Low-density and high-entropy alloy material and preparation method thereof

A high-entropy alloy and low-density technology, applied in the field of high-entropy alloys, can solve the problems of unreported bulk materials of low-density high-entropy alloys, and achieve the effects of good promotion and application prospects, simple and stable process, and reliable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Step 1: Design of low-density high-entropy alloy

[0044] AlSiCuNiTiCr series high-entropy alloy is designed, the specific composition of the selected high-entropy alloy is AlSiCuNiTiCr, and its theoretical density is 5.76g / cm 3 , according to the molar atomic ratio and mass fraction of the main elements in the high-entropy alloy AlSiCuNiTiCr, the mass of each component is calculated as pure Al powder 60.84g, pure Si powder 63.32g, pure Cu powder 143.30g, pure Ni powder 132.34g, Pure Ti powder 107.96g, pure Cr powder 117.24g and weigh the corresponding mass with an electronic balance, and then mix the powder on a V-type powder mixer for 15 hours until uniform.

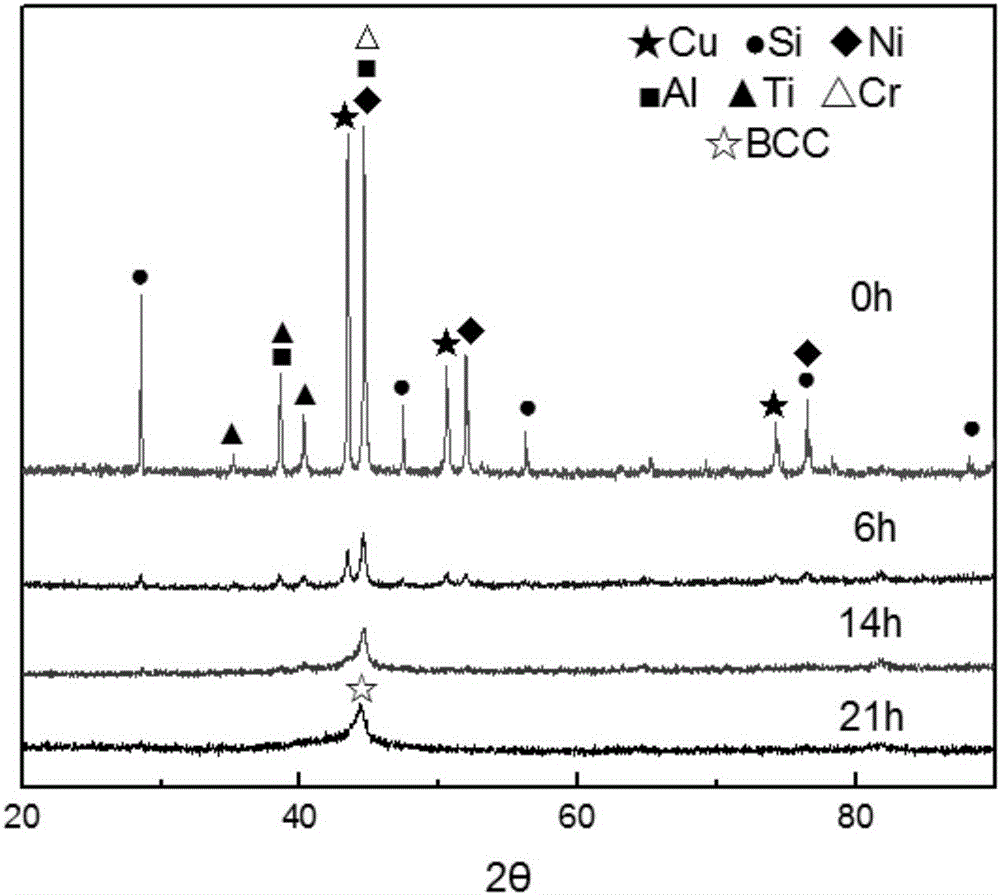

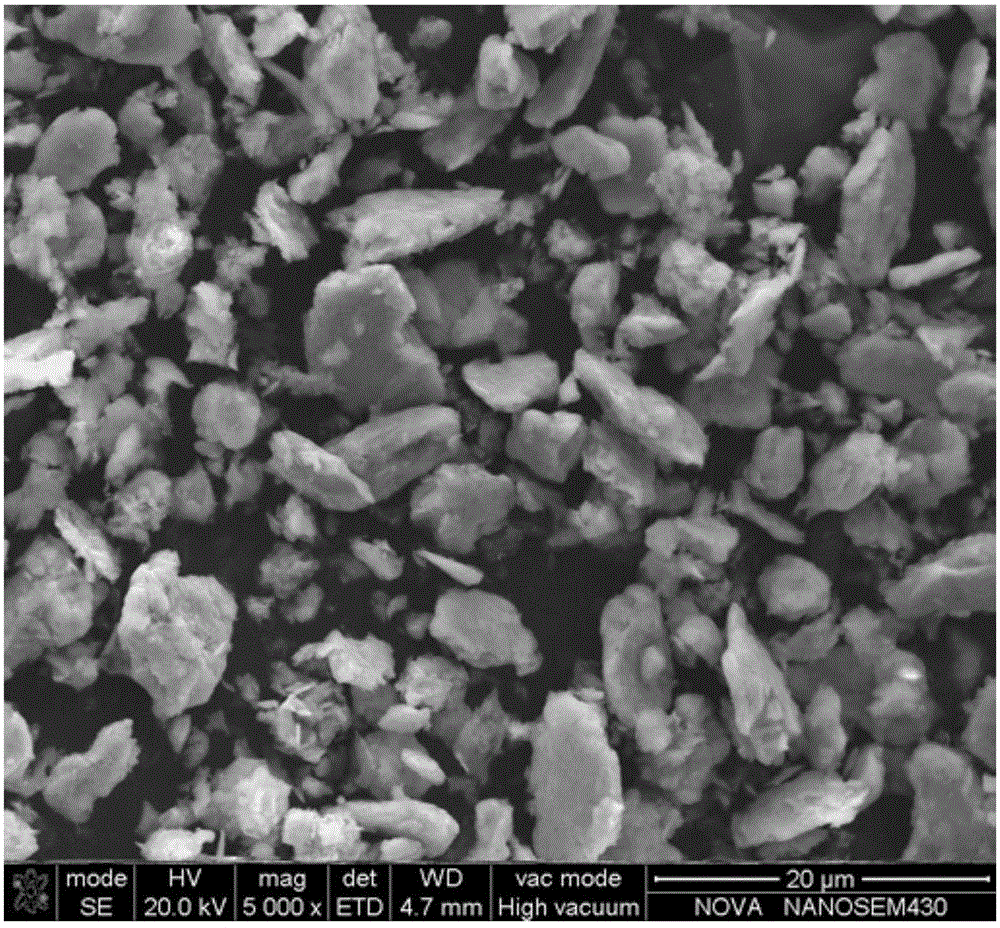

[0045] Step 2: Mechanical alloying to prepare low-density high-entropy alloy AlSiCuNiTiCr powder

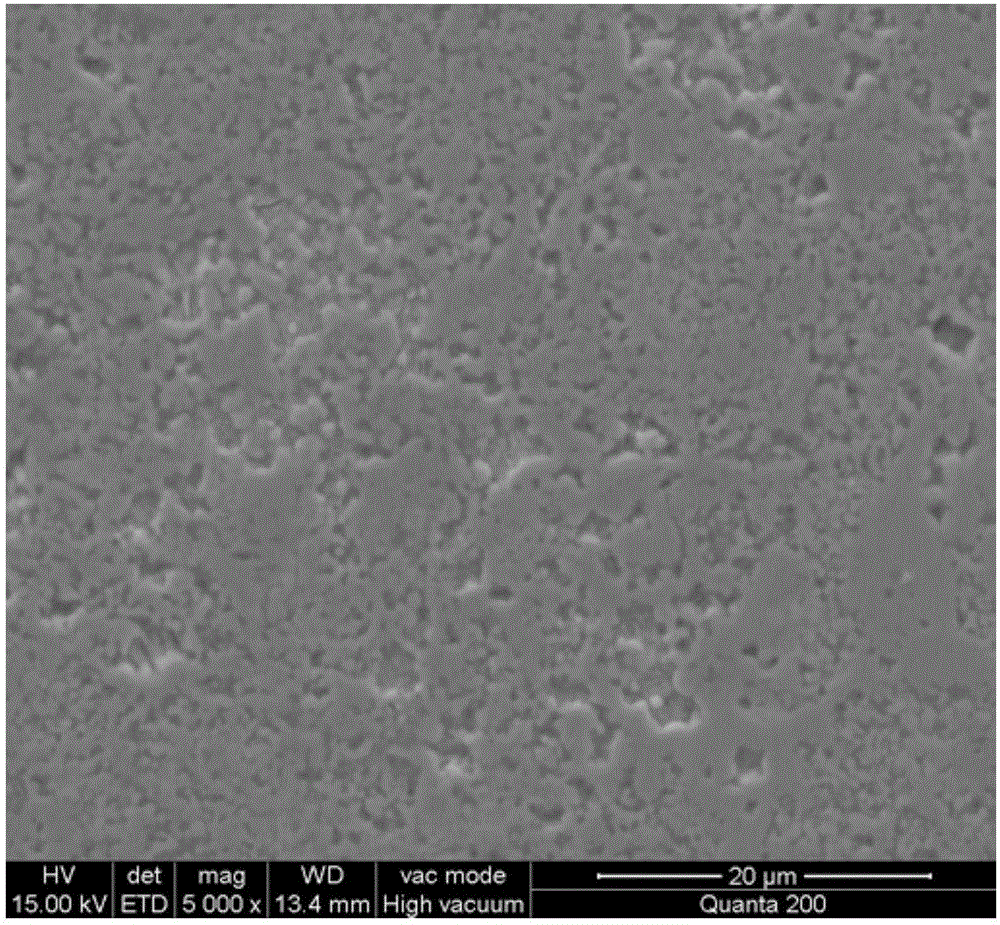

[0046] Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize and fill it with argon as a protective atmosphere, and perform mechanical alloying on a planetary ball mill, where t...

Embodiment 2

[0051] Step 1: Design of low-density high-entropy alloy

[0052] AlSiTiVCr series high-entropy alloy is designed, the specific composition of the selected high-entropy alloy is AlSiTiVCr, and its theoretical density is 4.52g / cm 3 , according to the molar atomic ratio and mass fraction of the main elements in the high-entropy alloy AlSiTiVCr, the mass of each component is calculated as pure Al powder 81.91g, pure Si powder 85.25g, pure Ti powder 145.35g, pure V powder 154.64g, Pure Cr powder is 157.85g, and the corresponding mass is weighed with an electronic balance, and then the powder is mixed on a V-type powder mixer for 24 hours until uniform.

[0053] Step 2: Preparation of low-density high-entropy alloy powder by mechanical alloying

[0054] Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize it and fill it with argon as a protective atmosphere, and perform mechanical alloying on a planetary ball mill, where the ball-to-material rat...

Embodiment 3

[0059] Step 1: Design of low-density high-entropy alloy

[0060] AlSiCuTiCr series high-entropy alloys were designed, and the specific composition of the selected high-entropy alloys was Al 0.5 SiCu 0.5 TiCr, its theoretical density is 4.96g / cm 3 , according to the high-entropy alloy Al 0.5 SiCu 0.5 The molar atomic ratio and mass fraction of each main element in TiCr, the mass of each component is calculated as pure Al powder 7.79g, pure Si powder 16.21g, pure Cu powder 18.34g, pure Ti powder 27.64g, pure Cr powder 30.02g , and use an electronic balance to weigh the corresponding mass, and then mix the powder on a V-type powder mixer for 10 hours until uniform.

[0061] Step 2: Preparation of low-density high-entropy alloy powder by mechanical alloying

[0062] Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize and fill it with argon as a protective atmosphere, and perform mechanical alloying on a planetary ball mill, where the ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com