Device for isolating and conveying fuel spheres of sphere bed high temperature reactor

A technology of conveying device and fuel ball, applied in the field of reactor engineering, can solve problems such as ball jamming failure, influence on availability and economy of nuclear power plants, dose irradiation of equipment maintenance personnel, etc., so as to ensure reliability and avoid jamming failure of broken balls Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

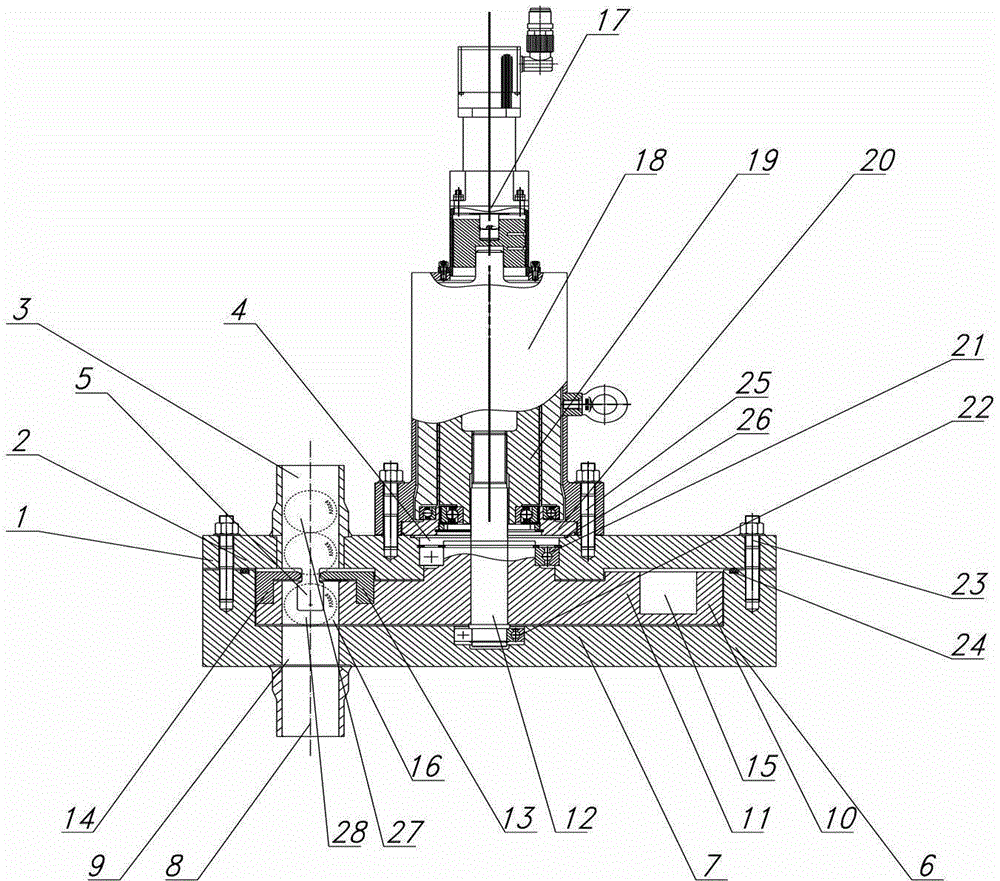

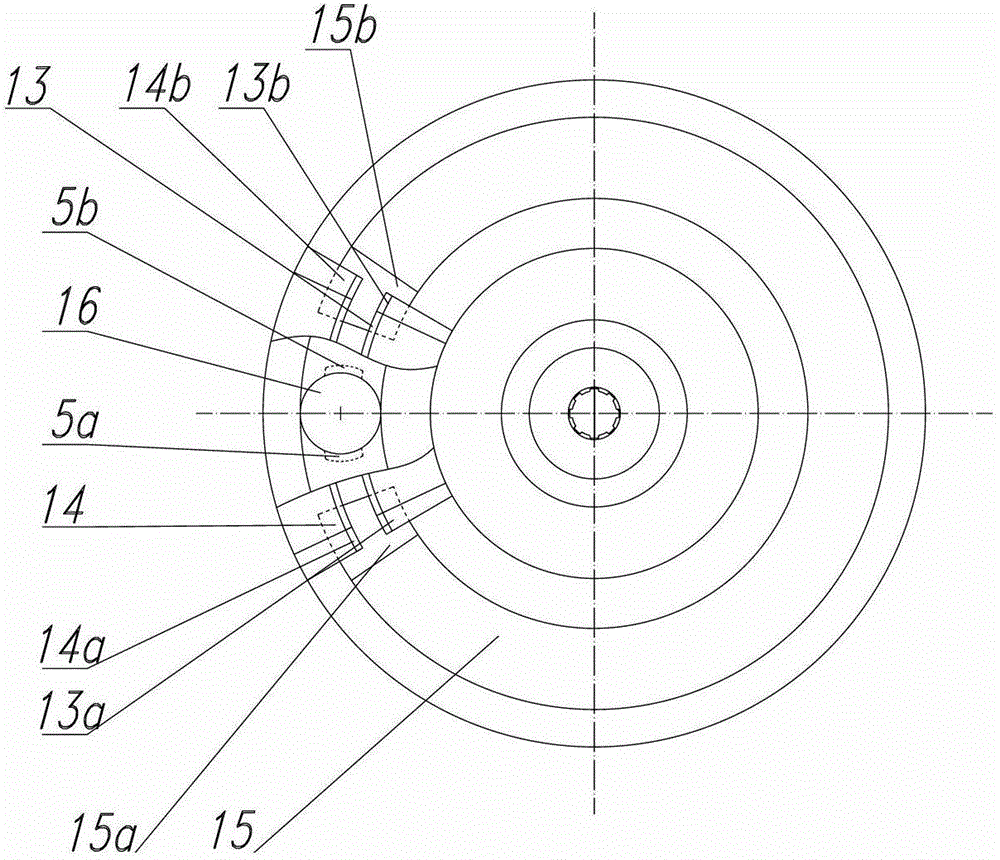

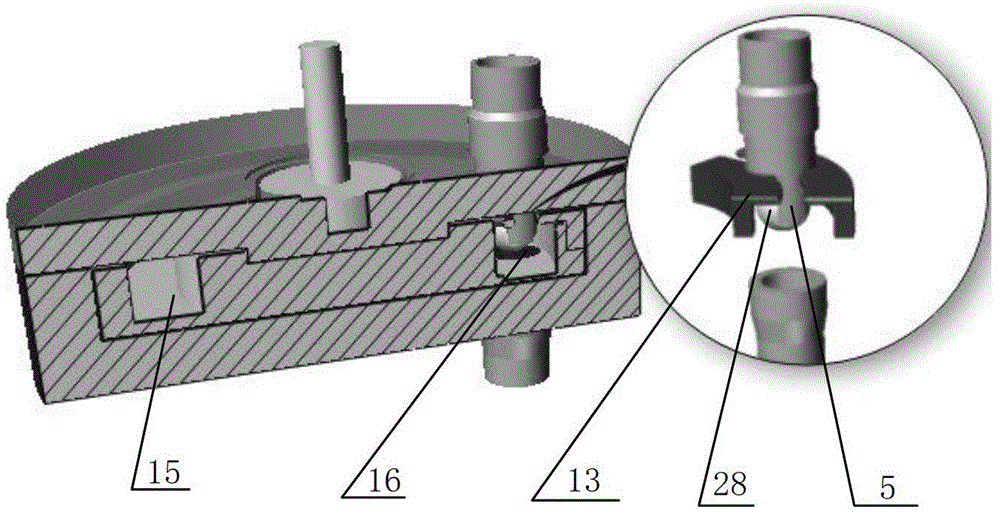

[0039] Such as figure 1 As shown, the spacer conveying device is a pressure-bearing mechanical device including an end cover assembly 1 , a box assembly 6 , a turntable assembly 10 and a drive assembly 17 .

[0040] Among them, the end cover assembly 1 is welded by the end cover 2 and the first connecting pipe 3, the end cover 2 is provided with a rotating shaft through hole 4, the bottom end of the first connecting pipe 3 has two ear plates 5a, 5b, the first connecting pipe The pipe diameter of 3 is slightly larger than the diameter of the fuel ball, and the value is 2-5mm. In this embodiment, the pipe diameter is 65 mm, which facilitates the smooth flow of fuel balls with a diameter of 60 mm. Different numbers of ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com