Light spot machine debugging system and light spot machine debugging method for medium/long-working-distance single-mode single-fiber collimators

A technology of working distance and debugging system, which is used in optical instrument testing, testing of optical fiber/optical waveguide equipment, and testing of machinery/structural components, etc. The effect of debugging accuracy, high pair-matching, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

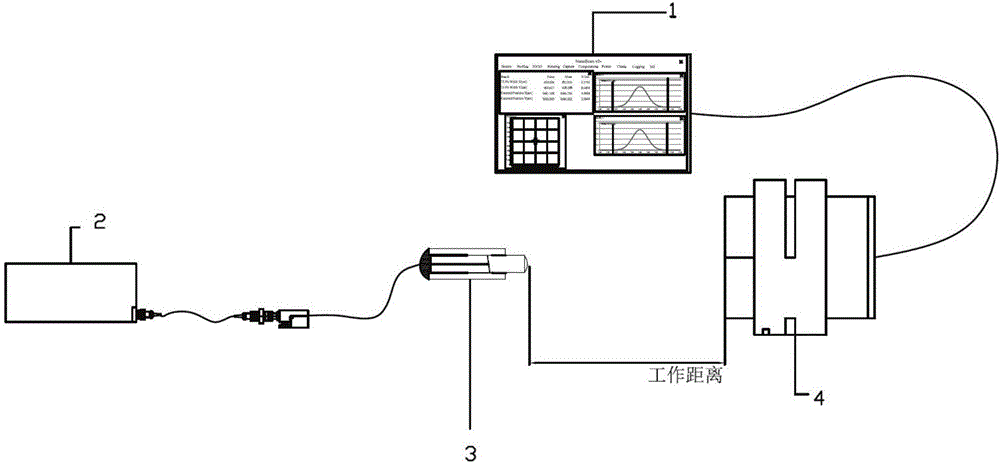

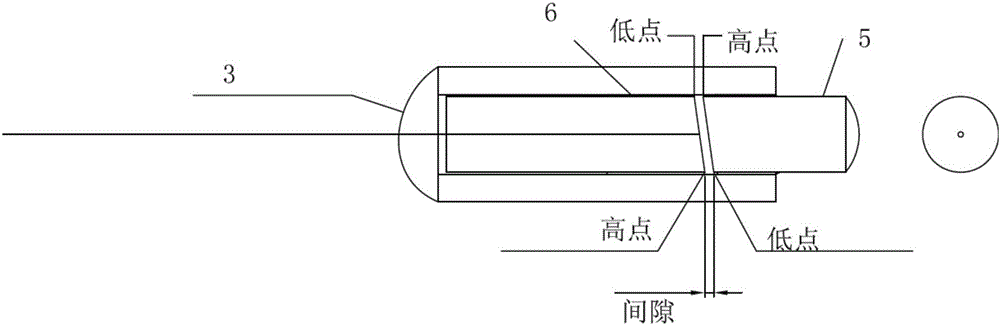

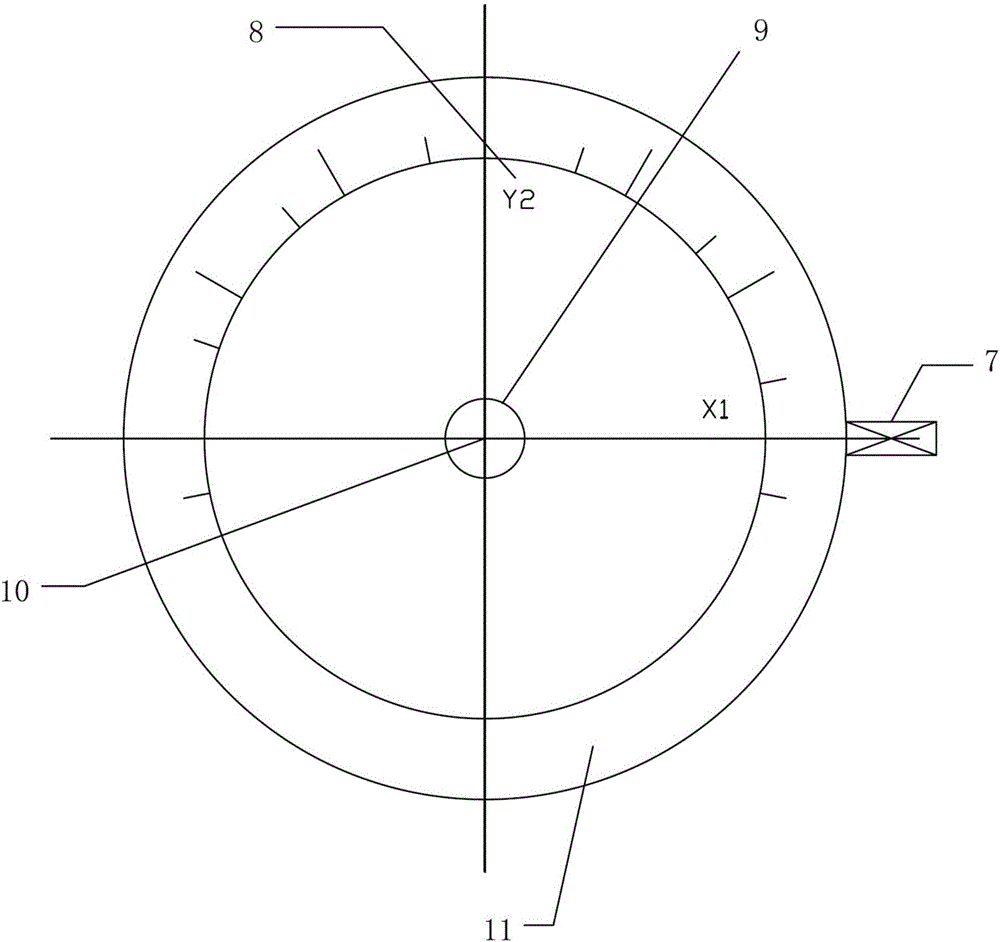

[0064] The spot machine debugging system of the medium and long working distance single-mode single-fiber collimator is characterized in that the debugging system includes a laser point light source, an adjustment frame, and a medium-long working distance single-mode single-fiber collimator arranged in sequence and a spot machine, the spot machine includes a probe, and the probe is movably installed in the debugging system, and the middle and long working distance single-mode single-fiber collimator is connected with the laser point light source , the medium and long working distance single-mode single-fiber collimator includes a single-mode single-fiber pigtail, a lens and a glass tube, and the single-mode single-fiber pigtail is movably installed on the adjustment frame, the The lens and the adjustment fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com