A method for measuring magnesium content in nuclear-grade zirconium sponge particles

A nuclear-grade sponge zirconium and magnesium content technology, applied in the field of chemical analysis, can solve the problems of accuracy and precision interference of instrumental analysis methods, failure to meet the detection requirements of zirconium and zirconium alloys, backward flame atomic absorption spectrometry technology, etc., to achieve Improve monitoring ability, broaden the measurement range, good representative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

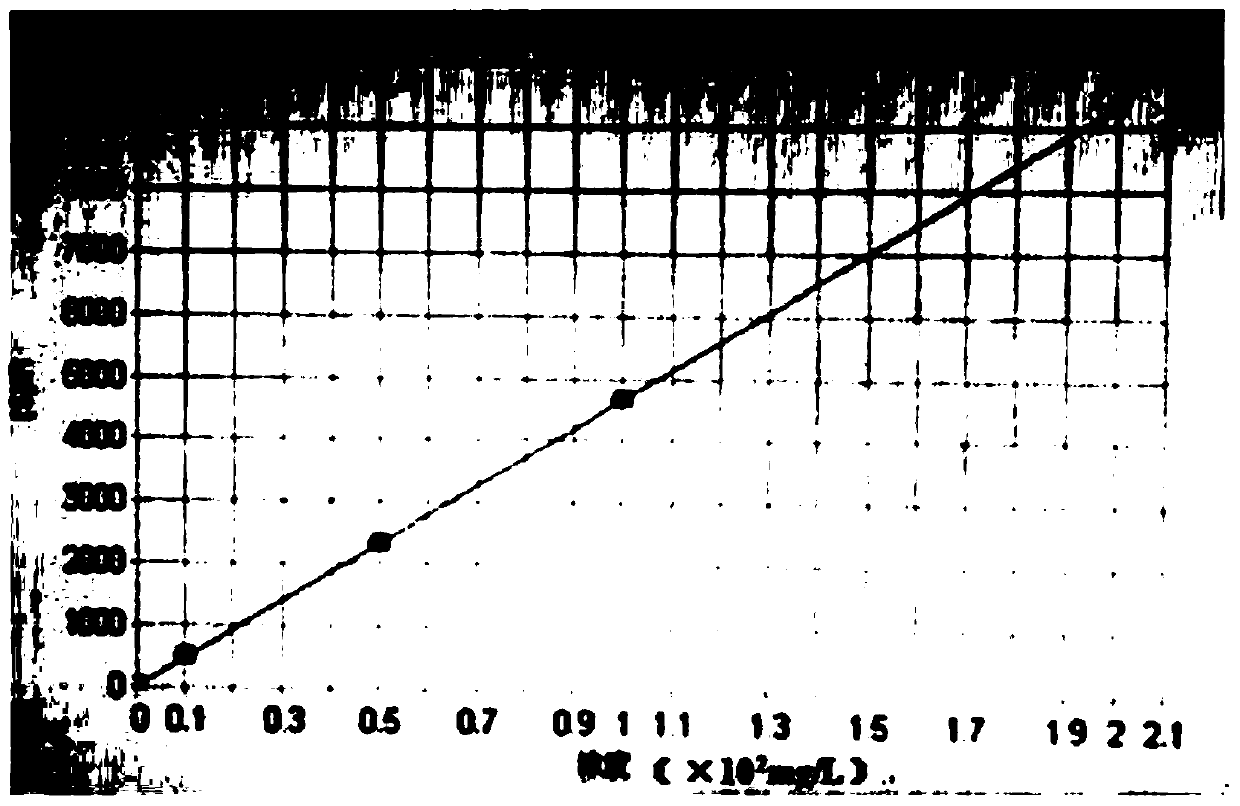

Image

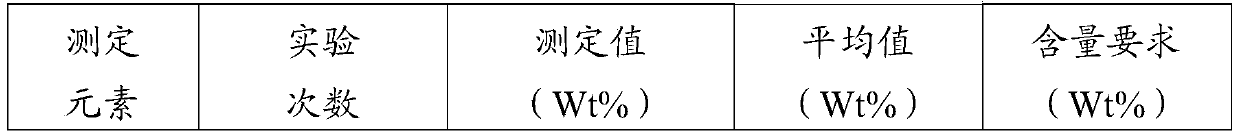

Examples

Embodiment 1

[0023] The method for measuring the magnesium content in the nuclear grade sponge zirconium particles of the present embodiment comprises the following steps:

[0024] Step 1. Sampling and weighing the nuclear-grade zirconium sponge particles by the heap cone quartering method;

[0025] In the specific implementation process of this embodiment, at first randomly extract nuclear-grade zirconium sponge particle samples from each batch of zirconium sponge, and the extraction quantity accounts for 20% of the number of buckets (but not less than 2 buckets). Take samples from the middle and lower parts respectively, each part takes about 1000g of samples, then mix the samples evenly, and divide them into about 500g by the heap cone quartering method, and then accurately weigh 400g of nuclear-grade zirconium sponge particle samples from it , accurate to 1.000g; the particle size of the nuclear-grade zirconium sponge particles is 1 mm to 100 mm;

[0026] Step 2, adding the nuclear-gr...

Embodiment 2

[0040] The method for measuring the magnesium content in the nuclear grade sponge zirconium particles of the present embodiment comprises the following steps:

[0041] Step 1. Sampling and weighing the nuclear-grade zirconium sponge particles by the heap cone quartering method;

[0042] In the specific implementation process of this embodiment, at first randomly extract nuclear-grade zirconium sponge particle samples from each batch of zirconium sponge, and the extraction quantity accounts for 20% of the number of buckets (but not less than 2 buckets). Take samples from the middle and lower parts respectively, each part takes about 1000g of samples, then mix the samples evenly, and divide them into about 700g by the heap cone quartering method, and then accurately weigh 625g of nuclear-grade zirconium sponge particle samples , accurate to 1.000g; the particle size of the nuclear-grade zirconium sponge particles is 1 mm to 100 mm;

[0043] Step 2, adding the nuclear-grade zirc...

Embodiment 3

[0056] The method for measuring the magnesium content in the nuclear grade sponge zirconium particles of the present embodiment comprises the following steps:

[0057] Step 1. Sampling and weighing the nuclear-grade zirconium sponge particles by the heap cone quartering method;

[0058] In the specific implementation process of this embodiment, at first randomly extract nuclear-grade zirconium sponge particle samples from each batch of zirconium sponge, and the extraction quantity accounts for 20% of the number of buckets (but not less than 2 buckets). Take samples from the middle and lower parts respectively, each part takes about 1000g of samples, then mix the samples evenly, and divide them into about 300g by the heap cone quartering method, and then accurately weigh 250g of nuclear-grade zirconium sponge particle samples , accurate to 1.000g; the particle size of the nuclear-grade zirconium sponge particles is 1 mm to 100 mm;

[0059] Step 2, adding the nuclear-grade zirc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com