Automatic descaling device and method for shafts

An automatic descaling and wellbore technology, applied in the direction of earthwork drilling, wellbore/well parts, cleaning tools, etc., can solve the problems of blade jamming, complicated operation of descaling system, long time-consuming cycle of descaling, etc., and achieve improvement Descaling ability, reducing the effect of stuck rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

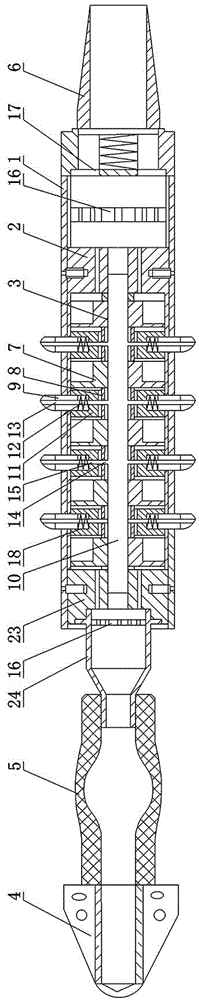

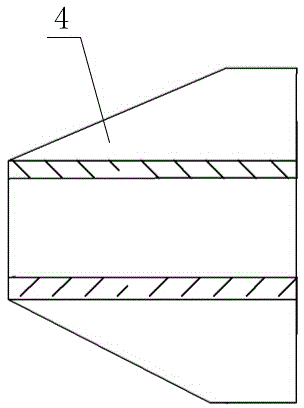

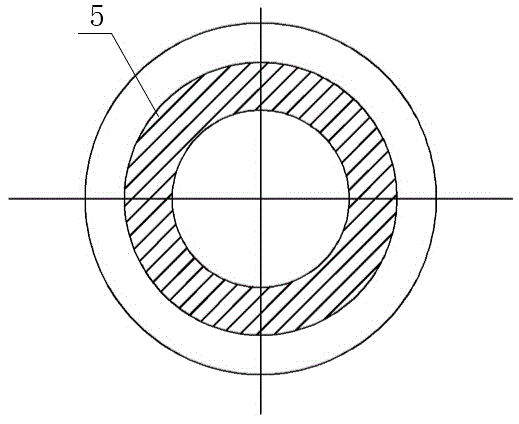

[0050] Such as figure 1 As shown, the wellbore automatic descaling device includes a pump casing 1, a pump body, a mandrel 3, a fluid inlet head 4, a rubber sleeve 5, a joint 6, an impeller 7 and a scraper device. The pump body includes a pump chamber The main body 2 and the cover body 23 that seals the pump cavity, the main body 2 is made of a cylindrical side wall and an axial end face that seals one end of the cylindrical side wall, the side wall and the axial end face surround a pump cavity that is open at one end, and the opening of the pump cavity Sealed by the cover body 23, the pump body is set in the pump casing 1, the main body 2 and the cover body 23 are fixedly connected with the pump casing 1 through pins, the mandrel 3 is set in the pump chamber, the main body 2 and the cover body 23 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com