Novel impeller feeder

An impeller feeder, a new type of technology, applied in conveyors, rotary conveyors, transportation and packaging, etc., can solve the problems of short blade maintenance cycle, large useless power consumption of the feeder, impeller can not rotate, etc. The effect of equipment maintenance, improving control accuracy, and preventing material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

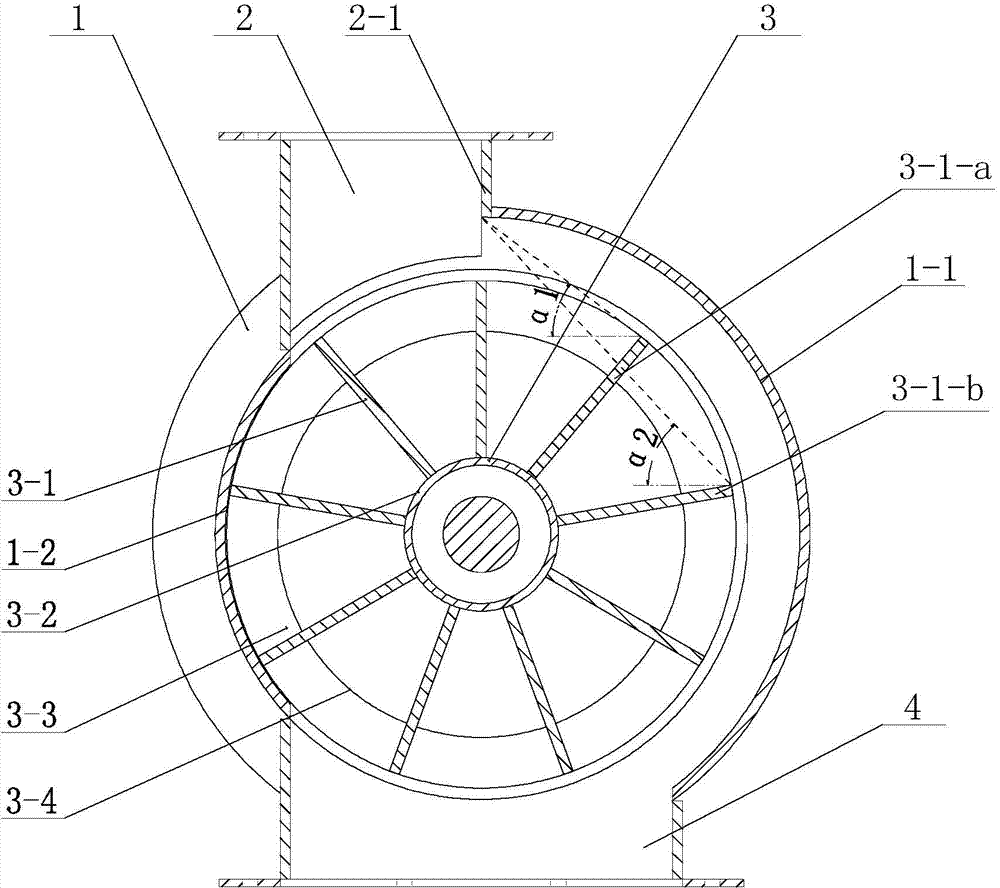

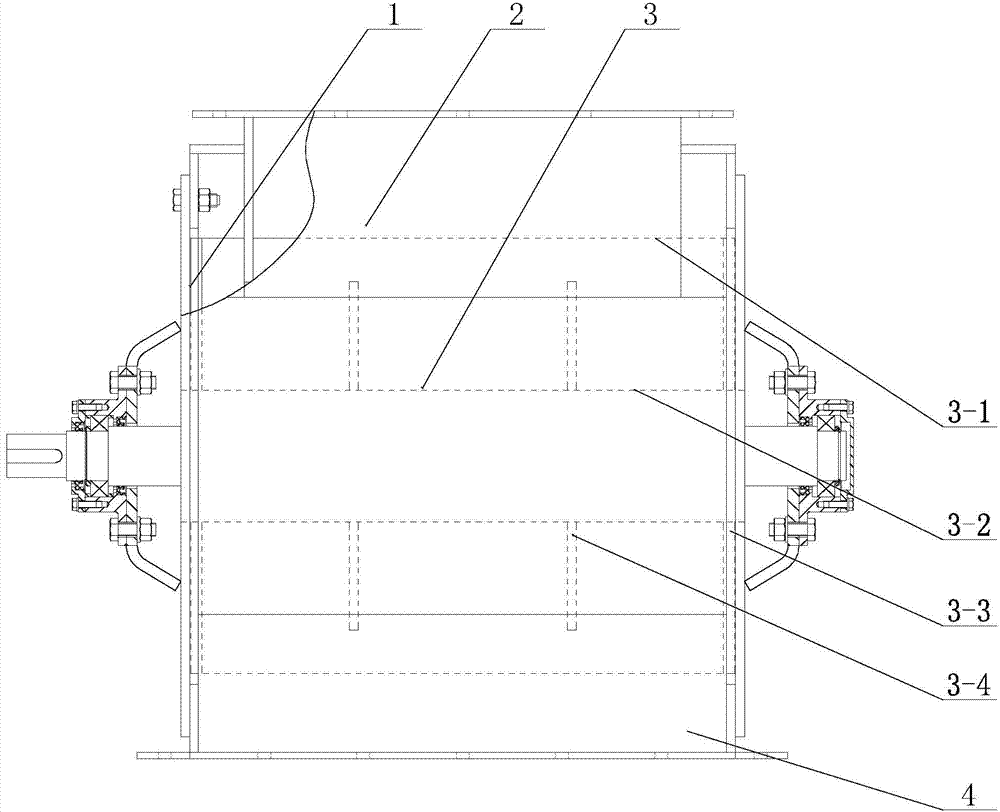

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

[0020] like figure 1 and 2 As shown, the novel impeller feeder of the present invention includes a casing 1, a material inlet 2, an impeller 3 and a material outlet 4. The casing 1 is a load-bearing main structure and also a slideway for material delivery. There is a material inlet 2 on the upper part of the casing 1, and the material inlet 2 can be installed vertically or inclined. In the case of an inclined arrangement, most of the height pressure of the material will be borne by the feeding connection chute. The bottom of the casing 1 is provided with a discharge port 4, because there is no use of multiple blades to close the material, so the discharge port 4 is arranged below the discharge channel. The impeller 3 is arranged inside the casing 1, and the impeller 3 is the basis for promoting material movement and transmitting power, and it includes a blade 3-1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com