Artificial pit mud and preparation method thereof

A kind of pit mud and artificial technology, applied in the field of wine making, can solve problems such as poor effect, peculiar smell of base wine, poor effect, etc., achieve broad application prospects and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

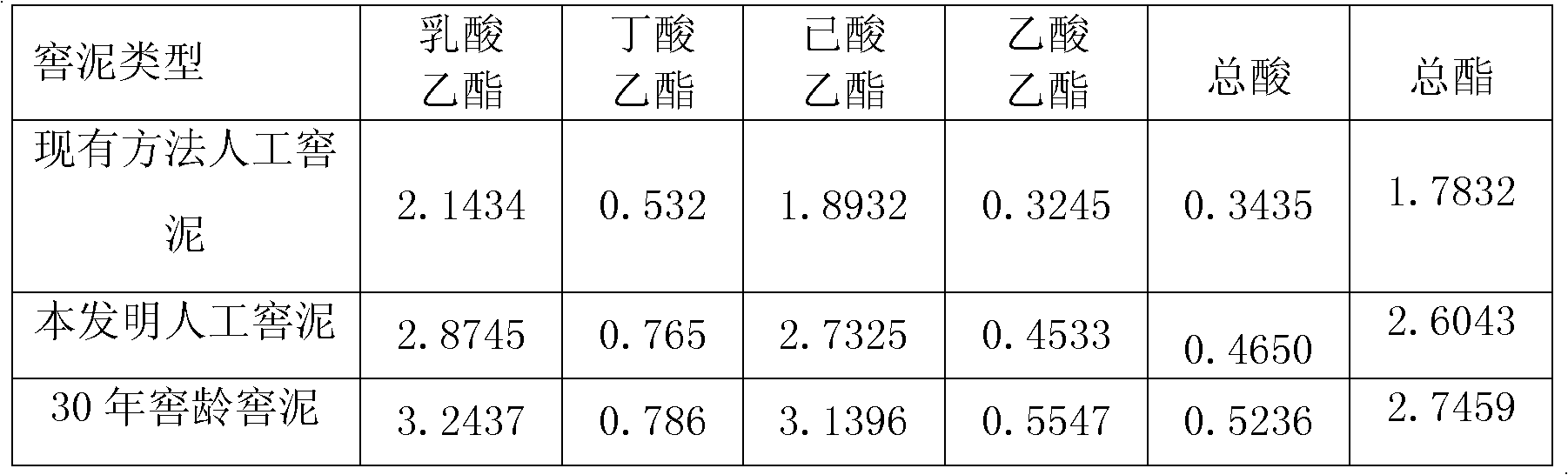

Examples

Embodiment Construction

[0021] The method for preparing artificial pit mud of the present invention comprises the steps:

[0022] a, take the yellow mud, add yellow water and tail water (tail water refers to the liquid formed after the end of the wine flow, its alcohol content is lower than 5% vol, and it contains a large amount of organic acids and a large amount of high boiling point esters substance), and mix evenly so that the water content of the yellow mud is 48-55wt%; wherein, the volume ratio of the added yellow water and tail water is 1:3-8 (the volume ratio is preferably 1:5);

[0023] B, get sealing pit mud, add yellow water and tail water, mix, make the water content of sealing pit mud be 48~55wt%; Wherein, the volume ratio of the yellow water that adds and tail water is 1: 2~5 (volume ratio preferably 1:4);

[0024] c, the yellow mud and the pit sealing mud of a, b steps are mixed by weight ratio 2~5: 1 (preferably by weight ratio 4: 1 is mixed), obtain base mud;

[0025] d. Take high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com