Preparation method of iron-based hydrotalcite

A hydrotalcite and iron-based technology, applied in chemical instruments and methods, inorganic chemistry, nickel compounds, etc., can solve the problems of harsh crystallization conditions, complex synthesis methods, high salt cost, etc., achieve uniform crystal phase and particle size, and prepare The effect of simple process and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

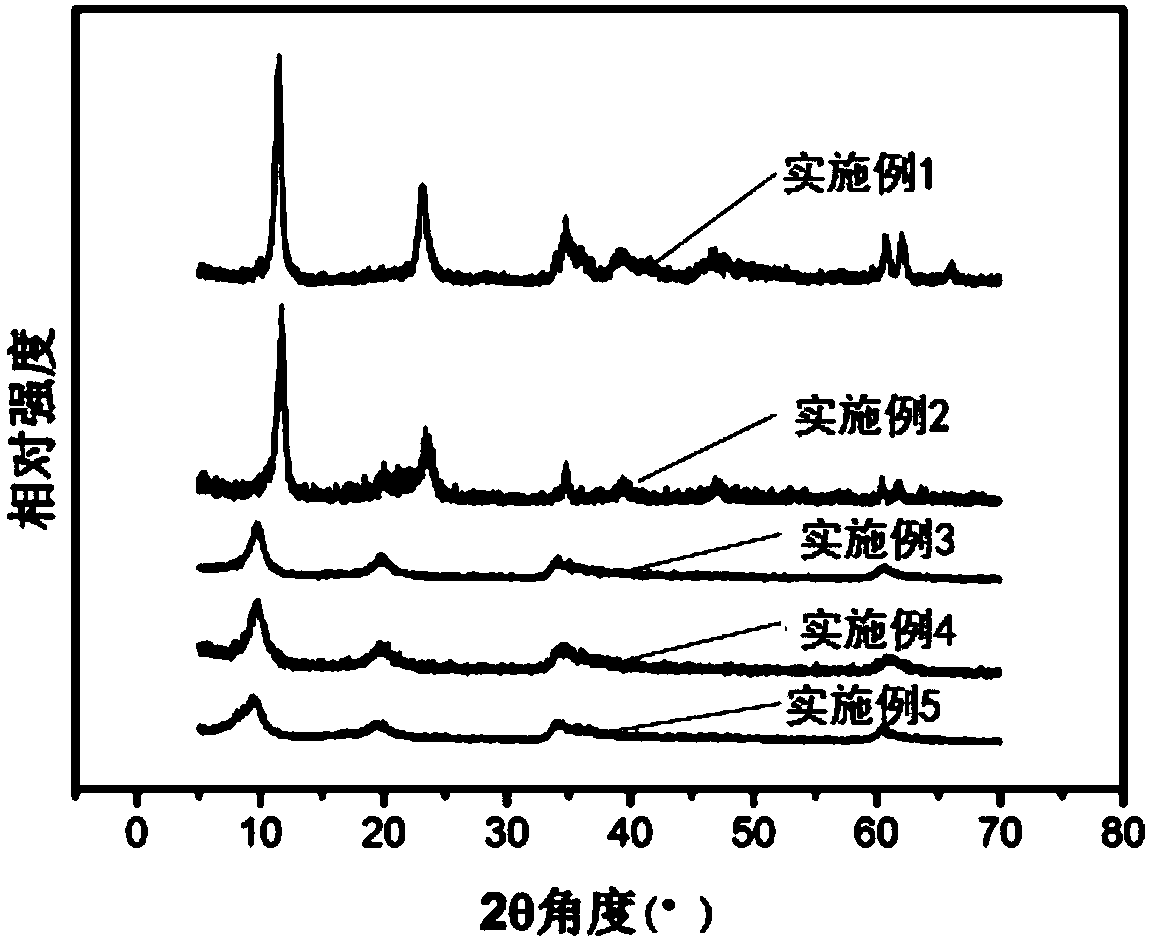

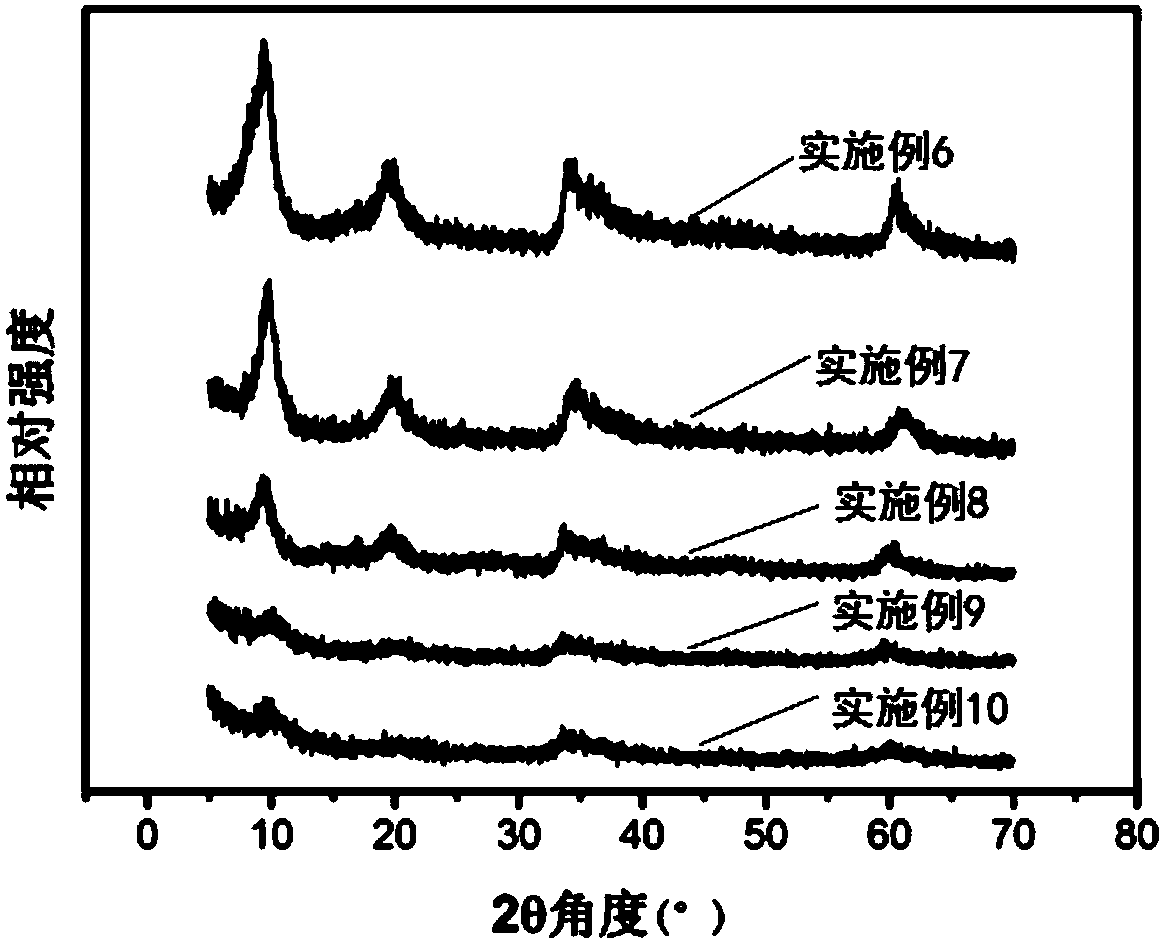

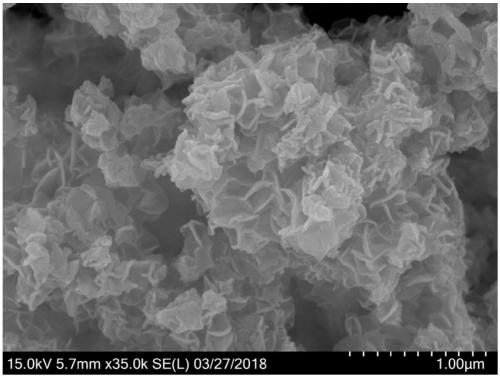

Embodiment 1

[0028] According to the molar ratio Ni:Fe=4:1, 2.700g of nickel sulfate hexahydrate and 0.714g of ferrous sulfate heptahydrate were added to 75mL of deionized water, and then a flow rate of 1m was introduced into the resulting solution. 3 Oxygen per hour, while gradually adding 1mol / L ammonia solution to control the pH of the reaction solution to 6.8-7.3, stirred and reacted at 40°C for 2 hours, then suction filtered and dried in a constant temperature drying oven at 150°C to obtain NiFe hydrotalcite.

Embodiment 2

[0030] In this example, according to Ni:Fe=2:1, 1.350 g of nickel sulfate hexahydrate and 0.714 g of ferrous sulfate heptahydrate were added to 75 mL of deionized water, and other steps were the same as in Example 1 to obtain NiFe hydrotalcite.

Embodiment 3

[0032] In this example, according to Ni:Fe=1:1, 0.675g of nickel sulfate hexahydrate and 0.714g of ferrous sulfate heptahydrate were added to 75mL of deionized water, and other steps were the same as in Example 1 to obtain NiFe hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com