Automatic nut tapping machine

A kind of nut tapping and automatic technology, applied in the direction of thread cutting machine, metal processing machinery parts, clamping, etc., can solve the problems of low processing efficiency and large energy consumption, and achieve the effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The automatic nut tapping machine provided by the specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

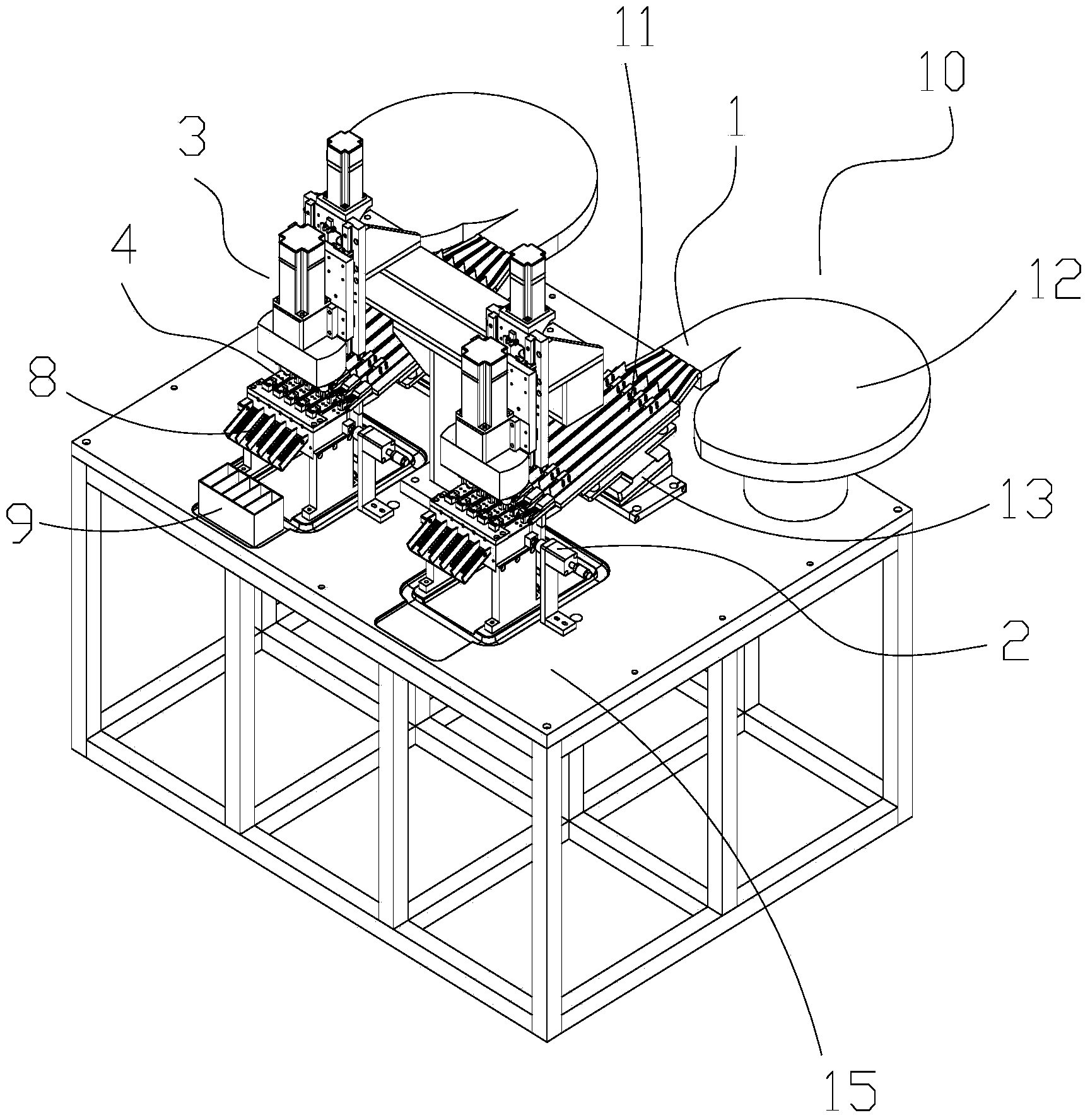

[0033] Such as figure 1 , 2 , 3 and 5, the automatic nut tapping machine includes a feeding device 1, a feeding device 2, a head tapping assembly 3 and a nut positioning device 4, wherein,

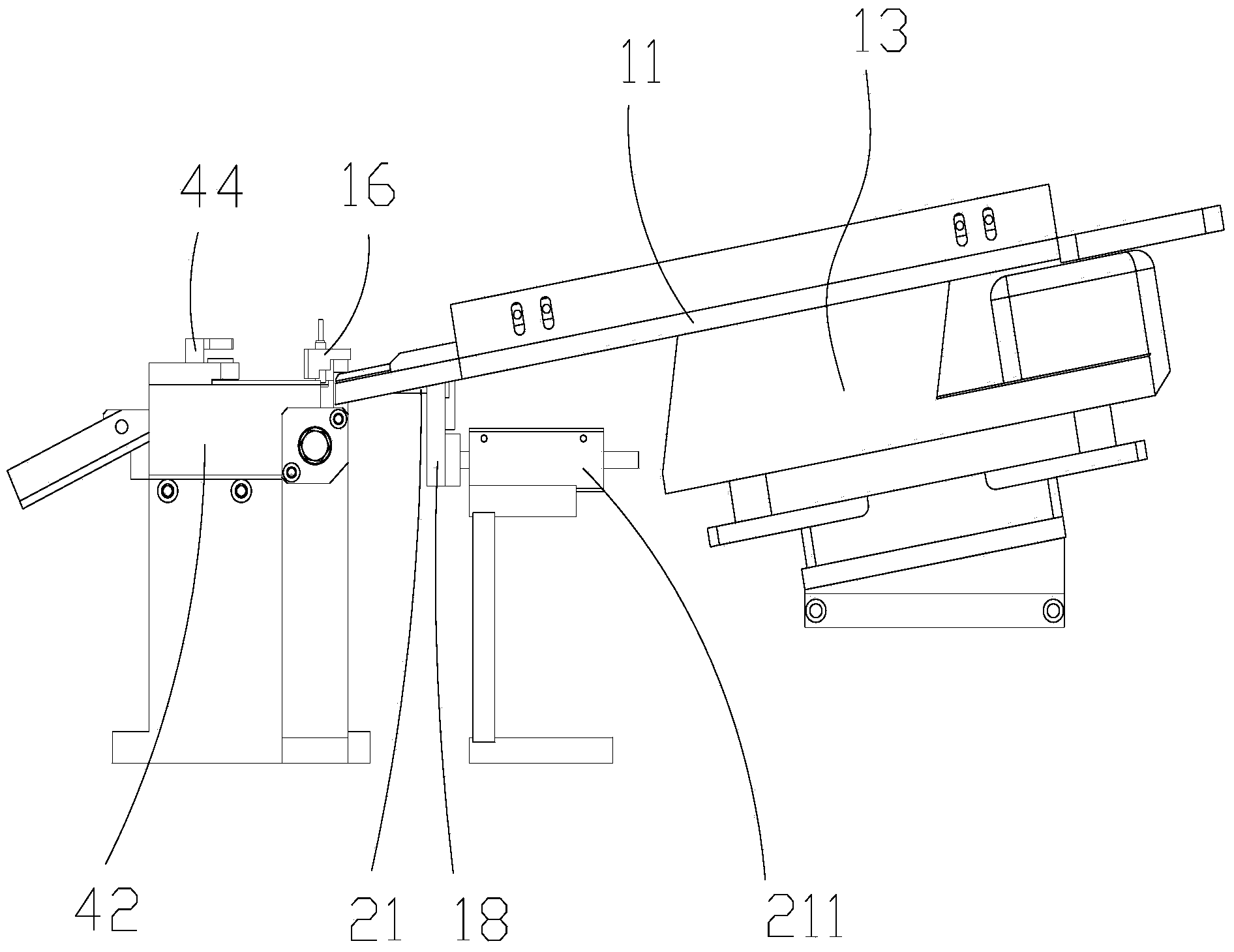

[0034] The nut positioning device 4 has a tapping channel 41 just below the tap 31 of the head tapping assembly 3;

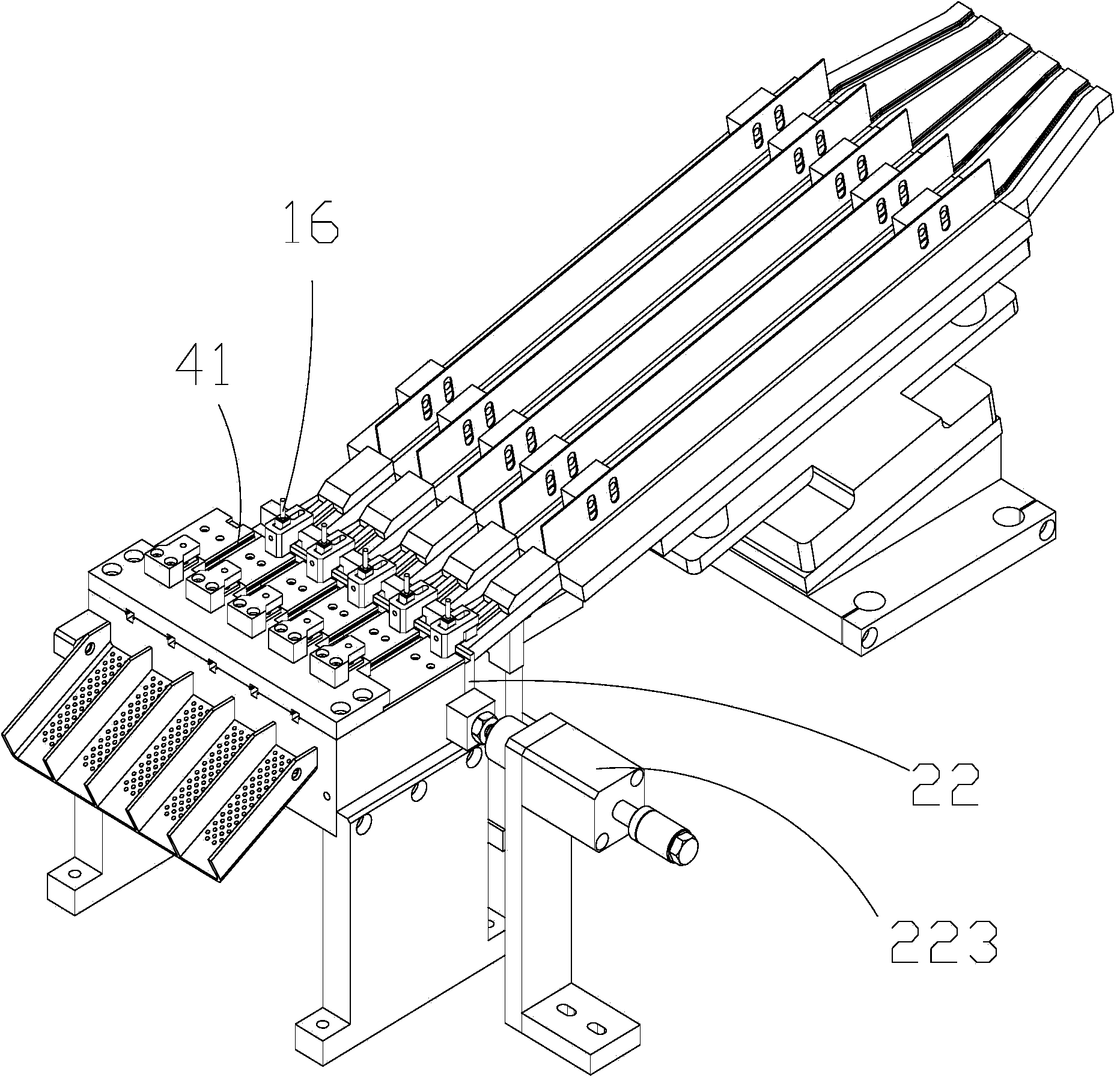

[0035] The feeding device 1 has a feeding track 11 located at the end of the tapping channel 41 and arranged staggered with the tapping channel 41;

[0036] The feeding device 2 comprises a feeding push rod 21, a material cutting push rod 22 and a sensor 16, wherein the feeding push rod 21 can slip into and slide out of the tapping channel 41 under the driving of the feeding cylinder 211; the cutting material pushing rod 22 There is a nut placement space 221 for placing nuts to be tapped on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com