Pre-coating film and preparation method thereof

A pre-coating and pre-gluing technology, applied in chemical instruments and methods, film/sheet adhesives, adhesive types, etc., can solve problems such as increased production costs, low processing efficiency, and film sticking, etc. Achieve the effect of low production cost, high processing efficiency and high transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

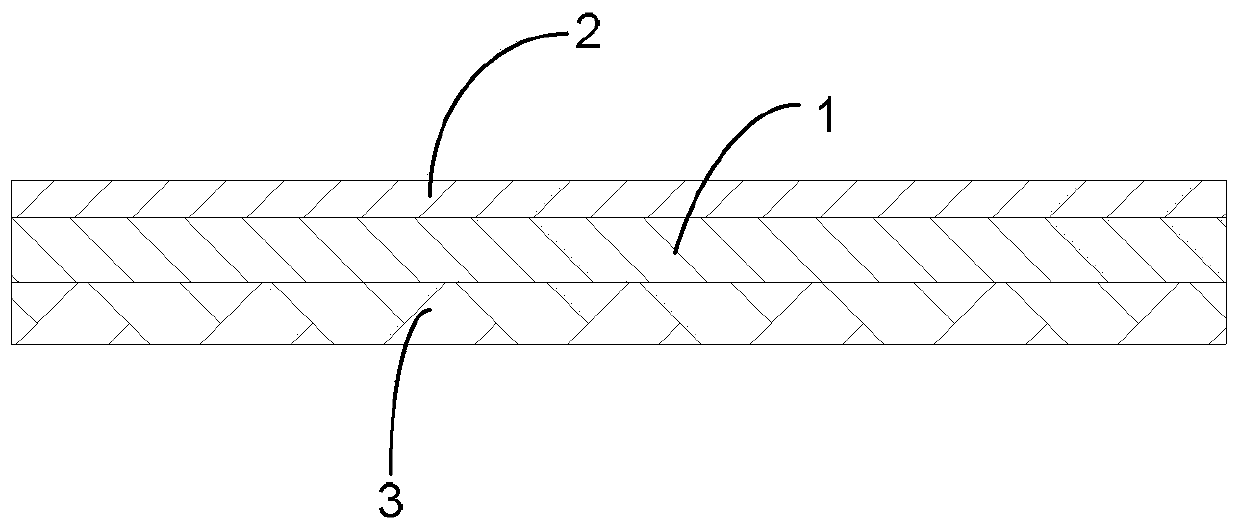

[0043] see figure 1 , the precoat film of the present invention comprises:

[0044] A substrate layer 1, the substrate layer 1 is a biaxially oriented polypropylene film layer or a biaxially oriented polyester film layer;

[0045] Glazing release layer 2, the glazing release layer 2 is arranged on the first surface of the substrate layer 1 and is formed by a modified glycidyloxypropyl trimethoxysilane solution;

[0046] A pre-coating layer 3, the pre-coating layer 3 is arranged on the second face of the substrate layer and is formed by polydisperse particle diameter styrene-acrylic composite emulsion, the particle size distribution of the polydisperse particle diameter styrene-acrylic composite emulsion is The range is 100-800nm, and the solid content is greater than 70%.

[0047] The preparation method of precoat film of the present invention may further comprise the steps:

[0048] 1. The substrate layer 1 is provided, and the substrate layer 1 is a biaxially oriented pol...

Embodiment 2

[0061] Embodiment 2 is basically the same as embodiment 1, and the difference is the preparation of polydisperse particle size styrene-acrylic composite emulsion, comprising the following steps:

[0062] (1) Preparation of large particle size seed emulsion: first put 15 parts by weight of butyl acrylate, 5 parts by weight of hydroxyethyl acrylate, 180 parts by weight of water, and 0.4 parts by weight of nonylphenol polyoxygen into the reactor. Vinyl ether, 0.015 parts by weight of sodium dodecylbenzenesulfonate, 0.2 parts by weight of sodium bicarbonate, and 0.8 parts by weight of ammonium persulfate were added to initiate polymerization, and reacted at 80°C for 45 minutes; 130 parts by weight of styrene, 100 parts by weight of methyl methacrylate, 3 parts by weight of acrylic acid, 70 parts by weight of water, 8 parts by weight of allyl octylphenol polyoxyethylene ether, 0.08 parts by weight of nonyl Phenol polyoxyethylene ether, 0.2 parts by weight of ammonium persulfate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com