Measurement method for particle size

A measurement method and particle size technology, which is applied in the field of high-temperature gas-cooled reactor fuel element manufacturing, can solve problems such as low efficiency, and achieve the effects of high measurement accuracy, large measurement sample volume, and fast measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

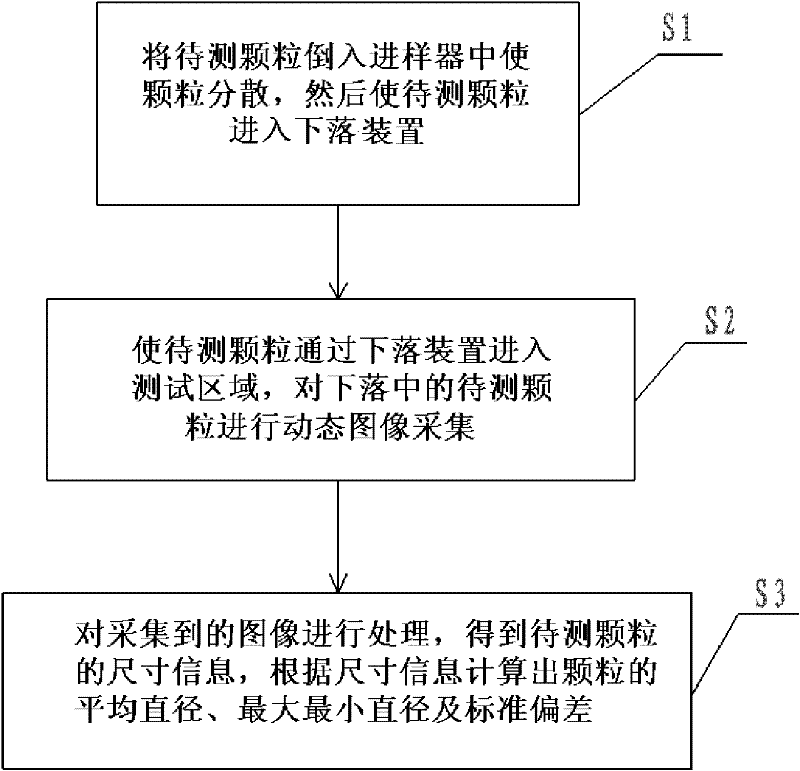

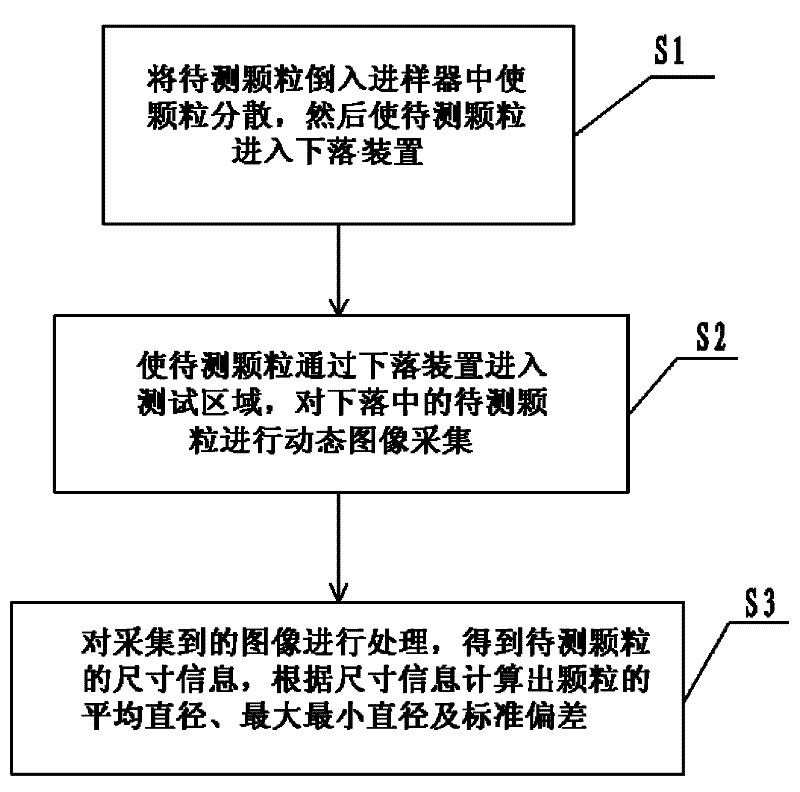

[0031] In order to solve the problems of cumbersome sample preparation, low test efficiency, single measurement parameter, and introduction of human error in the prior art, the purpose of the present invention is to provide a UO with simple operation, high test efficiency, and the ability to measure multiple parameters. 2 Core or clad granules and other powder or granule sizing methods. to UO 2 Taking the core as an example, the measurement method includes the following steps:

[0032] S1. Sample injection process:

[0033] a) Take a sample of about 1-20g, use a solvent (the solvent must not react with the sample, and the sample must be insoluble in the solvent) to ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com