Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Instrument error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Instrument error refers to the error of a measuring instrument, or the difference between the actual value and the value indicated by the instrument. There can be errors of various types, and the overall error is the sum of the individual errors.

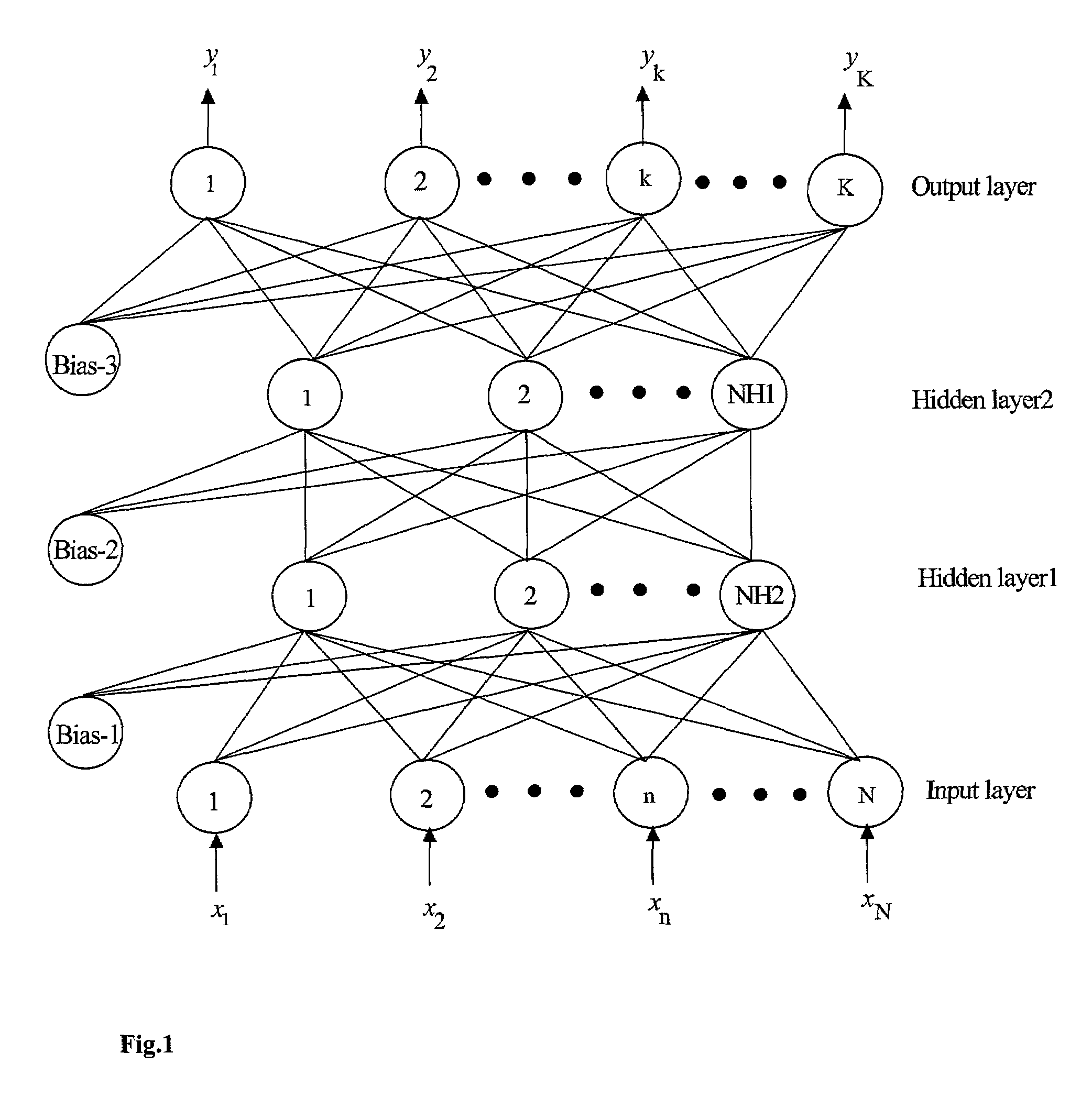

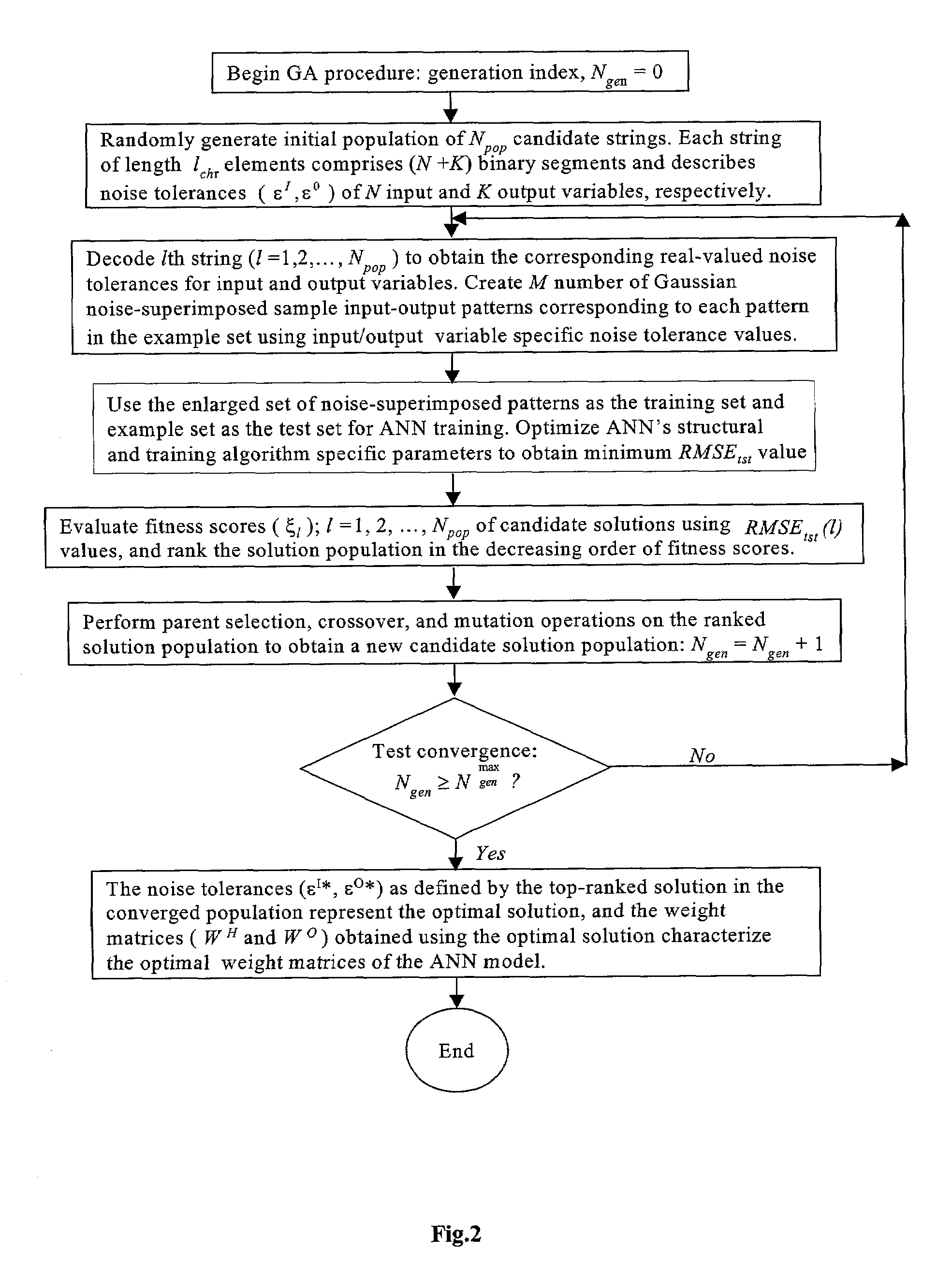

Performance of artificial neural network models in the presence of instrumental noise and measurement errors

ActiveUS20030191728A1Improve accuracy performanceImprove generalization performanceGenetic modelsDigital computer detailsObservational errorData set

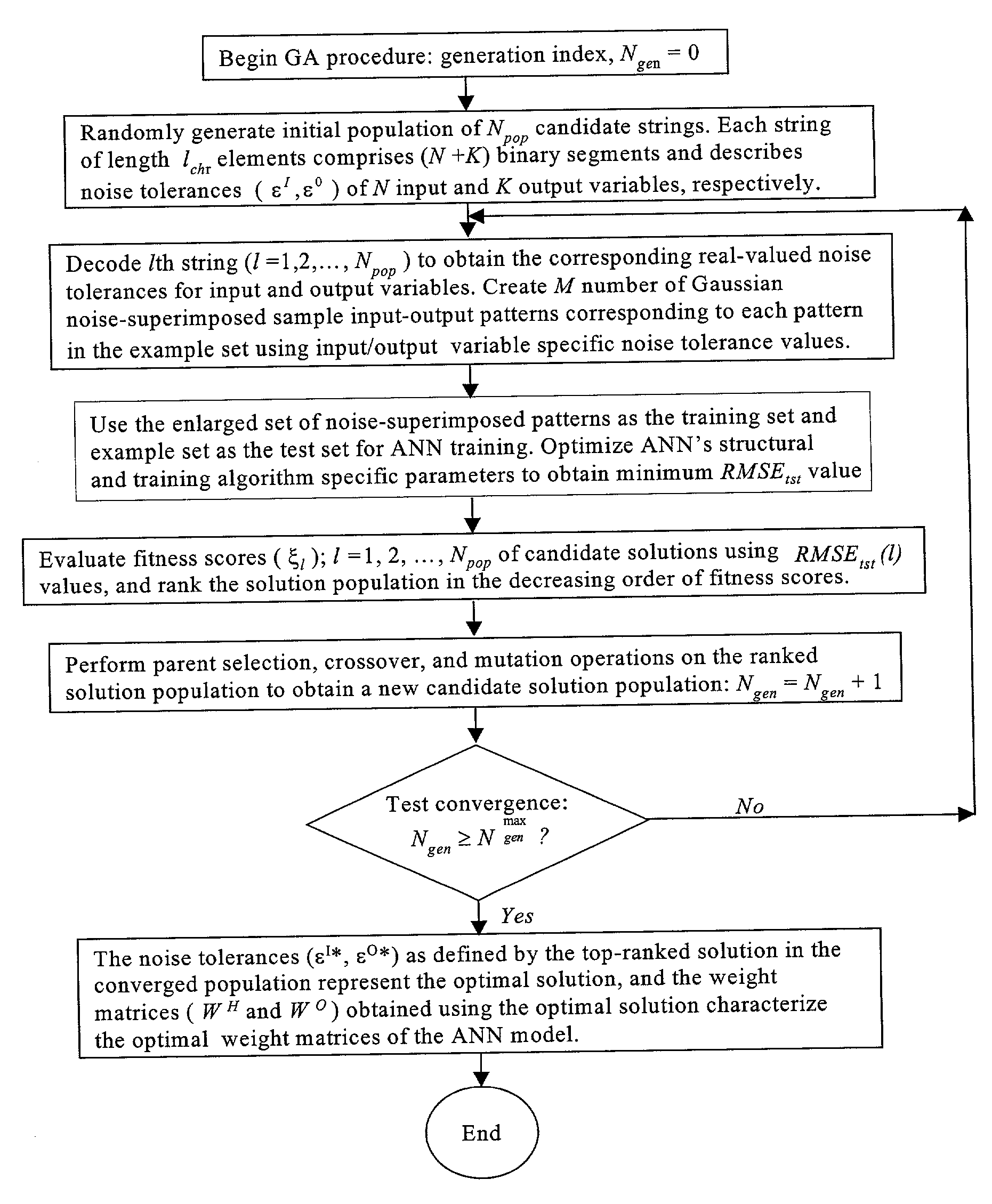

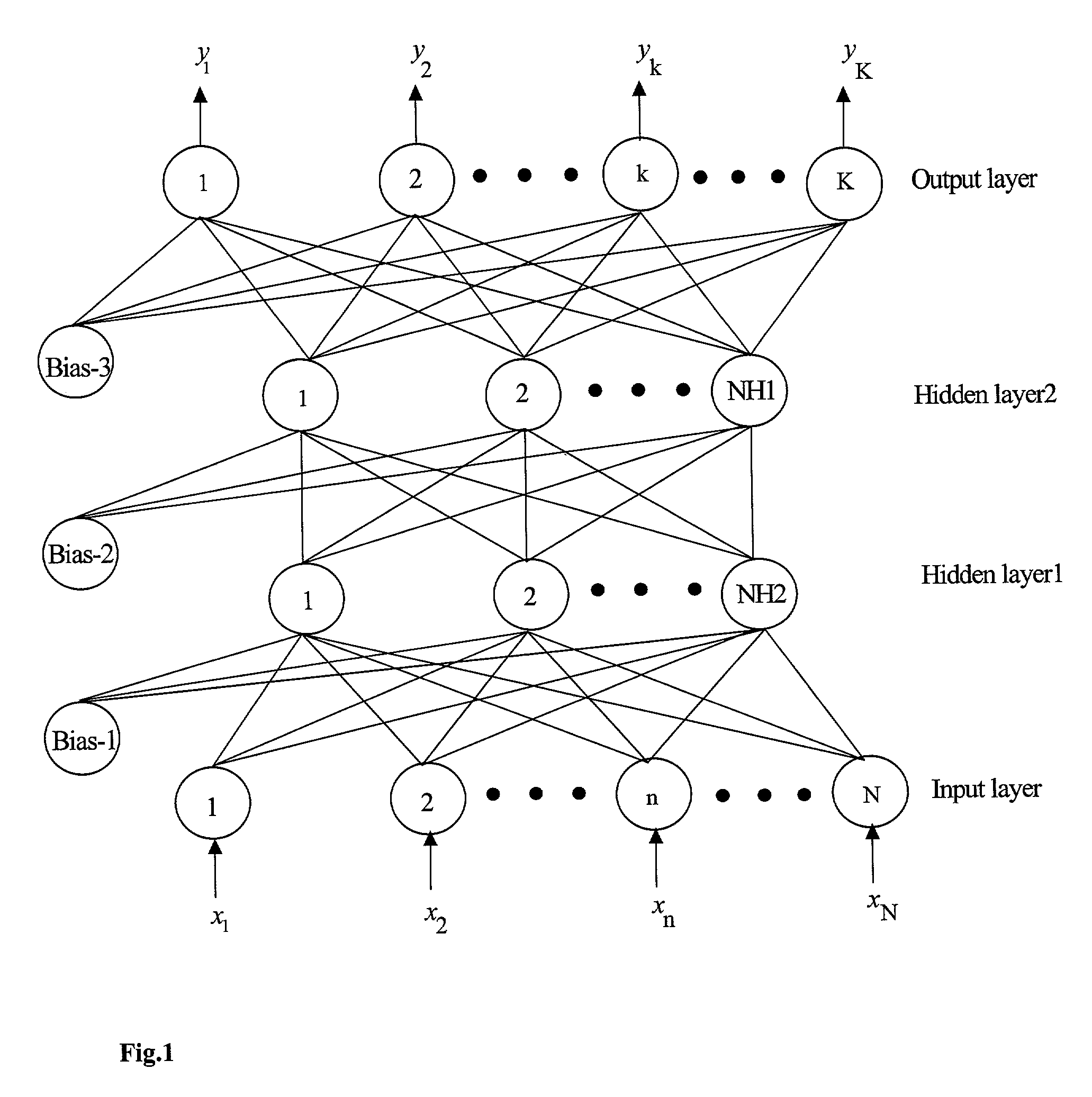

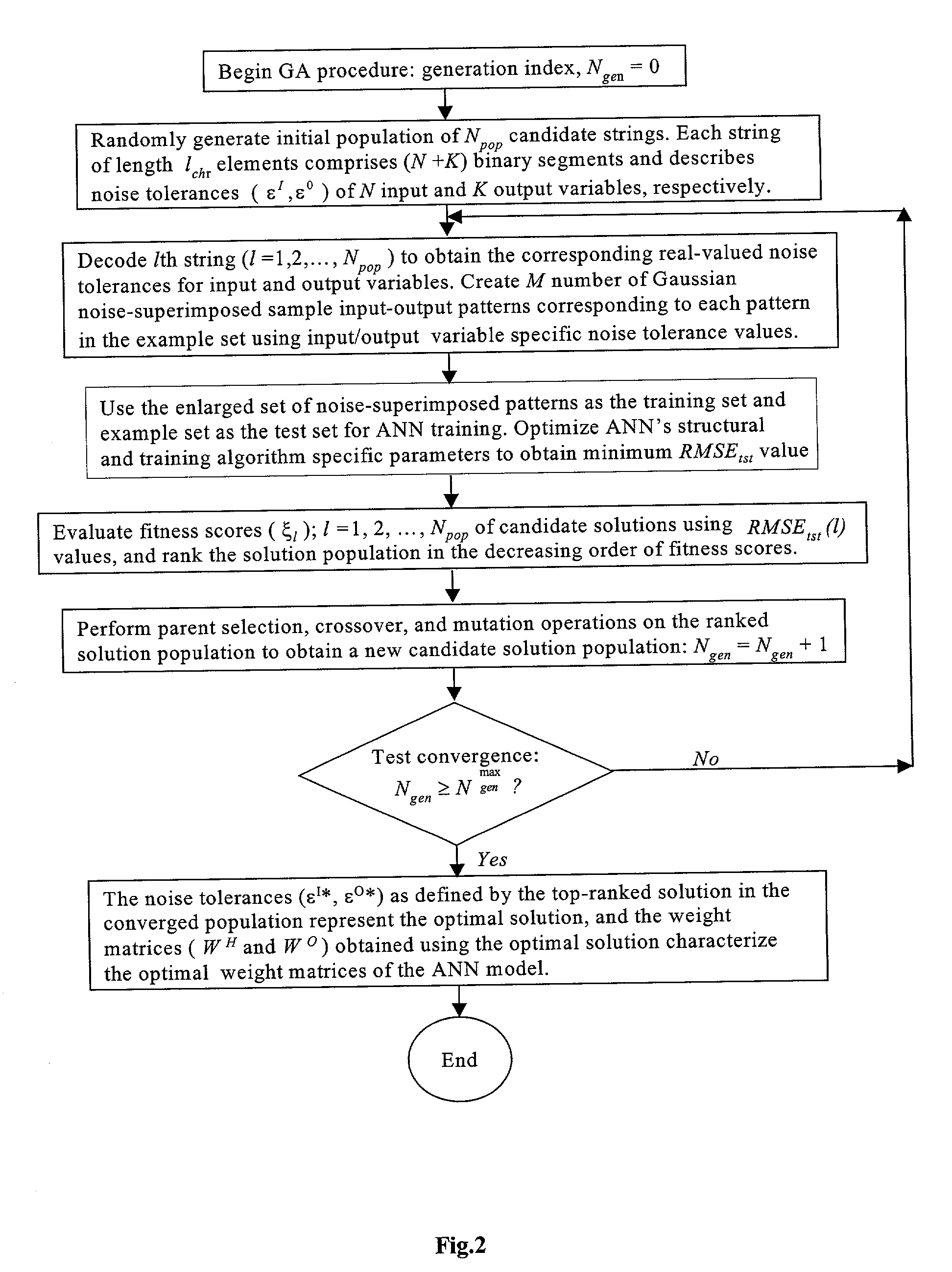

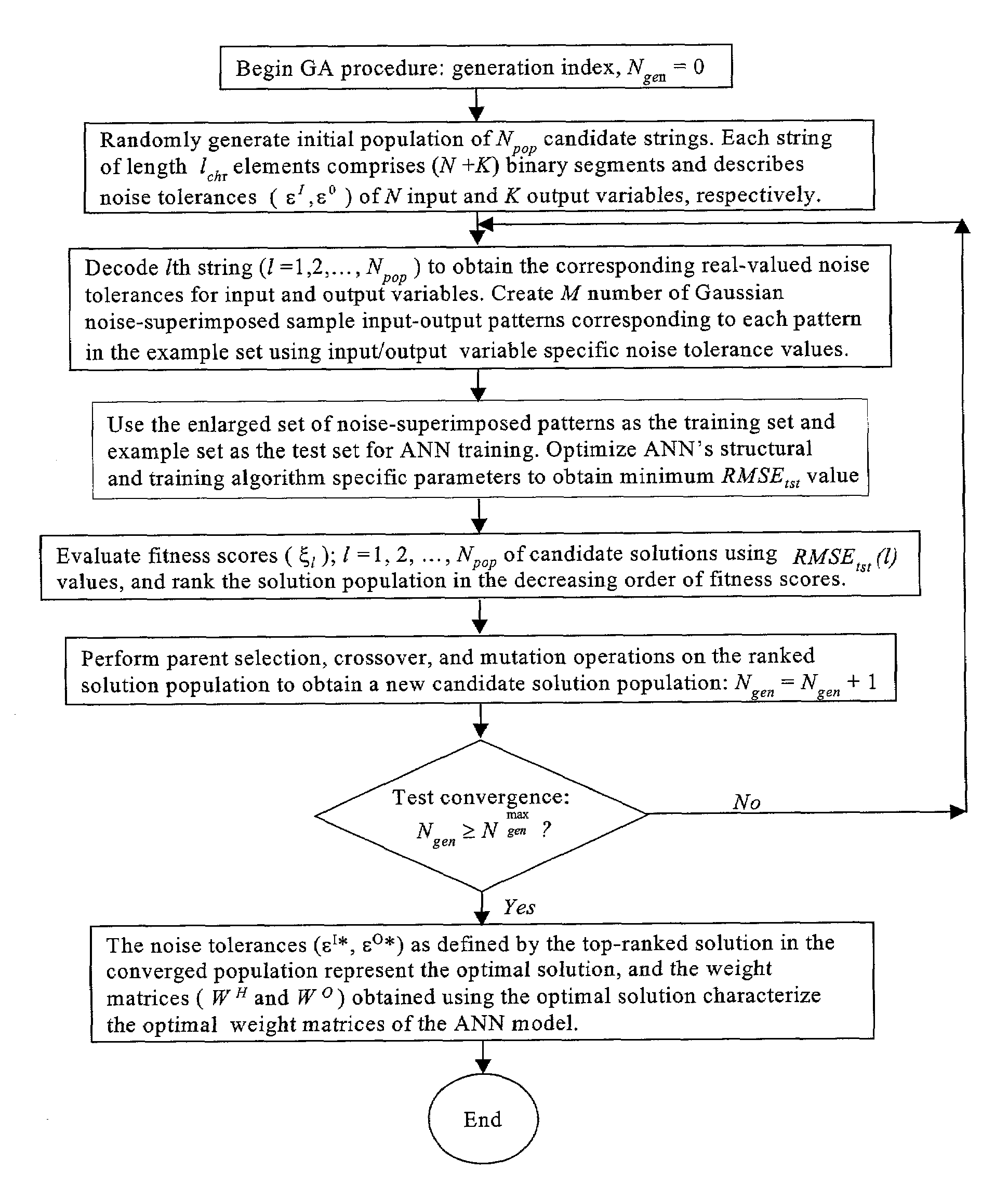

A method is described for improving the prediction accuracy and generalization performance of artificial neural network models in presence of input-output example data containing instrumental noise and / or measurement errors, the presence of noise and / or errors in the input-output example data used for training the network models create difficulties in learning accurately the nonlinear relationships existing between the inputs and the outputs, to effectively learn the noisy relationships, the methodology envisages creation of a large-sized noise-superimposed sample input-output dataset using computer simulations, here, a specific amount of Gaussian noise is added to each input / output variable in the example set and the enlarged sample data set created thereby is used as the training set for constructing the artificial neural network model, the amount of noise to be added is specific to an input / output variable and its optimal value is determined using a stochastic search and optimization technique, namely, genetic algorithms, the network trained on the noise-superimposed enlarged training set shows significant improvements in its prediction accuracy and generalization performance, the invented methodology is illustrated by its successful application to the example data comprising instrumental errors and / or measurement noise from an industrial polymerization reactor and a continuous stirred tank reactor (CSTR).

Owner:COUNCIL OF SCI & IND RES

Performance of artificial neural network models in the presence of instrumental noise and measurement errors

InactiveUS7313550B2Improve accuracyImprove performanceGenetic modelsDigital computer detailsObservational errorData set

A method is described for improving the prediction accuracy and generalization performance of artificial neural network models in presence of input-output example data containing instrumental noise and / or measurement errors, the presence of noise and / or errors in the input-output example data used for training the network models create difficulties in learning accurately the nonlinear relationships existing between the inputs and the outputs, to effectively learn the noisy relationships, the methodology envisages creation of a large-sized noise-superimposed sample input-output dataset using computer simulations, here, a specific amount of Gaussian noise is added to each input / output variable in the example set and the enlarged sample data set created thereby is used as the training set for constructing the artificial neural network model, the amount of noise to be added is specific to an input / output variable and its optimal value is determined using a stochastic search and optimization technique, namely, genetic algorithms, the network trained on the noise-superimposed enlarged training set shows significant improvements in its prediction accuracy and generalization performance, the invented methodology is illustrated by its successful application to the example data comprising instrumental errors and / or measurement noise from an industrial polymerization reactor and a continuous stirred tank reactor (CSTR).

Owner:COUNCIL OF SCI & IND RES

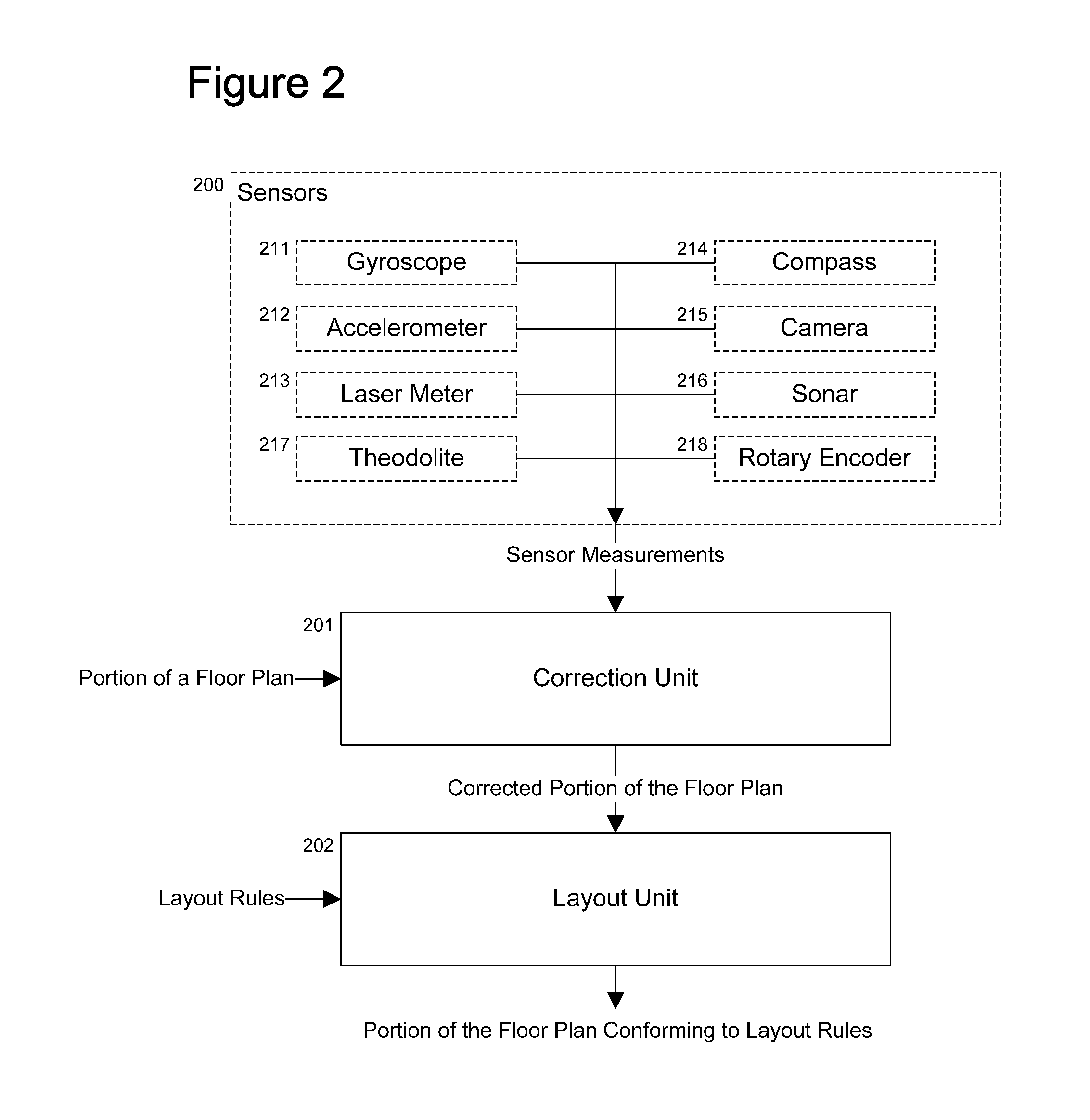

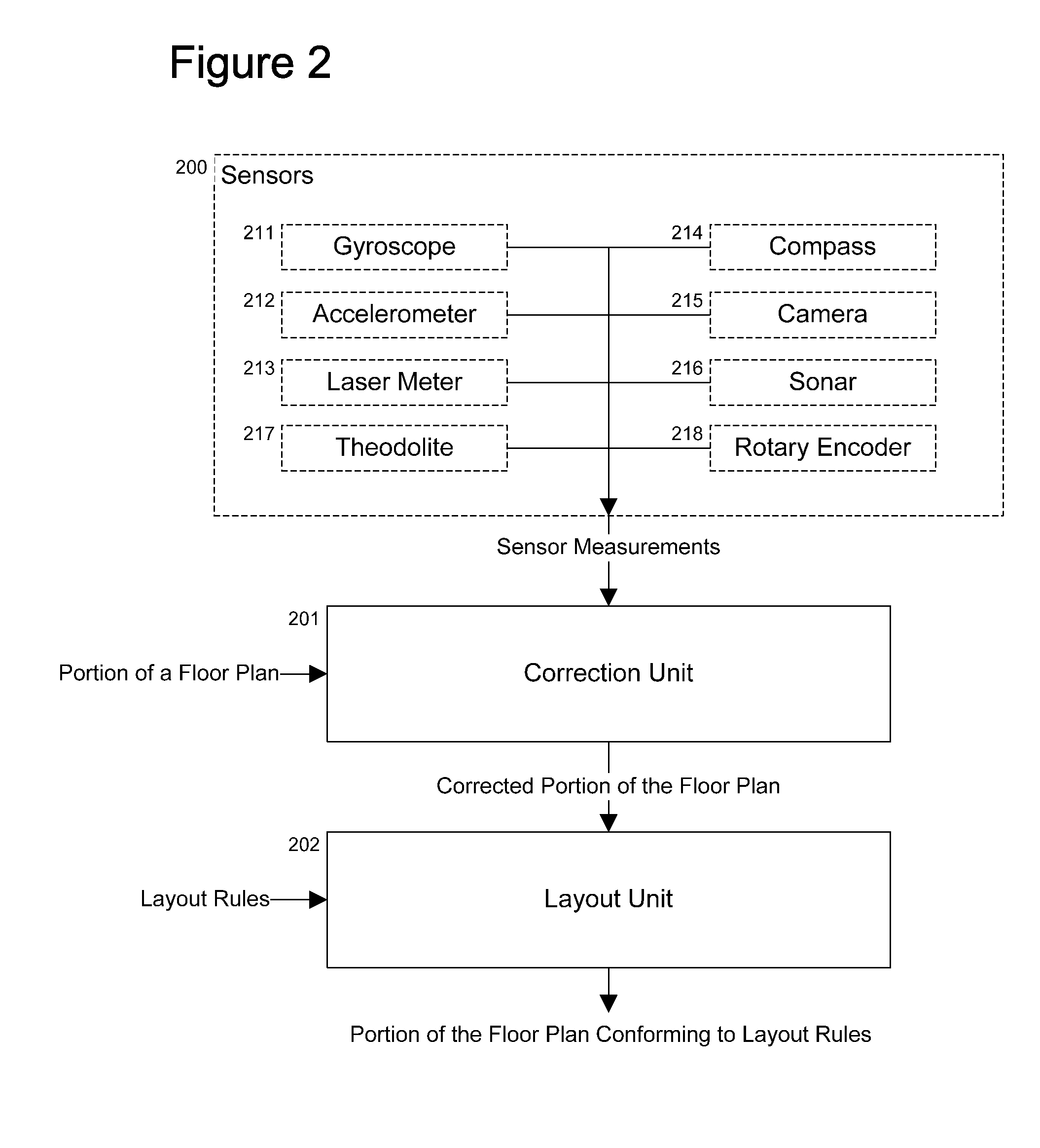

Apparatus, tool, and method for modifying a portion of a floor plan based on measurements made by one or more sensors

ActiveUS9151608B2Improve consistencyMaximizing symmetryGeometric CADNavigational calculation instrumentsBiomedical engineeringInstrument error

An apparatus, tool, and method for modifying a portion of a floor plan based on measurements made by one or more sensors. The apparatus comprises a correction unit for compensating the sensor measurements for instrument errors and a layout unit for improving the conformity of the portion of the floor plan to a set of layout rules. The apparatus may also comprise the sensors that made the measurements.

Owner:SENSOPIA

Method and apparatus for mura detection and metrology

Owner:MICRONIC LASER SYST AB

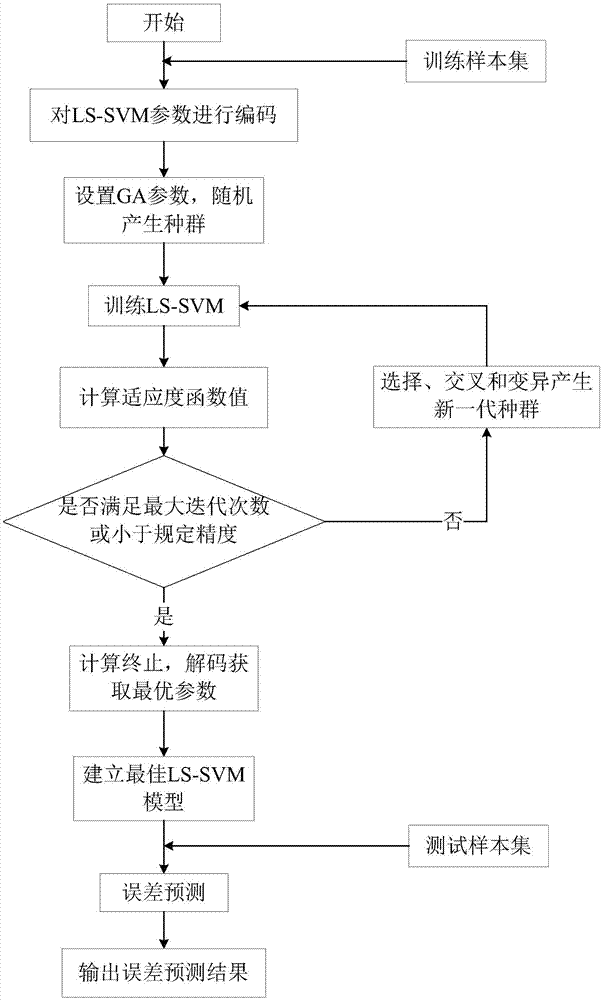

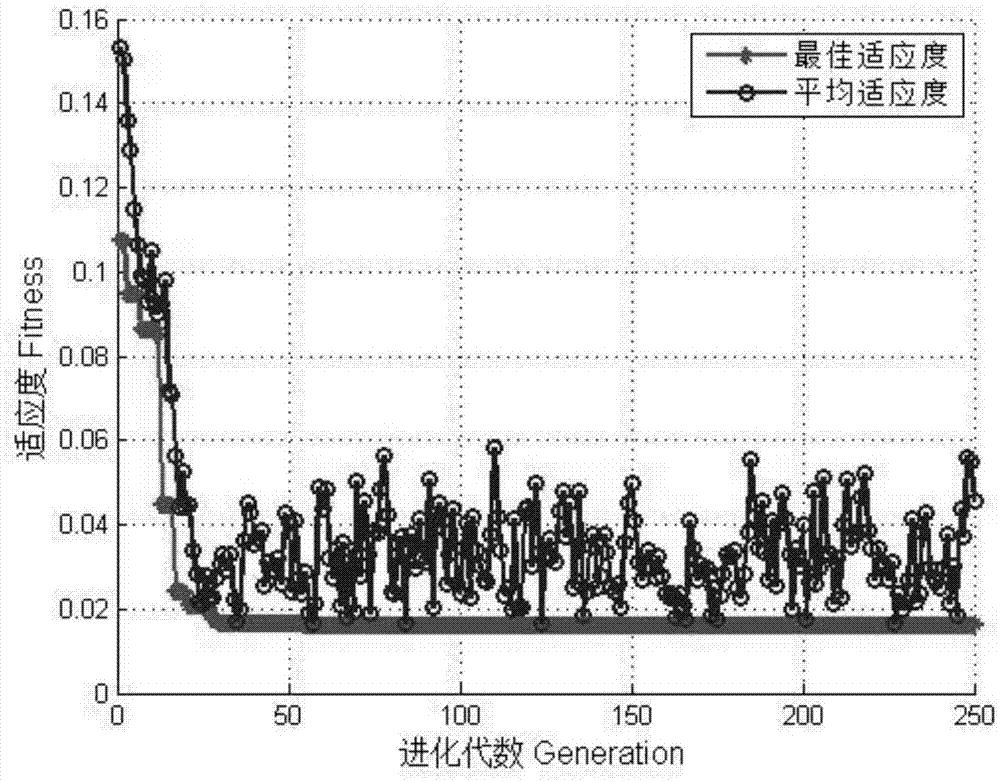

Mechanical temperature instrument error prediction method based on genetic-algorithm optimized least square support vector machine

ActiveCN105444923ASimplified Quadratic Programming ProblemReduce computing timeThermometer testing/calibrationData setAlgorithm

A mechanical temperature instrument error prediction method based on a genetic-algorithm optimized least square support vector machine is disclosed. The method comprises the following steps of (1) taking a tested characteristic parameter of a mechanical temperature instrument as model input, and taking an instrument error value and an error change rate acquired through sampling as model output; (2) carrying out pretreatment on original temperature error data; (3) selecting a Gauss radial kernel function as a kernel function of a least square support vector machine model; (4) using a genetic algorithm to optimize a parameter combination of the least square support vector machine; (5) constructing a mechanical temperature instrument error prediction model based on the genetic-algorithm optimized least square support vector machine; (6) inputting a data set and using a model obtained through training to carry out prediction; (7) comparing a temperature instrument error prediction result with an actual temperature error and analyzing a temperature error value and a change trend of a temperature error change rate. By using the method, precision is high; calculating is simple and engineering practicality is high.

Owner:邳州市润宏实业有限公司

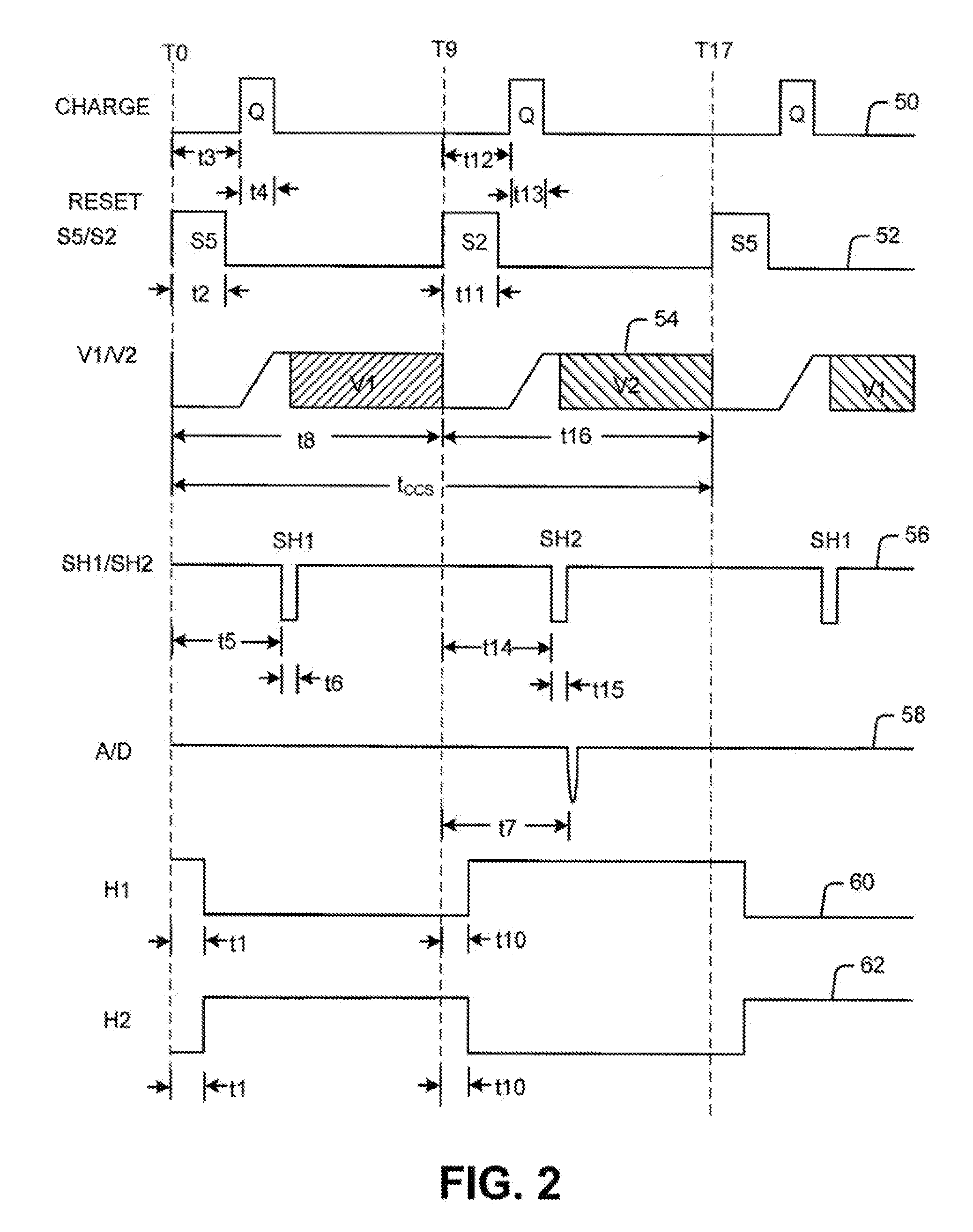

System and Method for Mitigating Errors in Electrostatic Force Balanced Instrument

ActiveUS20080295597A1Reduce errorsAcceleration measurement using interia forcesWeighing apparatus testing/calibrationElectrical polarityEngineering

System and method for mitigating errors in electrostatic force balanced instrument is provided. The system and method mitigate errors in measurement readings caused by charge buildup in force balanced instruments that employ charge pulses to generate an electrostatic force to null an inertial proof mass disposed between opposing electrodes. The system and method mitigate charge buildup by applying charge pulses to each opposing electrode of a sensing element for a given charge cycle time period in a normal polarity configuration followed by charge pulses to each opposing electrode of the sensing element for a second given charge cycle time period in a reverse polarity conjuration.

Owner:LITTON SYST INC

Apparatus, tool, and method for modifying a portion of a floor plan based on measurements made by one or more sensors

ActiveUS20120253725A1Improve consistencyMaximizing symmetryGeometric CADSurveying instrumentsBiomedical engineeringInstrument error

Owner:SENSOPIA

System and method for managing roadside parking spaces by means of linkage of radar and intelligent cameras

PendingCN107123303AHigh precisionReduce hidden dangersIndication of parksing free spacesWeather factorRadar

The invention relates to a system and method for managing roadside parking spaces by means of the linkage of a radar and intelligent cameras. According to the system and method, whether vehicles entering or leaving parking spaces exist is detected through the radar, the information of the vehicles entering or leaving the parking spaces is tracked and shot through an intelligent camera group; if the parking space entering or leaving information of the vehicles detected by the radar is consistent with the information of the vehicles tracked and shot by the intelligent camera group, a main controller sends the parking space entering or leaving information of the vehicles and the information of the vehicles to a data processing platform; and if the parking space entering or leaving information of the vehicles detected by the radar is inconsistent with the information of the vehicles tracked and shot by the intelligent camera group, the main controller sends an instruction to an enhancement processing module for secondary processing. According to the system and method of the invention, the radar, intelligent camera group and storage equipment are adopted to perform real-time monitoring on the roadside parking spaces, and therefore, hidden dangers caused by the inaccuracy of the information of the vehicles entering or leaving parking spaces due to factors such as instrument errors, shooting angles and weather factors can be eliminated, and the accuracy of parking management can be improved.

Owner:INTELLIGENT INTER CONNECTION TECH CO LTD

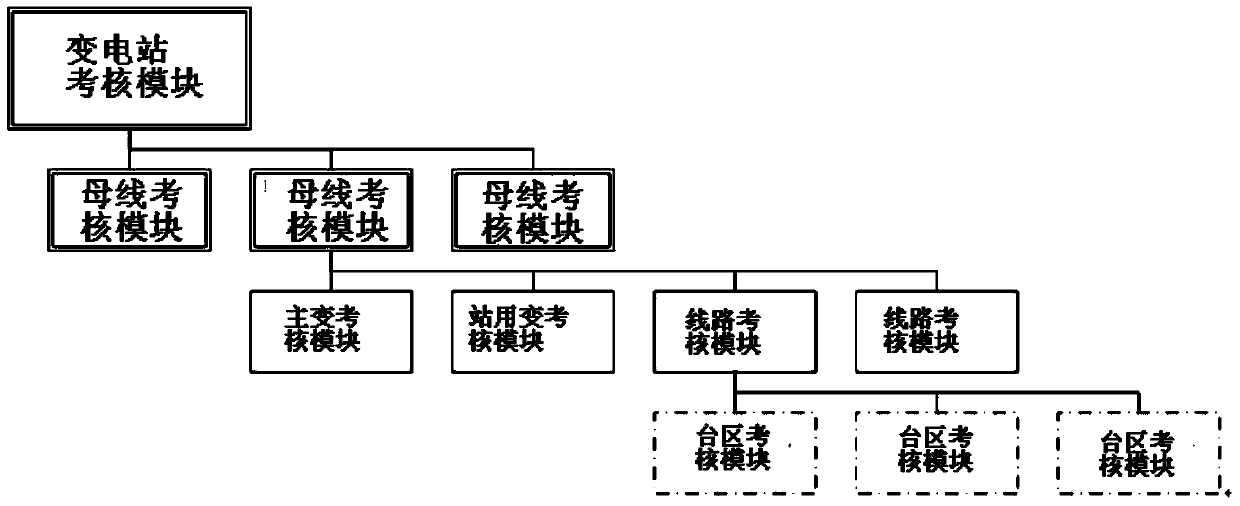

Online real-time calculation and analysis method of equipped wire loss

InactiveCN103995962ADoes not affect independent marketing line loss applicationsData processing applicationsElectrical testingAnalysis dataLow voltage

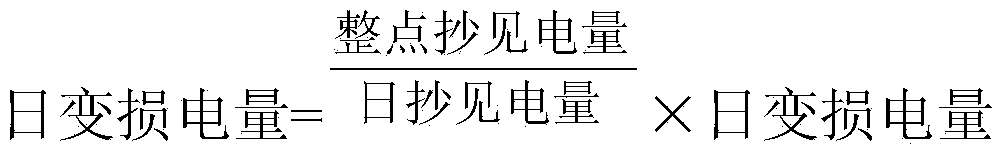

According to an online real-time calculation and analysis method of equipped wire loss, read electric quantity calculation and transformer power loss electric quantity calculation are performed, wherein an instrument error between an obtained collected integral point display number and a last integral point display number is multiplied by a multiplying power, and the read electric quantity of a main metering point is calculated; for electricity customers with a metering mode of high-voltage-side power supplying and low-voltage-side metering and without an examination meter on the high voltage side, when integral point electric quantity is calculated, the integral point transformer power loss electric quantity of a transformer is calculated according to user profiles and the type of the transformer based on the integral point read electric quantity; the read electric quantity of the main metering point is calculated according to the display number difference between an obtained collected daily zero point display number and a zero point display number of the last day is multiplied by the multiplying power. The online real-time calculation and analysis method has the advantages that the function of copying and reading data in real time is achieved, and the function becomes an important means for wire loss monitoring and analysis. Important analysis data such as instantaneous magnitude and alarming information are obtained, all system module data are integrated, high-speed calculation of mass data can be conducted independently, and independent marketing wire loss application of the function of an existing system is not affected.

Owner:STATE GRID CORP OF CHINA +1

Method and device for calibrating mobile phone production test system

InactiveCN104853021AGuaranteed accuracyQuick measurementSubstation equipmentGeneral purposeEngineering

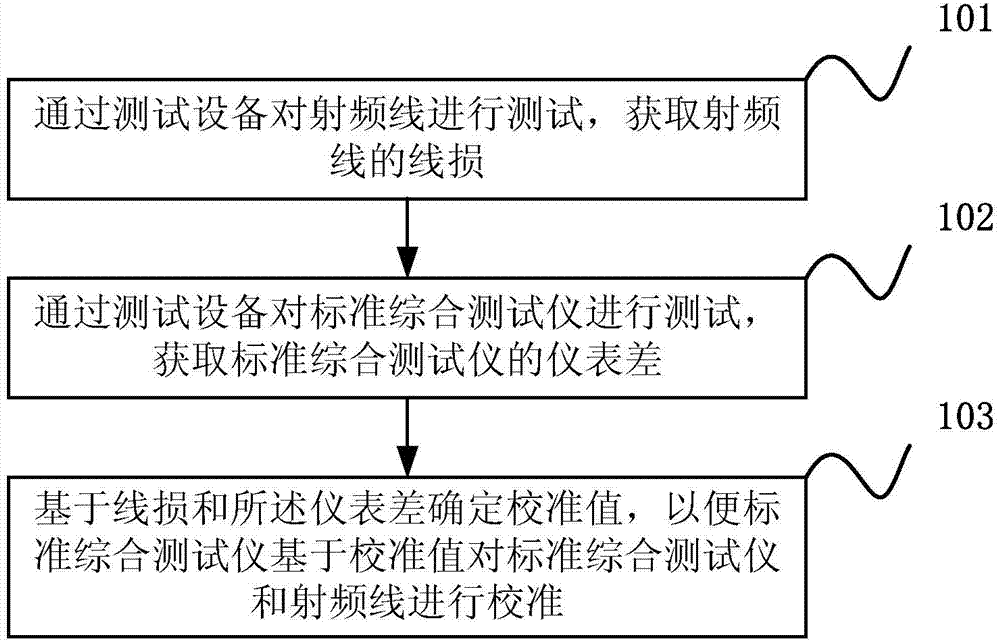

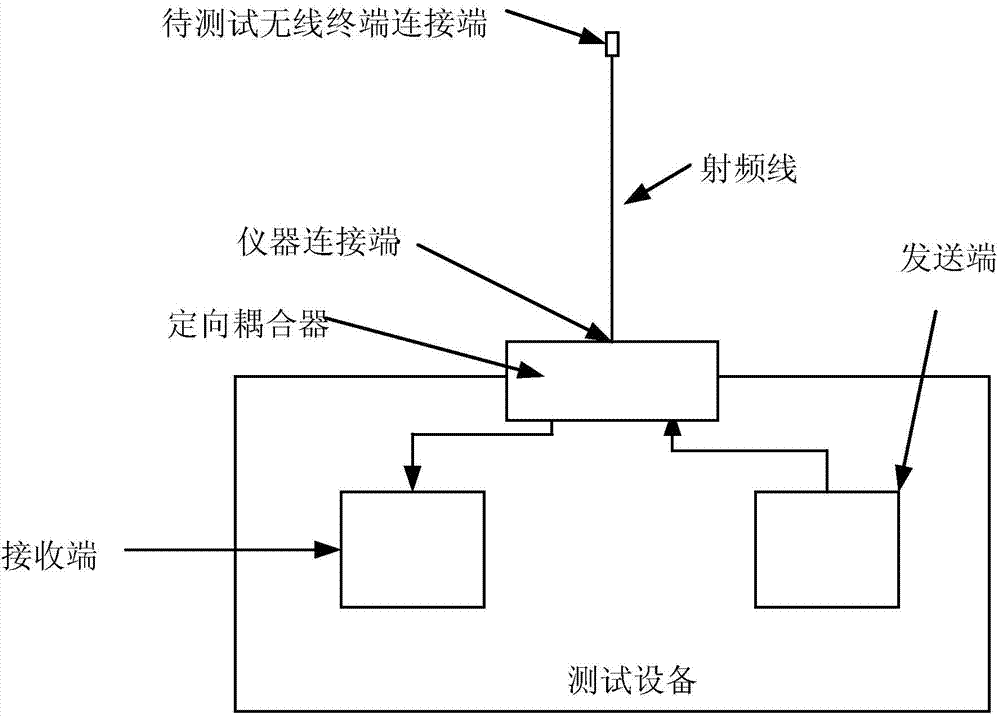

The invention discloses a method and a device for calibrating a mobile phone production test system. The method comprises: performing tests radio frequency lines through a test device, to obtain line loss of the radio frequency lines; performing tests on a standard general-purpose tester through the test device, to obtain instrument error of the standard general-purpose tester; and determining a calibration value based on the line loss and the instrument error, so that the standard general-purpose tester can calibrate the standard general-purpose tester and the radio frequency lines based on the calibration value, that is, the radio frequency lines and the standard general-purpose tester are calibrated through the test device. The device can rapidly measure while ensuring precision. The method and the device can be suitable for large-scale test wireless terminal systems.

Owner:WEIZHUN BEIJING ELECTRONICS TECH CO LTD

Sheet wheel flatness detection apparatus and method

ActiveCN105890550AQuick checkAutomatic detectionUsing optical meansInformaticsEngineeringGrinding wheel

The invention discloses a sheet wheel flatness detection apparatus and method. The sheet wheel flatness detection apparatus includes a frame, an object circular table, an XY axis slide unit, an XY axis slide unit driving mechanism, a laser displacement sensor, a data transmission system and an industrial computer, wherein the object circular table is arranged on the frame horizontally, and is in rotary connection of the upper surface of the frame; the XY axis slide unit is horizontally arranged on a frame platform; the laser displacement sensor is arranged on a moving piece of the XY axis slide unit; an output end of the laser displacement sensor is connected with an input end of the data transmission system; and the data transmission system is in communication connection with an industrial computer. The sheet wheel flatness detection apparatus and method utilize the high-accuracy measuring capability of the laser displacement sensor, and are integrated with an efficient data processing algorithm to realize quick, automatic and accurate detection of the sheet wheel flatness, and have the advantages of being quick and convenient in operation, effectively reducing the influence of a personal error and an instrument error on the detection result, being lower in the detection cost, and greatly improving the efficiency and accuracy for detection of the sheet wheel flatness.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

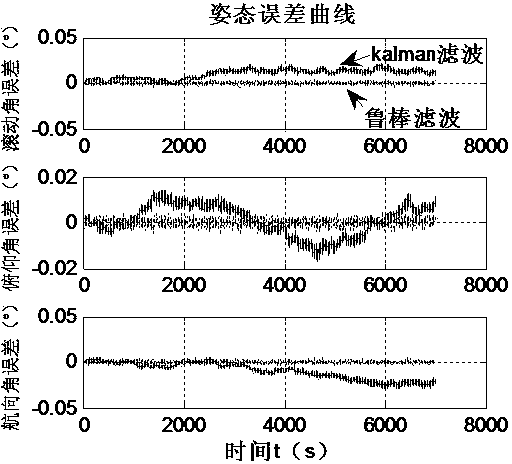

Aerospace vehicle combined navigation robust filtering method based on launching inertia coordinate system

InactiveCN104215244AAvoid affecting accuracyStable jobNavigational calculation instrumentsSimulationNavigation system

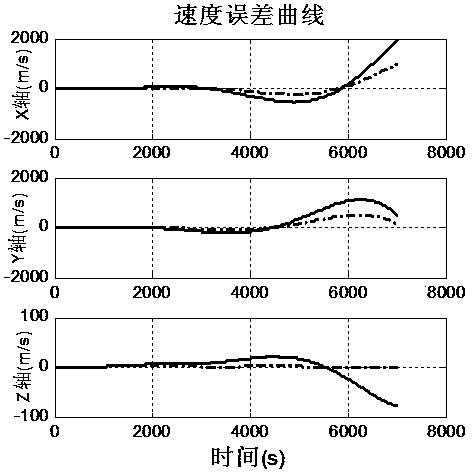

The invention discloses an aerospace vehicle combined navigation robust filtering method based on a launching inertia coordinate system, belonging to the technical field of air vehicle combined navigation. The aerospace vehicle combined navigation robust filtering method comprises the following steps of performing inertial navigation algorithm arrangement by taking the launching inertia coordinate system as a reference coordinate system, and constructing a position, speed and posture calculation model of an air vehicle under the launching inertia coordinate system; on the basis of the position, speed and posture calculation model, constructing an equation of navigation system error states including a basic navigation parameter error and an inertia instrument error, and obtaining a posture linear measurement equation through a conversion module according to original star sensor measurement information; and finally estimating and correcting all state values in the constructed state equation by the robust filtering method. According to the aerospace vehicle combined navigation robust filtering method disclosed by the invention, the influence, caused by a geophysical field, on the navigation system of the air vehicle can be effectively reduced; furthermore, under a condition that the navigation system model of the air vehicle is inaccurate, a filter can work stably; therefore, the precision of a combined navigation system is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

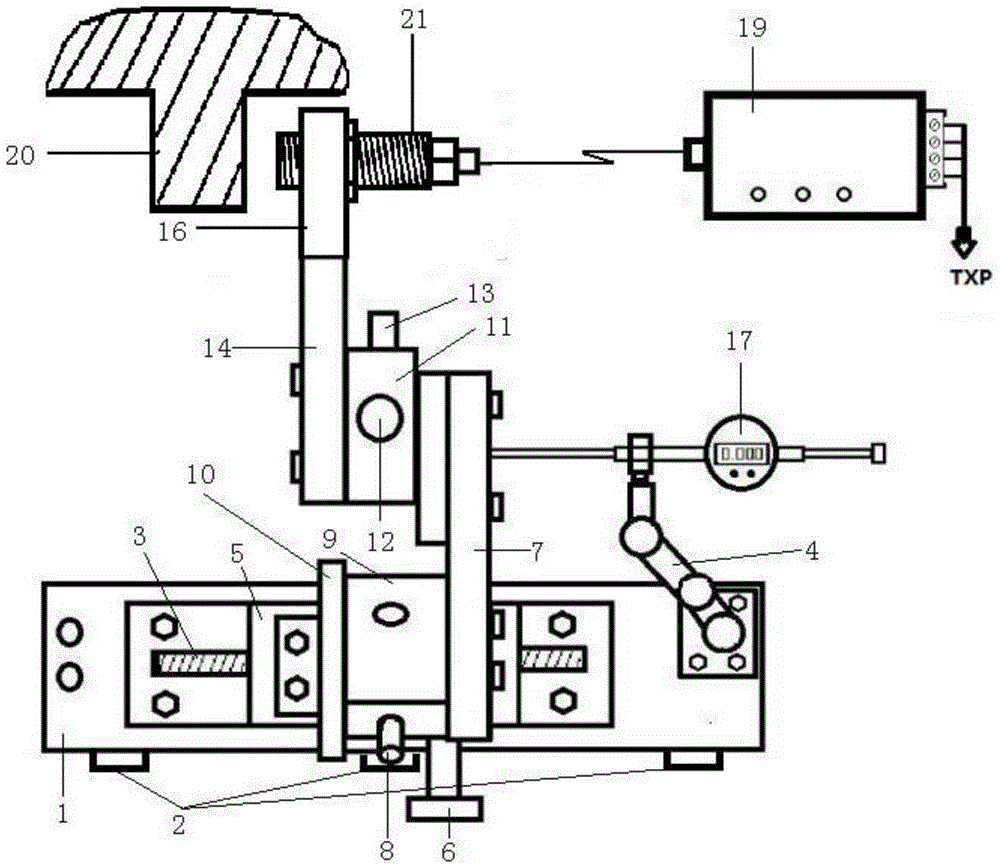

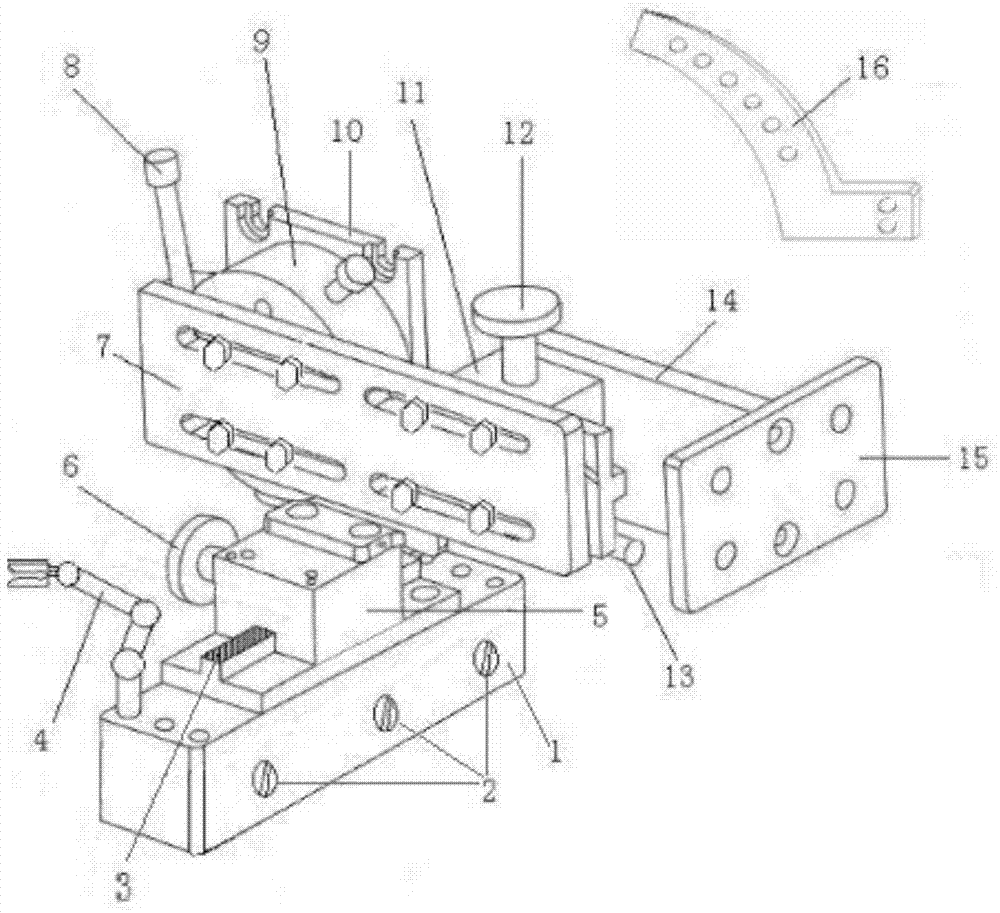

Steam turbine differential expansion and shaft displacement instrument portable verifying table

ActiveCN104897026AEasy to adjustSmall error precisionMechanical measuring arrangementsRotary stageMicrometer

The invention belongs to the field of nuclear power station instrument error verification and specifically relates to a steam turbine differential expansion and shaft displacement instrument portable verifying table for improving verification accuracy and reliability of steam turbine differential expansion and shaft displacement instruments. The steam turbine differential expansion and shaft displacement instrument portable verifying table comprises a magnetic pedestal, three locking switches, a guide rail, a dial indicator fixing arm, a translation table, a translation knob, a displacement table and rotating table connecting frame, a rotating table locking screw nut, a rotating table, a rotating table fixing frame, a displacement table, a displacement locking screw nut, a spiral micrometer knob, an instrument fixing module connecting support, a differential expansion instrument fixing module, a shaft displacement instrument fixing module, a dial indicator, a differential expansion instrument, a prepositioned device, a cam, and a shaft displacement instrument. The steam turbine differential expansion and shaft displacement instrument portable verifying table has beneficial effects of quickly and accurately adjusting a gap between the instrument and a steam turbine large shaft with error precision less than 0.1 mm; precisely controlling the moving stroke of the instrument and quickly completing total stroke; and achieving online verification of at least three shaft displacement so as to greatly improve work efficiency.

Owner:JIANGSU NUCLEAR POWER CORP

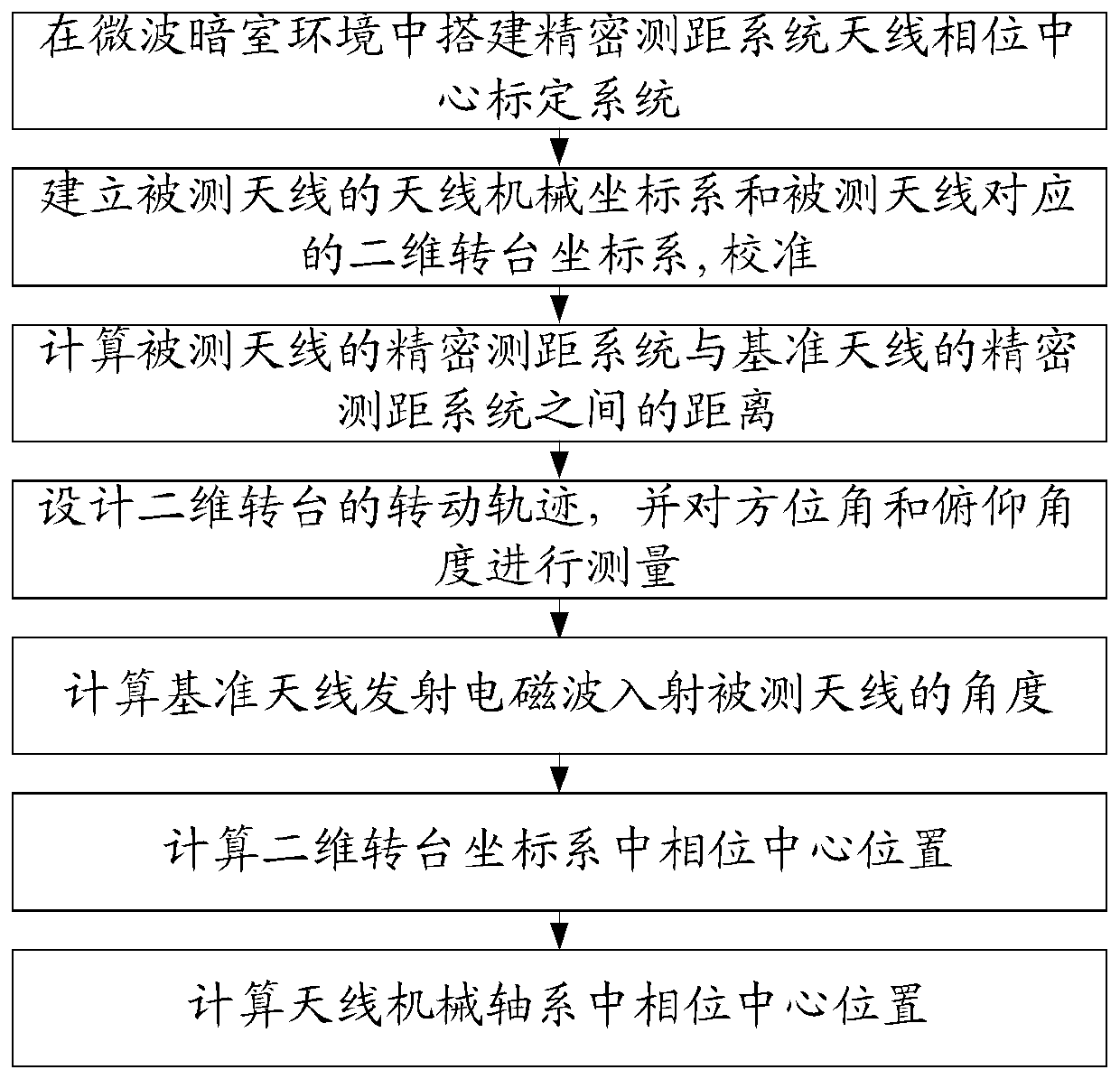

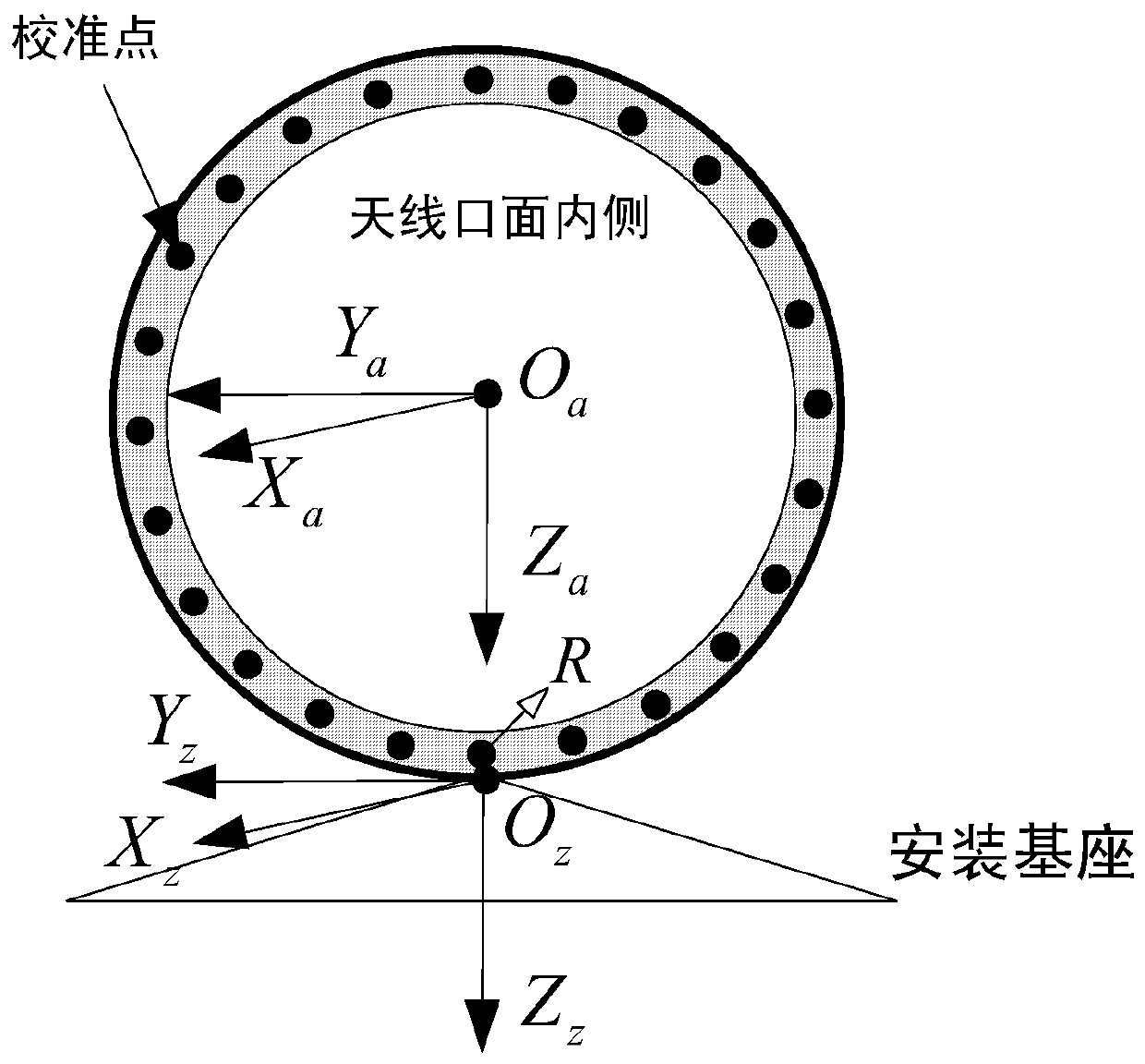

System calibration method for antenna phase center of precision ranging system

ActiveCN110618408ASolve technical problems of closed-loop calibrationThe method is simple and fastRadio wave reradiation/reflectionMicrowaveReference antenna

A system calibration method for an antenna phase center of a precision ranging system relates to the technical field of microwave measurement. The method includes the followings steps that of: step 1,establishing a calibration system of the antenna phase center of the precision ranging system in a microwave darkroom environment; step 2, establishing the antenna mechanical coordinate system of theantenna to be tested and the two-dimensional turntable coordinate system corresponding to the antenna to be tested, and calibrating; step 3, calculating the distance D between the precision ranging system of the measured antenna and the precision ranging system of the reference antenna; step 4, designing the rotation track of the two-dimensional turntable and measuring the azimuth and pitch angles; Step 5: Calculating the angle of the electromagnetic wave emitted by the reference antenna to the antenna to be tested; Step 6, calculating the phase center position in the coordinate system of thetwo-dimensional turntable; Step 7, calculating the phase center position in the antenna mechanical shafting. The invention reduces the error of the external auxiliary instrument and greatly improvesthe test accuracy, at the same time, the calibration method has the advantages of high automation degree, few auxiliary instruments outside the system, high test accuracy and simple and reliable method.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Attitude measurement method

PendingCN111878064AImprove ObservabilityAchieve best estimateSurveyNavigation by speed/acceleration measurementsGyroscopeHorizontal wells

The invention provides an attitude measurement method, relates to the technical field of directional drilling measurement while drilling, and aims to improve the observability of an inertial instrument error, inhibit the repeatability error of a gyroscope and improve the attitude measurement precision. According to the method, initial alignment is performed by adopting a method of respectively performing fine alignment at multiple positions. The method comprises the following steps of S1, taking the current attitude and speed data of the gyroscope as a first initial value, and performing finealignment at a first position; S2, enabling a strapdown inertial navigation system to be trans-positioned to the n position, and performing attitude and speed updating according to the last fine alignment result in the trans-positioning process; and S3, taking attitude updating and speed updating results as the n initial value, and performing n fine alignment at the n position to complete initial alignment of the strapdown inertial navigation system so as to realize attitude measurement. The scheme provided by the invention is suitable for horizontal attitude and azimuth measurement of a whole well inclined section of the horizontal well, and is especially suitable for attitude measurement application of directional drilling gyro measurement while drilling in large well inclined shafts and horizontal wells.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

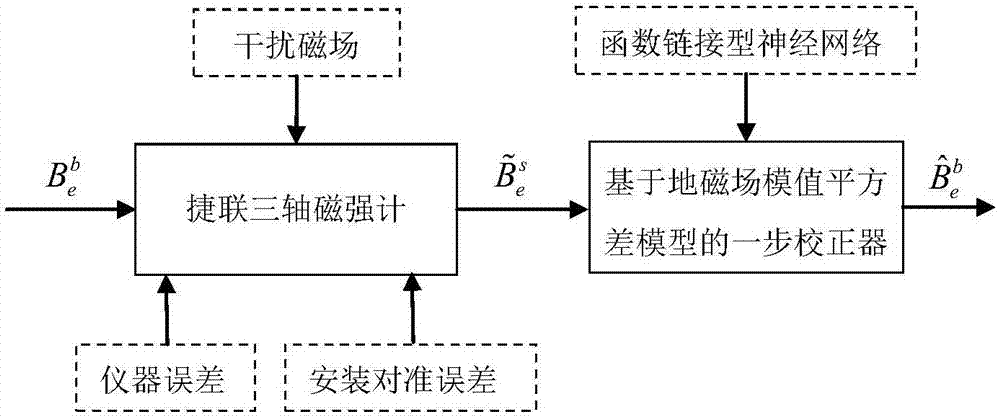

Strapdown three-axis magnetometer error one-step correction method based on functional link artificial neural network and field mode square difference

ActiveCN107290801AHigh measurement accuracyLow costNeural learning methodsElectric/magnetic detectionMeasurement precisionError correcting

The invention provides a strapdown three-axis magnetometer error one-step correction method based on a functional link artificial neural network and field mode square difference. The method comprises: establishing a measurement model of earth magnetic field module value square difference, dividing earth magnetic field measured data in different sensor attitudes into two groups, training a functional link artificial neural network which is formed by the measurement model of the field module square difference; using a neural network weight which is obtained by successful training to form an error corrector, performing error correction on instrumental errors, installation aligning errors, and disturbing magnetic fields of the three-axis magnetometer, to obtain a corrected earth magnetic field measured value. The method can further correct the instrumental errors, installation aligning errors, and disturbing magnetic fields of the strapdown three-axis magnetometer, improves measurement precision of the earth magnetic field, and has good robustness on measured noise in different levels. Using the correction method does not need auxiliary equipment to measure the earth magnetic field and carrier attitudes, and components of the error correcting device of thee strapdown three-axis magnetometer is simplified, and cost is reduced.

Owner:HARBIN ENG UNIV

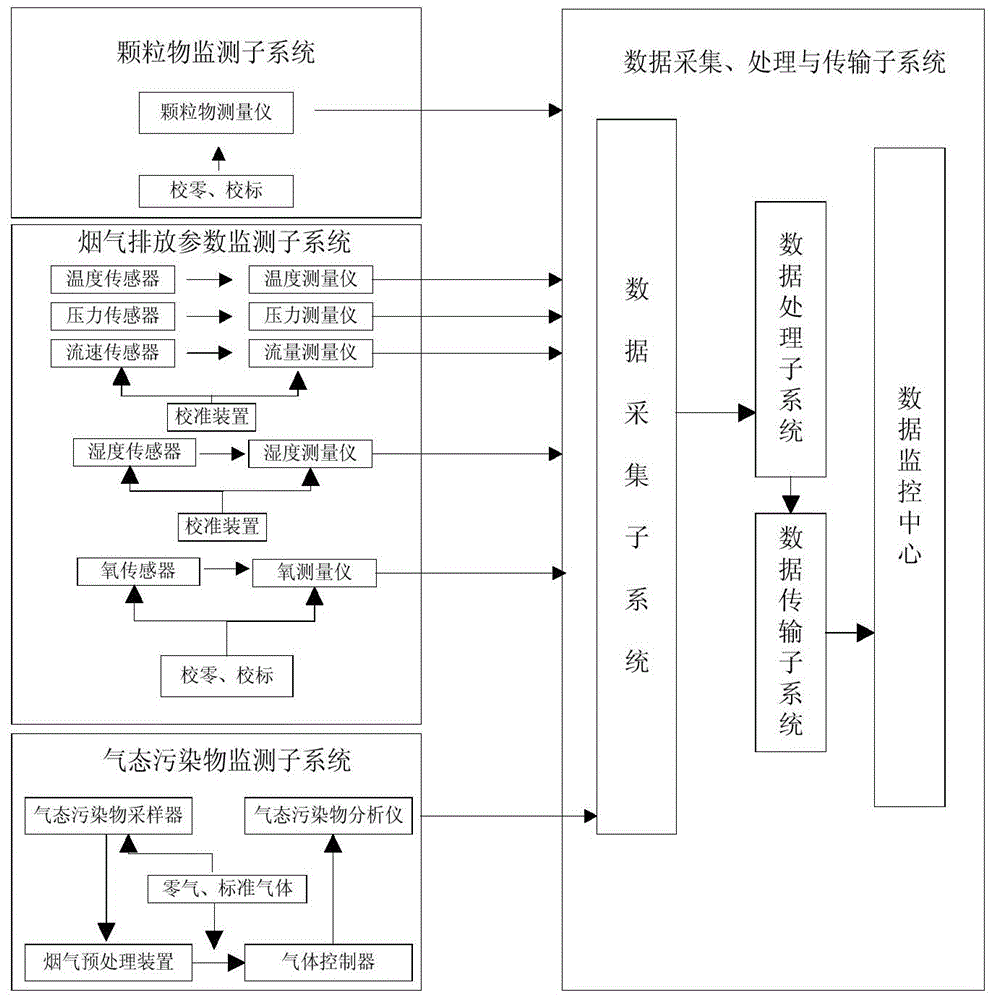

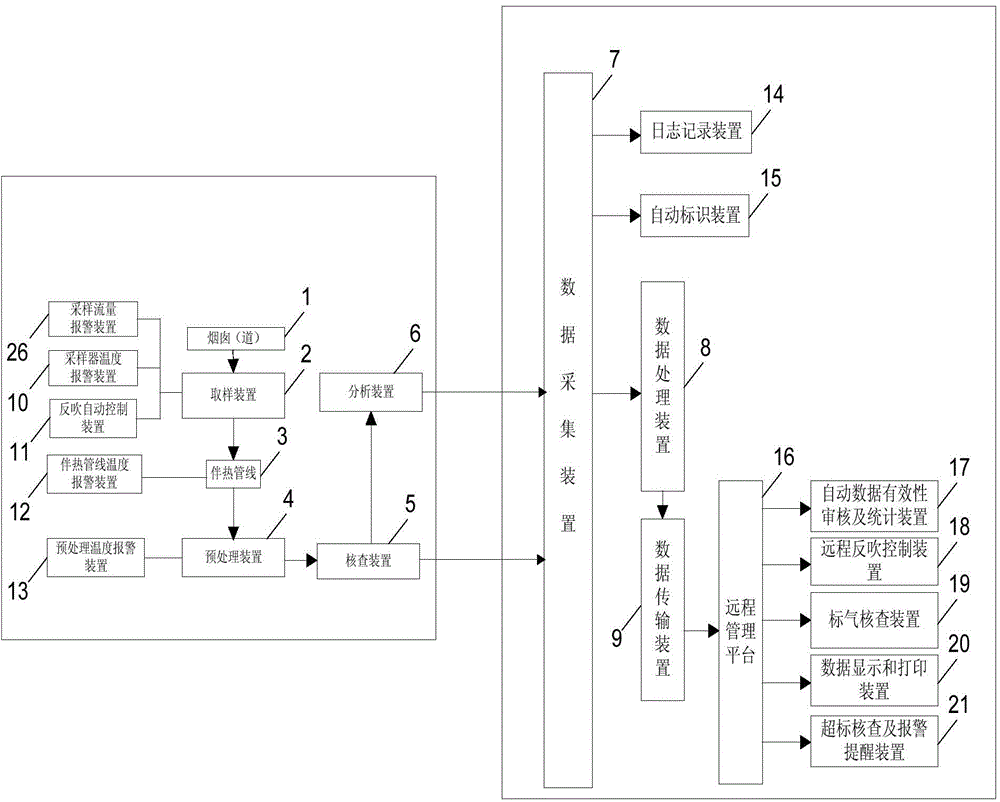

Continuous monitoring device for flue gas emissions and automatic verification method for validity of monitoring data

ActiveCN104678058AImprove data measurement accuracySolve technical problems that cannot prove the accuracy of measurement dataMaterial analysisFlue gasData acquisition

The invention discloses a continuous monitoring device for flue gas emissions and an automatic verification method for the validity of monitoring data. The device comprises a sampling device, a pretreatment device, an analysis device, a data acquisition device and a verification device, wherein the sampling device is connected with a flue, the pretreatment device is connected with the sampling device, the analysis device is connected with the pretreatment device, the data acquisition device and the verification device are connected with the analysis device, and a verification control device carries out automatic verification on the analysis device regularly and / or when the flue gas measured value monitored by the data acquisition device exceeds an emission limit value. According to the automatic verification method for the validity of monitoring data disclosed by the invention, through carrying out automatic verification on a gas analyzer regularly and / or when the flue gas measured value exceeds an emission limit value, and judging whether the instrument error of the gas analyzer is in an allowed range, valid data is identified, so that the technical problem that existing continuous monitoring devices for flue gas emissions can not evidence the accuracy of measurement data is solved, the evidencing to the accuracy of measurement data is realized, and the accuracy of data measuring of the continuous monitoring device for flue gas emissions is improved.

Owner:LIHE TECH (HUNAN) CO LTD

Method for fast detecting total nitrogen content in fertilizer

InactiveCN101153849ASuitable for rapid on-site determinationFast law enforcementMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationTotal nitrogenVisual examination

A quick detection method for total nitrogen content of fertilizer mainly includes the following steps: firstly, different standard contrasting solutions which are respectively corresponding to different nitrogen contents are prepared; secondly, sample contrasting solution is prepared and content of nitrogen in each form can be judged through contrasting the sample contrasting solution and each standard contrasting solution. The invention which can realize quick, simplified and highly sensitive detection is suitable for on-site quick determination by unprofessional staff; moreover, the invention can be used in on-site quick quantitative or semiquantitative detection of fertilizer quality by industrial and commercial authority, agricultural authority and quality and technical supervision administration, thereby realizing on-site quick law enforcement; meanwhile, the detection result realized by sample treatment and detection method of reagent is in excellent correlativity with national standard method; in addition, when instrument error is within +-1 percent, the error of visual examination during contrasting with a color card is within +-1.5 percent.

Owner:汤新华

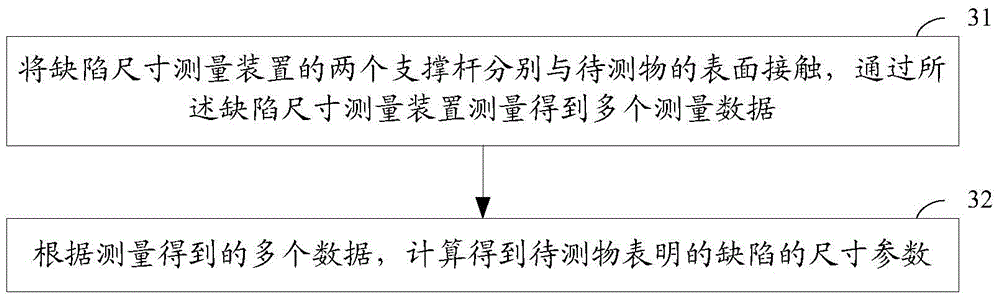

Defect size measurement device and method

InactiveCN104457565AHigh precisionReduce instrument errorUsing optical meansMeasurement deviceDefect size

The invention provides a defect size measurement device and method. The defect size measurement device comprises a ruler body, a laser displacement sensor and a data acquisition unit, wherein supporting rods perpendicular to the ruler body are arranged at the two ends of the ruler body; the upper end of the ruler body is provided with a linear guide rail in the extending direction of the ruler body; the front face of the ruler body is provided with multiple trigger knobs at preset intervals; the laser displacement sensor is arranged on the linear guide rail in a sliding mode; when the laser displacement sensor slides to the trigger knobs on the ruler body, the laser displacement sensor is triggered to measure the vertical distance between the current location and the surface of an object to be measured; the data acquisition unit is connected with the laser displacement sensor and stores data obtained by measurement of the laser displacement sensor. By the application of the defect size measurement device and method, the instrument error, installation error and operation error can be reduced effectively, it is ensured that measurement data are real and accurate, precision is high, and reliability is high.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

Leakage check method for main heat exchanger leakage of air separation plant

The invention relates to a leakage check method for the main heat exchanger leakage of an air separation plant. After an instrument error is removed and ice chest skimming sand is removed, the leakage check method comprises the following steps: sealing a liquid nitrogen inlet manifold at the bottom of a main heat exchanger and a high-pressure nitrogen gas discharging manifold at the top of the main heat exchanger; shutting off a high-pressure air manifold inlet valve at the top of the main heat exchanger and a high-pressure air manifold discharging valve at the bottom of the main heat exchanger; introducing high-pressure temporary leakage check nitrogen by the high-pressure air discharging manifold at the bottom of the main heat exchanger, wherein the pressure of the temporary leakage check nitrogen is above 3.2MPa; and finally, analyzing purity pollution. The method can be used for quickly and accurately judging which unit has air leakage, and therefore maintenance efficiency can be improved and loss brought by equipment faults is reduced.

Owner:ANHUI HUAIHUA

A method for determining that accident strategy value of a nuclear power plant base on the containment condition

ActiveCN109543941AGuaranteed safety marginMeet the design requirementsResourcesGuidelineNormal conditions

The invention belongs to the technical field of nuclear safety assessment and relates to a method for determining accident strategy value of a nuclear power plant based on a containment working condition. The method comprises the following steps: (1) determining a nominal value of a parameter fixed value in an accident handling strategy; (2) Judging and screening the key value of accident disposalstrategy; (3) Determining the instrument error of the key fixed value under the normal and unfavorable conditions of the containment; (4) Analyzing the influence of instrument error on accident handling guideline; (5) Calculation and verification of fixed value conformity analysis; (6) Verification and confirmation. A method for determining accident strategy value of nuclear power plant based oncontainment condition is disclosed, The instrument error under different containment conditions (normal condition and unfavorable condition) can be considered separately, and the influence of instrument error on the key fixed value in accident strategy can be optimized, and two sets of fixed value under normal condition and unfavorable condition can be obtained. Finally, whether the fixed value can meet the requirements of the criterion is judged by calculation and verification.

Owner:CHINA NUCLEAR POWER ENG CO LTD

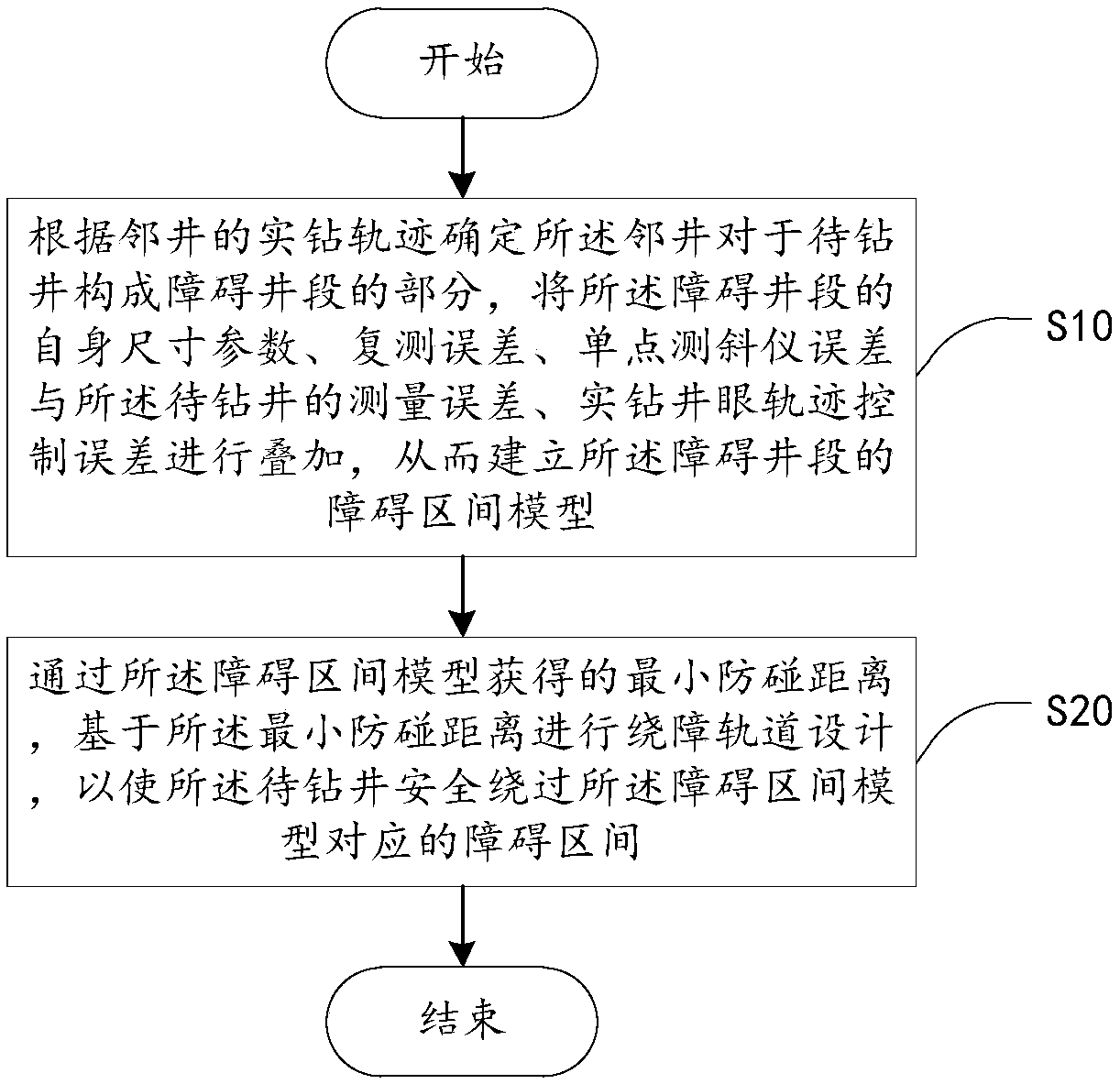

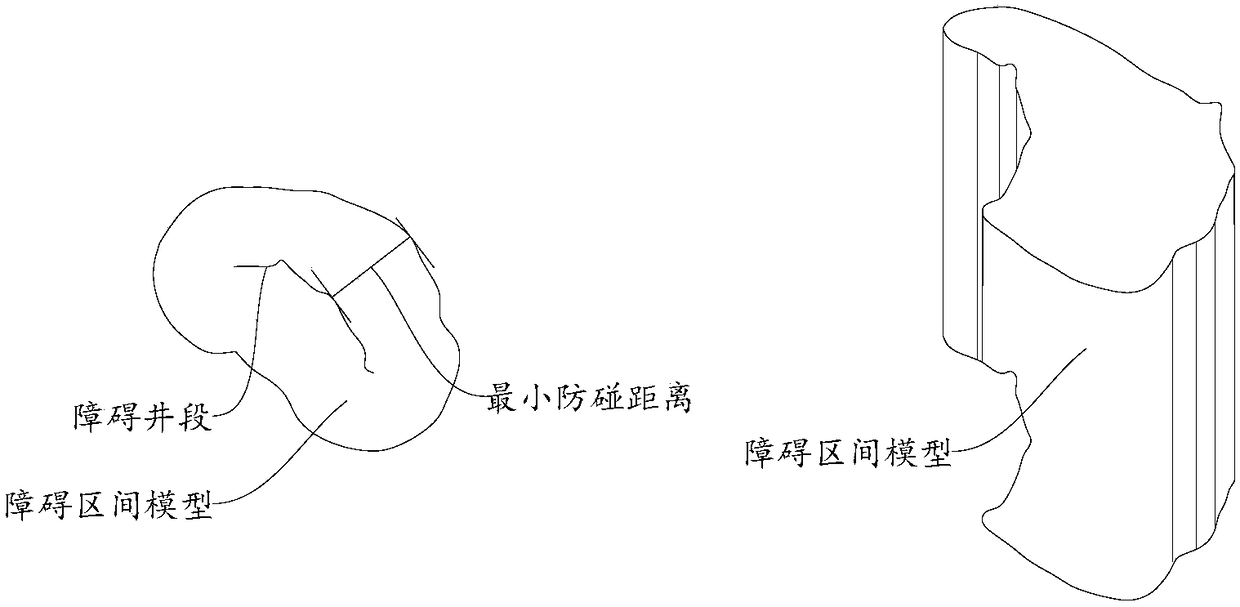

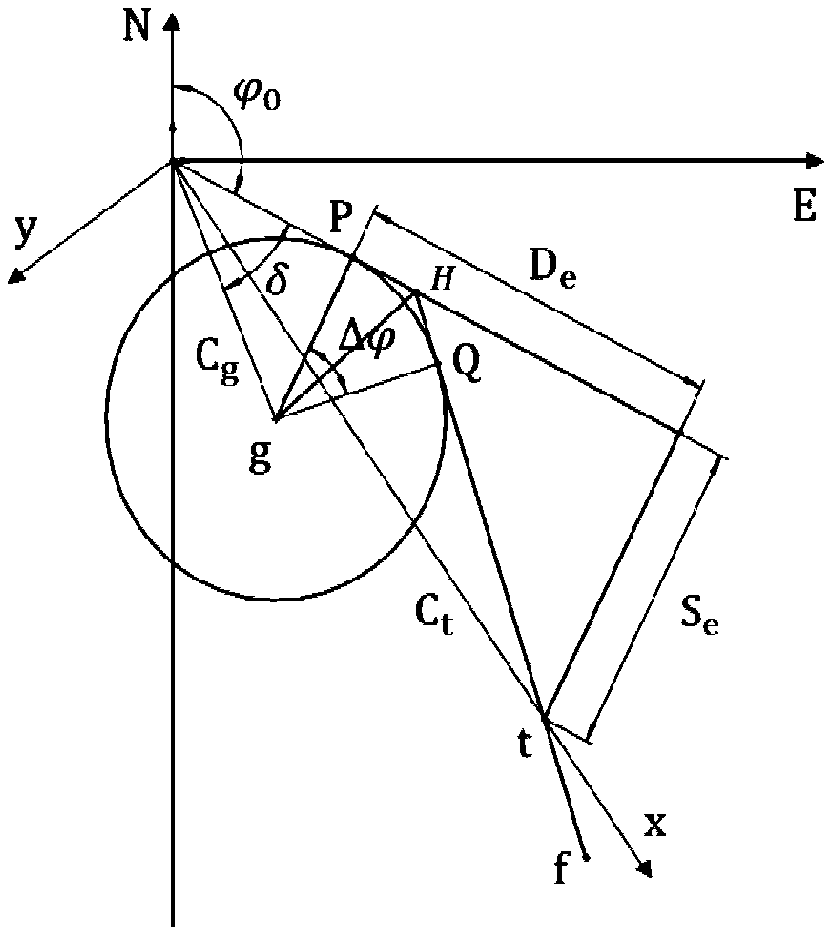

Three-dimensional barrier-bypassing well drilling design method and device, and computer storage medium

InactiveCN109139091AHigh precisionImprove securityDesign optimisation/simulationGas removalObservational errorWell drilling

The invention provides a three-dimensional barrier-bypassing well drilling design method and device, and a storage medium, and relates to the technical field of coalbed gas well drilling. The three-dimensional barrier-bypassing well drilling design method comprises the steps that the part of a barrier well section of an adjacent well to a to-be-drilled well is determined according to an actual drilling trajectory of the adjacent well, the self-size parameter, the repetition measurement error and the single shot instrument error of the barrier well section and the measurement error and the actual drilling well trajectory control error of the to-be-drilled well are superposed, and thus a barrier interval model of the barrier well section is established; and the minimum anti-collision distance is obtained through the barrier interval model, and a barrier-bypassing track is designed based on the minimum anti-collision distance, so that the to-be-drilled well safely bypasses a barrier interval corresponding to the barrier interval model. According to the three-dimensional barrier-bypassing well drilling design method, the barrier interval model is established through error superposition, thus the minimum anti-collision distance is more accurate, accordingly the barrier-bypassing well section is effectively shortened, and the safety factor of barrier-bypassing well drilling is increased.

Owner:李鹏飞

A Portable Calibration Platform for Steam Turbine Differential Expansion and Shaft Displacement Instrument

ActiveCN104897026BEasy to adjustSmall error precisionMechanical measuring arrangementsRotary stageDifferential pressure

The invention belongs to the field of instrument error calibration in nuclear power plants, and specifically relates to a portable calibration platform for steam turbine differential expansion and axial displacement instruments that improves the calibration accuracy and reliability of steam turbine differential expansion and axial displacement instruments; it includes a magnetic base, 3 Locking switch, guide rail, fixed arm of dial indicator, translation stage, translation knob, connecting frame between translation stage and rotation stage, rotation stage lock nut, rotation stage, rotation stage fixing frame, translation stage, displacement lock nut, screw gauge Micro-knob, instrument fixing module connection bracket, differential expansion instrument fixing module, shaft displacement instrument fixing module, dial indicator, differential expansion instrument, front-end device, cam and shaft displacement meter; the beneficial effects of the present invention are: fast and accurate adjustment The gap between the instrument and the large shaft of the steam turbine, the error accuracy is less than 0.1mm; the stroke of the instrument can be accurately controlled and the full stroke can be completed quickly; the displacement of at least three axes can be verified online at the same time, which greatly improves the work efficiency.

Owner:JIANGSU NUCLEAR POWER CORP

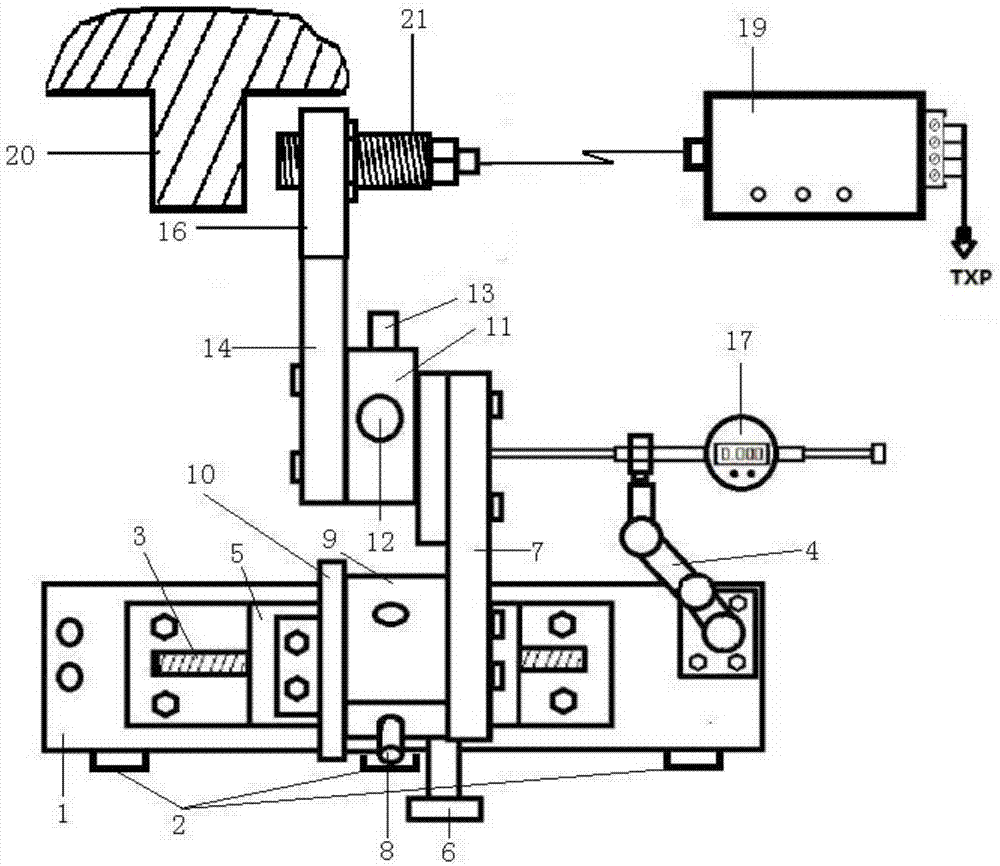

Chemical mechanical polishing method, chemical mechanical polishing system, and manufacturing method of semiconductor device

InactiveUS7234998B2Improve accuracyEasy to set upVacuum evaporation coatingSputtering coatingSemiconductorMaterials science

Setting a polishing rate and a polishing time in chemical mechanical polishing can be performed with high accuracy by considering a product wafer of an object to be polished, and an instrumental error between apparatuses to be used, etc. By using, as a calculating formula, a formula well approximating a portion of a curve representing a state of chemical mechanical polishing on a side showing a target polishing amount, the polishing rate and the polishing time can be set with high accuracy according to a state of chemical mechanical polishing for actually polishing a product wafer. In the calculating formula, a parameter “A” relating to a film property of a film of an object to be polished, a parameter “B” relating to a roughness state of a film surface, and a parameter “C” relating to an instrumental error differential between apparatuses of a chemical mechanical polishing apparatus are joined by operators.

Owner:TRECENTI TECHNOLOGIES INC

Method for determining output value of quartz accelerometer of inertial platform system

ActiveCN109029502AThe calculation method is accuratePerfect calculation methodMeasurement devicesAccelerometerError coefficient

The invention provides a method for determining an output value of a quartz accelerometer of an inertial platform system. The method comprises the following steps: 1, measuring an initial alignment angle between a geographic coordinate system and a carrier coordinate system of the inertial platform system; 2, measuring rotation angles of a platform body axis, an inner frame axis and an outer frameaxis of the inertial platform system; 3, giving each of the error coefficient values of the quartz accelerometer; and 4, taking each of the error coefficient values into an output value calculation formula of the quartz accelerometer to obtain an output value of the quartz accelerometer. The method takes each of the known error coefficients of the quartz accelerometer into a new output value calculation formula of the quartz accelerometer for calculation to obtain the output value of the quartz accelerometer. Compared to the traditional calculation method, the method provided by the inventioncomprehensively considers the influence of the platform system errors and the quartz meter's own instrument errors on the output value of the quartz accelerometer, which makes the output value of thequartz accelerometer more accurate, provides convenience for the error compensation for the quartz accelerometer, and is wide in applications.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

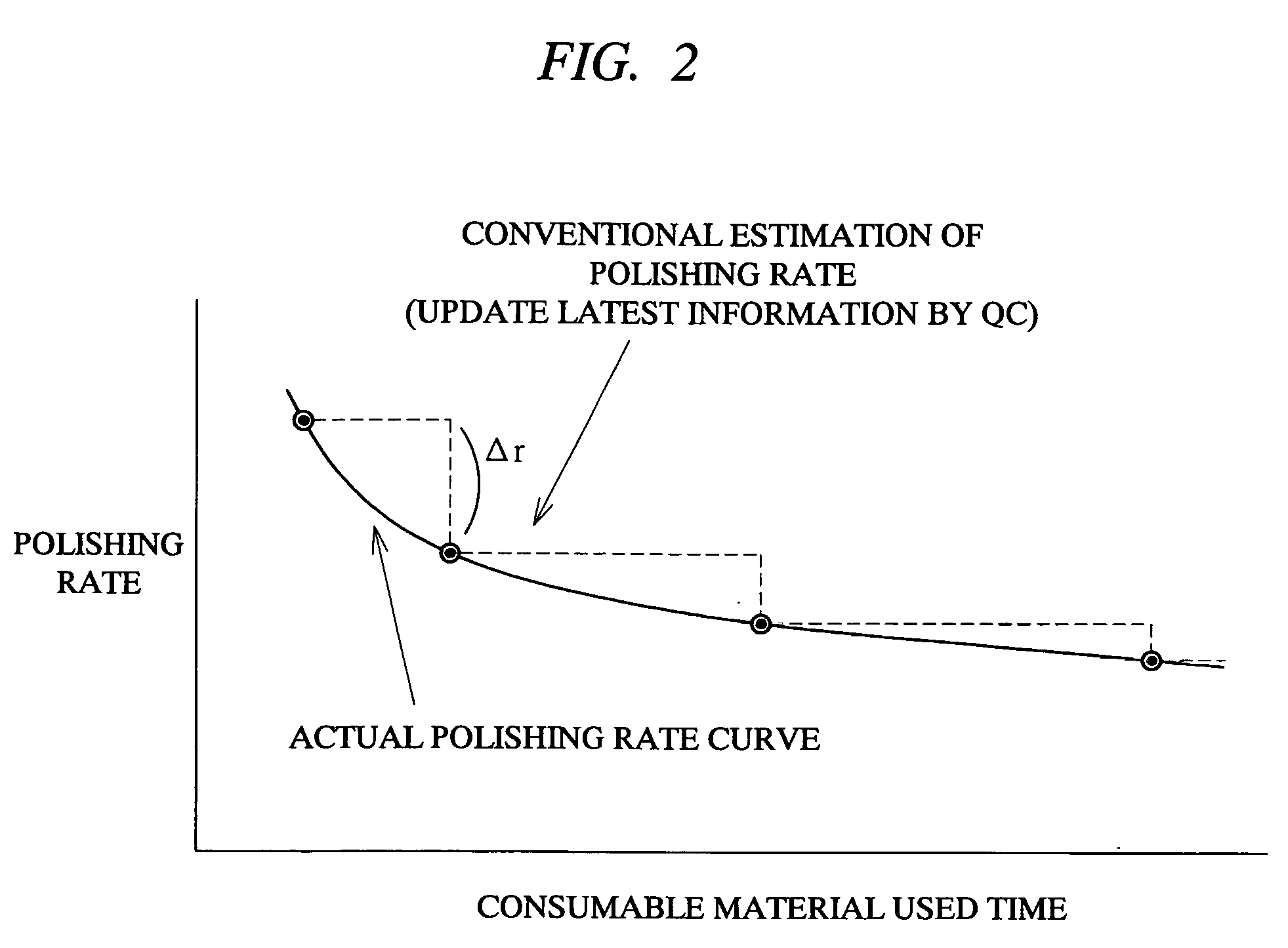

Method for processing data for drawing equal fuel consumption curve of universal characteristic of diesel engine

ActiveCN105160072AEasy to drawImprove consistencySpecial data processing applicationsDiesel engineInstrumentation

The invention provides a method for processing data for drawing an equal fuel consumption curve of a universal characteristic of a diesel engine. The method comprises the following multiple steps of: 1) data arrangement based on rotational speed parameter regularization; 2) descending sorting of data according to a principle of first-rotational speed and last-torque; 3) torque percent calculation and irregular data deletion at each rotational speed; 4) exception judgment and deletion of fuel consumption rate data; 5) torque based fuel consumption value trend fitting and interpolation replacement; and 6) data forming. Compared to the prior art, the method has the following advantages: the data for invalidly drawing the equal fuel consumption curve can be deleted, so that irregular change of a fuel consumption rate value caused by instrument errors is avoided and convenience is provided for various drawing tools to draw a more reasonable equal fuel consumption curve with relatively good consistency.

Owner:CHINA NORTH ENGINE INST TIANJIN

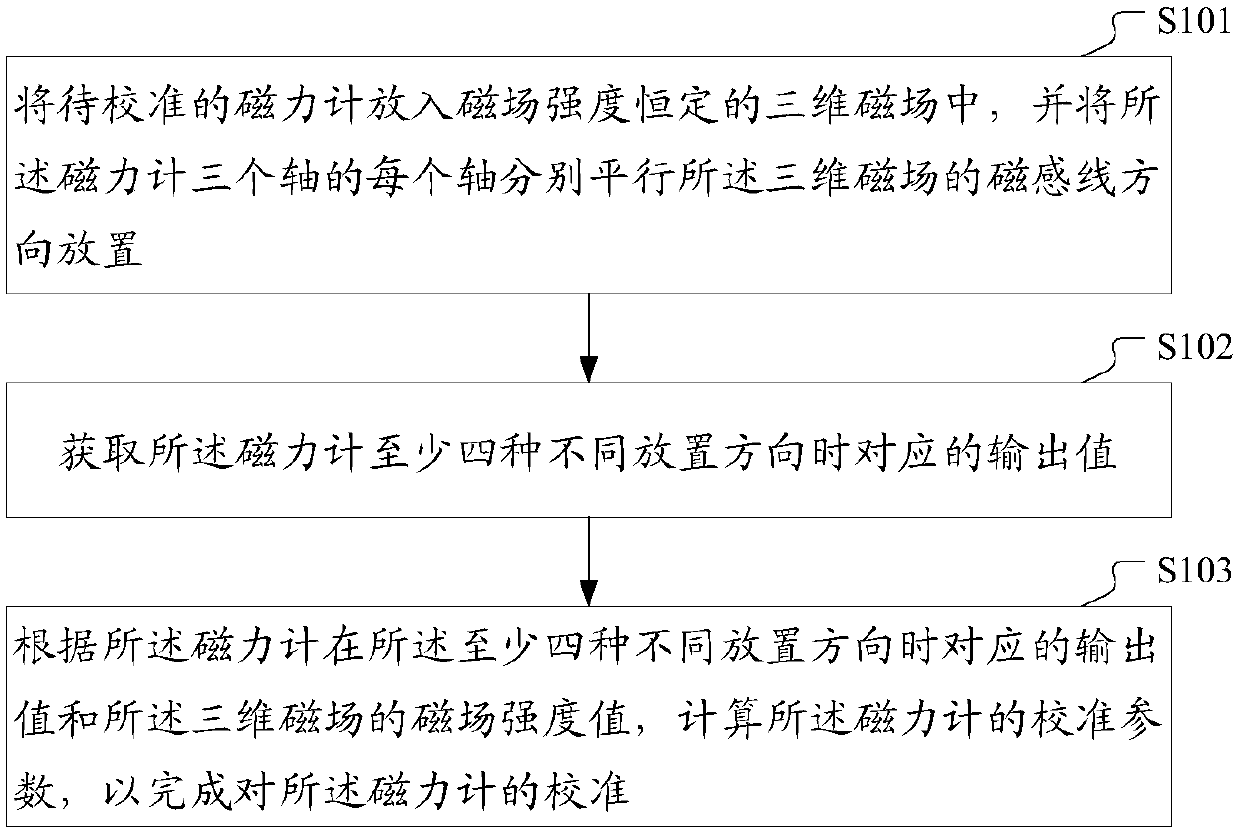

Magnetometer calibration method and device

ActiveCN107861084AEliminate instrument errorsThe calibration experiment environment is stableMagnetic measurementsElectrical measurementsCondensed matter physicsInstrument error

The invention discloses a magnetometer calibration method. The method comprises the steps of placing a magnetometer to be calibrated in a three-dimensional magnetic field with the magnetic field strength being constant, and respectively enabling each of the three axes of the magnetometer to be placed in a mode of being parallel to a magnetic induction line direction of the three-dimensional magnetic field; acquiring output values corresponding to at least four different placement directions of the magnetometer; and calculating a calibration parameter of the magnetometer according to the outputvalues corresponding to at least four different placement directions of the magnetometer and a magnetic field strength value of the three-dimensional magnetic field so as to complete calibration forthe magnetometer. The magnetometer calibration scheme disclosed by the invention is stable in calibration implementation experimental environment, comprehensive in calibration parameter and higher inaccuracy and calibration speed compared with a single-axis calibration scheme, can eliminate an instrument error of the magnetometer and achieves chip-level three-axis simultaneous calibration for themagnetometer.

Owner:GEER TECH CO LTD

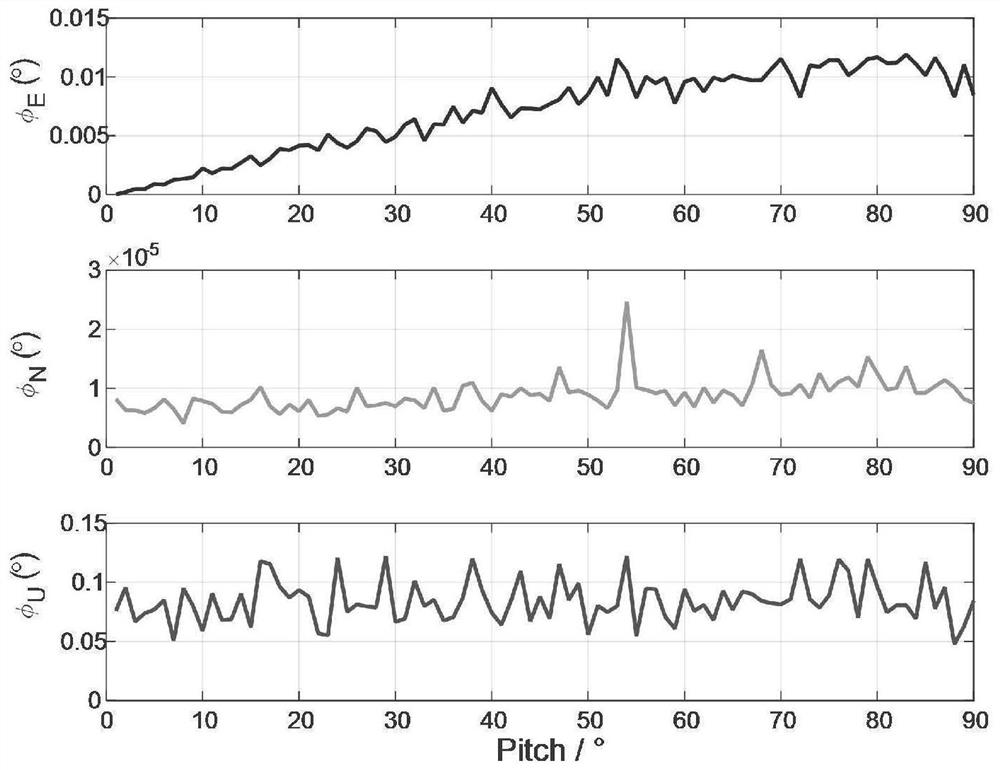

Method for measuring and analyzing measurement error of biomimetic polarized navigation carrier

ActiveCN105928543AMaximize utilizationUnlimited timeNavigational calculation instrumentsObservational errorStatistical physics

The invention discloses a method for measuring and analyzing the measurement error of a biomimetic polarized navigation carrier. The method comprises the following steps: (1) arranging a plurality of carriers in a preset area, obtaining the relative azimuth angles between carriers, and taking the relative azimuth angles as the baseline of measuring true value of biomimetic polarized navigation carriers; (2) subjecting each carrier to t-th power azimuth angle measurement and calculation to obtain a set of measured azimuth angle values; (3) changing the preset area, rearranging the carriers, and repeating the step (2) to obtain another set of measured azimuth angle values; (4) repeating step (3) for several times, then calculating the data obtained in the step (2) and (3) to obtain the statistic error (L'kjt) of each carrier; (5) calculating the statistic error (L'kjt) obtained in the step (4), separating the random errors and instrument errors, and evaluating the error of the biomimetic polarized navigation carrier according to the error parameter values of random errors and instrument errors. The provided method can complete large and complicated calculation task high efficiently.

Owner:PEKING UNIV

Legal instrument error correction result optimization method and device

The invention discloses a legal instrument error correction result optimization method and device, and the method comprises: recording user operation information for each error point after the error correction of a legal instrument and the generation and display of a modification prompt of each error point in the legal instrument; extracting an optimizable item from the recorded error points; forthe optimizable item, carrying out statistics on user operation information to obtain a feedback adjustment parameter value of the optimizable item; and when the feedback adjustment parameter value meets the optimization processing condition, performing optimization processing on the corresponding optimizable item according to the optimization processing method corresponding to the feedback adjustment parameter value. The feedback adjustment parameter value of each optimizable item is obtained by recording and counting the user operation information of the optimizable item, and the corresponding optimizable item is optimized when the feedback adjustment parameter value meets the optimization processing condition, so that the error correction accuracy of the system on legal documents is improved.

Owner:BEIJING GRIDSUM TECH CO LTD

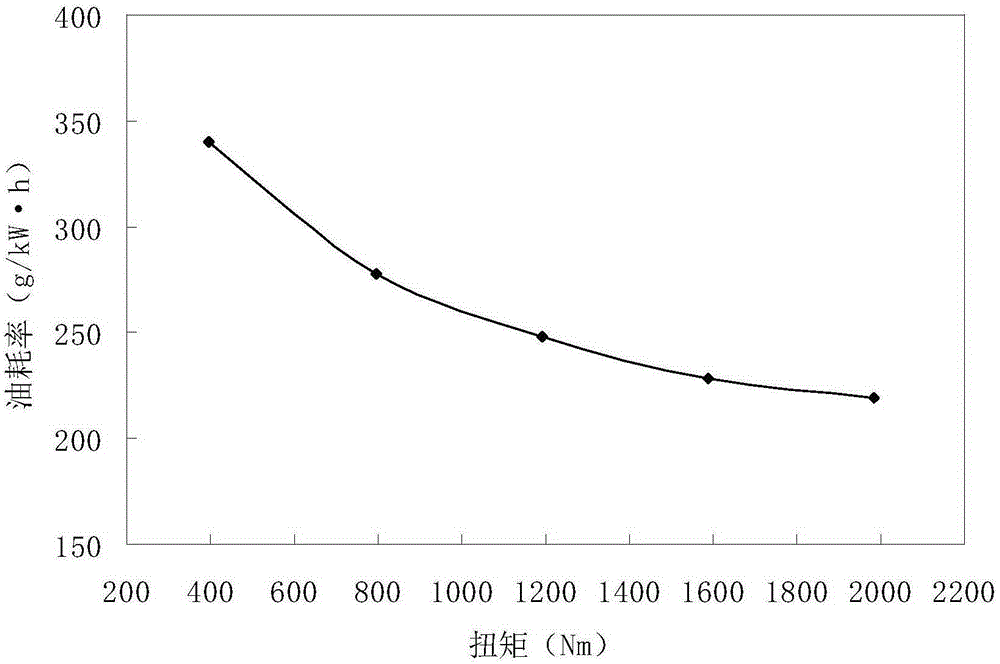

Steam turbine differential expansion and valve position instrument verifying device

ActiveCN104897025ASolve the problem of not being able to complete the verificationSolve the accuracy problemMechanical measuring arrangementsNuclear powerControl line

The invention belongs to the field of nuclear power station instrument error verification and relates to a steam turbine differential expansion and valve position instrument verifying device. The steam turbine differential expansion and valve position instrument verifying device achieves convenient and fast verification operation of differential expansion and valve position instruments, ensures accurate and reliable steam turbine differential expansion and valve position instrument verification, improves maintenance efficiency of steam turbine displacement instruments, and guarantees stable operation of a unit. The steam turbine differential expansion and valve position instrument verifying device comprises a verifying assembly, a control box, a portable computer, a USB data line, a control line, a universal adjusting support, a standby clamp C, and a locking handle C. The verifying assembly is connected with the control box through a control line. The control box is connected with the portable computer through the USB data line. The standby clamp C and the locking handle C are installed on the verifying assembly.

Owner:JIANGSU NUCLEAR POWER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com