Chain shaft of chain saw

A chain shaft and chain saw technology, applied in the field of machinery, can solve the problems of production waste, increase production cost, uneven stress distribution on the head of the chain shaft, etc., and achieve the effect of reducing production cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

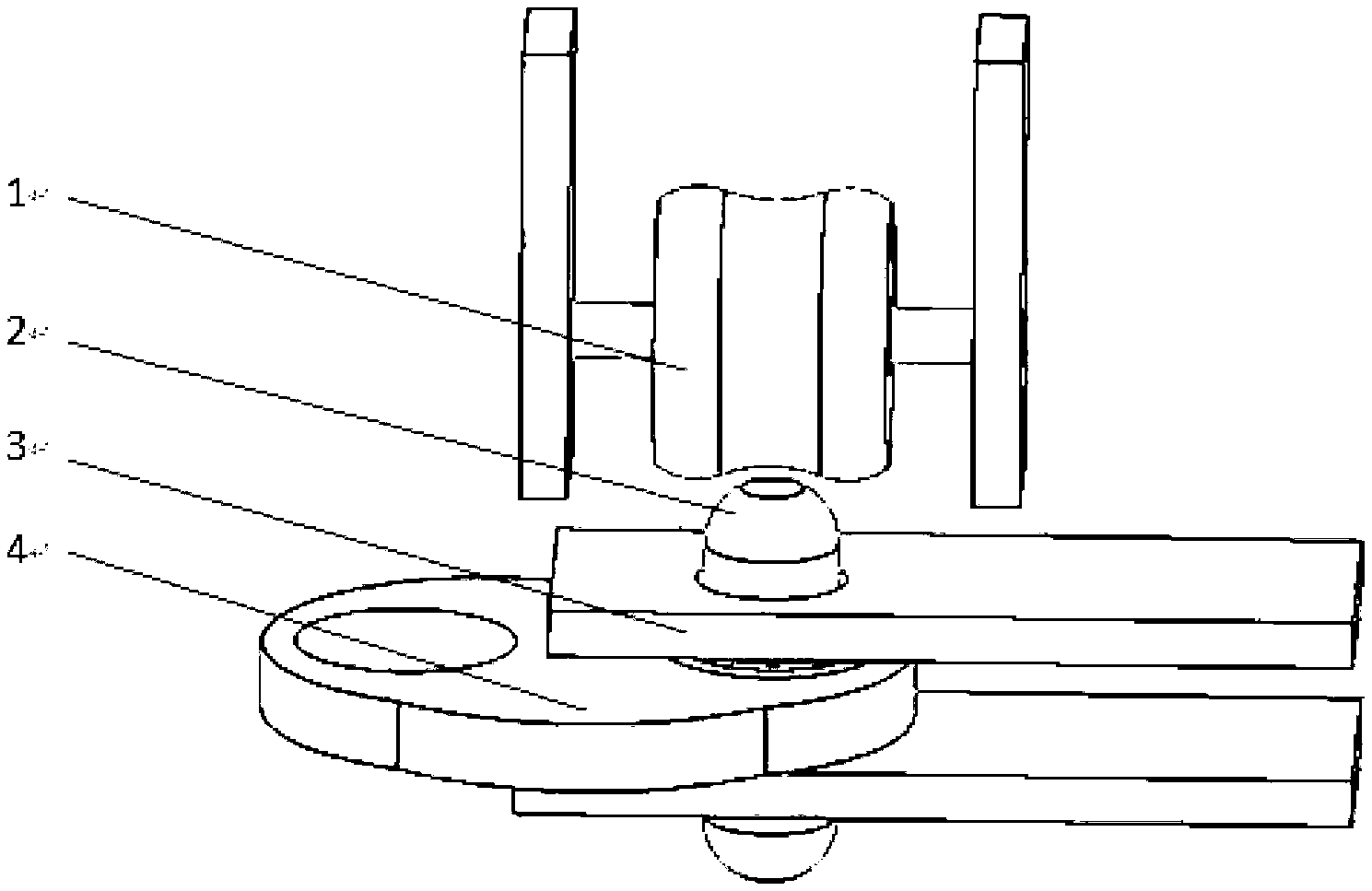

Embodiment 1

[0017] Because the head of the chain shaft in Example 1 adopts a circular arc wave structure, the problem that the riveting wheel is easily damaged during the riveting process of the riveting machine is solved, the production efficiency is improved, and the production cost is reduced.

Embodiment 2

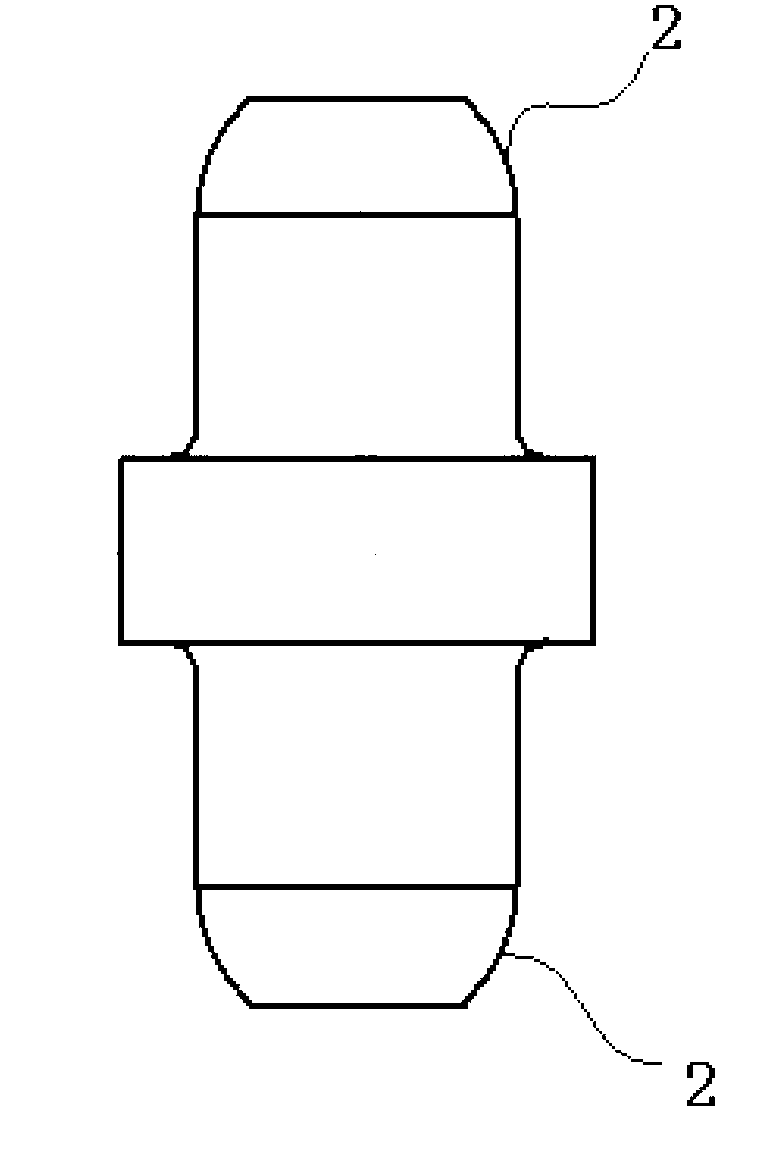

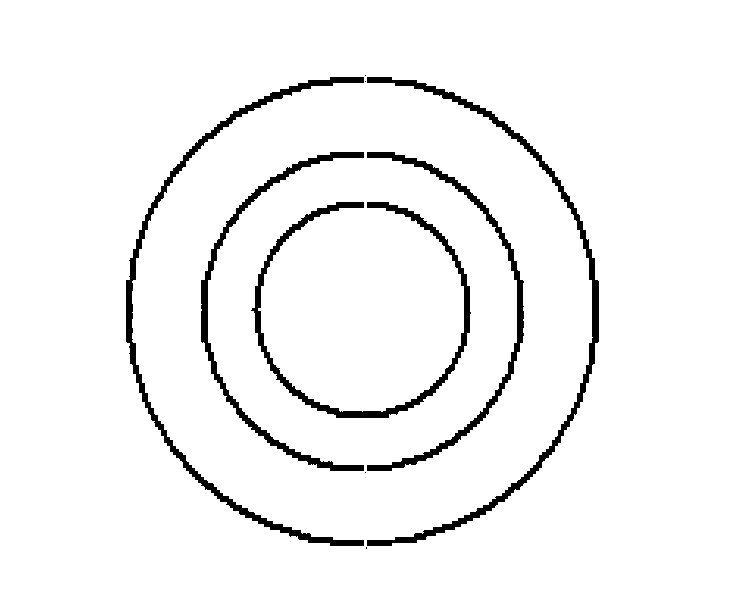

[0018] Embodiment 2, the end of the chain saw chain shaft can be hemispherical, so as to adapt to the riveting wheel of the same shape.

Embodiment 3

[0019] Embodiment 3, the end of the chain shaft of the chain saw can be a circular frustum with an arc-shaped side surface, so as to be compatible with the riveting wheel of the same shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com