A kind of alloy material with antifouling application and preparation method thereof

A technology for alloy materials and uses, which is applied in the field of alloy materials with anti-scaling purposes and its preparation, can solve the problems of unfriendly environment, secondary pollution of the environment, huge economic costs, etc., and achieve the improvement of free energy of reaction and strong descaling ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing an alloy material with an anti-fouling application, comprising the following steps:

[0056] Step 1. Select smelting raw materials:

[0057] The smelting raw materials are selected in the following two ways:

[0058] Method 1. Each component is smelted in pure metal form Cu-CATH-2, Zn99.99, Ni99.50, Sn99.99, Mn99.5, Al99.5, Au99.99;

[0059] Method 2. The high melting point component Mn is added in the form of master alloy CuMn22, and the rest is smelted with pure metal Cu-CATH-2, Ni99.50, Al99.5, Zn99.99, Sn99.99, Au99.99;

[0060] Step 2, ingredient calculation:

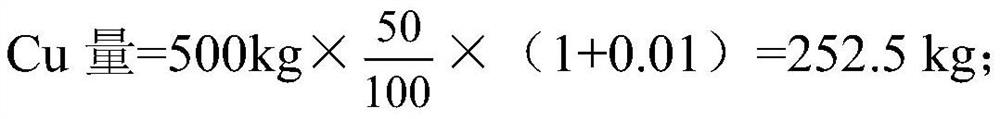

[0061] Calculate the mass of each element required in smelting by the mass percentage of the set alloy elements Cu, Zn, Ni, Sn, Al, Mn, Au, and use the mass of each element to calculate the intermediate alloy or pure alloy required in smelting metal content;

[0062] Step 3. Select the melting tool;

[0063] Step 4: Select a smelting process for...

Embodiment 1

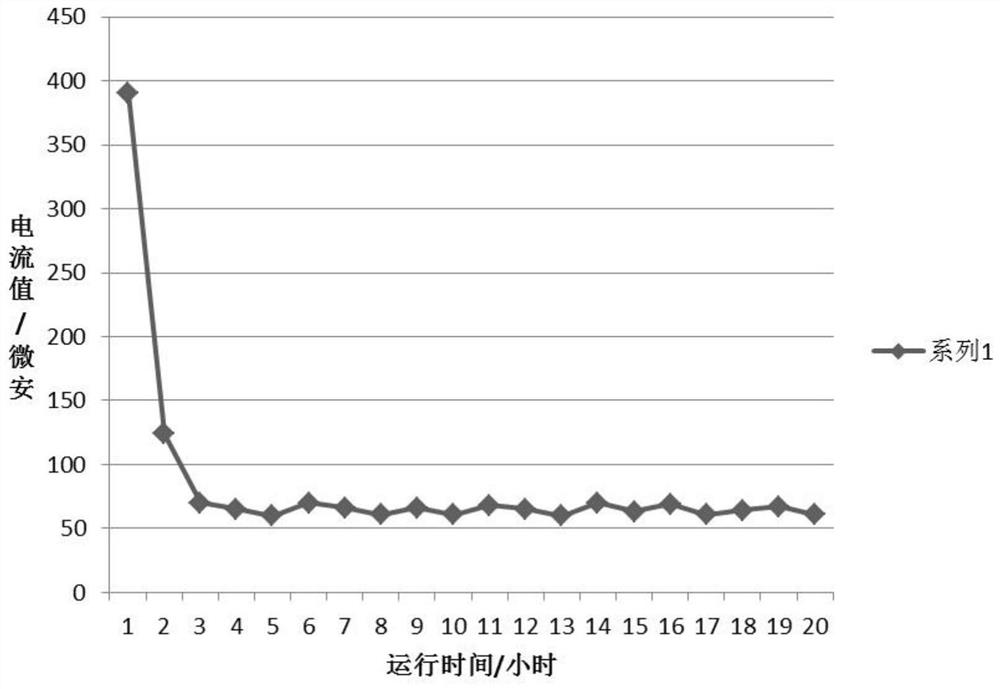

[0077] In this example, the diameter The alloy test chip made of the alloy material of the present invention is put into the calcium carbonate solution with a flow rate of 1m / s and a concentration of 4900mg / mol, and the relationship between the current value and time is measured, as figure 1 As shown, it can be seen that the metal elements Au and Au added in the present invention are metal elements with the highest electrode potential, which can improve the free energy of reaction on the surface of the alloy, and have stronger descaling ability than similar products.

[0078] In this embodiment: the mass percentages of the components of the alloy material are: Cu=50%, Zn=25%, Ni=16%, Sn=2.45%, Al=3.5%, Mn=3%, Au=0.05% , the tested alloy with this composition has the best descaling ability.

[0079] Specific application cases:

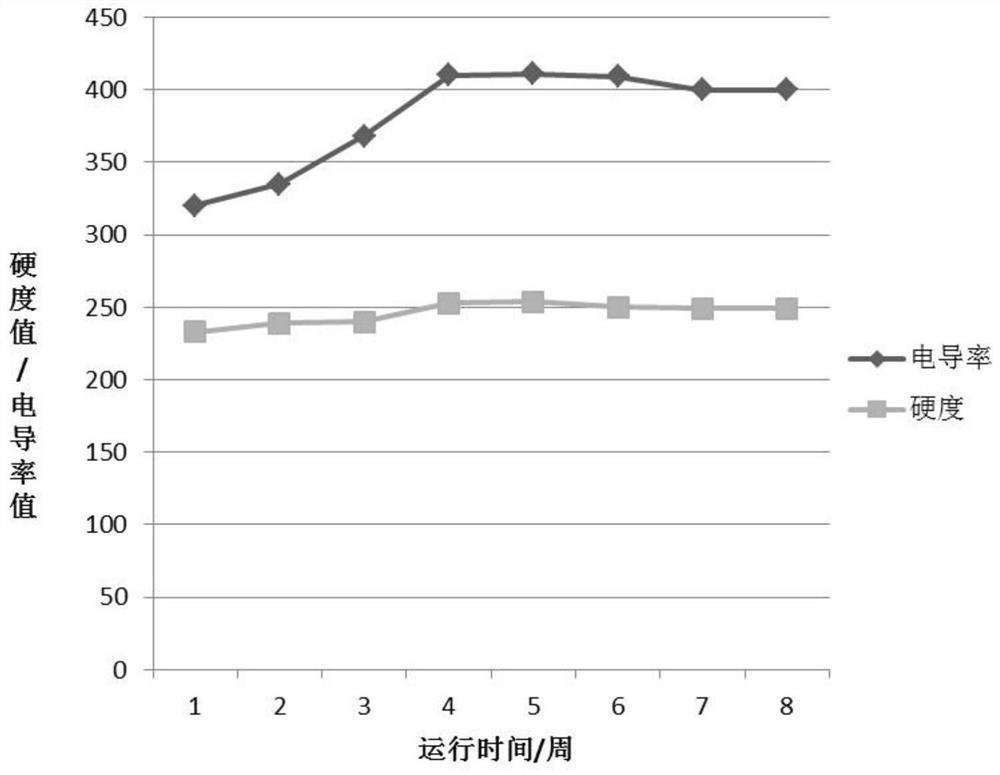

[0080] Case 1. A heat exchanger in a chemical plant in China, because the circulating water contains a large amount of calcium and magnesium ions an...

Embodiment 2

[0125] In this example, the mass percentages of each component of the alloy material are: Cu=55%, Zn=23%, Ni=14%, Sn=2.47%, Al=2.5%, Mn=3%, Au=0.03% , batching calculation, smelting tool and smelting process are all similar to embodiment 1, no further elaboration will be given.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com