Calibrating method of weighing sensor of belt scale

A technology of weighing sensor and calibration method, applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of inability to detect the accumulated error of the weighing sensor in real time, low debugging efficiency, and large maintenance, so as to improve the debugging efficiency and accuracy. , Conducive to automation, the effect of reducing maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] This implementation method is for better understanding of the present invention, and is not used to limit the conditions of the present invention.

[0049] Belt scale load cell calibration method, including:

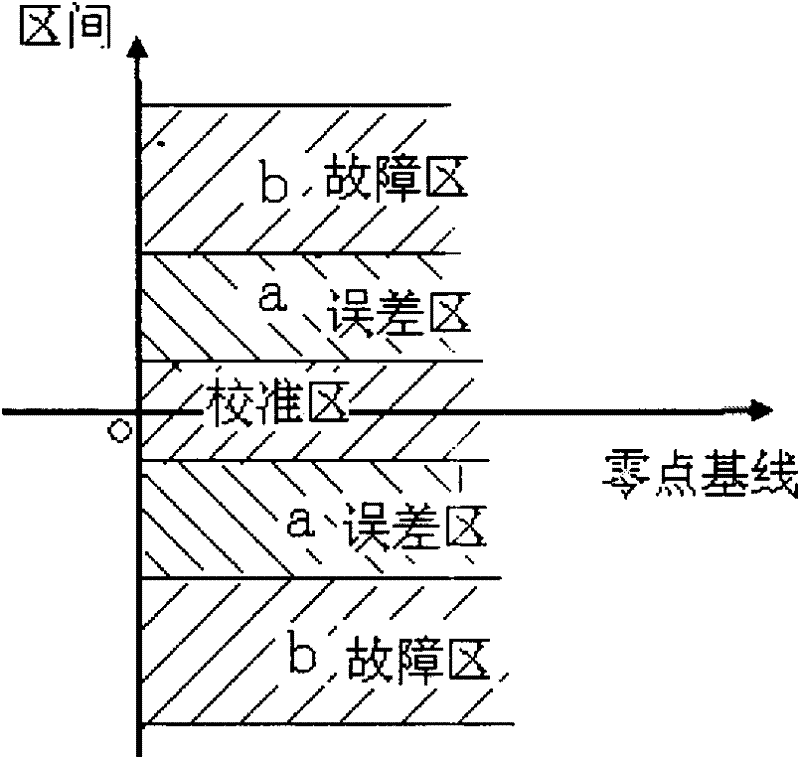

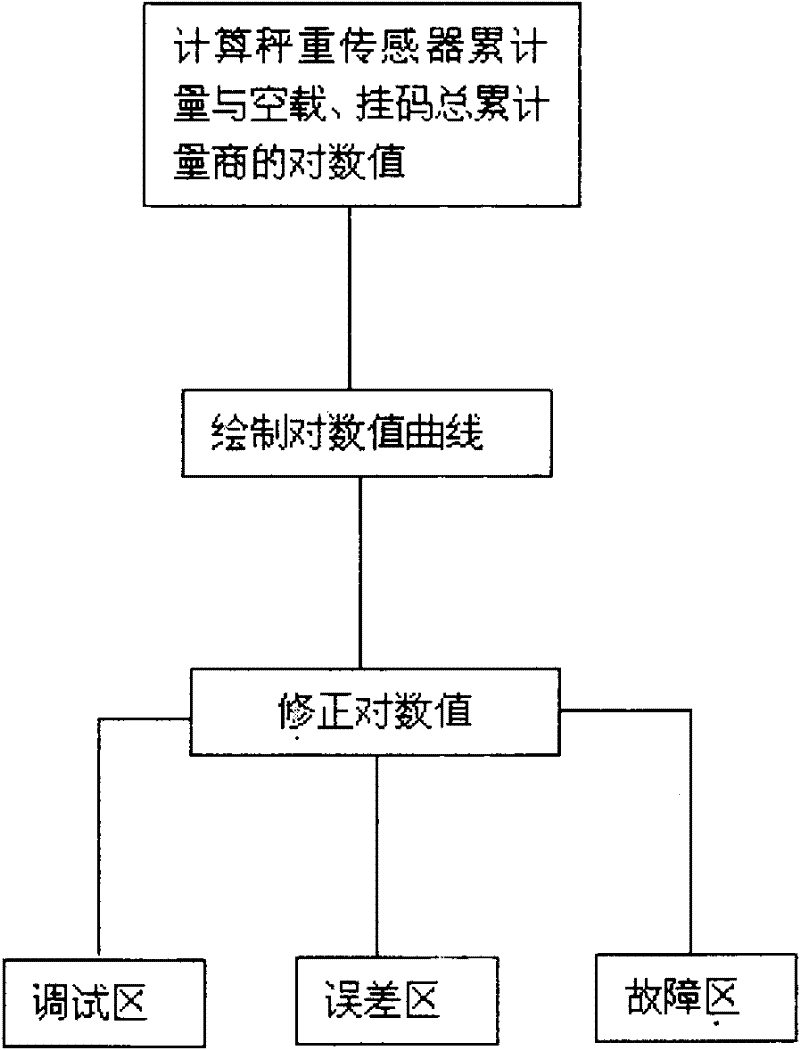

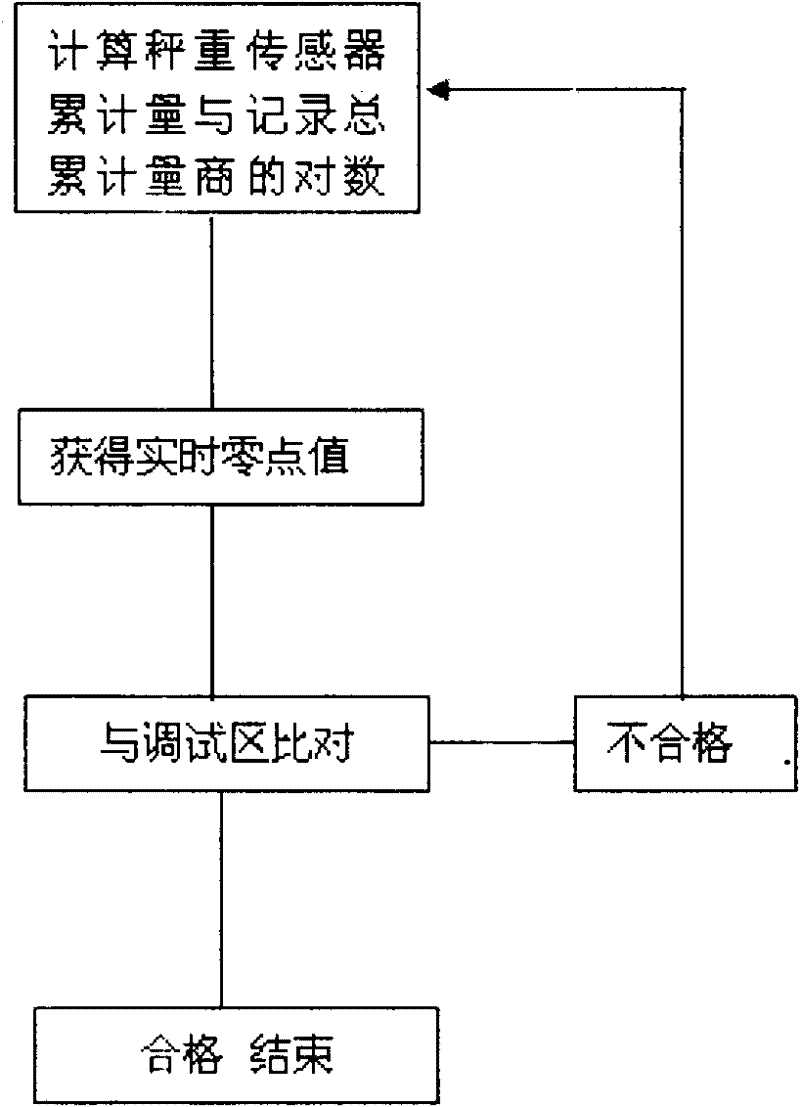

[0050] 1. The accumulator calculates the cumulative amount and total cumulative amount of a single load cell under different working conditions when the weighing system is in good condition, and calculates the logarithmic value of the quotient of the cumulative amount of a single load cell and the total cumulative amount respectively. In the section, a set of logarithmic curves with zero as the base point is obtained, and the maximum and minimum values of the curves are corrected. The corrected interval with zero as the base point is used as the standard area for comparison, and records of various working conditions Standard area and total cumulative amount, where: the cumulative amount includes the cumulative amount in the state of no-load, chain code and weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com