Preparation method of precision casting fused quartz powder and quartz powder produced by same

A technology of fused silica powder and precision casting, which is applied in the field of investment precision casting, can solve the problems of difficult to control the uniformity and stability of grading particles, difficult to meet production needs, and complicated process, so as to reduce the particle grading process, The effect of improving production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A preparation method of fused silica powder for precision casting:

[0022] (1) Use a hammer crusher to crush the massive quartz stone into 4-10 mesh quartz sand, sort and remove impurities such as feldspar and mica, and use a drum dry magnetic separator for magnetic separation at a field strength of 6000-7000 Gauss;

[0023] (2) Use the pickling device equipped with an ultrasonic generator to pickle and remove impurities from the quartz sand. The lining material of the pickling tank is polytetrafluoroethylene, the ultrasonic frequency is 25-35Hz, the ultrasonic power is 400-600W, and hydrochloric acid is used. : Mixed acid with a mass ratio of oxalic acid of 1-2:1, the dosage is 30-40kg / t each time, and the temperature is room temperature; the specific process is: use the mixed acid solution to soak the quartz sand for 3-5 hours, stir 2-3 times in the middle, Then treat it in the ultrasonic field for 40-60 minutes, and flow away the surface solution;

[0024] (3) Use ...

specific Embodiment approach 1

[0033]Specific embodiment 1, use a hammer crusher to crush a certain amount of quartz stone into 4-10 mesh quartz sand, pick out impurities such as feldspar and mica, and put it into a drum dry magnetic separator for magnetic separation under a field strength of 7000 gauss . Place the magnetically separated quartz sand in a pickling device equipped with an ultrasonic generator, add a mixed acid (hydrochloric acid: oxalic acid ratio of 1:1) solution at a rate of 40kg / t to soak for 4 hours at room temperature, stir twice in the middle, and then Treat for 60 minutes under the action of ultrasonic field (frequency 35Hz, power 400W), and flow away the surface solution. Put the pickled quartz sand into a container, add pure water to soak at room temperature for 2.5 hours, and then wash it in an ultrasonic field (frequency 20Hz, power 100W) for 30 minutes. Put the washed quartz sand into an oven, dry it in an air atmosphere at 300°C for 3 hours, take it out and cool it to room tempe...

specific Embodiment approach 2

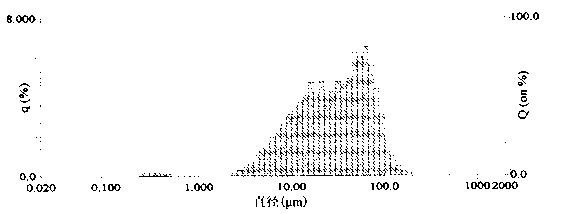

[0035] The difference between this embodiment and Embodiment 1 is that the ball milling time is 70 min, the ball mill speed is 50 r / min, and other steps and parameters are the same as Embodiment 1. Prepared fused silica powder is recorded as 2# product. The product SiO 2 The purity is 99.91%, and the particle size distribution range is shown in the attached figure 2 , the median particle size is 27.2 μm, the average particle size is 37.2 μm, and the rheological viscosity of the configured silica sol coating (powder-liquid ratio is 1.75) is 28.27s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com