Solid solution composition of cerium zirconium compound oxide with high specific surface and method for preparing the same

A composite oxide and high specific surface technology, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve problems such as complex processes and expensive manufacturing costs, and achieve The effect of simplifying the preparation process, low cost, and easy industrial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

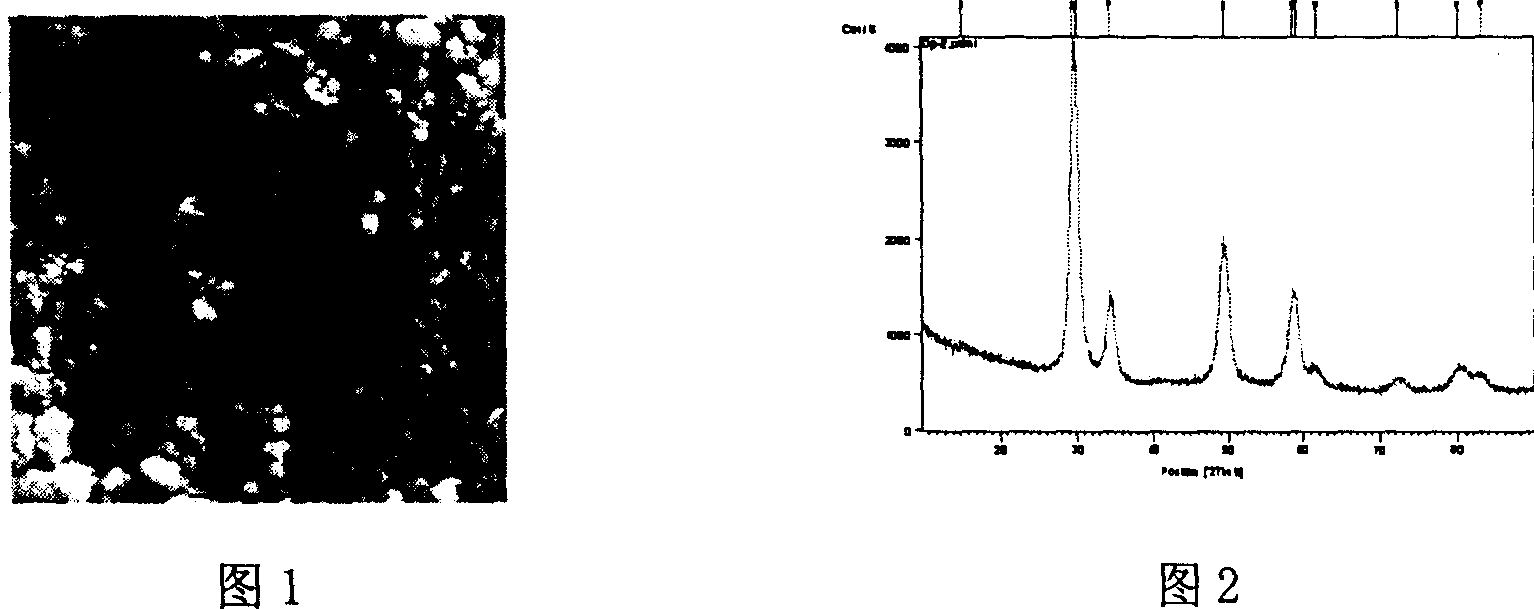

[0042] By composition Ce 0.24 Zr 0.68 La 0.08 Na z o w Take cerium, zirconium, and lanthanum liquids (total molar number of ions: 1 mol) and mix them, add 0.02 g of sodium nitrate, mix well and then add them to 6M ammonia water. In the kettle, hydrothermal reaction was carried out at 160°C for 5 hours, and the reaction pressure was 0.8Mpa. The product was cooled, filtered, generally dried at 110°C, and calcined at 600°C to obtain 133.8 grams of cerium-zirconium composite oxide solid solution with a sodium oxide content of 200ppm. Fresh specific surface (600°C, 3 hours) is 108.17m 2 / g, 950℃, after 2 hours of aging, the specific surface is 36.16m 2 / g, 1050℃, after 2 hours of aging, the specific surface is 23.38m 2 / g.

Embodiment 2

[0044] By composition Ce 0.67 Zr 0.21 La 0.12 Na z o w Take cerium, zirconium, and lanthanum liquids (total mole number of ions: 1 mol) and mix them, then add 0.02 g of sodium nitrate, mix well, add them to 6M ammonia water, stir and precipitate the suspension to a pH value of 10, and filter. The filter cake was washed twice with twice the weight of ethanol each time, vacuum-dried at 110° C., and calcined at 600° C. to obtain 150.8 grams of cerium-zirconium composite oxide solid solution with a sodium oxide content of 200 ppm. Fresh specific surface (600°C, 3 hours) is 88.52m 2 / g, 950℃, after 2 hours of aging, the specific surface is 24.56m 2 / g, 1050℃, after 2 hours of aging, the specific surface is 10.16m 2 / g.

Embodiment 3

[0046] By composition Ce 0.24 Zr 0.68 La 0.08 Na z o w Take cerium, zirconium, and lanthanum liquids (total molar number of ions is 1 mol) and mix them, add 0.20 g of sodium nitrate, mix well and add them to 6M ammonia water. After stirring and sedimenting, the pH value of the suspension is 10. In the reaction kettle, hydrothermal reaction was carried out at 160°C for 5 hours, and the reaction pressure was 0.8Mpa. The product was cooled, filtered, dried at 110°C, and calcined at 600°C to obtain 132.5 grams of cerium-zirconium composite oxide solid solution with a sodium oxide content of 1000ppm. Fresh specific surface (600°C, 3 hours) is 100.13m 2 / g, 950℃, after 2 hours of aging, the specific surface is 32.27m 2 / g, 1050℃, after 2 hours of aging, the specific surface area is 18.35m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com