Scavenger for clearing away PVC (polyvinyl chloride) polymer in top condenser of polymerization kettle

A technology of scavenger and condenser, applied in detergent composition, soap detergent composition, surface active non-soap compound and washing composition, etc., can solve the problems of chemical cleaning solution literature reports, etc., and achieve powerful descaling Ability, easy to use, large amount of polymer removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

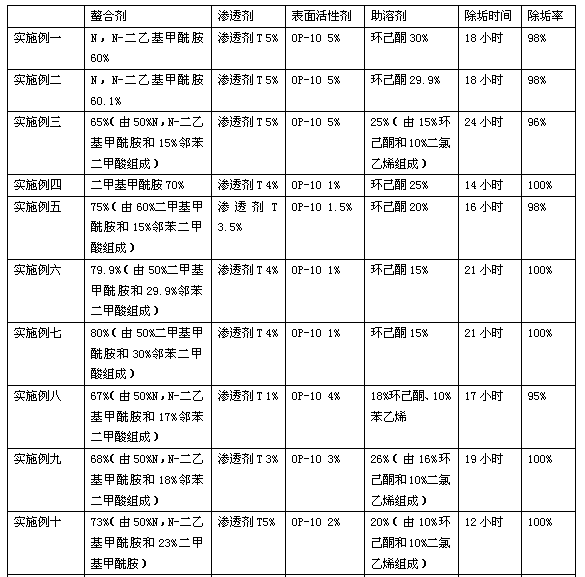

Embodiment 1

[0026] Embodiment one: a PVC polymer scavenger in the condenser on the top of the polymerization kettle, the scavenger is composed of the following components by weight percentage: chelating agent N, N-diethylformamide 60%, penetrant T 5% , Surfactant OP-10 5%, cosolvent cyclohexanone 30%.

[0027] The preparation method of the product PVC polymer scavenger of the present invention: take by weighing various raw materials according to the raw material composition of above-mentioned PVC polymer scavenger, add raw materials such as chelating agent, penetrant, surfactant, co-solvent in the reaction vessel and stir, After fully dissolving, stir evenly, and finally fill.

[0028] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control it...

Embodiment 2

[0029] Embodiment two: basically the same as embodiment one, the difference is: the PVC polymer scavenger in the condenser on the top of the polymerization tank is made up of the following components by weight percentage: chelating agent N, N-diethylformazan Amide 60.1%, penetrant T 5%, surfactant OP-10 5%, cosolvent cyclohexanone 29.9%.

[0030] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control its temperature at 60 to 85 ℃, after about 18 hours, the white blocky PVC polymer has completely dissolved and turned into a transparent viscous liquid. The PVC polymer is completely dissolved, and the removal rate of PVC polymer reaches 98%.

Embodiment 3

[0031] Embodiment three: basically identical with embodiment one, difference is: PVC polymer scavenger is made up of the following components by weight percentage in the condenser on the top of polymerization kettle: chelating agent 65% (from 50%N, N-two ethyl formamide and 15% phthalic acid), penetrant T 5%, surfactant OP-10 5%, cosolvent 25% (composed of 15% cyclohexanone and 10% dichloroethylene).

[0032] The application test of the above-mentioned product: take a certain amount of the product PVC polymer scavenger of the present invention and put it into a container, put a certain amount of white PVC polymer block into the product scavenger of the present invention, and heat it in a water bath to control its temperature at 60 to 85 ℃, after about 24 hours, the white blocky PVC polymer has completely dissolved and turned into a transparent viscous liquid. The PVC polymer is completely dissolved, and the removal rate of PVC polymer reaches 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com