Large view field off-axis three-reflector system and adjusting method

An off-axis three-mirror technology with a large field of view, which is applied to optical components, optics, instruments, etc., can solve problems such as unfavorable engineering, difficult operation of system installation and adjustment, and difficult detection of convex aspheric surface processing, so as to achieve the difficulty of installation and adjustment The effect of low, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

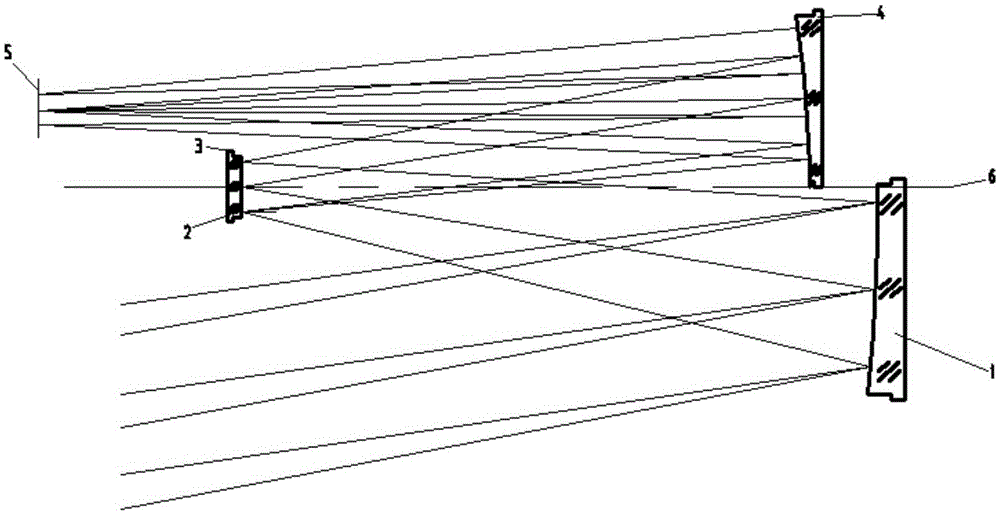

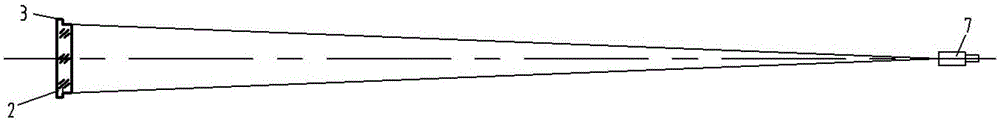

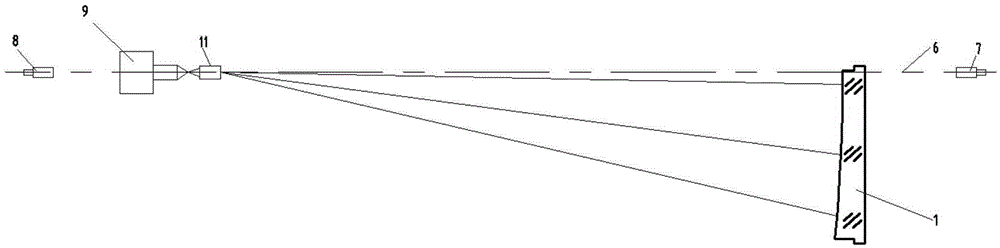

[0046] Such as figure 1As shown, the designed large field of view off-axis three-mirror system primary mirror 1 is an off-axis hyperboloid mirror; the secondary mirror is a convex spherical mirror 2; 3 is the aperture stop of the system, which is arranged on the secondary mirror 2; The mirror is an off-axis secondary concave oblate spherical mirror 4; 5 is the focal plane of the system; 6 is the optical reference axis of the system, which is the parent axis of the main mirror 2 and the third mirror 4. The target light from infinity is reflected by the primary mirror 1 to the secondary mirror 2, and then reflected by the secondary mirror 2 into the third mirror 4, and finally the three mirrors image the light to the image surface 5. The structural form adopted by the present invention is beneficial to reduce the difficulty of system processing and assembly, especially the use of coaxial spherical mirror for the secondary mirror reduces the difficulty of later optical glass proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com