Double-core servo driving system and servo motor online modeling method

A servo drive and storage module technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as the difficulty of debugging personnel, and achieve the effects of reducing debugging time, increasing debugging accuracy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

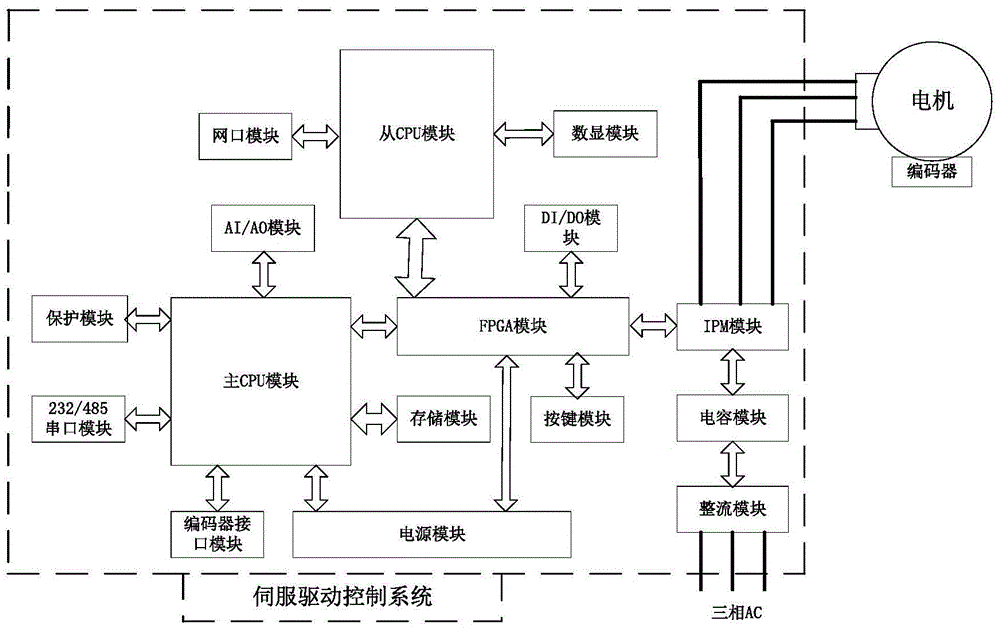

[0044] Such as figure 1 , a dual-core servo drive system comprising:

[0045] The main CPU module is used for the calculation of the control algorithm;

[0046] From the CPU module, it is used to collect motor status data in real time and establish a motor mathematical model;

[0047] FPGA module, used for data exchange intermediary and collection of related signals;

[0048] A storage module for storing signal data and programs;

[0049] The encoder interface module is connected with the motor encoder to receive the pulse signal of the photoelectric encoder attached to the motor or the output signal of the rotary encoder;

[0050] Key module, used to configure the input parameters and control mode of the servo driver,

[0051] The main CPU module is connected with the slave CPU module through the FPGA module, the encoder interface module and the storage module are connected with the main CPU module, and the button module is connected with the FPGA module.

[0052] Specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com