Polydisperse large-particle-size silica sol and preparing method thereof

A technology of silica sol and large particle size, which is applied in the field of chemical engineering, can solve the problems of environmental pollution, difficult removal of organic alkali, poor stability of silica sol system, etc., and achieve the effect of improving polishing efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

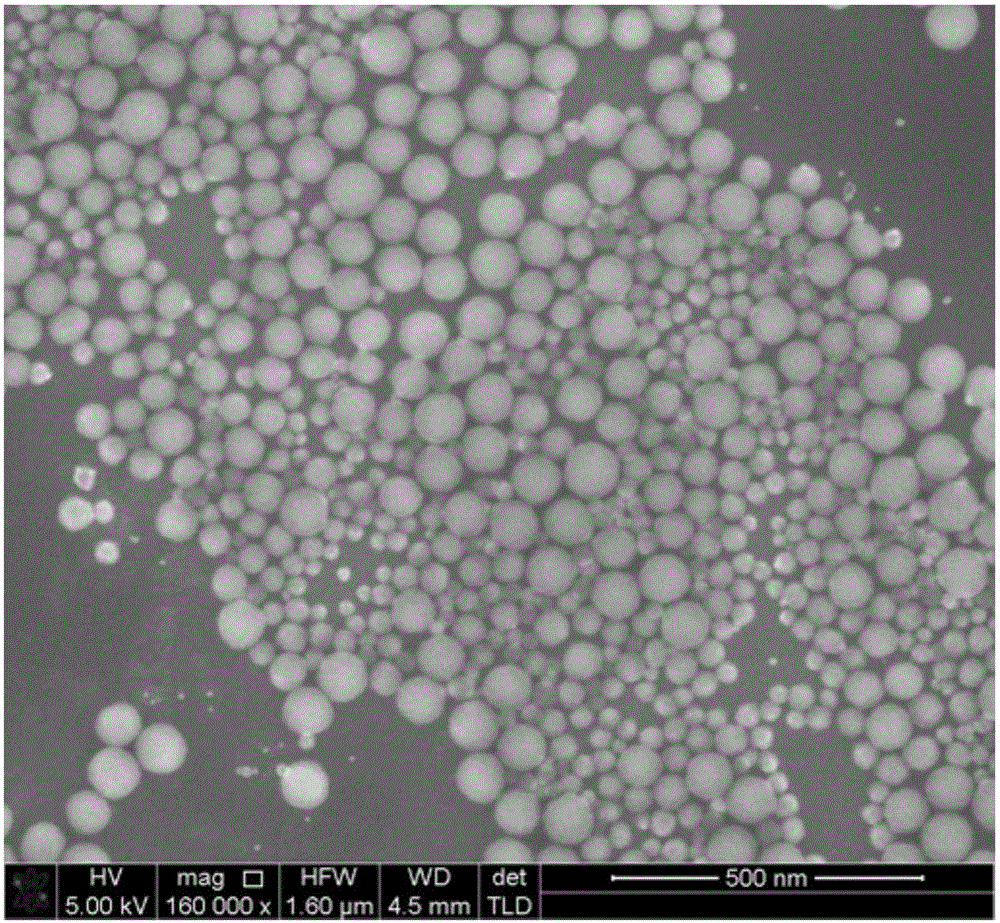

[0028] Embodiment 1 Polydisperse large particle size silica sol and preparation method thereof

[0029] Step (1) Dilute the concentrated water glass with pure water to a silicon dioxide content of 4%, stir evenly and add it into the regenerated strong acid type cation exchange resin (polybenzenesulfonic acid type) for cation exchange to obtain Active silicic acid, active silicic acid has a pH of 2.85 and a silica content of 4%.

[0030] Step (2) Take 1000mL of 1wt% potassium hydroxide solution, stir and heat to 98°C, and pump 4000ml of active silicic acid prepared in the above step (1) through a peristaltic pump at a speed of 8ml / min. After the addition of active silicic acid, the temperature was continued for 0.5 hours. Naturally cool to room temperature to prepare a monodisperse spherical silica sol with a particle size of 20nm-30nm as a seed crystal.

[0031] Step (3) Weigh 800ml of the seed crystal prepared in the above step (2) as the mother liquor, stir and heat to boi...

Embodiment 2

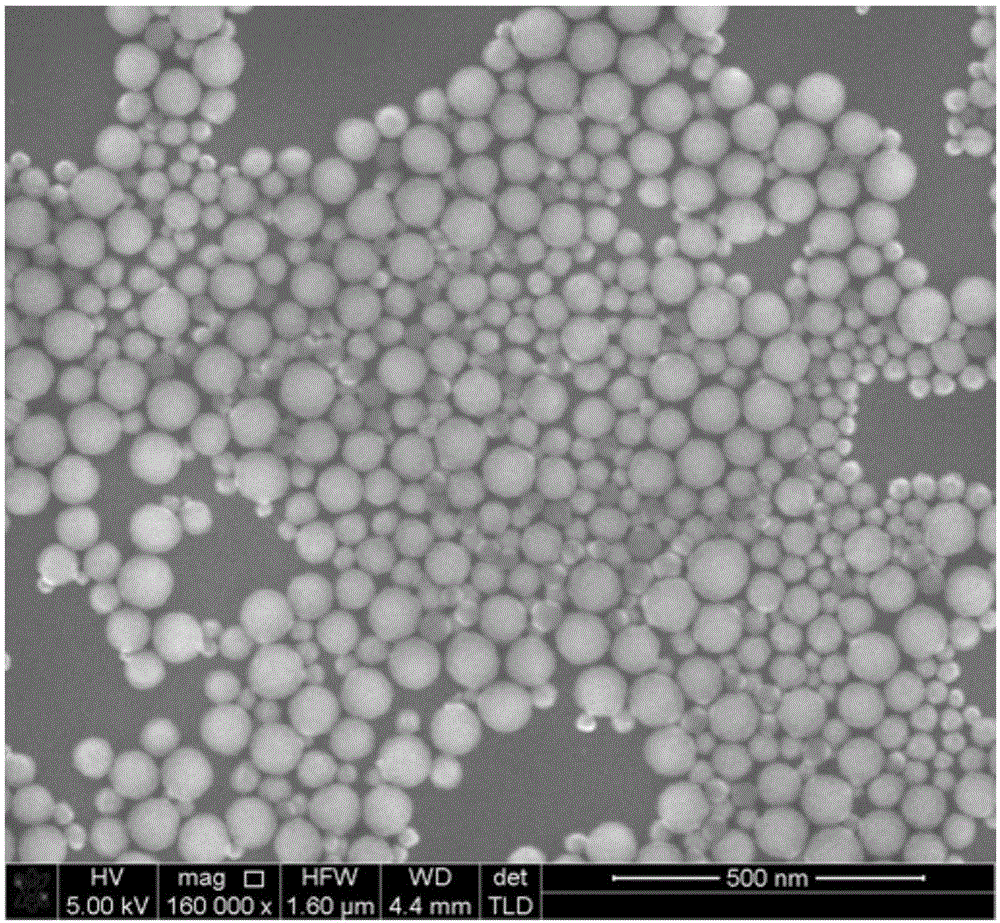

[0033] Embodiment 2 Polydisperse large particle size silica sol and preparation method thereof

[0034] Step (1) Dilute the concentrated water glass with pure water to a silica content of 2%, stir evenly and add it into the regenerated strong acid type cation exchange resin (polybenzenesulfonic acid type) for cation exchange to obtain active Silicic acid, active silicic acid has a pH of 3.0.

[0035] Step (2) Take 1500mL of 0.3wt% sodium hydroxide solution, stir and heat to 100°C, and pump 3500ml of active silicic acid prepared in the above step (1) through a peristaltic pump at a speed of 3.5ml / min. After the addition of silicic acid was completed, the temperature was continued for 1.5 hours. Naturally cool to room temperature to prepare a monodisperse small-diameter spherical silica sol with a particle diameter of 20nm-30nm as a seed crystal.

[0036] Step (3) Weigh 1000ml of the seed crystal prepared in the above step (2) as the mother liquor, stir and heat to boiling, ad...

Embodiment 3

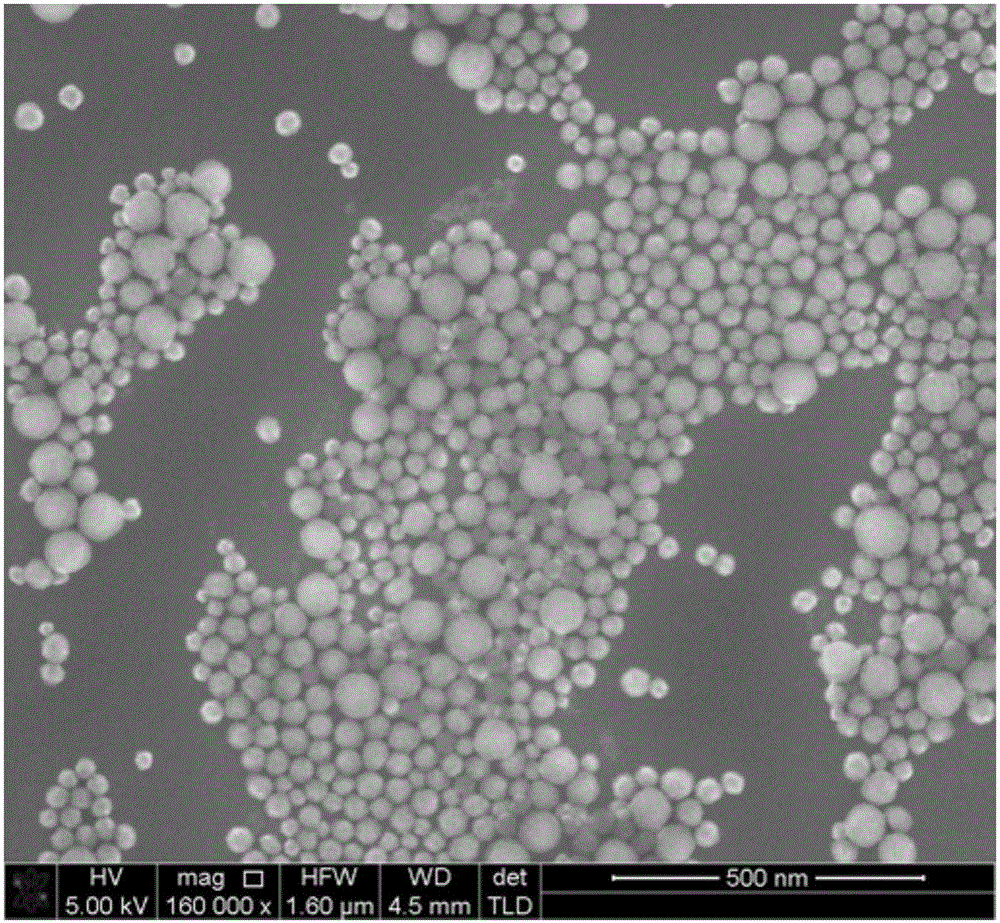

[0038] Embodiment 3 Polydisperse large particle size silica sol and preparation method thereof

[0039]Step (1) Dilute the concentrated water glass with pure water to a silica content of 6%, stir evenly and add it into the regenerated strong acid type cation exchange resin (polybenzenesulfonic acid type) for cation exchange to obtain active Silicic acid, active silicic acid has a pH of 2.74.

[0040] Step (2) Take 1500mL of 0.3wt% sodium hydroxide solution, stir and heat to 100°C, and pump 3500ml of active silicic acid prepared in the above step (1) through a peristaltic pump at a speed of 3.5ml / min. After the addition of silicic acid was completed, the temperature was continued for 2 hours. Naturally cool to room temperature to prepare a monodisperse small-diameter spherical silica sol with a particle diameter of 20nm-30nm as a seed crystal.

[0041] Step (3) Weigh 800ml of the seed crystal prepared in the above step (2) as the mother liquor, stir and heat to boiling, add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com