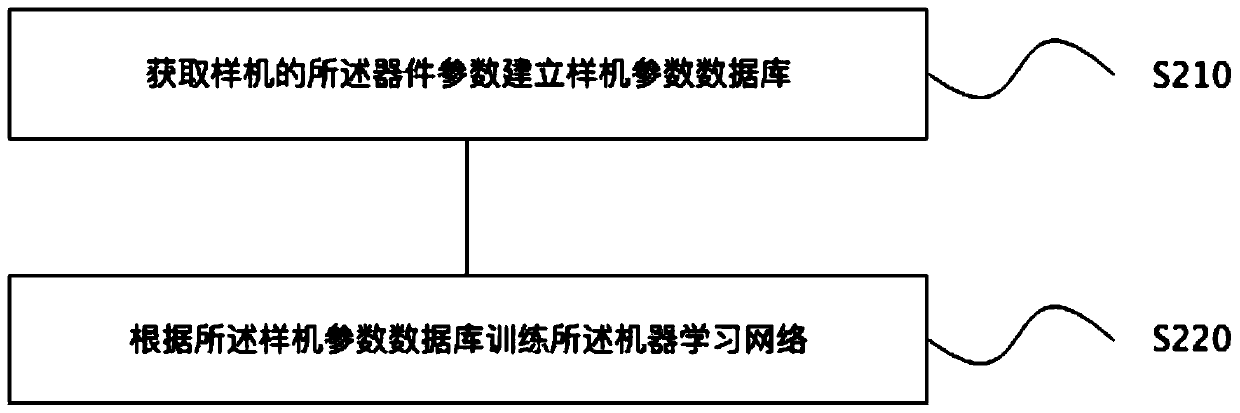

Microwave cavity filter intelligent debugging method based on particle swarm optimization algorithm

ActiveCN109783905AReduce modeling difficultyReduce the difficulty of debuggingNeural learning methodsSpecial data processing applicationsParticle swarm optimizationElectromagnetic simulation

The invention provides a microwave cavity filter intelligent debugging method based on a particle swarm optimization algorithm, and the method comprises the steps: firstly, randomly changing the length D of each coupling screw in an electromagnetic simulation model of a microwave cavity filter into a cavity, obtaining a corresponding dissipation parameter S, and constructing an original sample data set; secondly, preprocessing the data in the sample data set; based on a block modeling method and a BP neural network, performing training to obtain an electromechanical characteristic model of themicrowave cavity filter; and finally, based on the electromechanical characteristic model and a particle swarm optimization algorithm, debugging the microwave cavity filter to be adjusted. The adjustment amount of each coupling screw is determined through a particle swarm optimization algorithm, so that the value of the value function is continuously reduced until the output of the microwave cavity filter meets the preset performance index, and the debugging process of the microwave cavity filter is completed. The debugging method has the beneficial effects that the debugging difficulty is reduced, the debugging precision and the debugging speed are improved, and the practicability and the applicability are high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

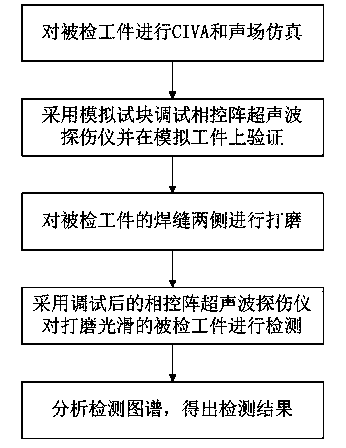

Small-diameter tube nondestructive testing method based on phased array ultrasonic flaw detector

ActiveCN104297340AHigh debugging accuracyHigh sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesWeld seamNondestructive testing

The invention provides a small-diameter tube nondestructive testing method based on a phased array ultrasonic flaw detector. The small-diameter tube nondestructive testing method comprises the following steps: carrying out CIVA and sound field simulation on a detected workpiece; debugging the phased array ultrasonic flaw detector by a simulation test block and verifying on a simulated workpiece; grinding two sides of a welding seam of the detected workpiece, detecting the detected workpiece ground smoothly by the debugged phased array ultrasonic flaw detector; and analyzing the detection graph to obtain a detection result. The method can perform CIVA and sound field simulation on the detected workpiece before field detection, and adopts an appropriate comparison test block and the simulation workpiece for debugging the phased array ultrasonic flaw detector; the method adopts different scanning modes according to the different thicknesses of the simulation workpieces in a debugging process, can improve the debugging precision, can improve the field detection sensitivity, can prevent repeated detection, saves the detection time and reduces the detection cost.

Owner:中能建建筑集团有限公司 +2

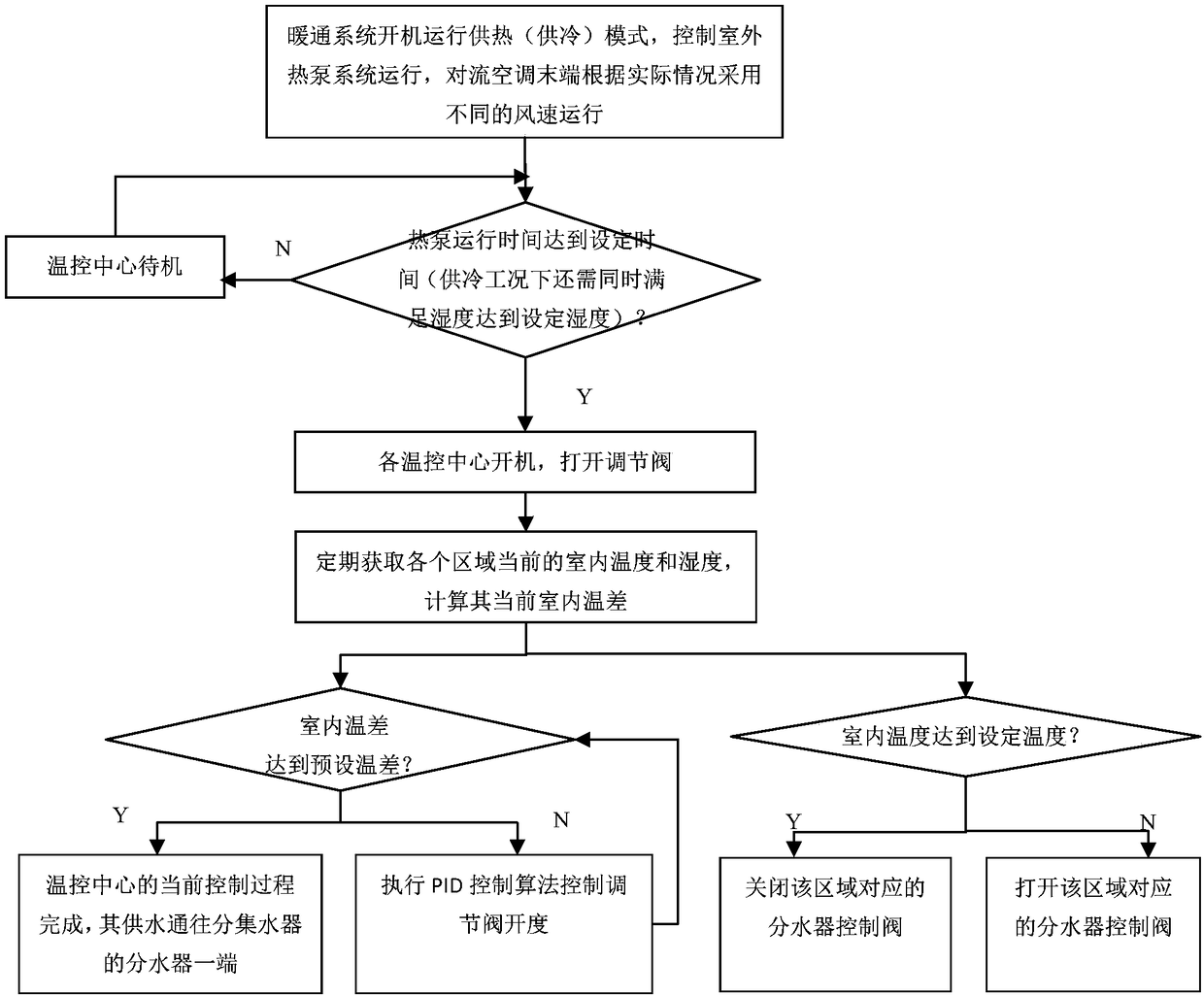

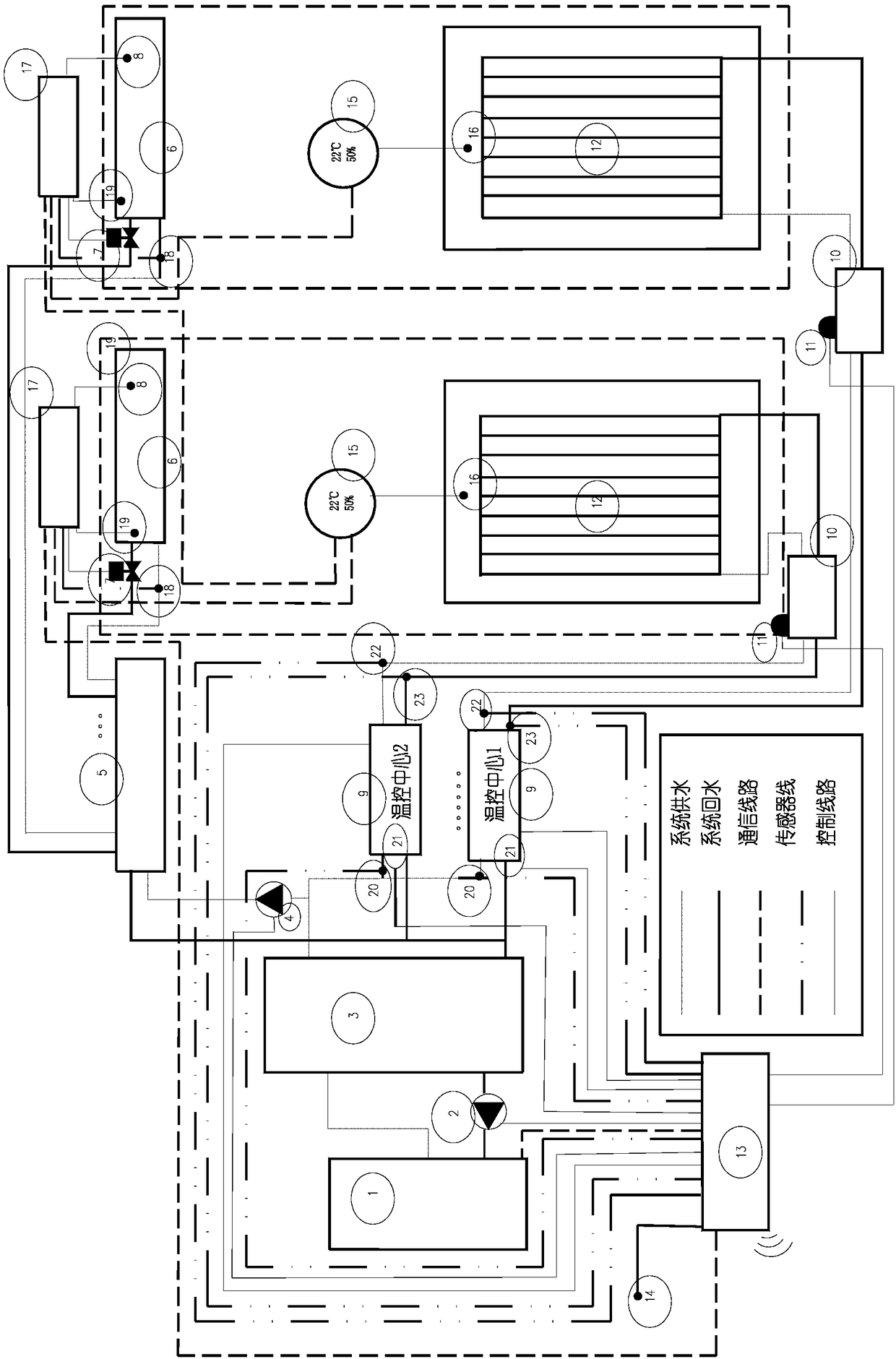

Control method for convection and radiation adaptive supply heating and ventilation system

ActiveCN108489027AStrong timelinessHigh debugging accuracyMechanical apparatusSpace heating and ventilation safety systemsEngineeringIndoor air temperature

A control method of a convection and radiation adaptive supply heating and ventilation system. The system includes a system master controller and an outdoor heat pump system, a temperature control center, an outdoor temperature sensor, an indoor temperature humidity sensor, a convection air conditioning terminal, and a radiant air conditioning terminal respectively connected to the system master controller. In operation, the system master controller compares the detection temperature to the set temperature, the convection air conditioner terminal is operated to quickly adjust the indoor air temperature when the temperature difference is large, and the convection air conditioner terminal is turned off or weakened after the temperature difference is less than a certain value to operate the radiant air conditioner termnial to increase comfort.

Owner:陈旸

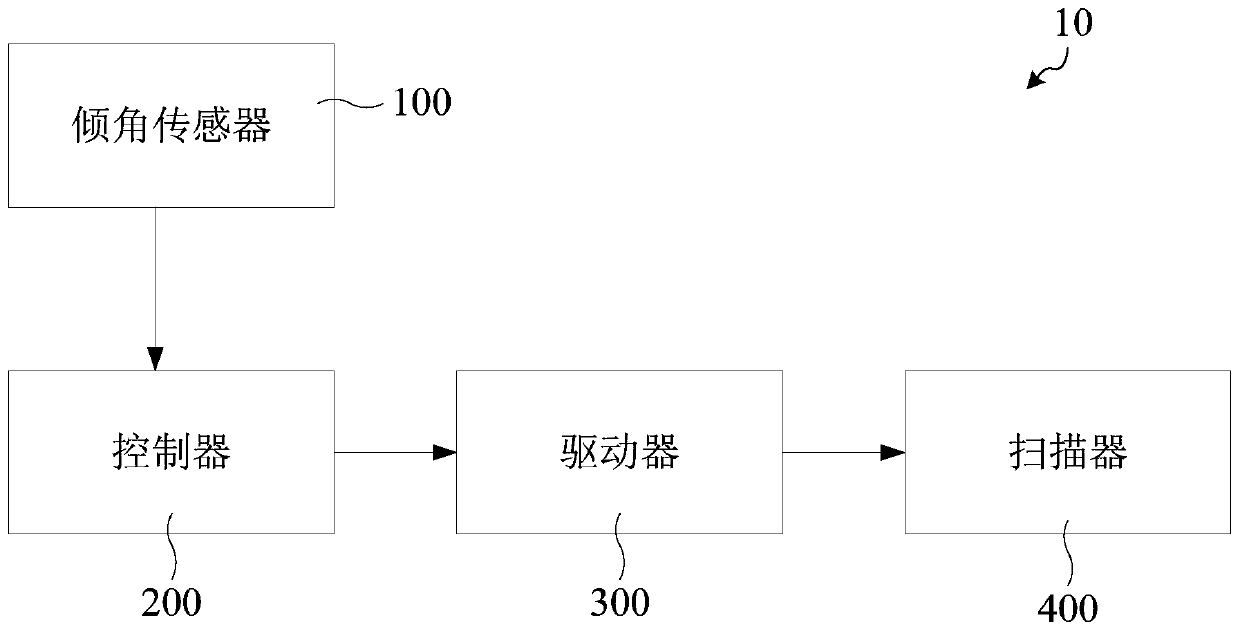

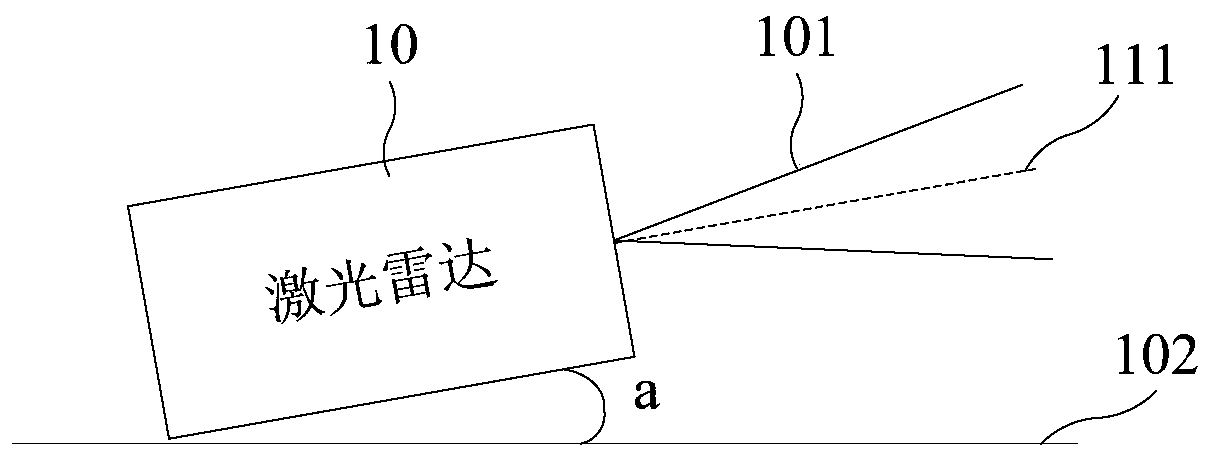

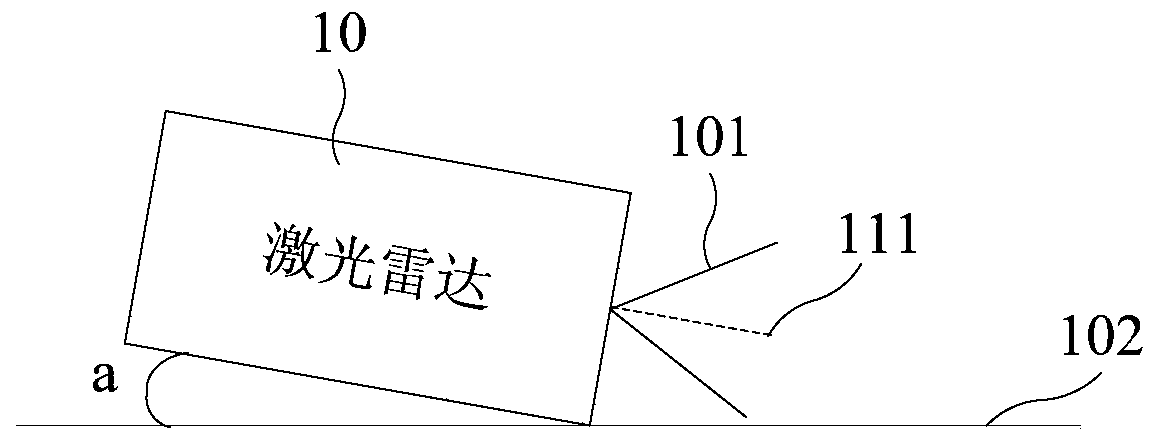

Laser radar, equipment and laser radar installation angle calibration method

PendingCN109870700ARealize automatic compensationNo labor consumptionElectromagnetic wave reradiationRadarOptoelectronics

The invention discloses a laser radar, equipment and a laser radar installation angle calibration method. The laser radar comprises a tilt angle sensor, a controller, a driver and a scanner, wherein the tilt angle sensor, the controller, the driver and the scanner are sequentially connected in series; the tilt angle sensor is used for detecting an installation angle of the laser radar; the controller is used for obtaining an actual deflection angle of the scanner according to the installation angle and a target inclination angle of a laser beam emitted by the scanner, and generating a drivinginstruction carrying the actual deflection angle; and the driver is used for driving the scanner to deflect the actual deflection angle according to the driving instruction. According to the technicalscheme provided by the embodiments of the invention, the automatic compensation of an installation error of the laser radar is realized, no manual consumption is generated, the man-hour is short, andthe measurement and debugging precision is high.

Owner:LEISHEN INTELLIGENT SYST CO LTD

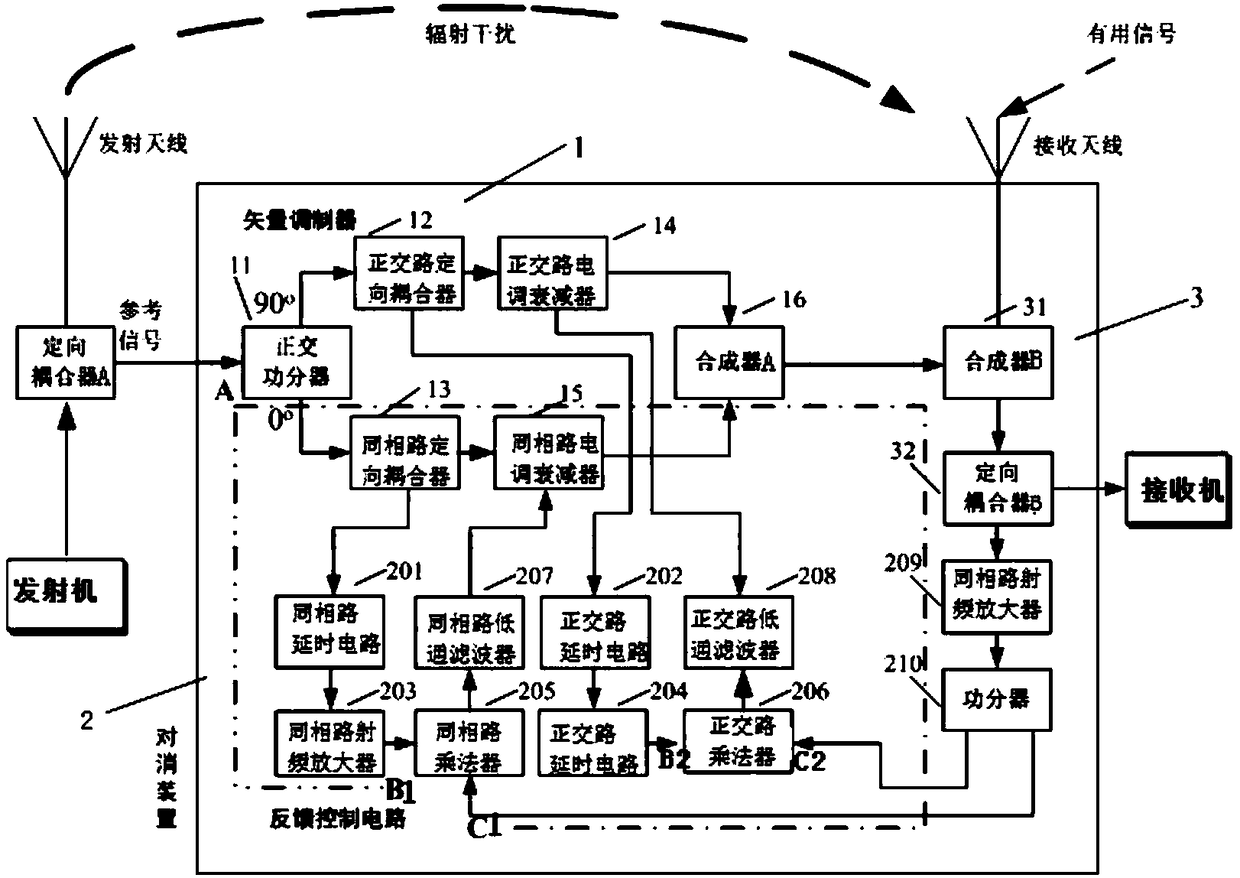

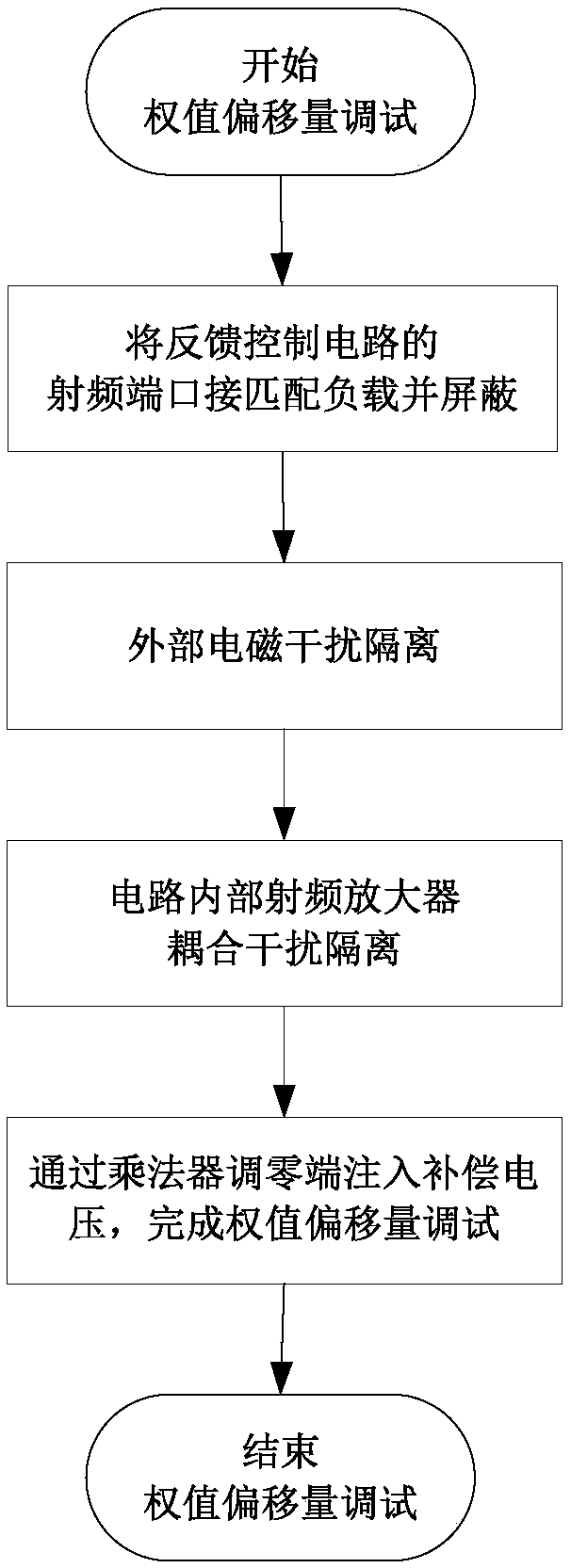

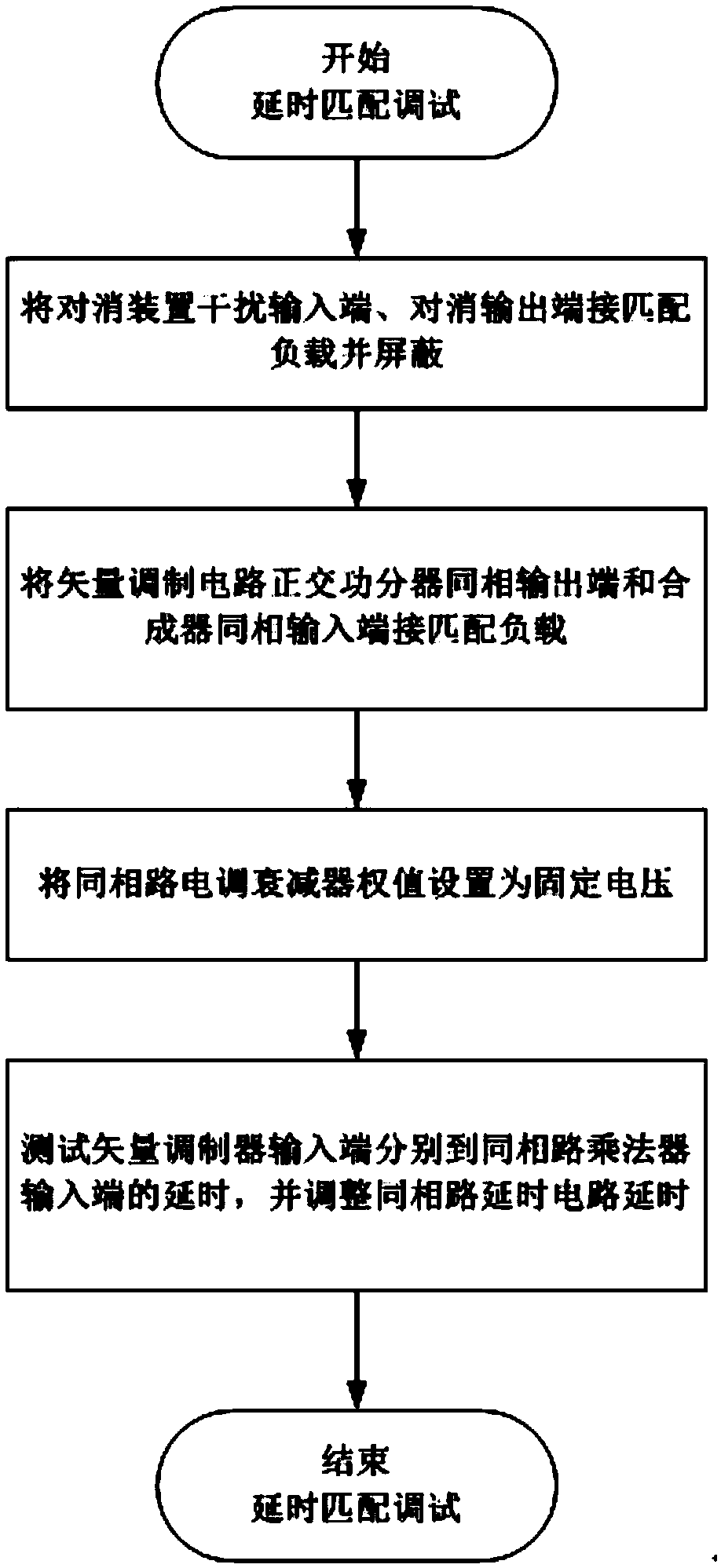

Radio-frequency adaptive interference cancellation device and debugging method thereof

ActiveCN109120288AReduced measurement VSWRHigh debugging accuracyTransmissionRadio frequencyTime delays

The invention provides a radio-frequency adaptive interference cancellation device, and the device comprises a vector modulation circuit, a feedback control circuit, and a synthesis and feedback circuit. An output end of a directional coupler A is electrically connected with the input end of the vector modulation circuit. The directional coupler A transmits a reference signal to a vector modulator, and the output end of the vector modulator is electrically connected with the input end of the feedback circuit. The output end of the feedback circuit is electrically connected with the input end of the feedback control circuit. The vector modulator is electrically connected with a feedback controller, and the output end of a transmitter is electrically connected with the input end of the directional coupler A. The output end of the feedback circuit is electrically connected with the input end of a receiver. Aiming at ironing out the defects in the prior art, the invention provides the radio-frequency adaptive interference cancellation device and a debugging method therefor, so as to achieve the zero-drift precise inhibition of a multiplier in the radio-frequency adaptive interference cancellation device and the precise matching of time delay.

Owner:NAVAL UNIV OF ENG PLA

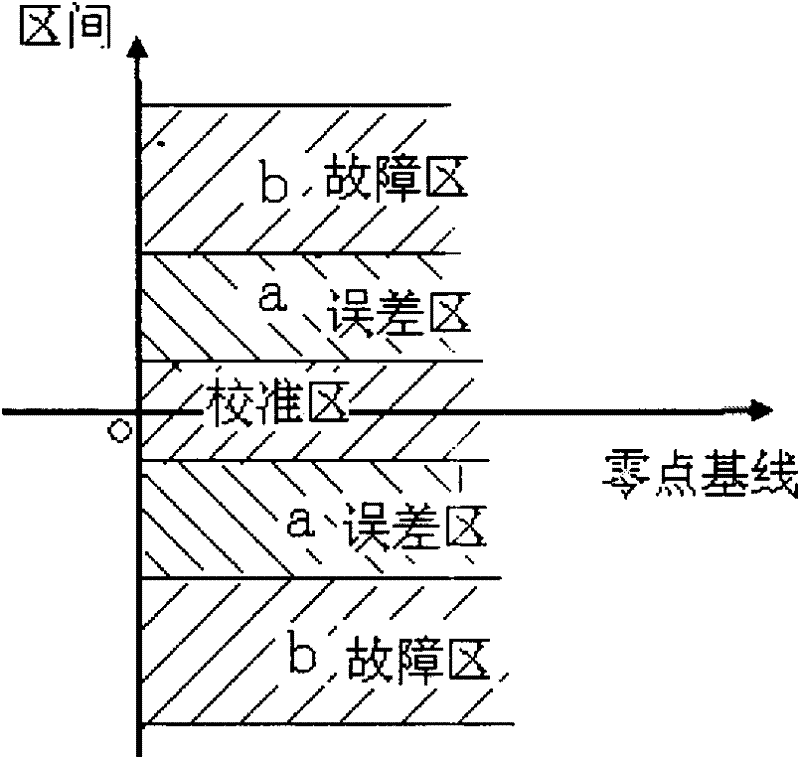

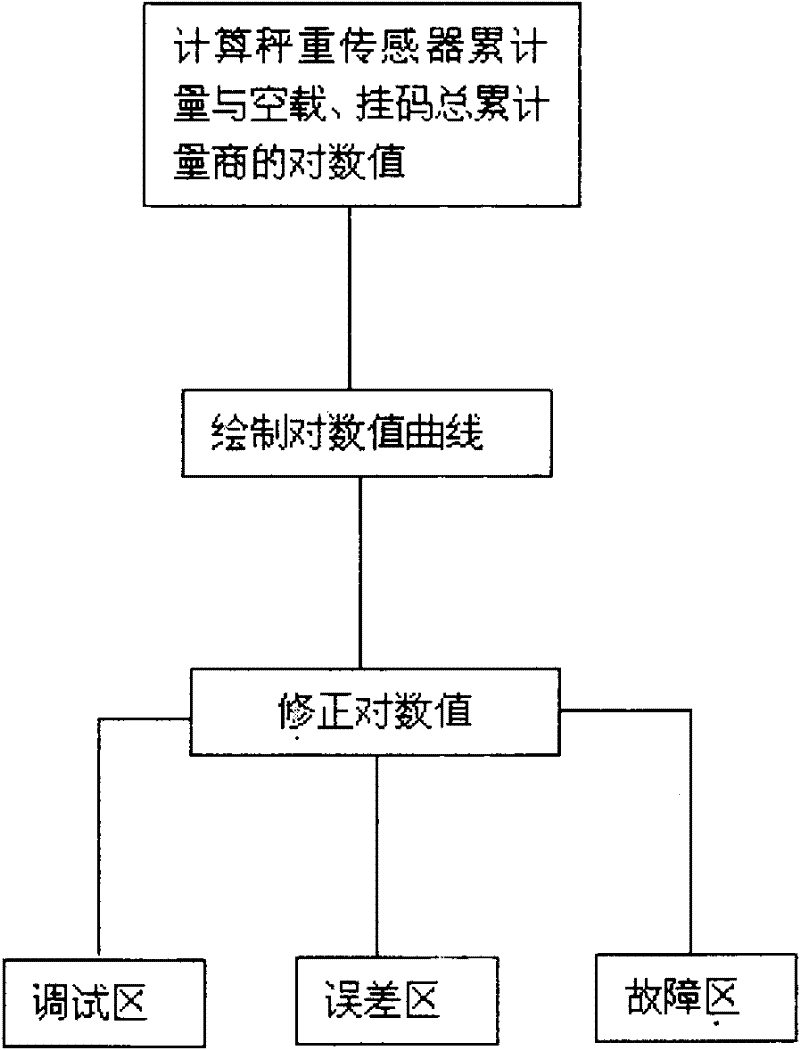

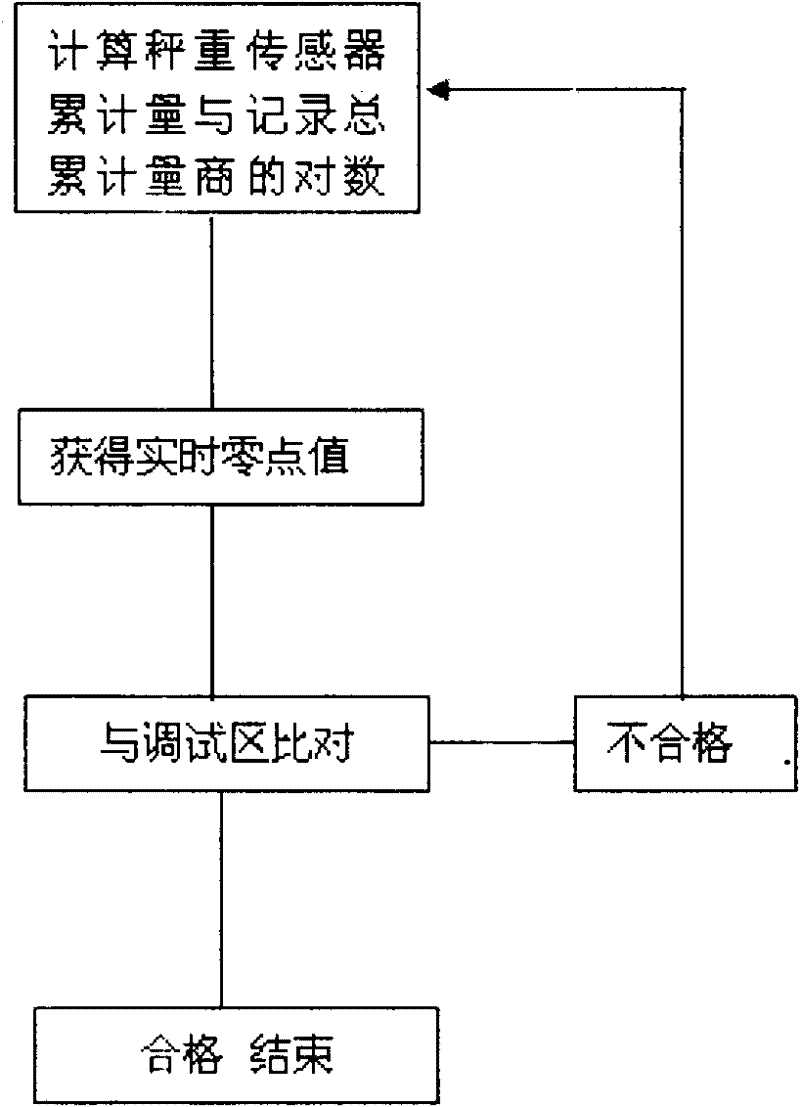

Calibrating method of weighing sensor of belt scale

InactiveCN102359813AImprove debugging efficiency and accuracyCalibration is accurateWeighing apparatus testing/calibrationTime zeroFailure rate

The invention discloses a calibrating method of a weighing sensor of a belt scale, belonging to the technical field of dynamic weighing. The calibrating method is characterized by comprising the following steps of: obtaining a comparative standard value range by collecting actual weighing values, obtaining a real-time zero value by using logarithm values of different combinations of accumulative amounts to be compared with the standard value, automatically tracking and judging an error tendency of the accumulative amounts of the weighing sensor, further diagnosing the position and system where the error is; and calibrating the weighing sensor according to the error curve. The calibrating method has the advantages: structurally, a mature general technology is adopted, the calibrating method can be used for timely, accurately and reliably judging errors, is not only convenient to check and but also has the function of fault prevention so that traditional breakdown maintenance turns into beforehand maintenance, thereby substantially reducing the failure rate.

Owner:王化顺

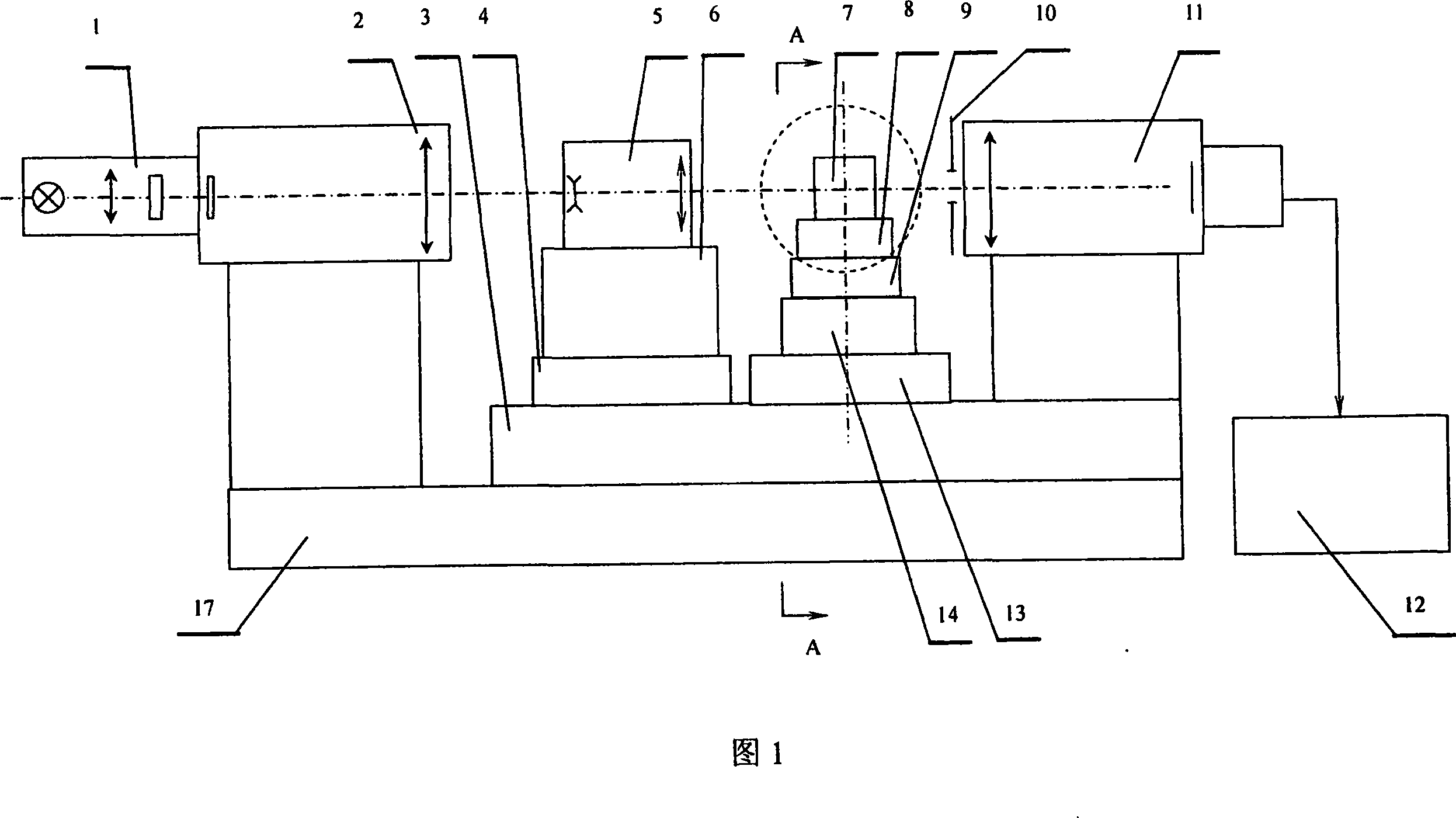

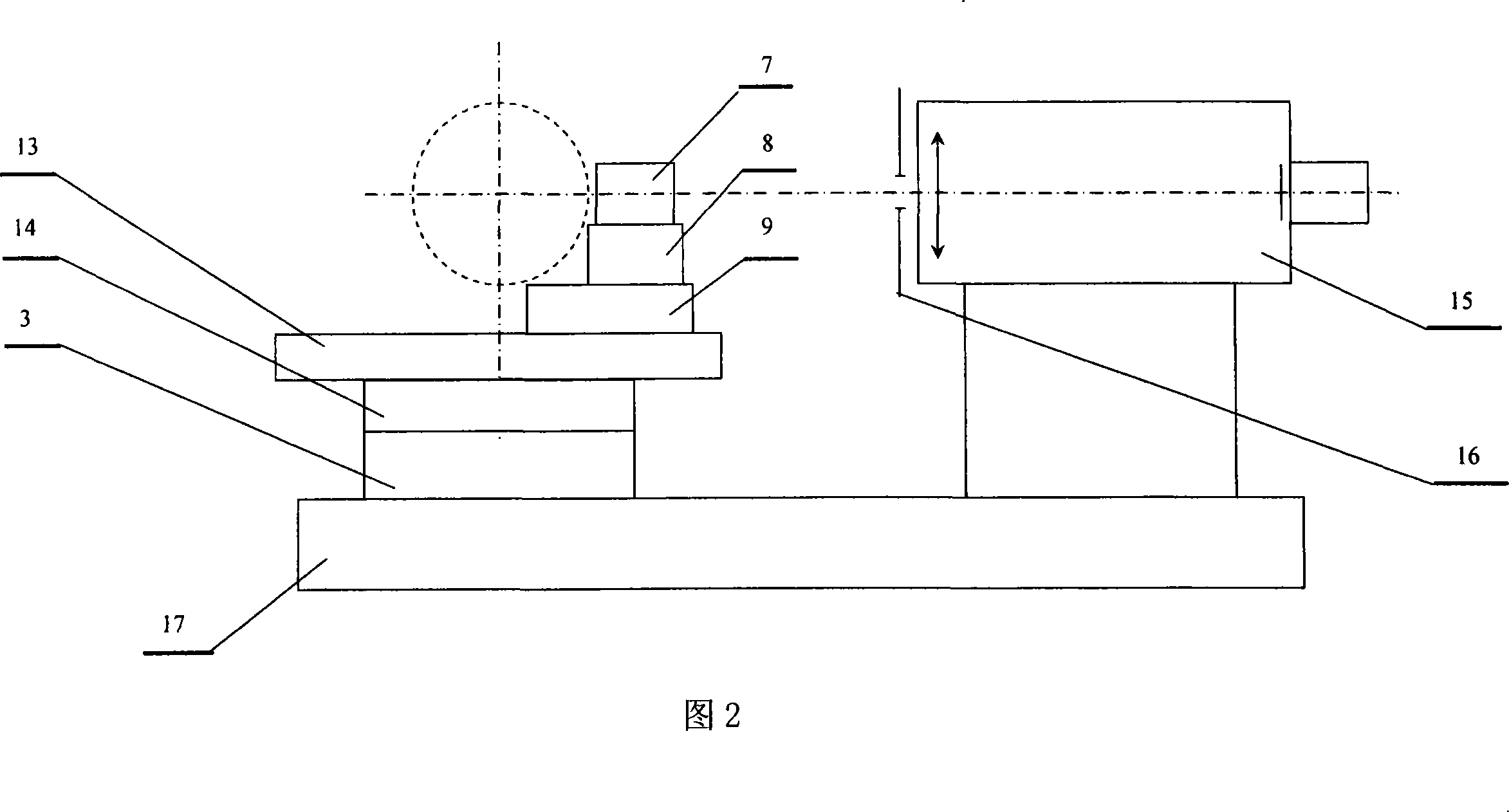

1.064um laser range finder transmitting antenna debugging method and apparatus

InactiveCN101086530AHigh debugging accuracyNarrow beam divergenceOptical rangefindersElectromagnetic wave reradiationLaser rangingEyepiece

The invention relates to an antenna modulating method and equipment for a 1.064 mu m laser distance measurement machine. It aims at the working wave length of the laser distance measurement machine, with parallel light ocular incident coming from the emitting antenna, modulating the focal surface and repetition of the focal surface of the ocular, when the object lens overlaps with the focal surface of the object lens and ocular lens, with beam from the object lens as parallel light.

Owner:中国航空工业第一集团公司第六一三研究所

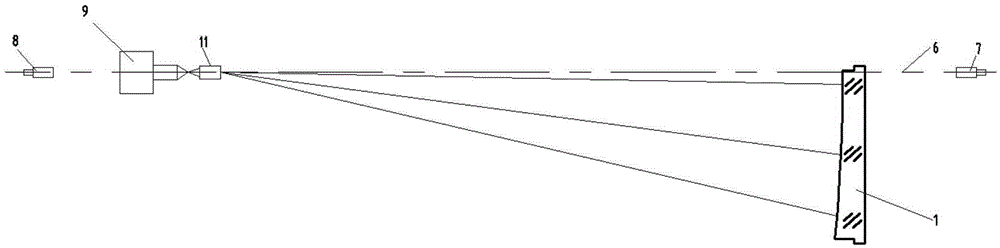

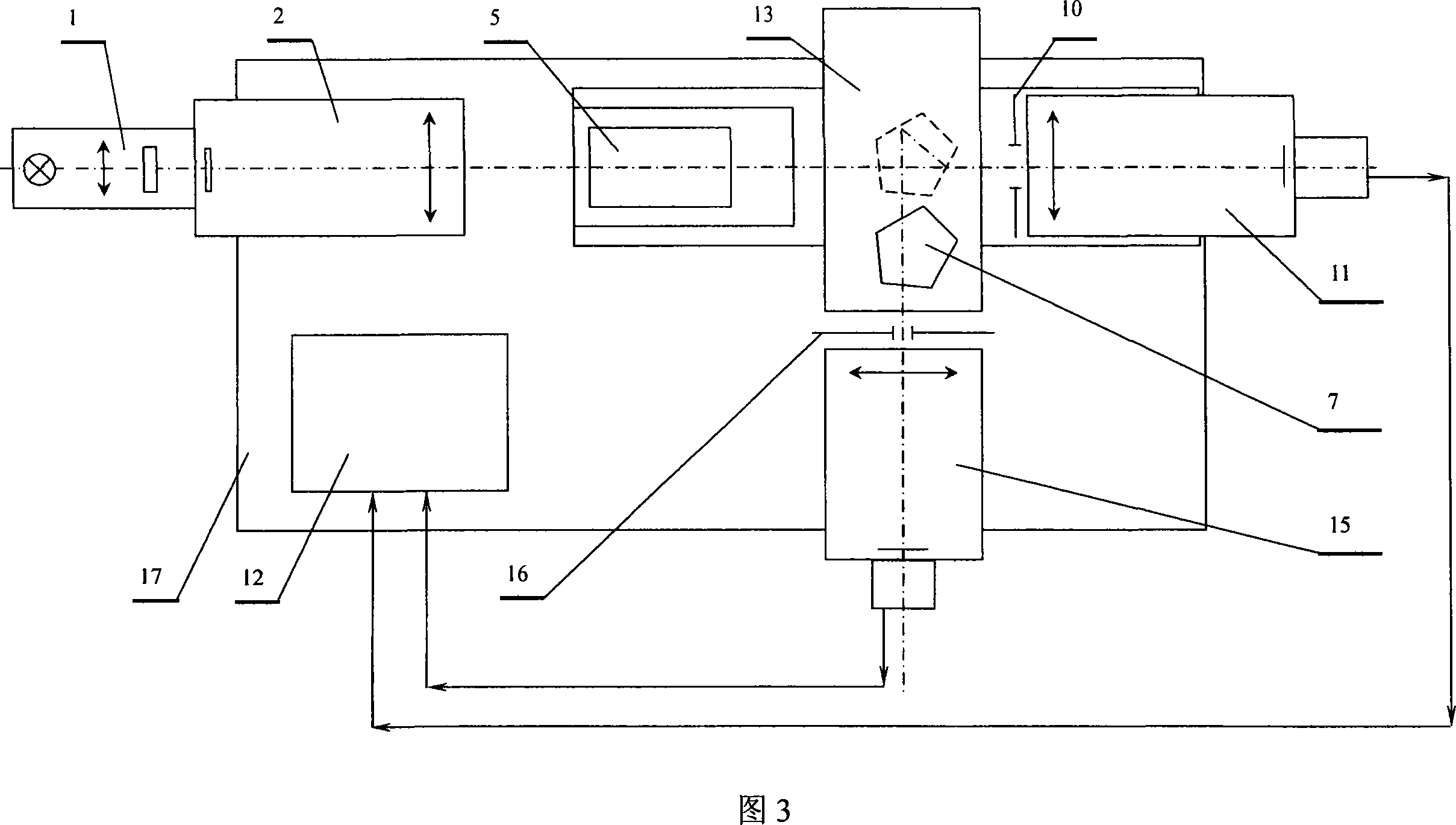

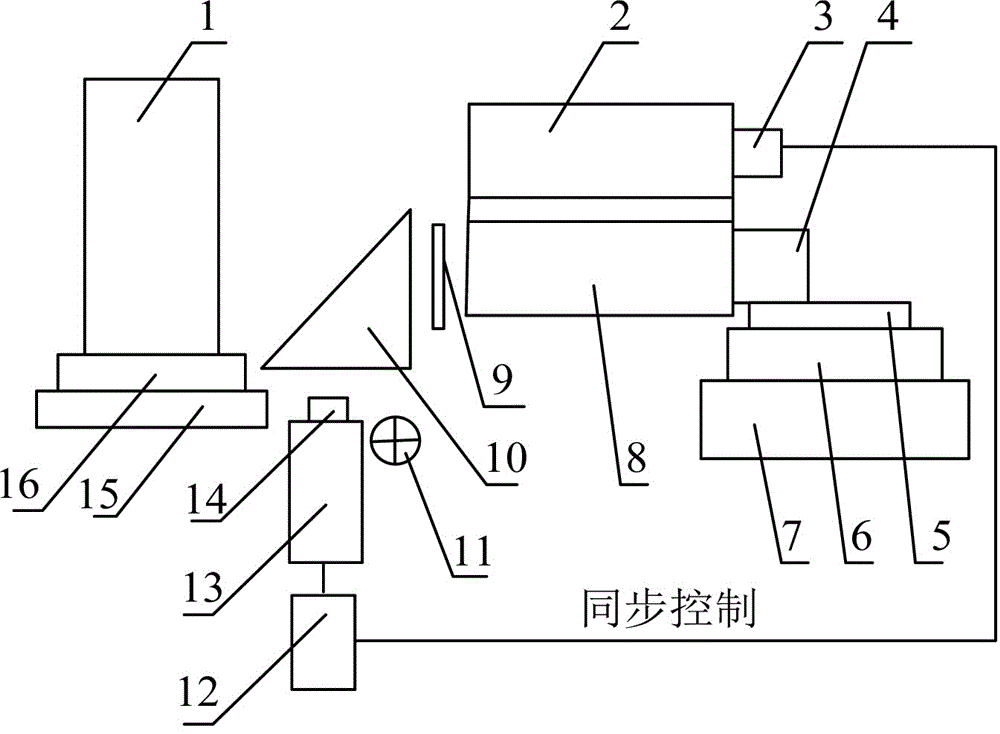

Optical axis debugging system and method of laser range finder

The invention discloses an optical axis debugging system of a laser range finder. The optical axis debugging system comprises a laser, an illumination light source and a CCD camera with a CCD lens, wherein the laser is connected with an emission optical system, and a computer is connected between the CCD camera and the laser. The optical system is connected with the receiving optical system, and the receiving optical system is connected with a detector module, and an attenuating film, a right angle prism and a corner cube prism are arranged in front of the receiving optical system. The invention also discloses a debugging method. The optical axis debugging system can monitor the sharpness of the target surface of the detector assembly in real time, adjust the position of the detector assembly to the optimal position by the adjusting device, and direct the laser spot to the target surface of the detector assembly for optical axis debugging, so that the system is visual and efficient.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

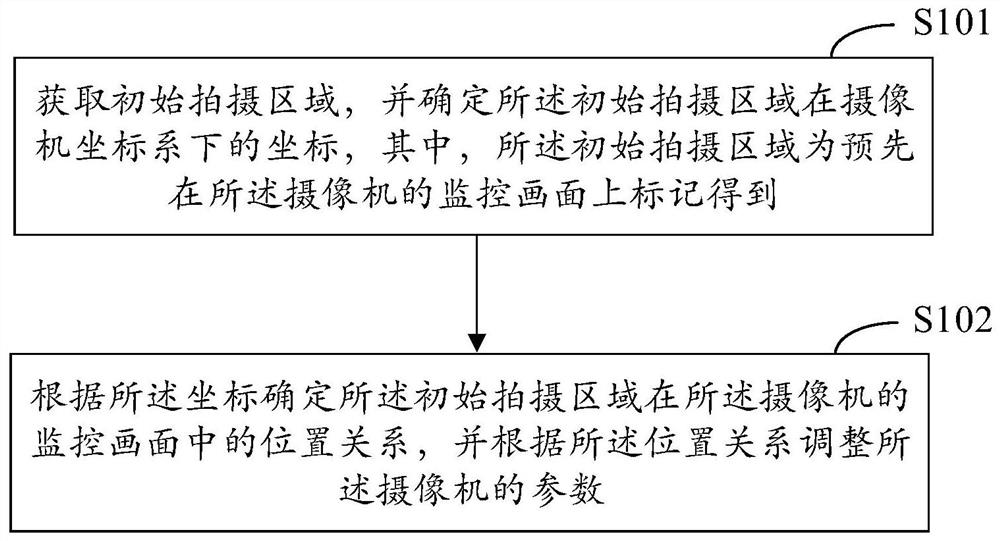

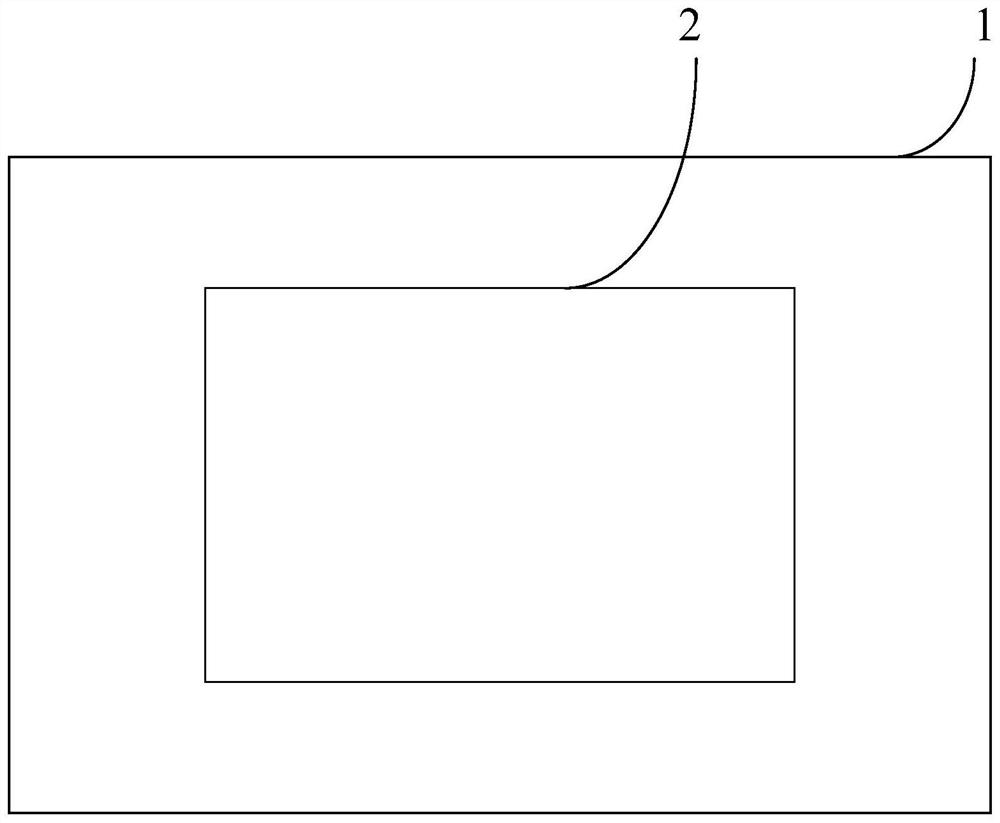

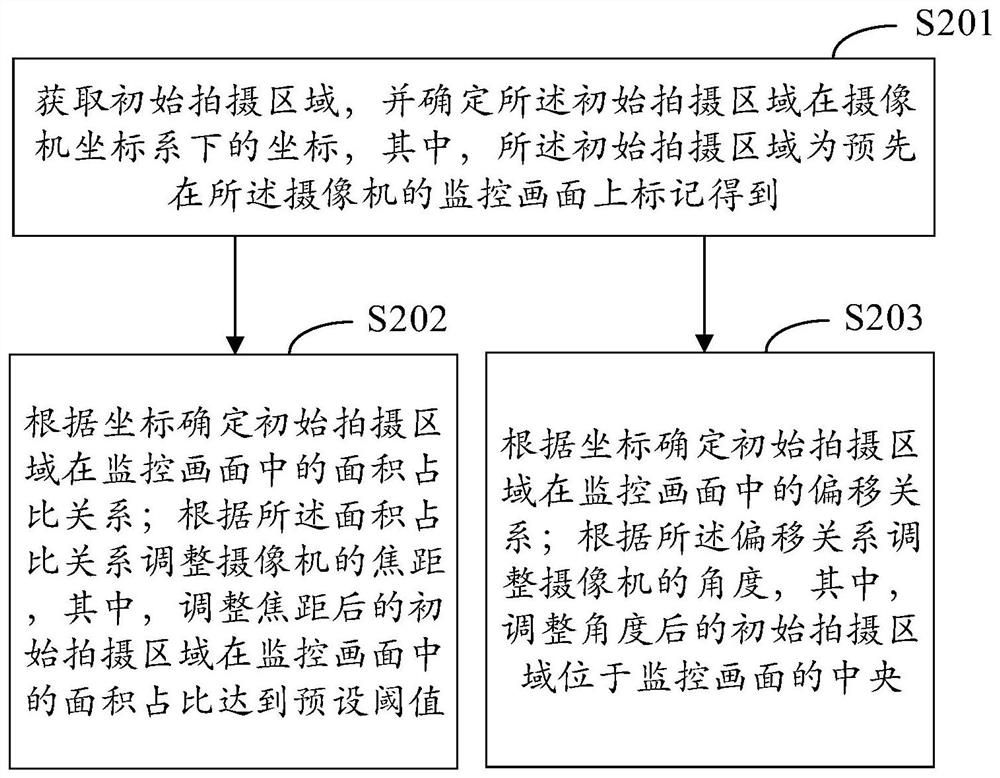

Debugging method and device of intelligent face monitoring camera, camera and medium

ActiveCN111757098AImprove accuracy and efficiencyImprove debugging efficiencyImage enhancementImage analysisEngineeringComputer graphics (images)

The invention discloses a debugging method and a debugging device of an intelligent face monitoring camera, the camera and a medium, and relates to the technical field of camera debugging and image processing. The debugging method is implemented by the specific steps of: acquiring an initial shooting region, and determining coordinates of the initial shooting region in a camera coordinate system,wherein the initial shooting region is obtained by marking a monitoring picture of a camera in advance; and determining a position relationship of the initial shooting region in the monitoring pictureof the camera according to the coordinates, and adjusting parameters of the camera according to the position relationship. By means of the pre-marked initial shooting region, parameter debugging is automatically achieved through the camera, professional technicians do not need to conduct debugging according to experience, and the debugging efficiency and precision are improved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

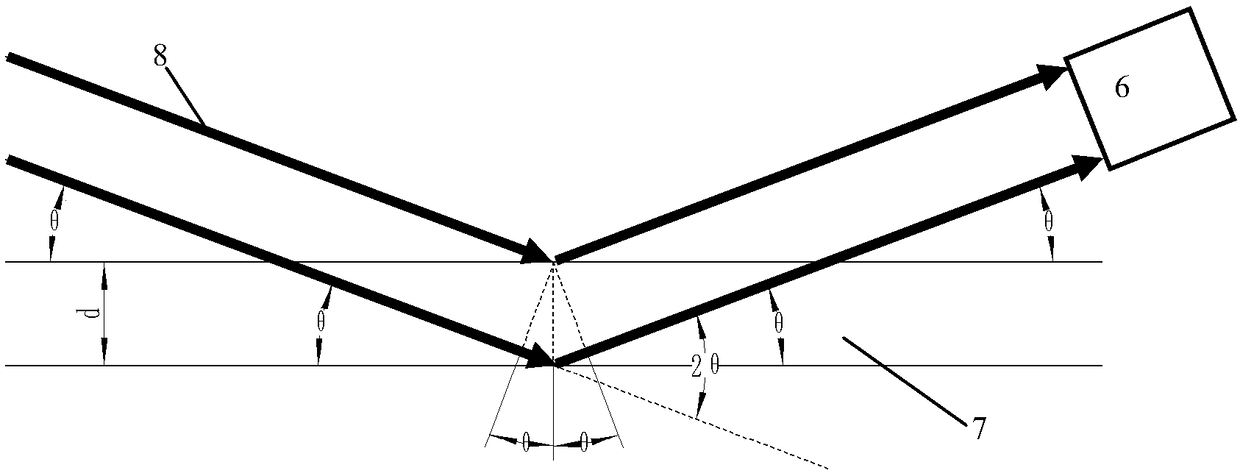

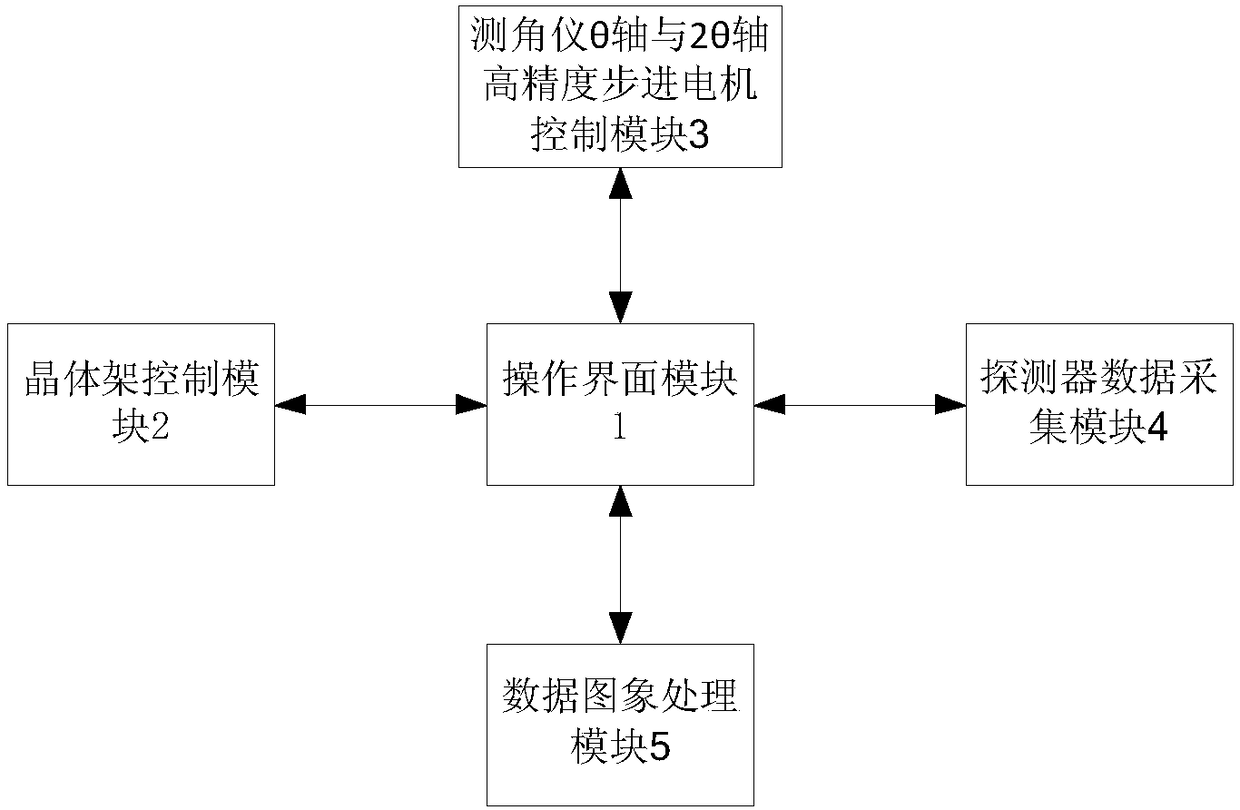

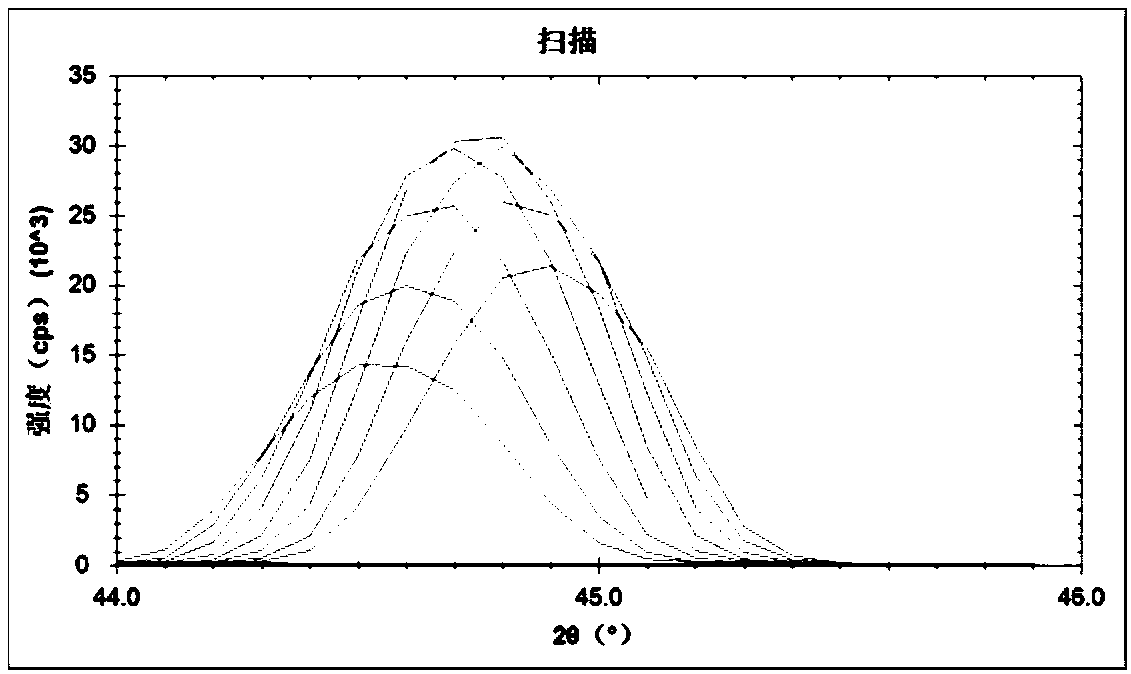

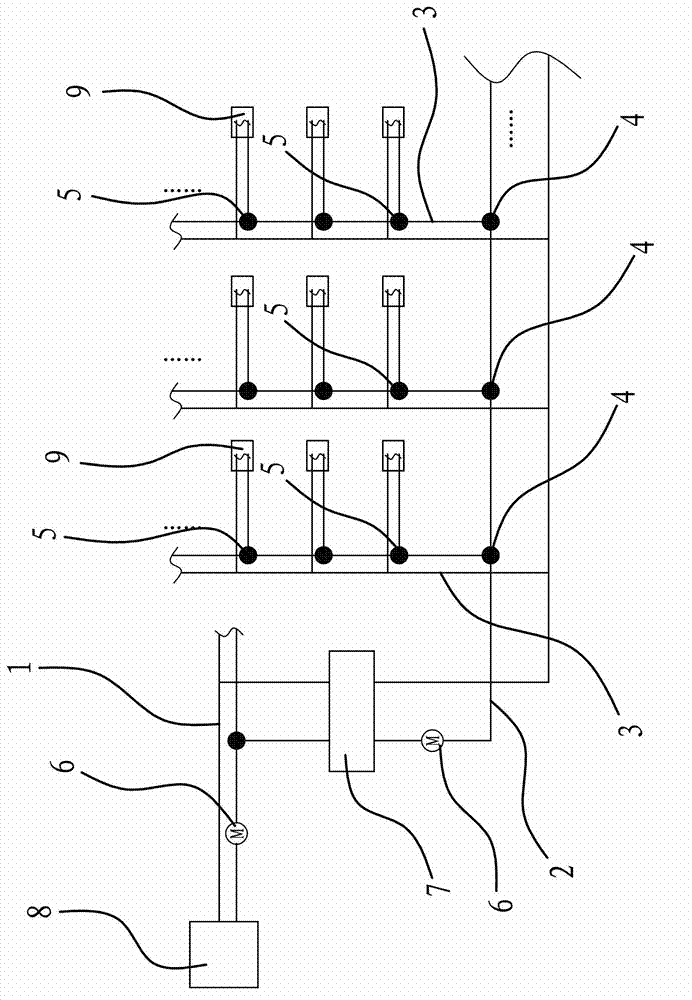

Automatic debugging and correcting system and method of light-splitting path for X-ray fluorescence spectrometer

PendingCN108152313AFor precise fine-tuningIncrease collection intensityMaterial analysis using wave/particle radiationX-rayData acquisition module

The invention relates to an automatic debugging and correcting system and method of the light-splitting path for an X-ray fluorescence spectrometer with sequential wavelength dispersion. The automaticdebugging and correcting system comprises an operation interface module, a crystal-frame control module, a goniometer theta-axis and 2theta-axis high-accuracy stepping motor control module, a detector data acquisition module and a data image processing module. The automatic debugging and correcting system selects the spectral line of a measured element as a reference spectral line of a calibration goniometer, calculating out a crystal glancing angle and a detector emergence angle by a Bragg equation, rotating a theta axis and a 2theta axis of the goniometer to specified positions, realizing automatic adjustment of the positions of crystals and a detector by controlling a stepping motor, the crystal frame and the detector arranged at the theta axis and the 2theta axis and obtaining a crystal correction factor so as to correct the crystal glancing angle and the detector emergence angle. The automatic debugging and correcting system and method have the advantages that remote and automatic debugging for the light splitting path can be realized, debugging persons can be protected from X-ray radiation, the dependency on the debugging experience of the debugging persons can be reduced and the debugging efficiency and accuracy can be improved.

Owner:NCS TESTING TECH

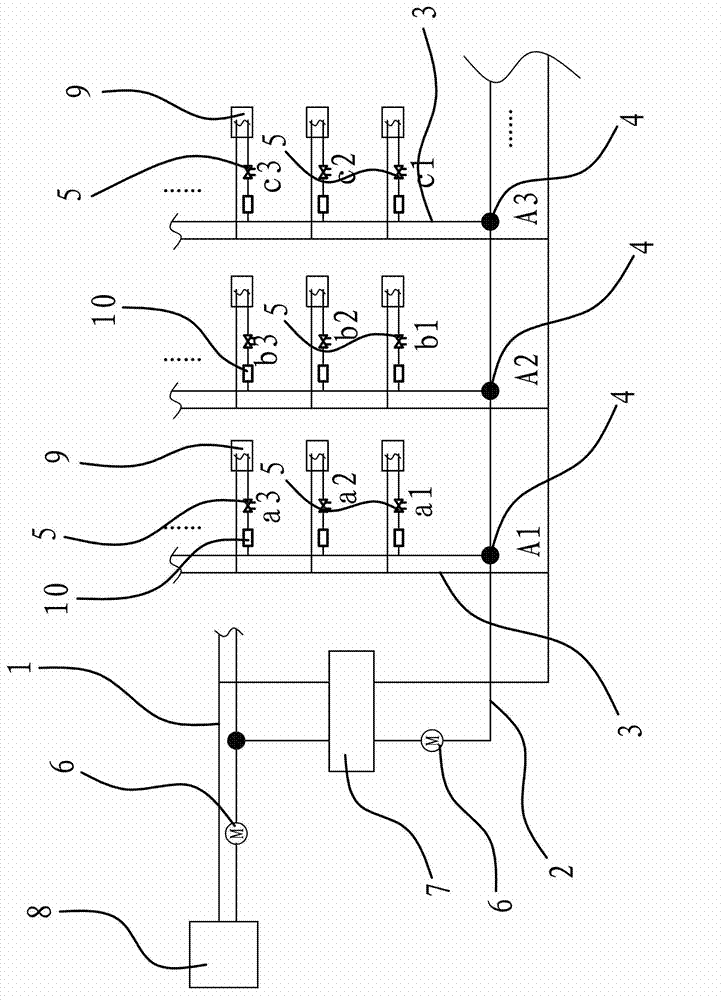

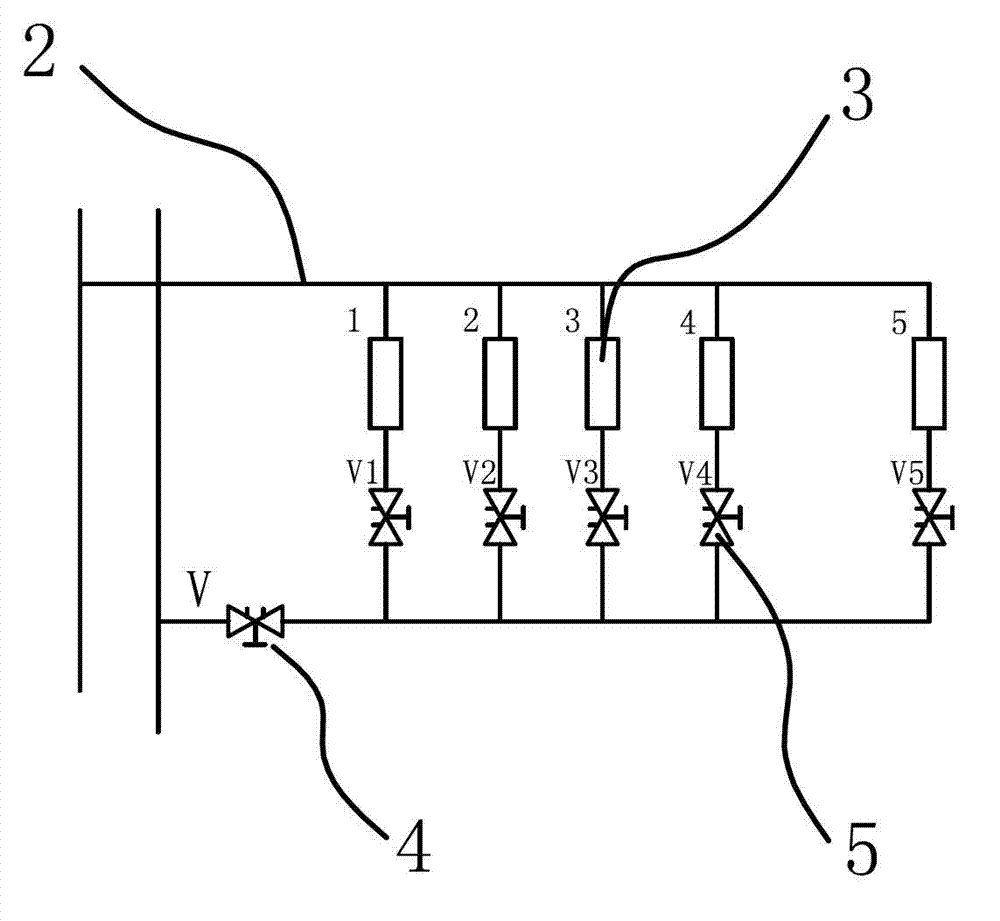

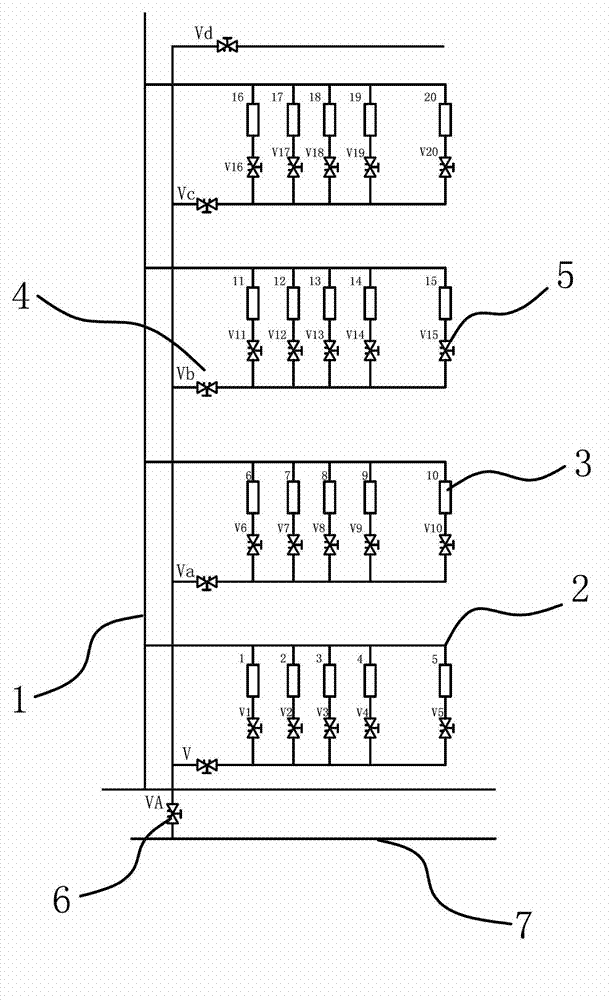

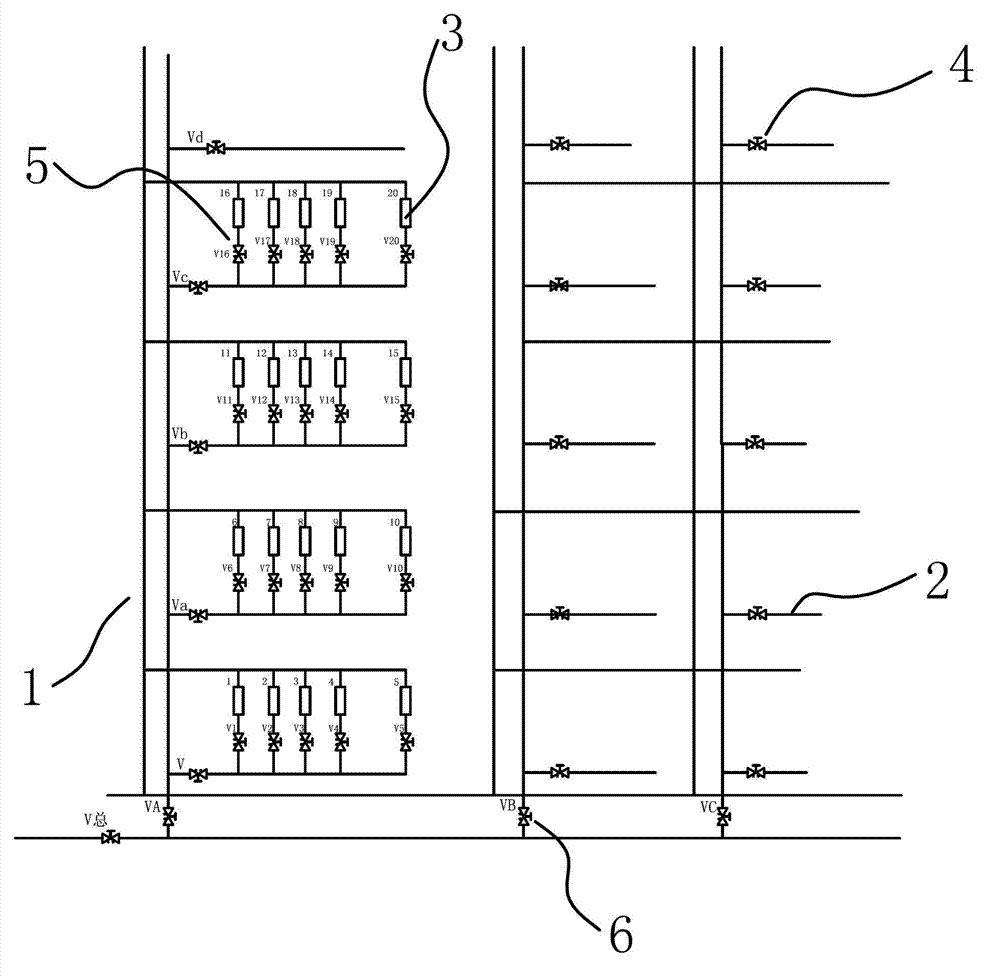

Heating and ventilation system and flow regulation method therefor

InactiveCN103115395ANo wasteImprove heating qualityLighting and heating apparatusSpace heating and ventilation detailsTraffic capacityEngineering

The invention provides a heating and ventilation system and a flow regulation method therefor, belongs to the technical field of heating and ventilation projects and solves the problems that the existing heating and ventilation system is inconvenient to construct, regulate and maintain and the flow regulation method is complex. The heating and ventilation system comprises a primary pipe network, a heat exchanger and a secondary pipe network, wherein the primary network is connected to a heating station to form a circulating loop and the secondary pipe network forms another circulating loop. The secondary pipe network is provided with a plurality of user ends. Each user end is provided with a regulating valve. A bypass network which can form a circulating loop is parallelly connected to the primary pipe network and / or the second pipe network. A plurality of user ends are connected to the bypass networks in parallel. An access end of the bypass network is provided with a control valve. The flow regulation method for the heating and ventilation system includes the steps of A, regulation preparation; B, regulation of the secondary pipe network; C, regulation of the bypass network; and D, precise regulation. The heating and ventilation system and the flow regulation method therefor have the advantages of low cost, high regulation precision and the like.

Owner:卓旦春

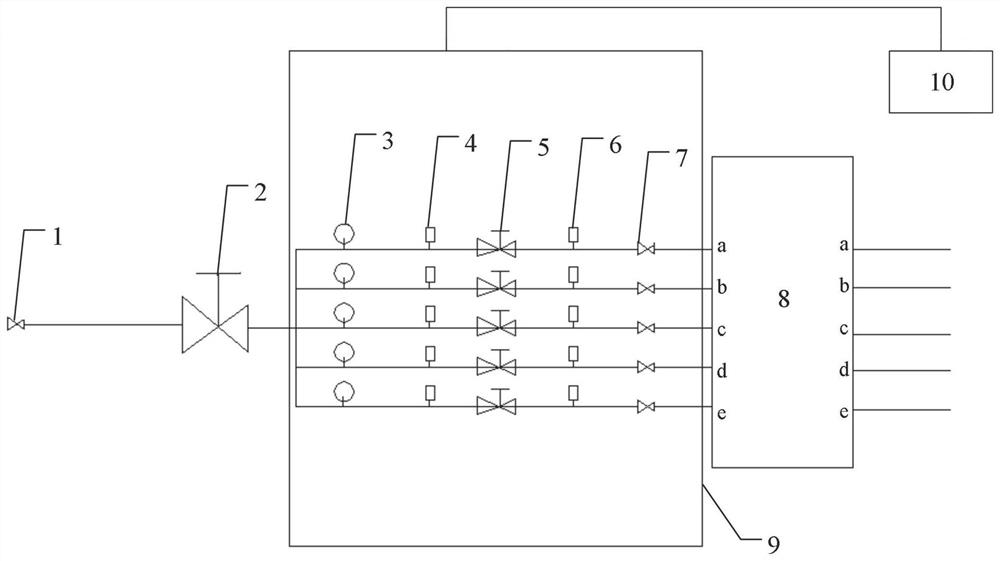

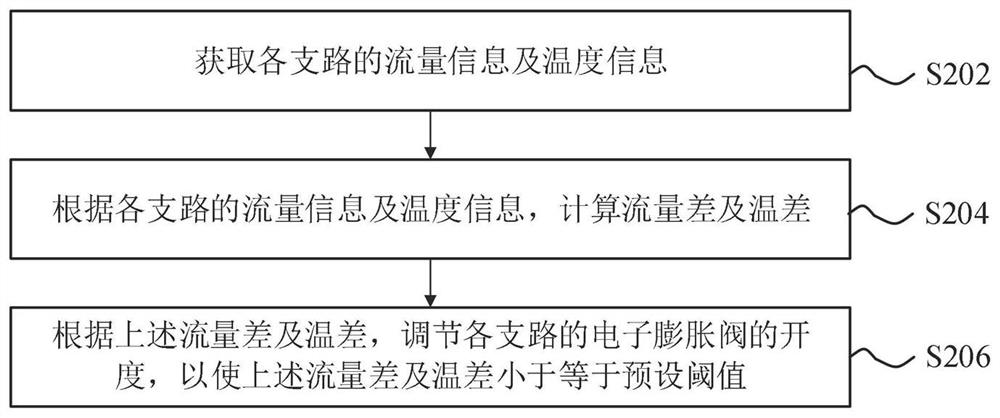

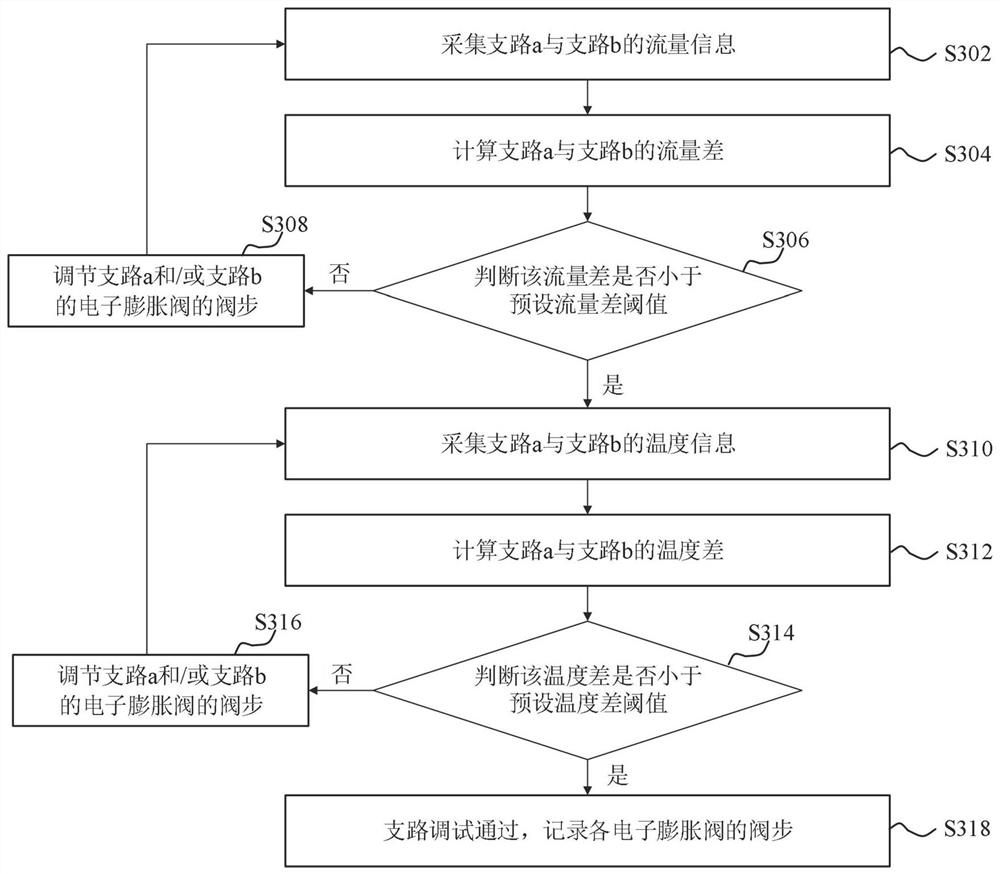

Heat exchanger flow path debugging method, device and equipment

ActiveCN111964232AScientific and precise debuggingReduce human experimental laborMechanical apparatusSpace heating and ventilation safety systemsEngineeringTemperature difference

The invention provides a heat exchanger flow path debugging method, device and equipment. The heat exchanger flow path debugging method comprises the following steps: obtaining the flow information and temperature information of each branch, wherein the temperature information comprises first temperature in front of an electronic expansion valve and second temperature behind the electronic expansion valve; according the flow information and temperature information of each branch, calculating the flow difference and temperature difference, wherein the temperature difference comprises first temperature difference and second temperature difference; the first temperature difference is the difference value between the first temperature and the second temperature of each branch; the second temperature difference is the difference value between the first temperature of two branches or the difference value between the second temperature of two branches; and according to the flow difference andthe temperature difference, adjusting the opening degree of the electronic expansion valve of each branch to enable the flow difference and the temperature difference to be equal to or less than thepreset threshold values. According to the heat exchanger flow path debugging method, flow path optimization is more systematic, manpower experimental labor can be reduced at the same time, and flow path debugging is more scientific and preciser.

Owner:NINGBO AUX ELECTRIC +1

Human-computer interactive debugging method of EC (Electronic Computer) by inputting character string command based on UART (Universal Asynchronous Receiver/Transmitter) terminal

InactiveCN101859277AImprove debugging efficiency and accuracyLow costSoftware testing/debuggingSystem developmentInteractive debugging

The invention discloses a human-computer interactive debugging method of an EC (Electronic Computer) by inputting a character string command based on a UART (Universal Asynchronous Receiver / Transmitter) terminal, which comprises the following steps of: firstly, adding and analyzing a character string of specified format, received from a serial terminal, to an EC firmware to obtain a related command and parameters, and executing codes of the command; then, realizing interactive debugging with EC by using the character string receiving and sending functions of a serial terminal tool in an operating system of HOST. The method can be used for carrying out human-computer interactive debugging on the development of EC and other embedded systems provided with the UART interface, and can perform reading and writing debugging by using a command to instantly obtain required feedback results; the operating state of each module of the firmware can be visually observed, the problem that the traditional debugging method using a bright LED lamp is not visualized and not convenient is completely solved, the debugging efficiency and accuracy are greatly increased, and meanwhile, the method has low realization cost, great flexibility and high efficiency.

Owner:JIANGSU LEMOTE TECH CORP

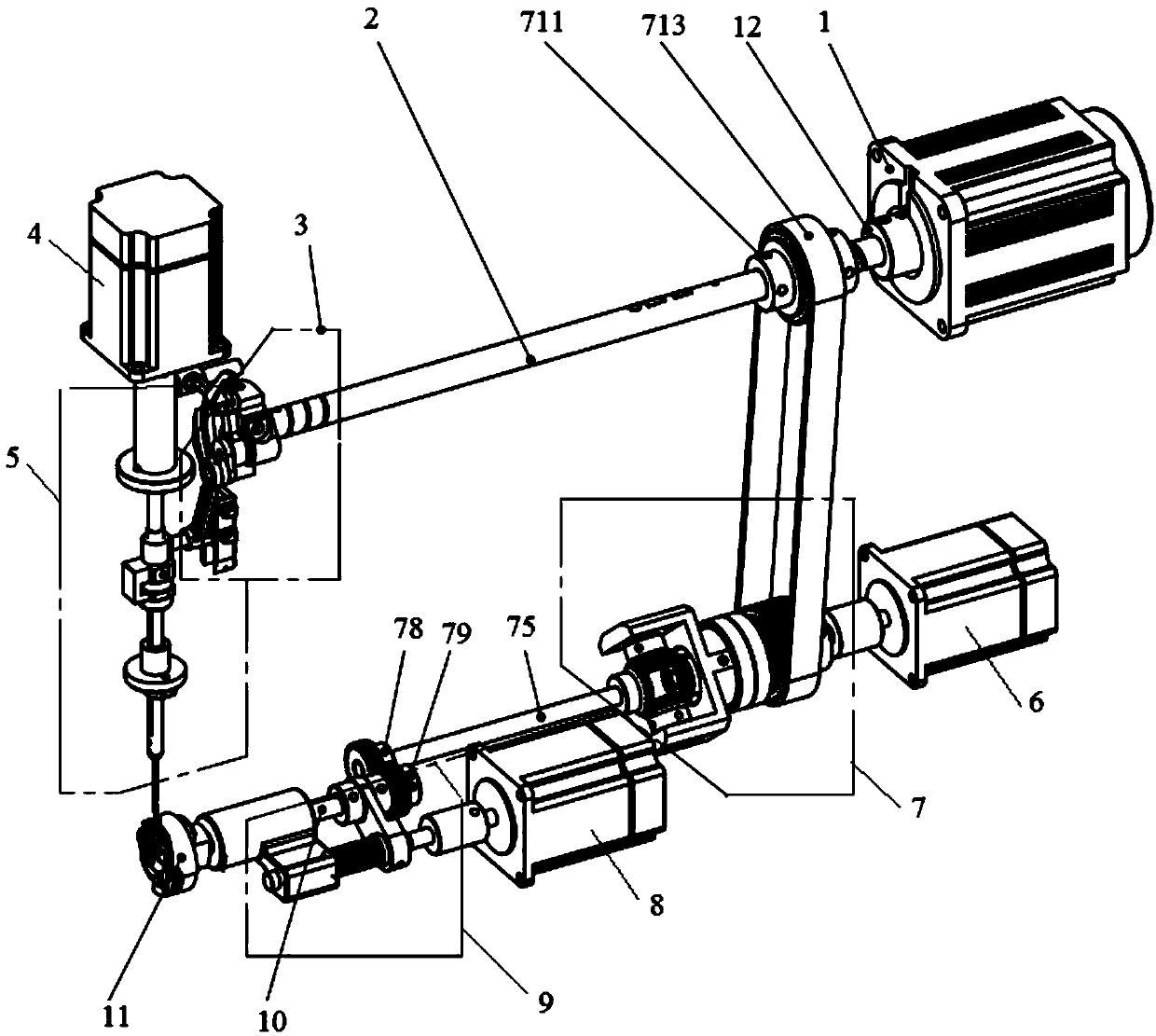

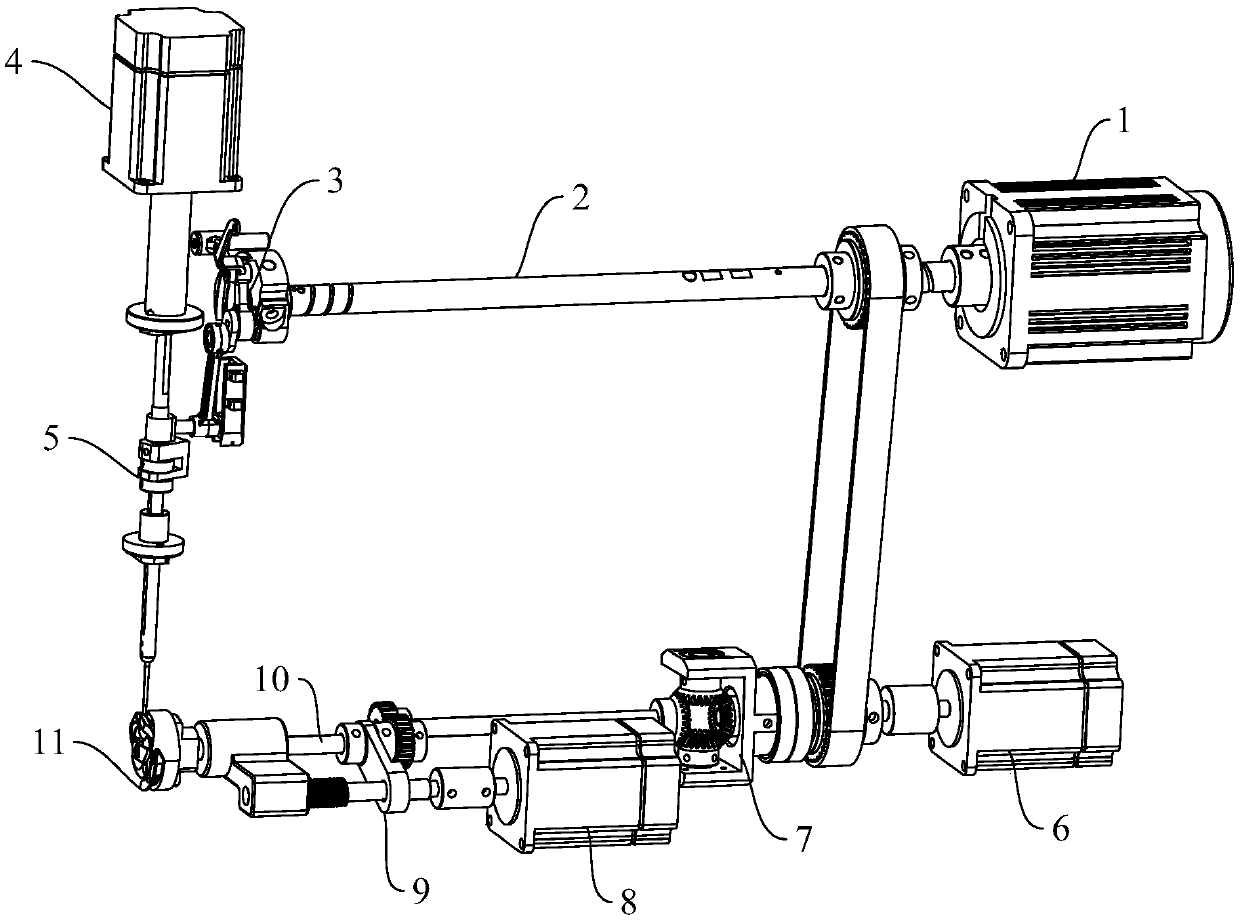

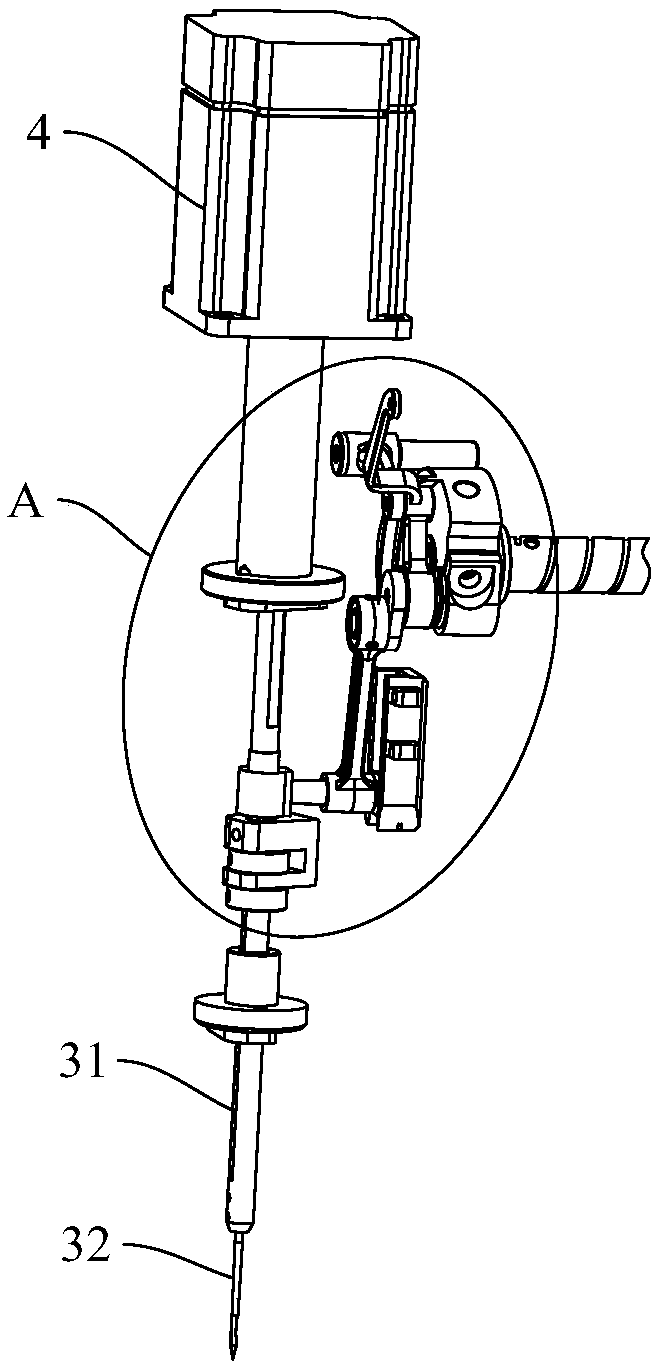

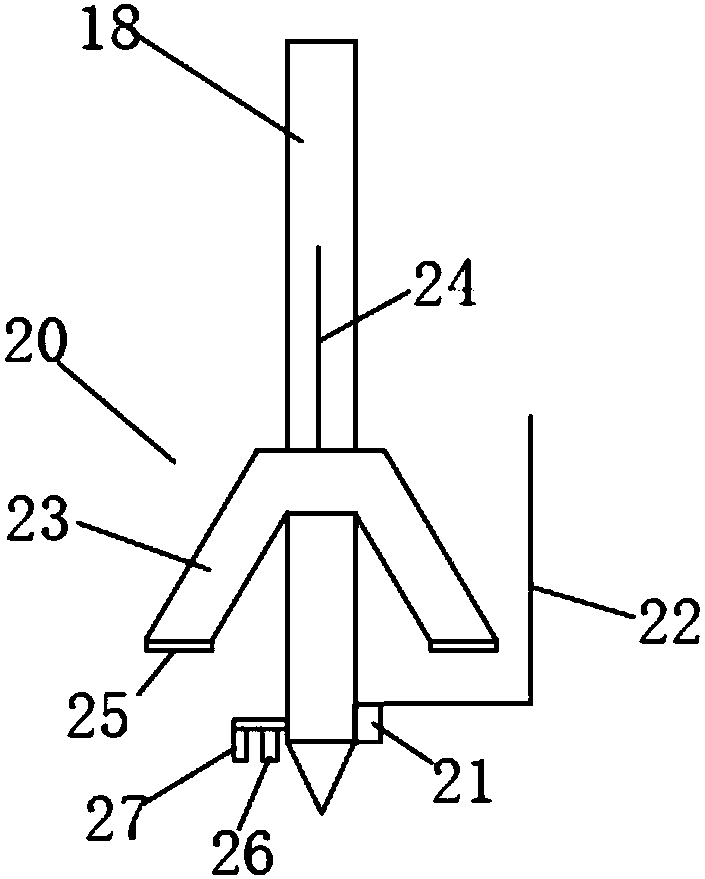

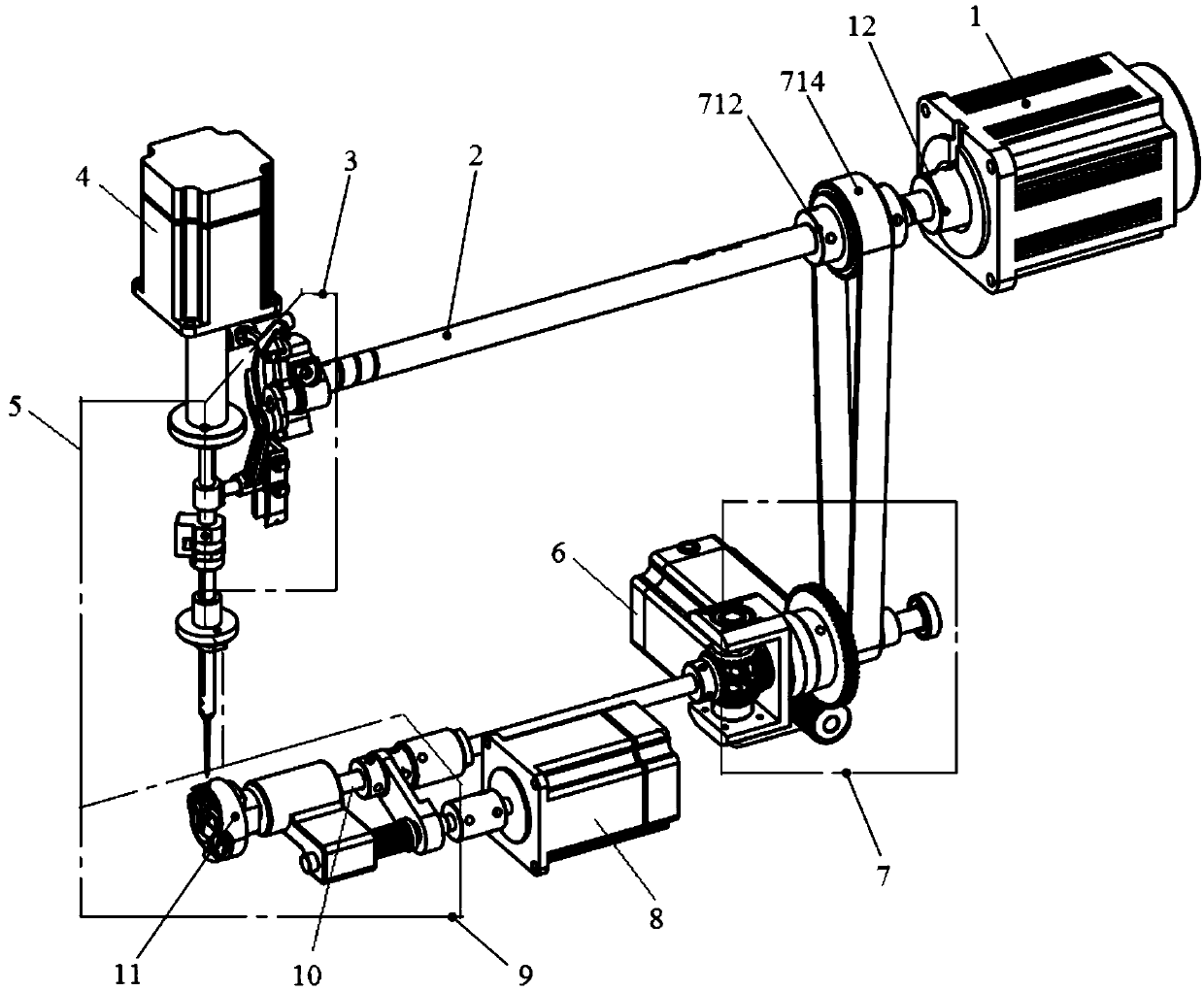

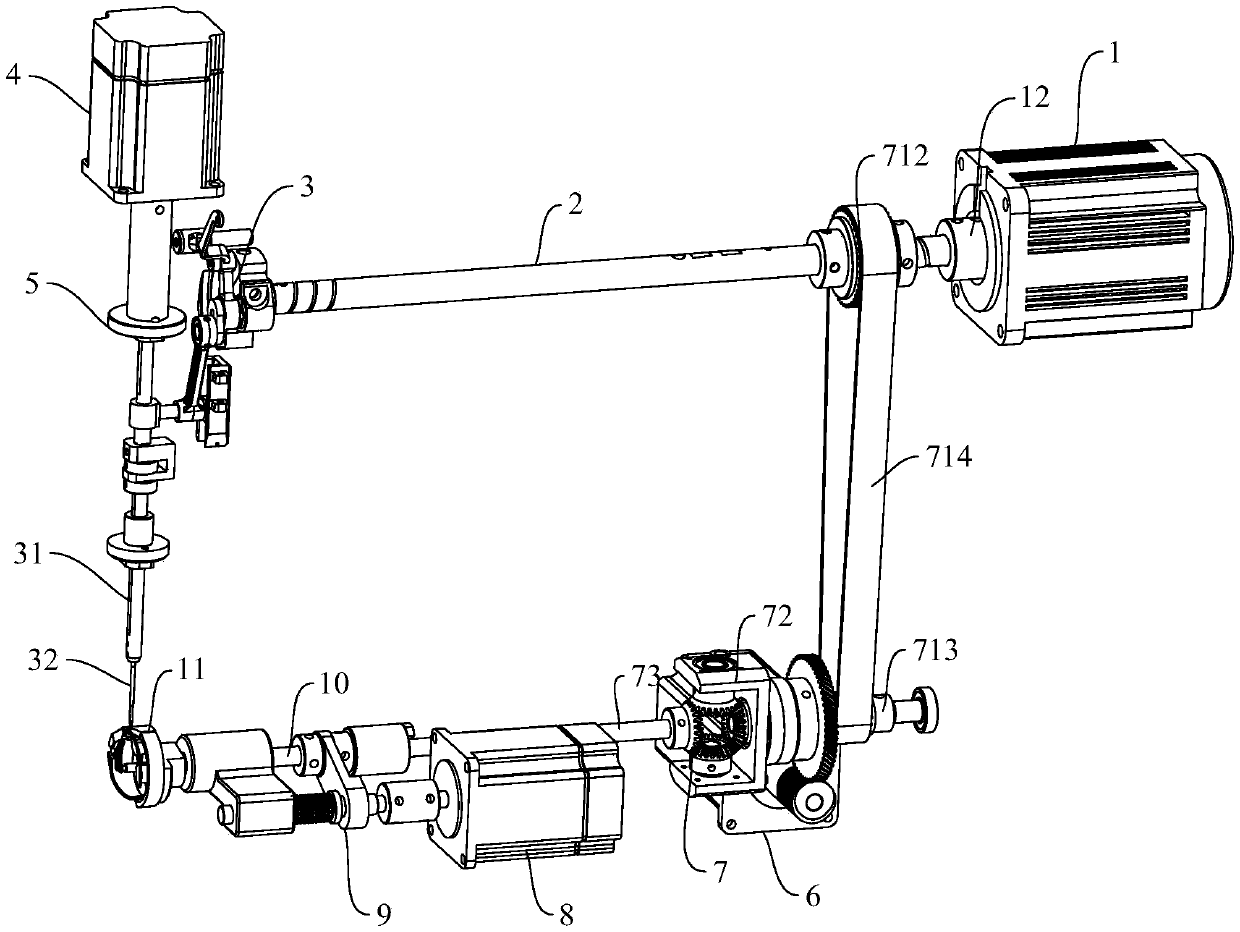

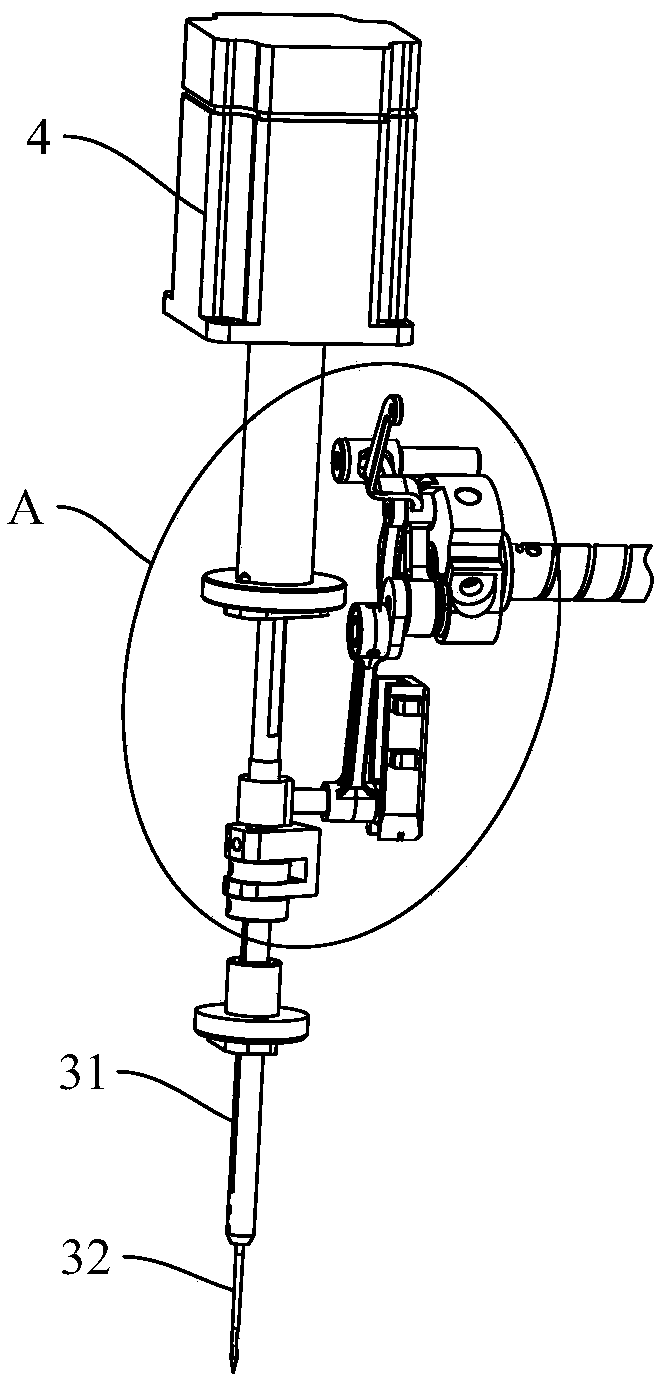

Needle and shuttle cooperation automatic adjustment mechanism and sewing machine

ActiveCN111118758ARealize automatic adjustmentImprove debugging efficiencyTake-up devicesNeedle barsElectric machineryControl theory

The present invention provides a needle and shuttle cooperation automatic adjustment mechanism. The needle and shuttle cooperation automatic adjustment mechanism comprises a main motor, an upper shaft, a needle driving and thread take-up assembly with a needle rod and a frame needle, a lower shaft, a rotating shuttle, a needle rod height adjustment driving source, a rotating shuttle angle adjustment driving source, a rotating shuttle position adjustment driving source, a needle rod height adjustment mechanism connected between the needle rod height adjustment driving source and the needle rod,a rotating shuttle angle adjustment mechanism connected between the rotating shuttle angle adjustment driving source and the lower shaft, and a rotating shuttle position adjustment mechanism connected between the rotating shuttle position adjustment driving source and the lower shaft, wherein the needle rod height adjustment driving source drives the needle rod to move in the vertical direction through the needle rod height adjusting mechanism; the rotating shuttle angle adjustment driving source drives the lower shaft to rotate around the self axis through the rotating shuttle angle adjusting mechanism; and the rotating shuttle position adjustment driving source drives the lower shaft to move in the self axial direction through the rotating shuttle position adjusting mechanism. The height of the needle rod, the angle of the rotating shuttle and the left-right position of the rotating shuttle can be automatically adjusted, so that the debugging efficiency and the debugging accuracy ofneedle and shuttle cooperation are improved.

Owner:BULLMER ELECTROMECHANICAL TECH

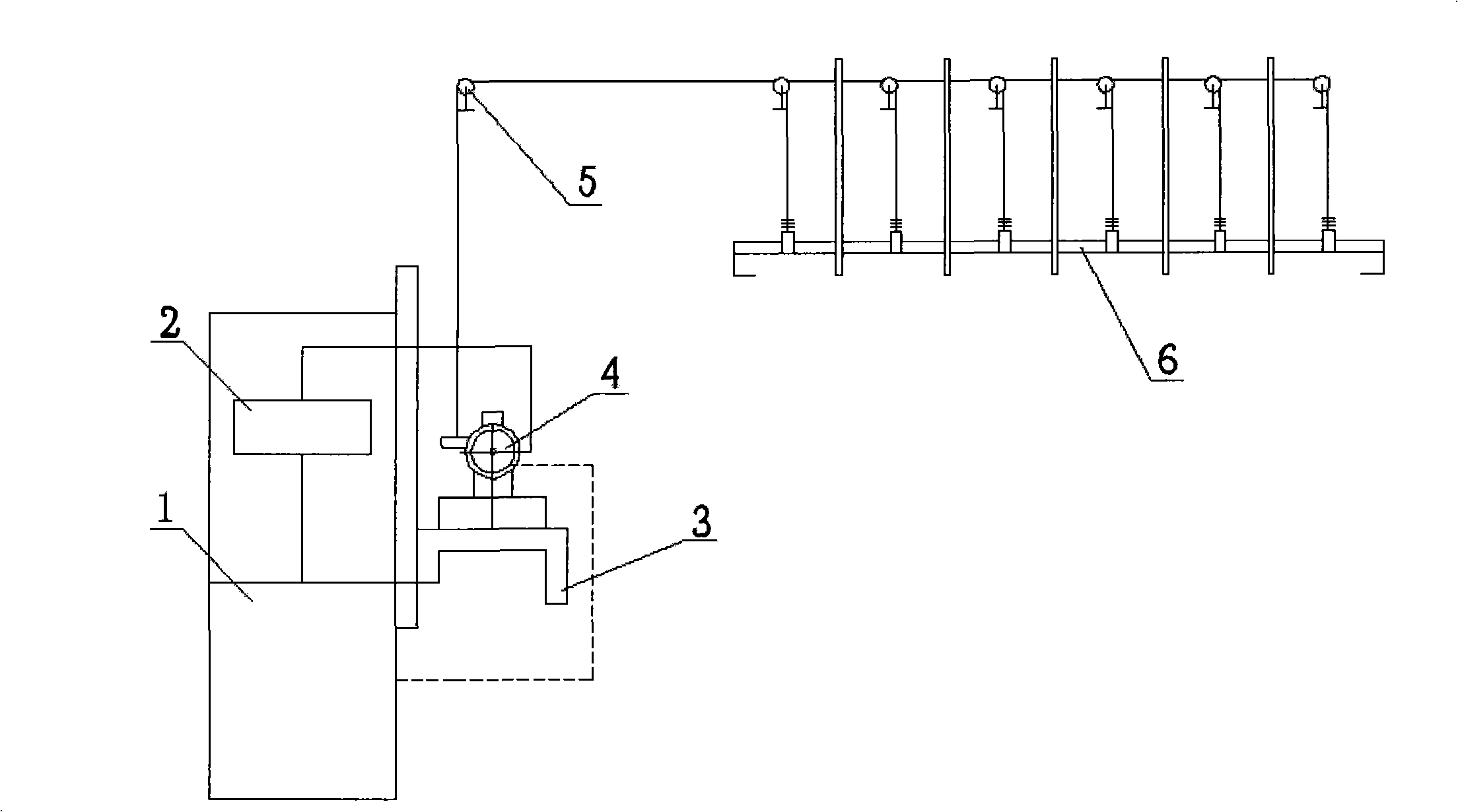

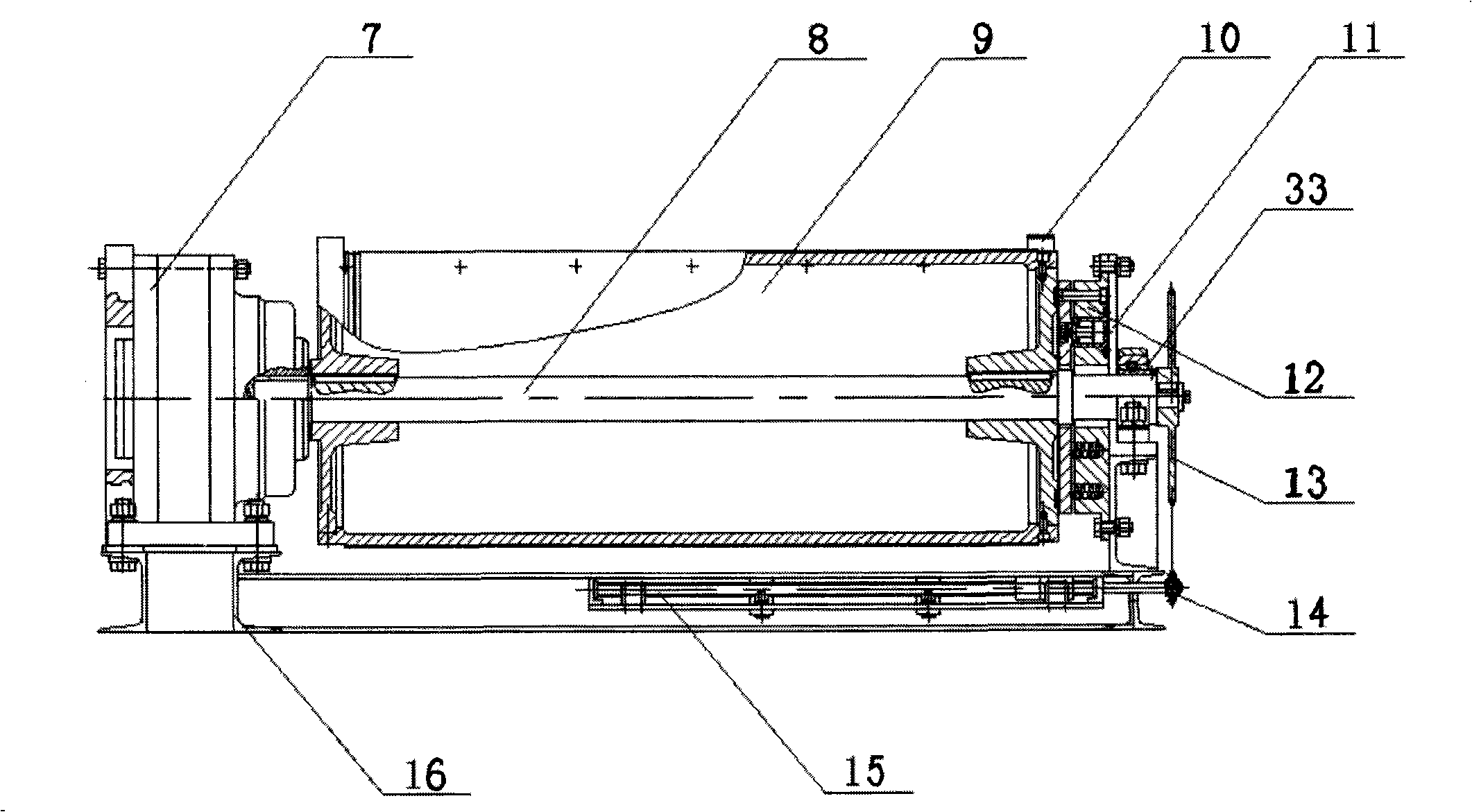

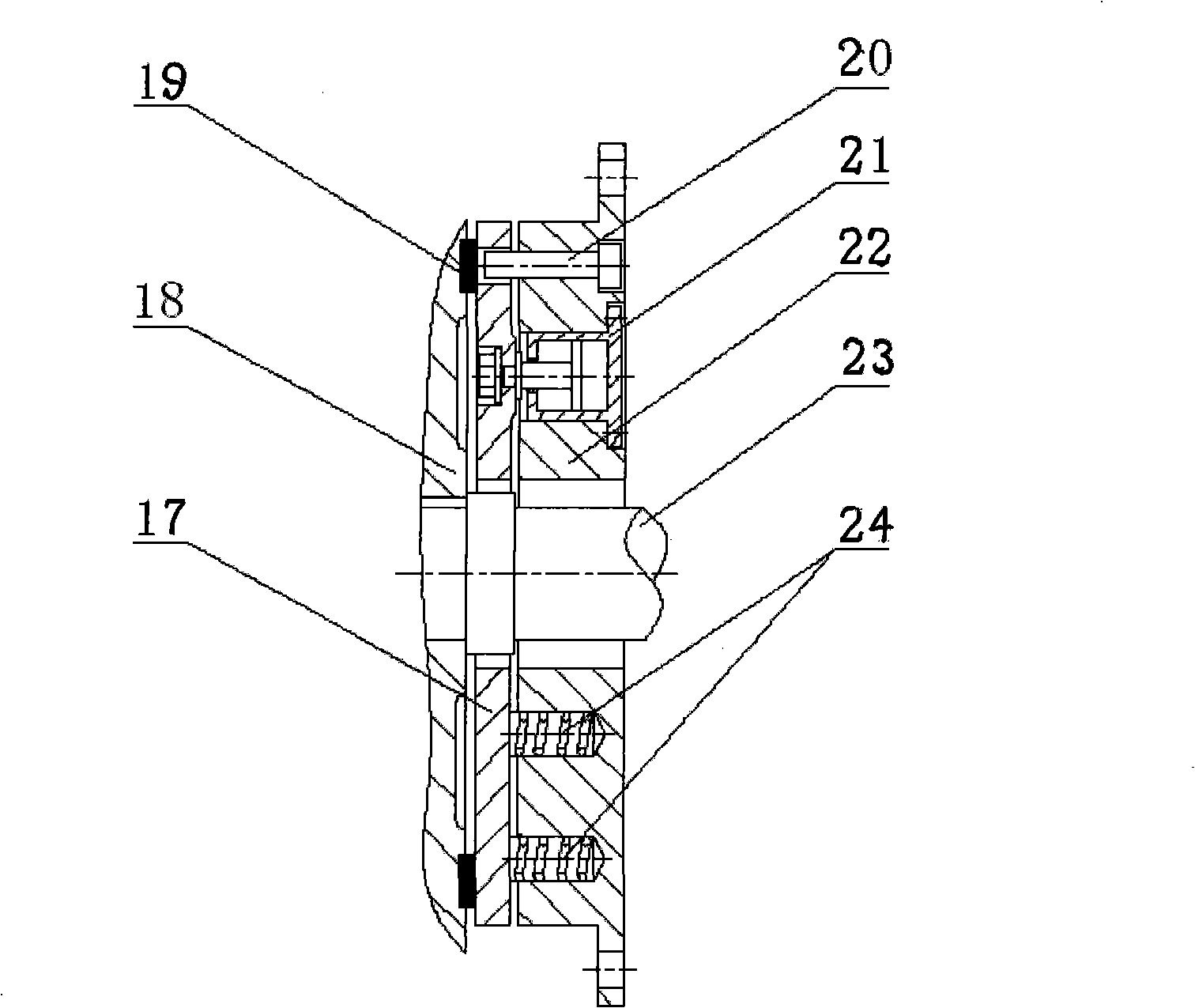

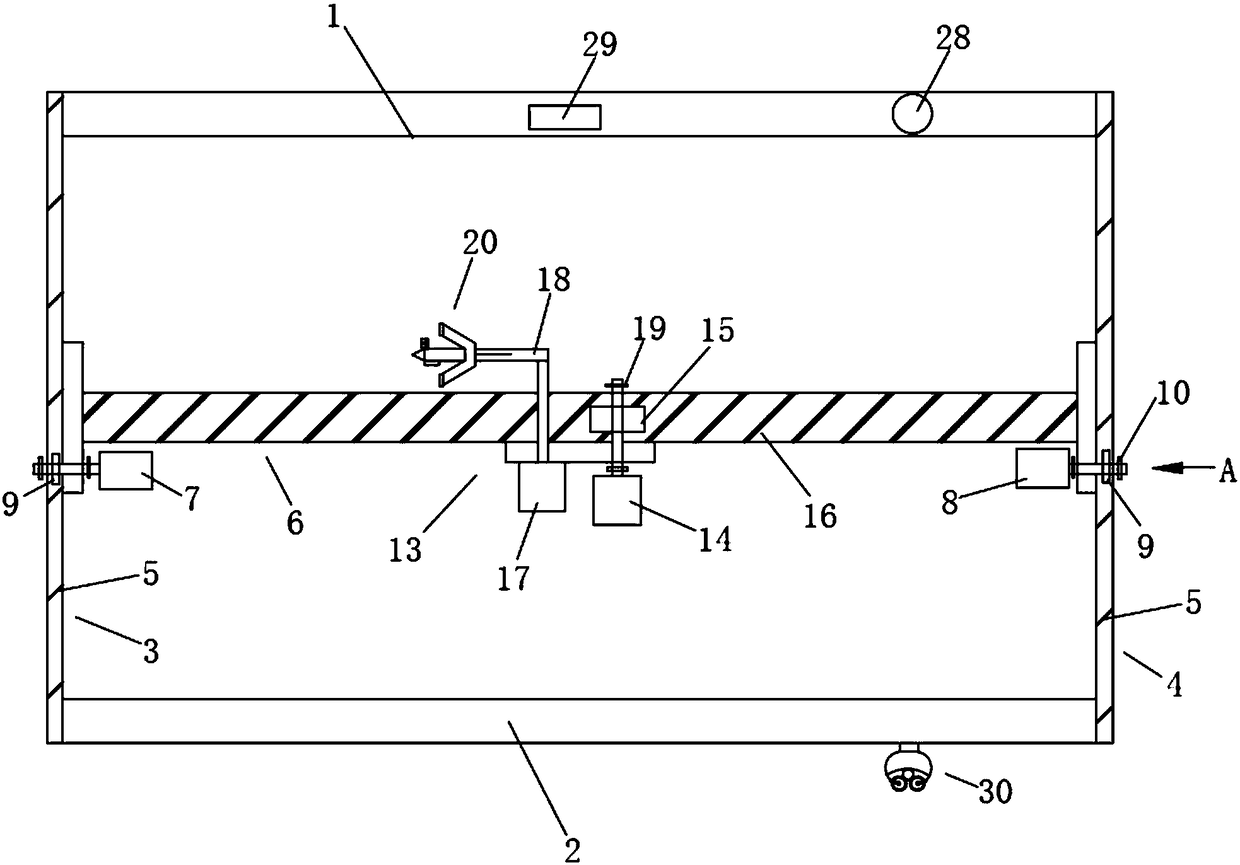

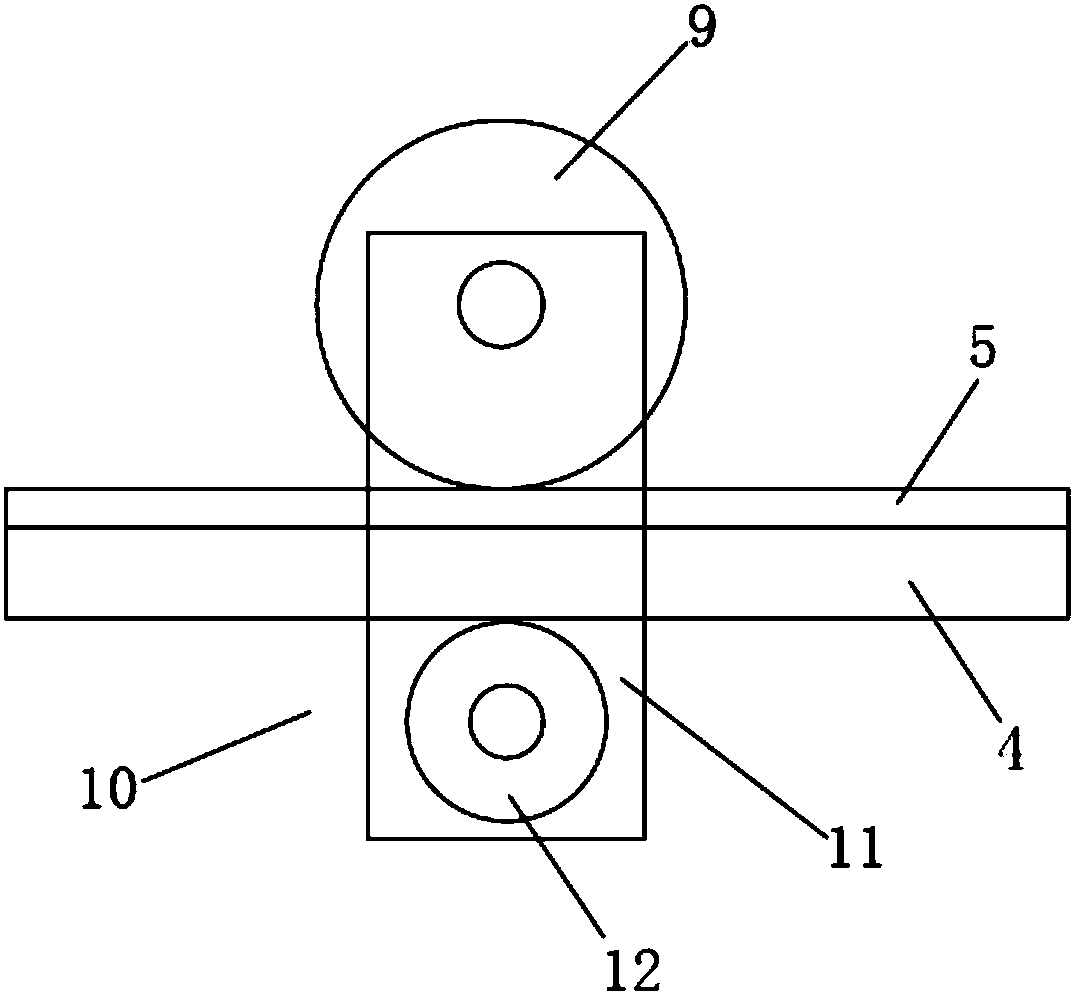

Hydraulically driven and controlled stage hanger rod system

InactiveCN101254889AInput signal power is smallReduce dead zonePortable liftingRoundaboutsHydraulic motorControl system

A hydraulically driven and controlled stage suspender system comprises a pulley system (5); a suspender (6); and a driver (4) disposed on an overbridge (3), wherein a pump station (1) and a control system (2) connected with the driver (4) are disposed on the overbridge (3); the driver (4) comprises a pedestal (16); a hydraulic motor (7) is disposed on the pedestal (16); one end of a transmission shaft (8) is connected with the dynamic output terminal of the hydraulic motor (7); a roll (9) is disposed on the transmission shaft (8); a position retainer (10) is disposed on the roll (9); the other end of the transmission shaft (8) is disposed on a support (11) on the end of pedestal (16) through an insert bearing with housing (33); a hydraulic brake (12) is disposed at a position on the support (11) corresponding to the end surface of the roll; and a proportional lead screw (15) is disposed on the pedestal (16). The stage suspender system has the advantages of convenient control, reliability and high efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

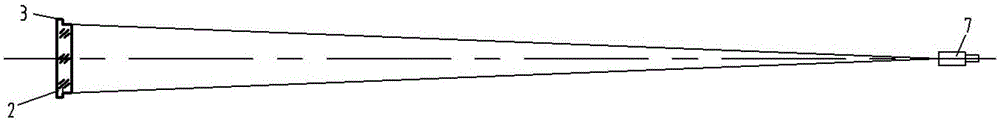

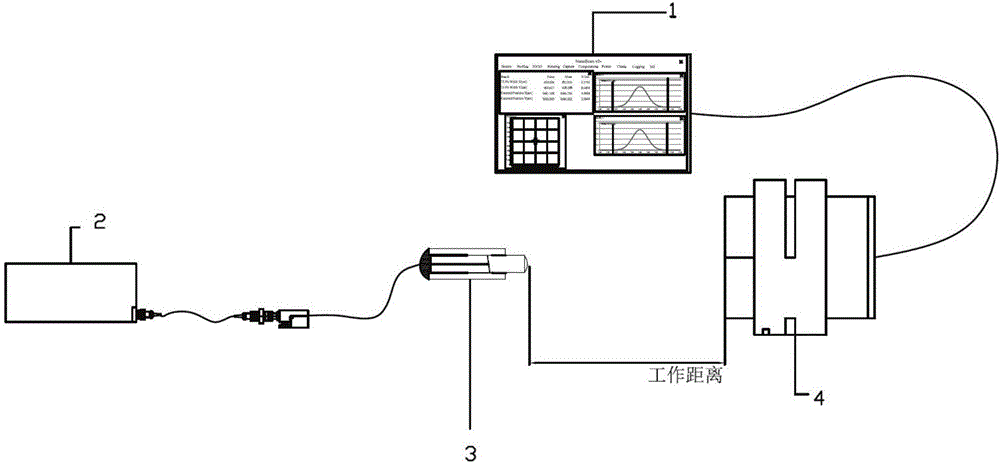

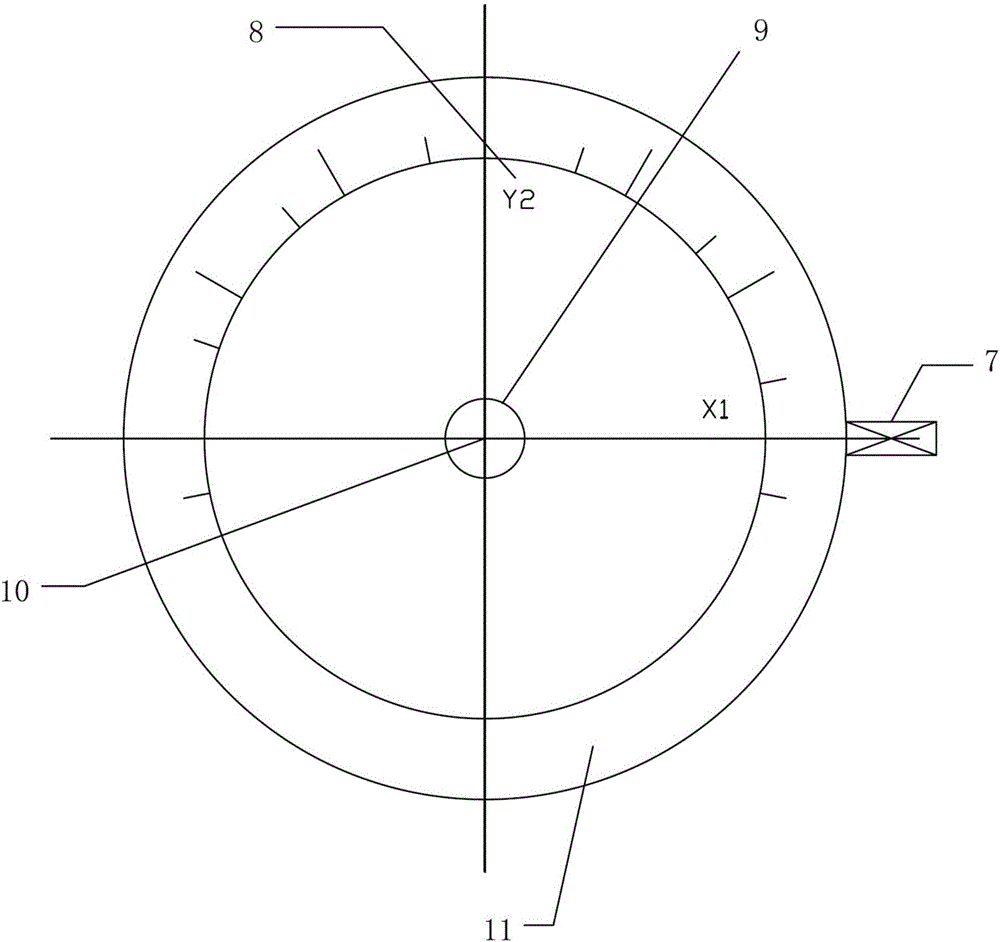

Light spot machine debugging system and light spot machine debugging method for medium/long-working-distance single-mode single-fiber collimators

ActiveCN106500964ALow insertion lossHigh pairwise compatibilityTesting fibre optics/optical waveguide devicesLight spotFirst pass yield

The invention relates to a light spot machine debugging system and a light spot machine debugging method for medium / long-working-distance single-mode single-fiber collimators. The system comprises a laser point light source, a light spot machine, a medium / long-working-distance single-mode single-fiber collimator, a five-dimensional adjusting frame, and a sliding table. The laser point light source is connected with the medium / long-working-distance single-mode single-fiber collimator. The light spot machine is connected with a computer. The medium / long-working-distance single-mode single-fiber collimator is arranged on the five-dimensional adjusting frame. The light spot machine is arranged on the sliding table. By using the light spot machine debugging system and the light spot machine debugging method for medium / long-working-distance single-mode single-fiber collimators, the light path debugging difficulty is reduced, the debugging precision is improved, the medium / long-working-distance single-mode single-fiber collimator has smaller insertion loss and higher degree of pairing, and the consistency and first-pass yield of products are higher, the debugging time is reduced, and the work efficiency of employees is improved. The system and the method are also applicable to medium / long-working-distance single-mode single-fiber collimators of which the medium / long working distance is at specific bands, such as 850nm and 1060nm.

Owner:上海中科光纤通讯器件有限公司 +2

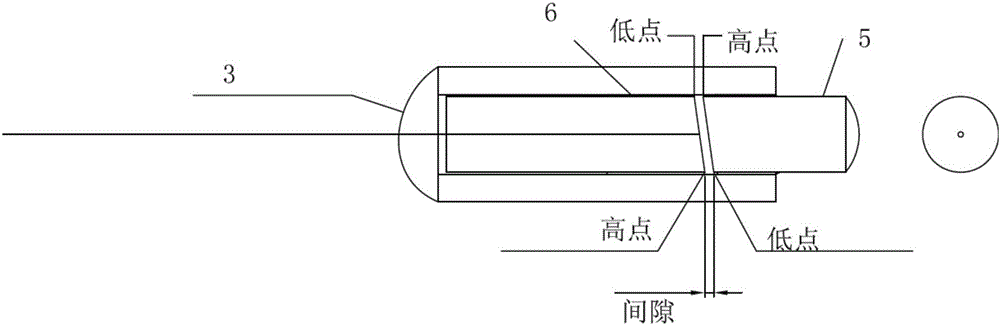

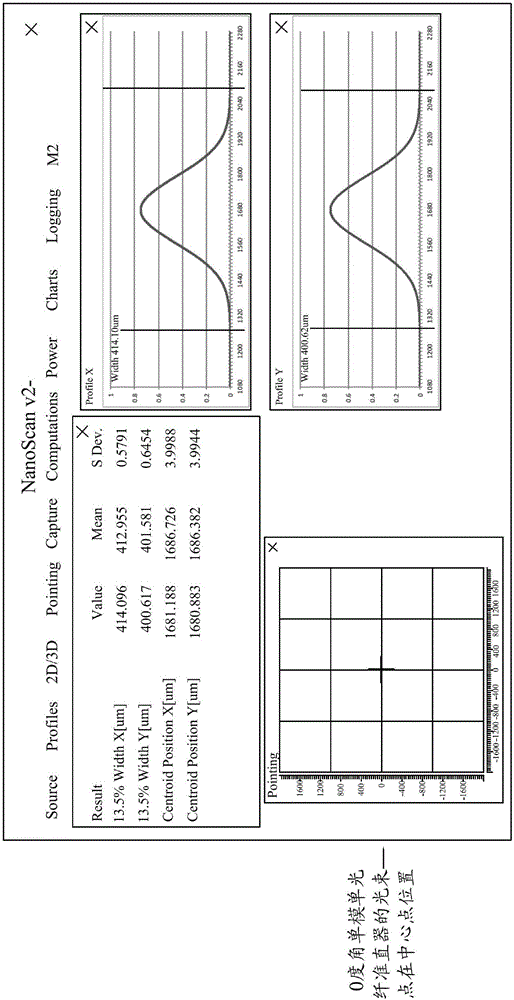

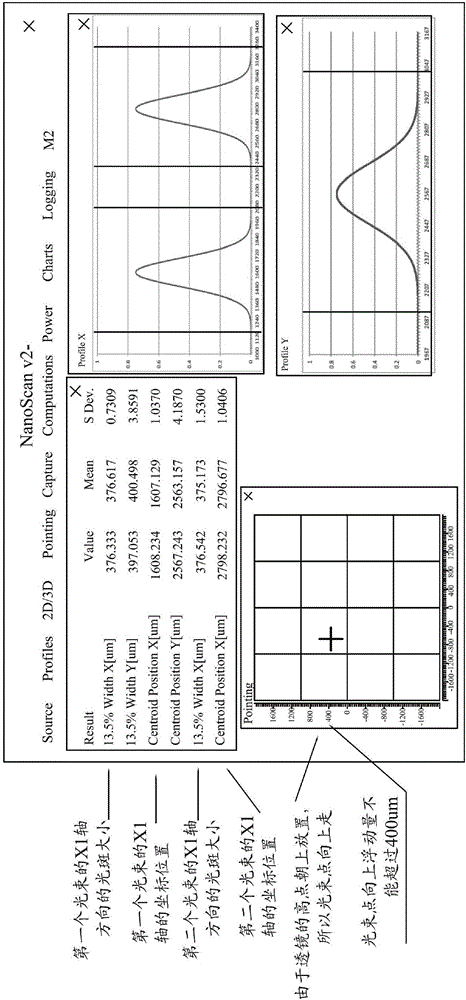

System and method for debugging single-mode broadband double-fiber collimator and thereof

The invention relates to a system and method for debugging a single-mode broadband double-fiber collimator. The system for debugging the single-mode broadband double-fiber collimator comprises an FP-LD laser light source with a wavelength of 1550nm, a Photon Nano Scan spot device, a one-dimensional adjusting bracket, a five-dimensional adjusting bracket, a computer and a to-be-debugged single-mode broadband double-fiber collimator, wherein the FP-LD laser light source with a wavelength of 1550nm is arranged at one end of the single-mode broadband double-fiber collimator; the to-be-debugged single-mode broadband double-fiber collimator is arranged on the one-dimensional adjusting bracket on the five-dimensional adjusting bracket; the one-dimensional adjusting bracket is used for adjusting a clearance between a single-mode double-fiber pigtail and a lens in the single-mode broadband double-fiber collimator; the Photon Nano Scan v2 spot device is interconnected with the computer; the debugging of the single-mode broadband double-fiber collimator is realized by debugging the five-dimensional adjusting bracket; the spot device is used for double beam debugging. The debugging method according to the invention is simple and convenient in operation, high in debugging result consistency, low in insertion loss and high in yield, and can be widely applied to the field of optical fiber communication.

Owner:上海中科光纤通讯器件有限公司 +2

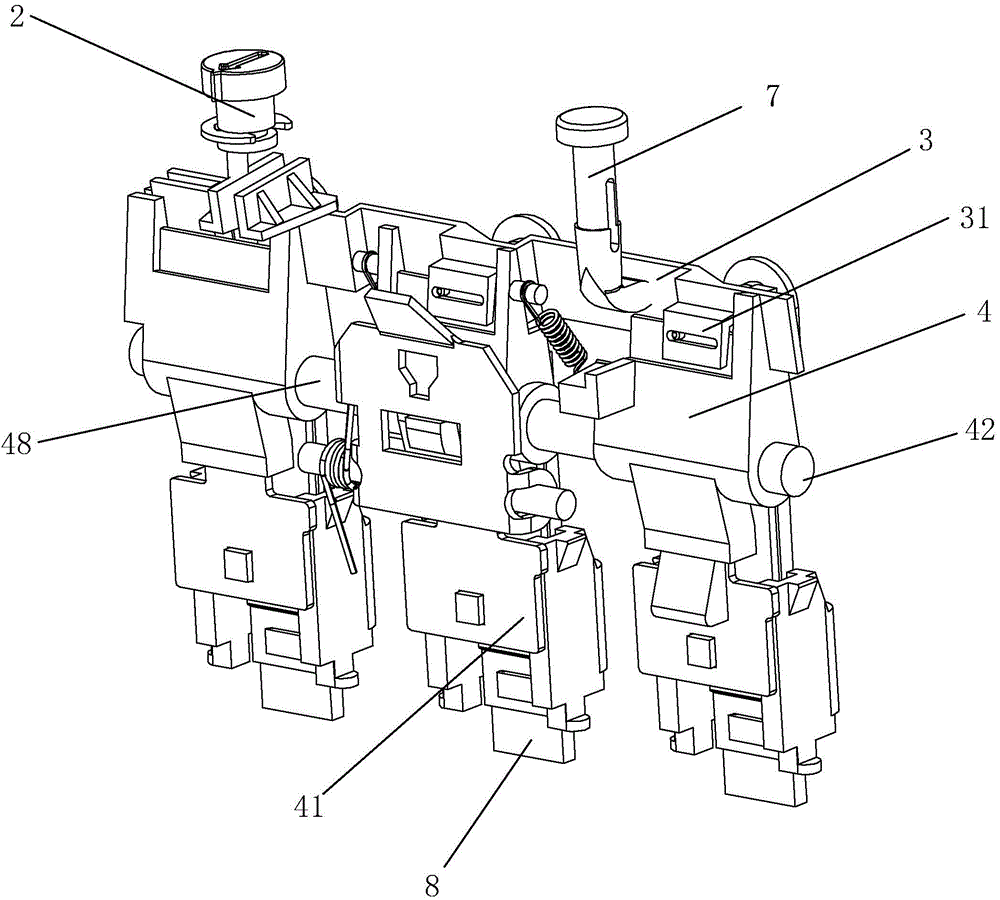

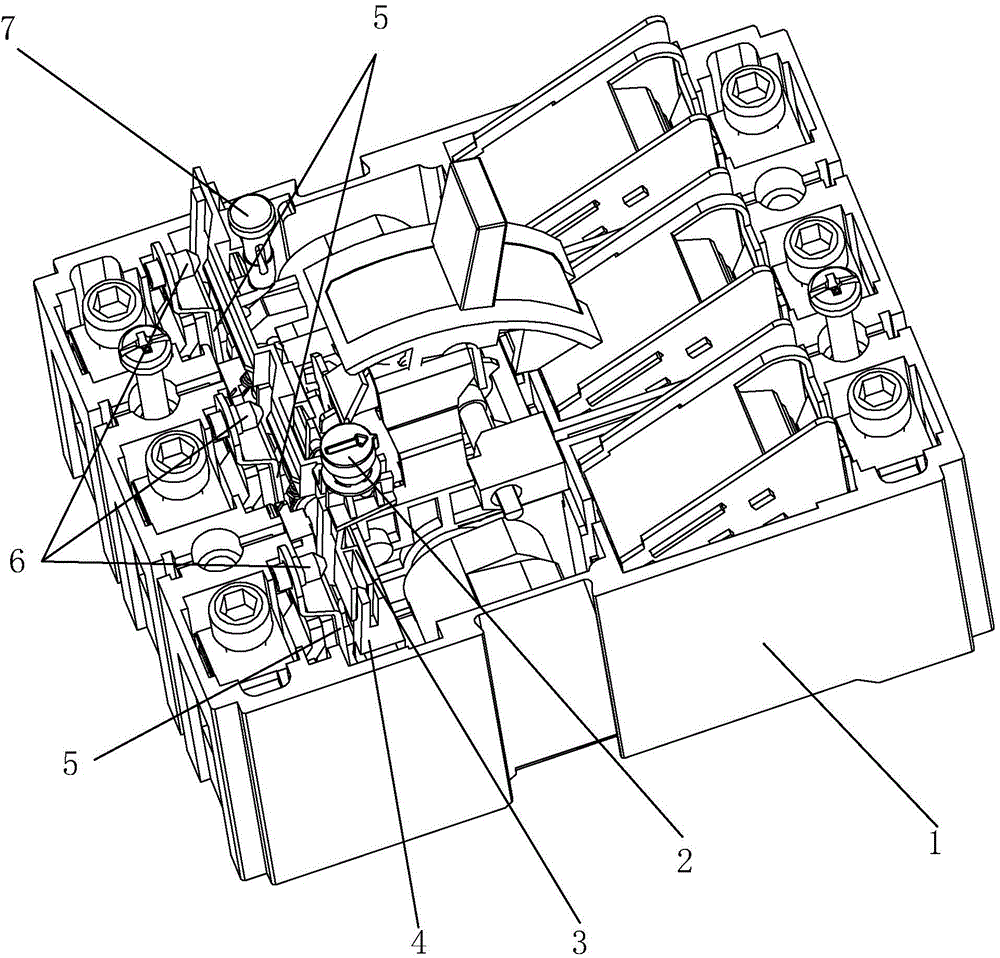

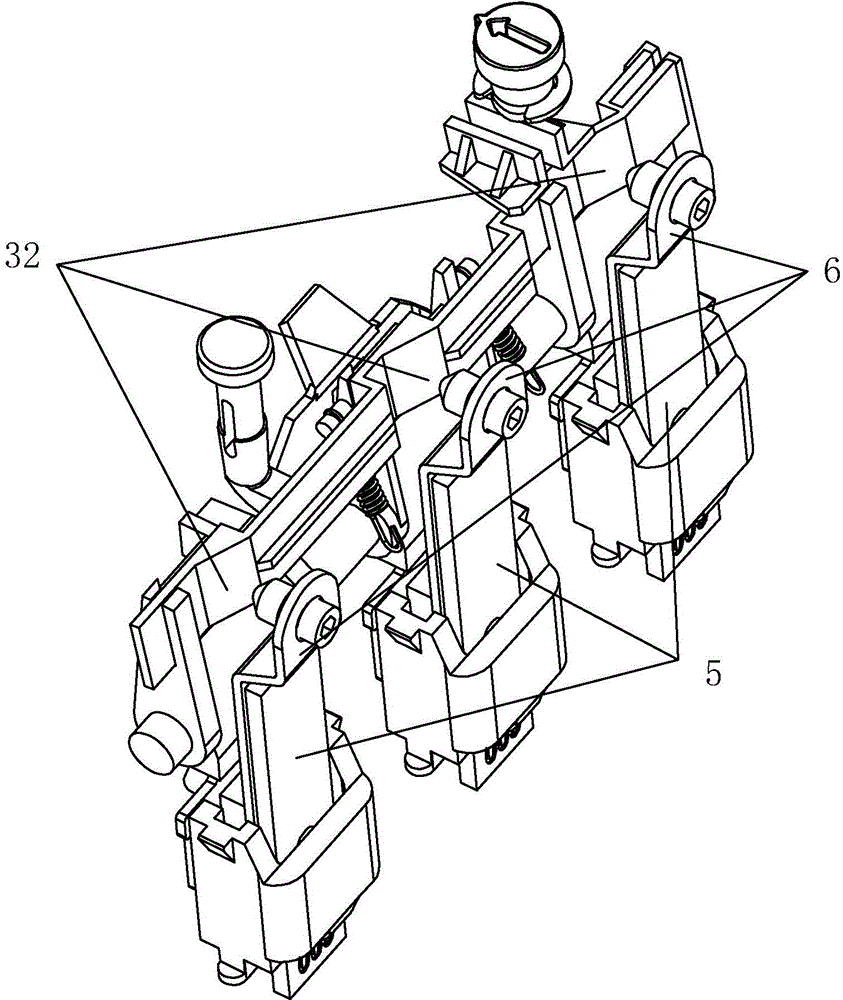

Molded case circuit breaker

ActiveCN104008934AConvenient factory debuggingIncrease productivityProtective switch operating/release mechanismsCircuit breakerBimetallic strip

The invention discloses a molded case circuit breaker. The molded case circuit breaker comprises a case body. The case body is provided with a traction assembly, adjusting screws, bimetallic strips and static iron cores. The adjusting screws are fixedly connected with the bimetallic strips. The static iron cores are fixedly connected with the bimetallic strips. The traction assembly comprises instantaneous traction rods and a delay traction rod. The instantaneous traction rods include movable iron cores and a fixed shaft. The movable iron cores correspond to the static iron cores in position. The fixed shaft and the case body are fixed axially. The delay traction rod is movably arranged on the instantaneous traction rods and can move in the arrangement direction of the instantaneous traction rods. The position, corresponding to the adjusting screws, of the delay traction rod is provided with inclined planes, and the inclined planes interact with the adjusting screws. According to the molded case circuit breaker provided with the instantaneous traction rods and the delay traction rod, the instantaneous traction rods and the delay traction rod are mutually independent and have no interference with one aother when the instantaneous tripping function and the delayed tripping function are adjusted, and delivery debugging of the molded case circuit breaker is facilitated.

Owner:浙江之路电气有限公司

Drawing and writing machine

InactiveCN108422774ALow costCultivate imagination and creativityWriting aidsTeaching apparatusGear wheelMechanical equipment

The invention provides a drawing and writing machine, and relates to the technical field of mechanical equipment. The drawing and writing machine comprises a first supporting frame, a second supporting frame, a first Y-direction rail and a second Y-direction rail; the first Y-direction rail and the second Y-direction rail are each provided with a rack; an X-direction rail is arranged between the first Y-direction rail and the second Y-direction rail; the two sides of the X-direction rail are provided with a first Y-direction stepping motor and a second Y-direction stepping motor, and both thefirst Y-direction stepping motor and the second Y-direction stepping motor are connected with first gears; the first gears are rotationally connected to the first racks and further provided with firstlimiting mechanisms; and the X-direction rail is provided with a writing mechanism. The drawing and writing machine has the beneficial effects of being simple in structure, convenient to operate, high in practicality and capable of assisting drawing and writing advantageously.

Owner:FOSHAN UNIVERSITY

Cassegrain system primary and secondary mirror optical axis consistency debugging method

PendingCN112859357ASelf-aligning precisionSolve the technical problem that the optical axis cannot be determinedOptical elementsOptical axisCollimator

The invention discloses a Cassegrain system primary and secondary mirror optical axis consistency debugging method which utilizes a large-aperture collimator, an internal focusing telescope and a standard ball to realize Cassegrain system primary mirror and secondary mirror optical axis consistency debugging by using an auto-collimation method. An advantage is that the standard ball whose diameter is the same as that of the central hole of the primary mirror is used, a primary mirror optical axis is explicitly expressed through a primary mirror center hole with high coaxial precision. The standard ball is arranged in a central hole of the primary mirror, the center of the standard ball is located on the axis of the central hole of the primary mirror, the curvature center of the reflecting surface of the primary mirror and the center of the standard ball are subjected to auto-collimation through the focusing function of an internal focusing telescope, a curvature center image and a standard ball center image are located on the optical axis of the internal focusing telescope at the same time, and the optical axis of the internal focusing telescope is the optical axis of the primary mirror. And the position of the secondary mirror is adjusted to enable the optical axis of the secondary mirror to be coaxial with the optical axis of the internal focusing telescope to complete primary and secondary mirror optical axis consistency debugging. According to the method, the assembling efficiency and the adjusting quality of the optical axis consistency of the Cassegrain system can be effectively improved.

Owner:西安应用光学研究所

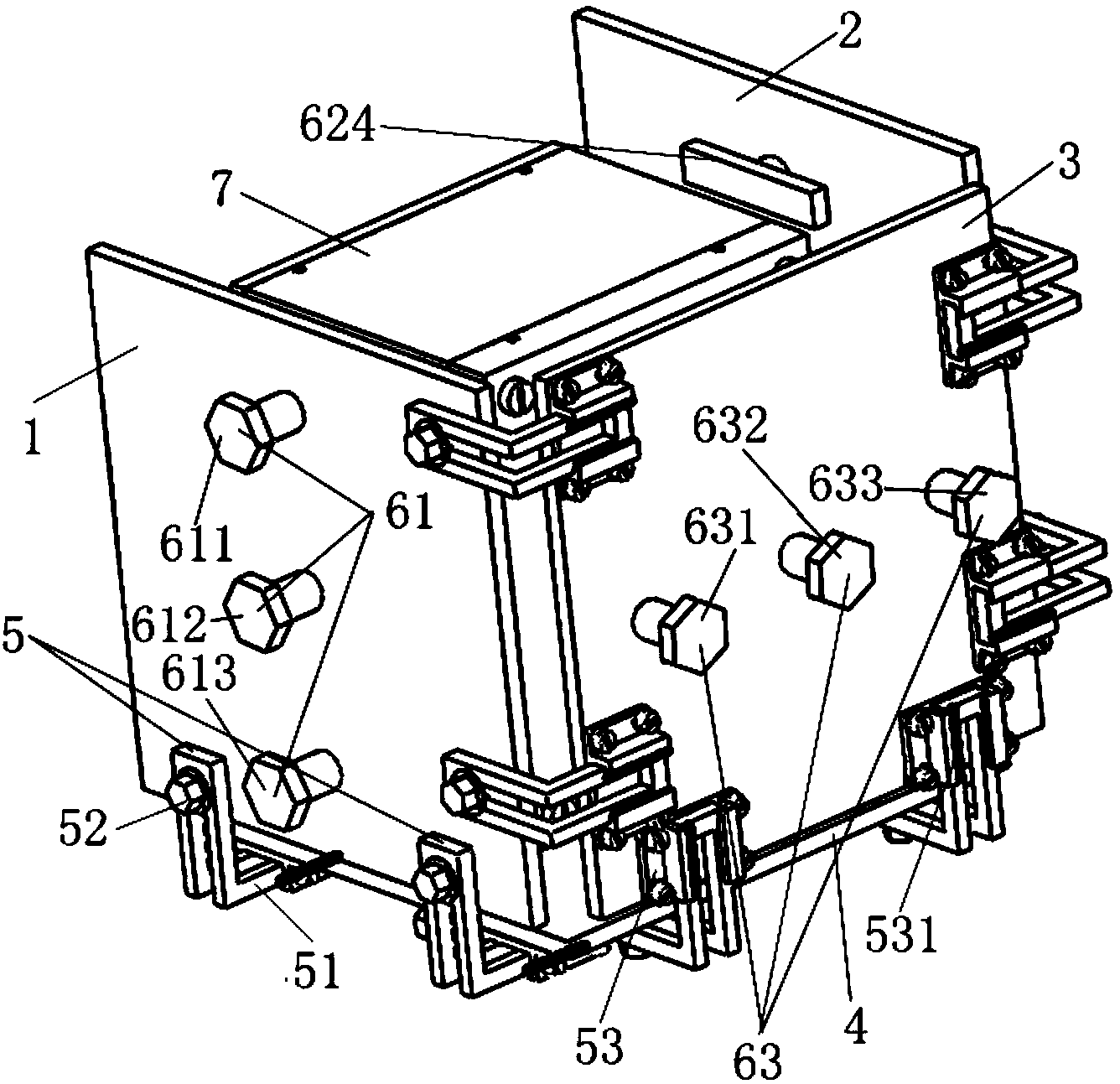

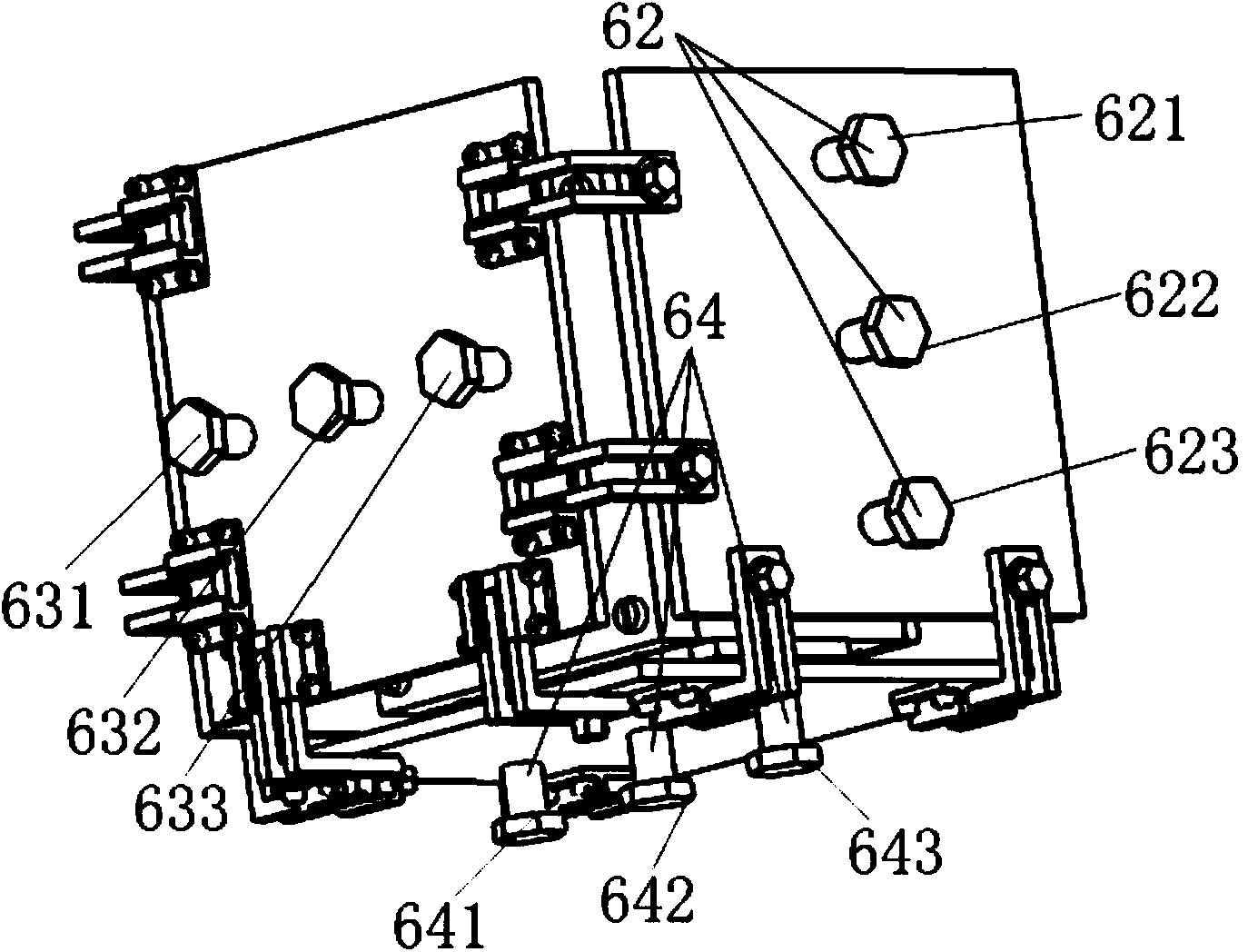

Debugging clamp of detector assembly

The invention discloses a debugging clamp of a detector assembly, and belongs to the field of debugging equipment of the detector assembly. The debugging clamp comprises four baffle plates, a plurality of adjusting type guide rail connecting assemblies and a plurality of adjusting screw assemblies, wherein one baffle plate of the four baffle plates is a bottom baffle plate, the other three baffle plates of the four baffle plates are respectively arranged above three edges of the bottom baffle plate and are all vertical to the bottom baffle plate, and debugging space which is used for placing a to-be-debugged detector assembly is defined by the four baffle plates; every two adjacent baffle plates of the four baffle plates are connected through at least one adjusting type guide rail connecting assembly, and the positions, which are relative to other baffle plates, of the each baffle plate can be adjusted by each baffle plate through the corresponding adjusting type guide rail connecting assembly which is connected with the corresponding baffle plate; each baffle plate is provided with at least one adjusting screw assembly, and an adjusting block arranged at the front end of each adjusting screw assembly is arranged in the debugging space.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Debugging method of static balance valve

InactiveCN103034251AReduce the impact of interferenceEasy to operateEqualizing valvesSafety valvesTerminal unitControl theory

The invention provides a debugging method of a static balance valve and belongs to the technical field of hydraulic systems. The debugging method of the static balance valve solves the problems that the prior static balance valve is low in debugging efficiency and the like, and comprises the following steps: A selecting a maximum flow ratio stand pipe; B selecting a maximum flow ratio branch pipe; C selecting a minimum flow ratio terminal unit; D adjusting a terminal balance valve on terminal unit; E adjusting terminal balance valves on all terminal units on the maximum flow ratio stand pipe; F adjusting branch balance valves of all branch pipes on the maximum flow ratio stand pipe; G adjusting stand balance valves of all stand pipes; repeting the steps mentioned above and finally adjusting the flow ratio of a main balance valve of the hydraulic system to be one, flow ratios of all other balance valves are accordingly to be one. The debugging method of the static balance valve has the advantages of being high in debugging success rate, debugging efficiency and the like.

Owner:卓旦春

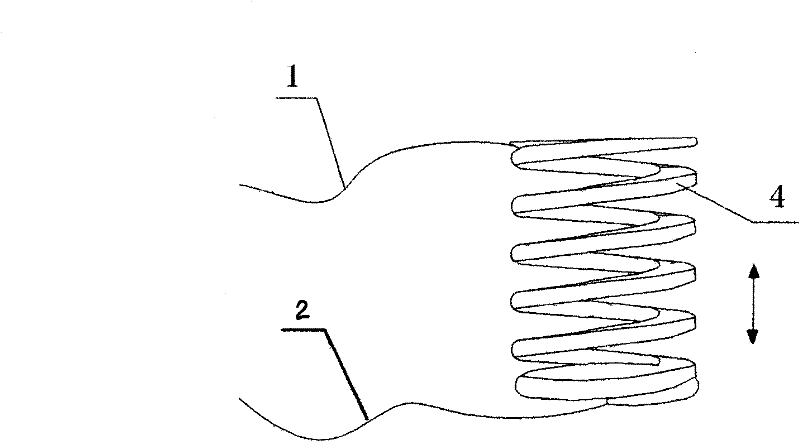

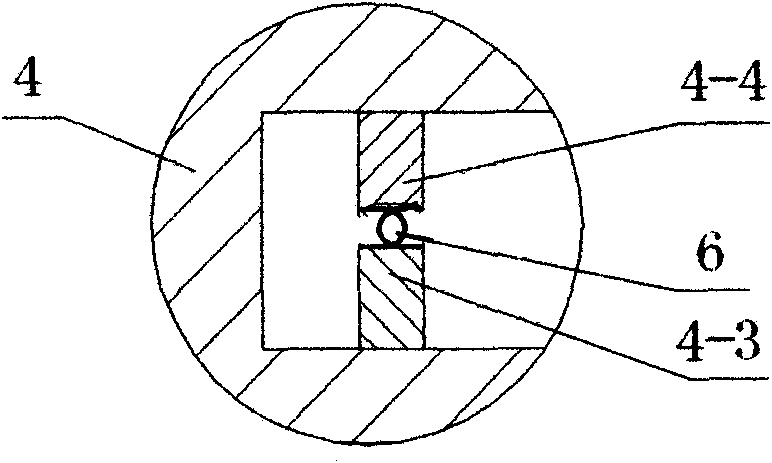

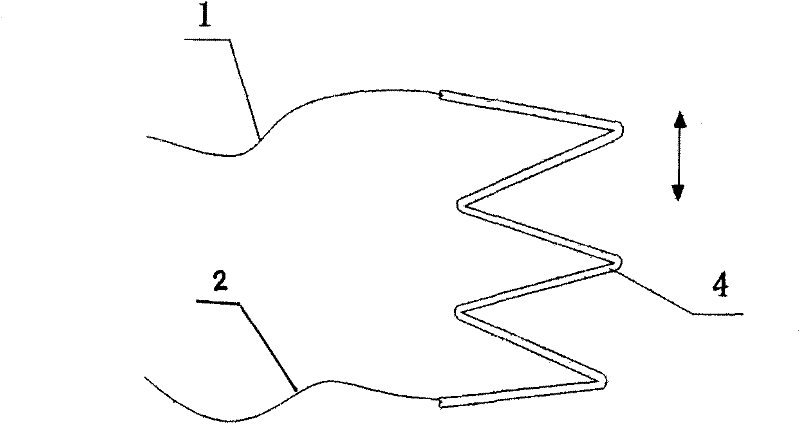

All-fiber precision variable optical attenuator

InactiveCN102207584AIncrease the lengthHigh debugging accuracyCoupling light guidesUltrasound attenuationLight guide

The invention discloses an all-fiber precision variable optical attenuator, which comprises a curved shell, and a plurality of side A deformation teeth and a plurality of side B deformation teeth which are arranged continuously; and the side A deformation teeth and the side B deformation teeth are arranged in a staggered way, and a light guide optical fiber is clamped between the side A deformation teeth and the side B deformation teeth. Distances between the plurality of side A deformation teeth and the plurality of side B deformation teeth, which are distributed along the curved shell, can be changed simultaneously by changing a space between two ends of the curved shell, so that a bending radius of the light guide optical fiber clamped between the side A deformation teeth and the side B deformation teeth can be changed, namely a bending loss coefficient of the light guide optical fiber is changed; therefore, an attenuation amplitude of an input optical signal is changed. The all-fiber precision variable optical attenuator disclosed by the invention is simple in structure, rational in design, convenient to process and manufacture, flexible in using manner, high in sensitivity, low in cost and good in use effect, and has wide market application prospect.

Owner:XIAN JINHE OPTICAL TECH

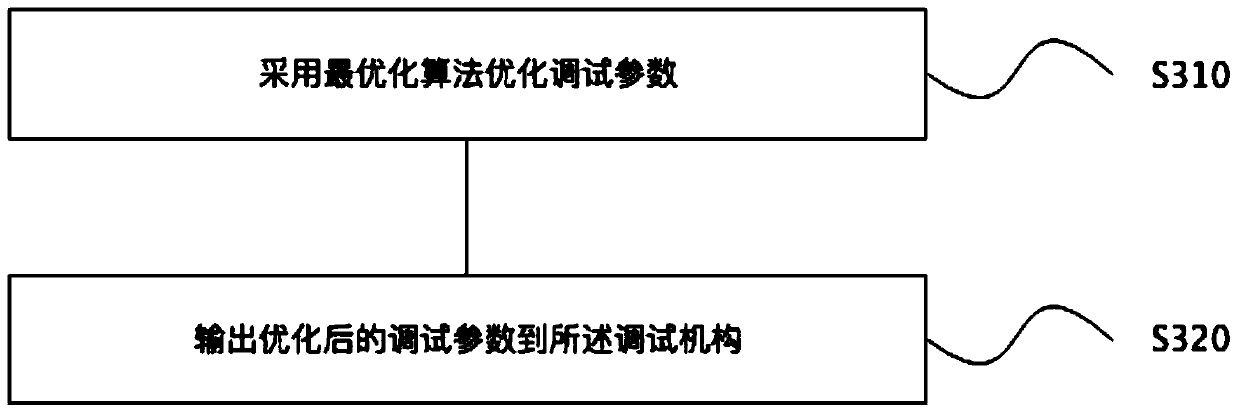

Radio frequency device debugging method, device, equipment and system and storage medium

InactiveCN109696618ATo achieve the purpose of automatic debuggingIncrease productivityRadiofrequency circuit testingRadio frequencyLearning network

The invention discloses a radio frequency device debugging method, device, equipment and system and a storage medium. The method comprises the steps of acquiring device parameters of a tested machineto serve as input data of a trained machine learning network; determining debugging parameters of a debugging mechanism through the machine learning network according to the input data; and outputtingthe debugging parameters to the debugging mechanism, wherein the debugging mechanism is used for adjusting the tested machine according to the debugging parameters. The method disclosed by the invention realizes the purpose of automatic debugging, and achieves the effects of improving the production efficiency and reducing the production cost.

Owner:徐晨阳

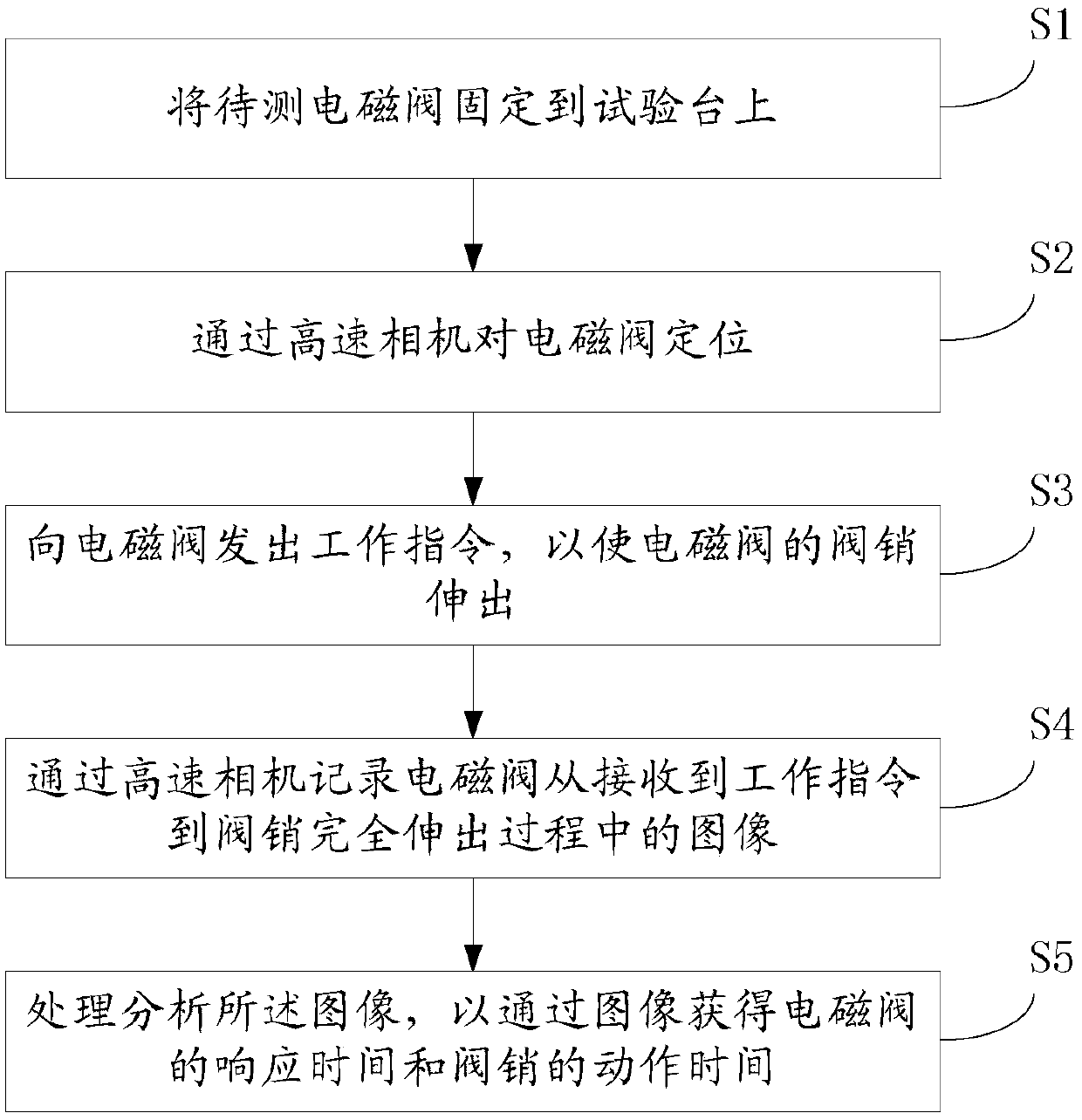

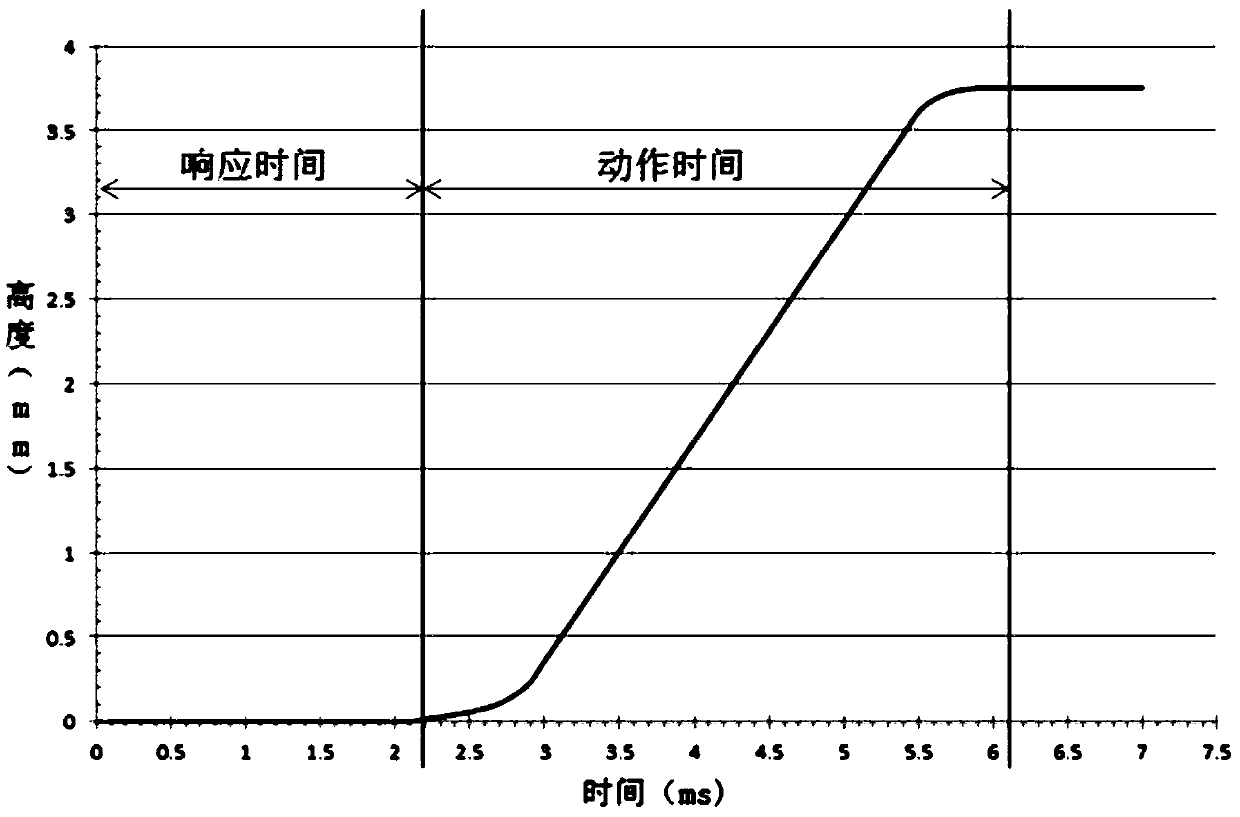

Electromagnetic valve response time testing method

The invention discloses an electromagnetic valve response time testing method which comprises the steps of fixing a to-be-tested electromagnetic valve on a testing bench; fixing the electromagnetic valve through a high-speed camera; transmitting a working instruction to the electromagnetic valve so that a valve pin of the electromagnetic valve extends out; receiving the image of the electromagnetic valve in a process from receiving the working instruction to total extension of the valve pin through the high-speed camera; and processing and analyzing the image so as to obtain the response timeof the electromagnetic valve and the action time of the valve pin through the image. The electromagnetic valve response time testing method has advantages of realizing testing to the response time andthe action time of the electromagnetic valve, facilitating debugging of the electromagnetic valve in use, and improving debugging precision of the electromagnetic valve.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Automatic adjustment mechanism for needle-shuttle cooperation and sewing machine

ActiveCN111118759ARealize automatic adjustmentImprove debugging efficiencySewing-machine control devicesNeedle barsElectric machineryControl theory

Owner:BULLMER ELECTROMECHANICAL TECH

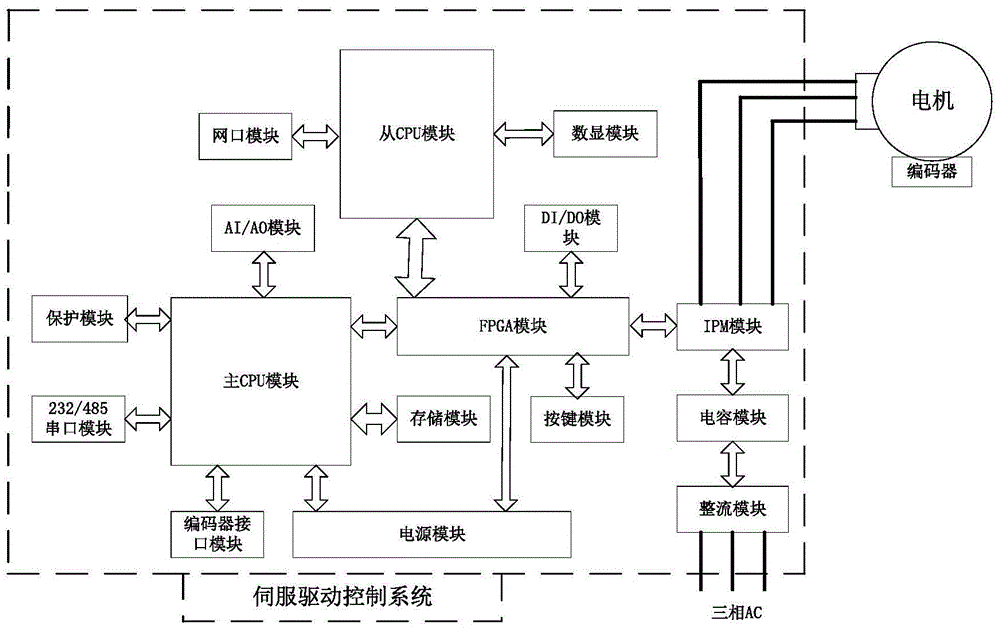

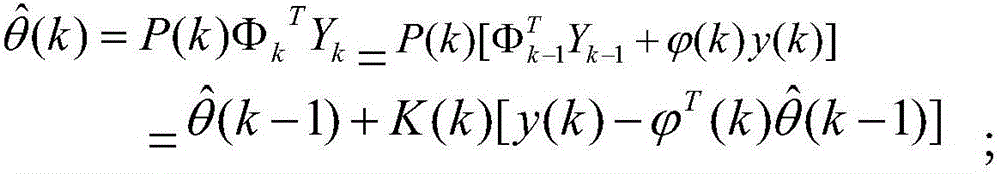

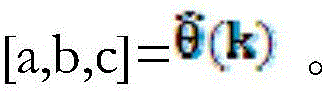

Double-core servo driving system and servo motor online modeling method

ActiveCN105759604AIncrease productivityReduced commissioning timeAdaptive controlDual coreControl parameters

The invention discloses a double-core servo driving system. The double-core servo driving system comprises a master CPU module used for calculation of a control algorithm; a slave CPU module used for acquiring motor state data in real time and establishing a motor mathematics model; an FPGA module used for acquiring data exchange media and correlation signals; a storage module; an encoder interface module connected with a motor encoder for receiving photoelectric encoder pulse signals or rotary encoder output signals carried by a motor; and a button module used for configuring input parameters and a control mode of a servo driver, wherein the master CPU module is connected with the slave CPU module through the FPGA module, the encoder interface module, the storage module and the master CPU module are connected, and the button module is connected with the FPGA module. The invention further discloses a servo motor real-time online modeling method. The servo control system provided by the invention can calculate a system model in real time so that debugging personnel can select corresponding control parameters according to motor model, and thus the production efficiency is improved.

Owner:张碧陶

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com